Symmetric permanent-magnetic suspension system and permanent-magnetic suspension train rail system

A magnetic levitation and symmetrical technology, applied in the field of rail transit, can solve the problems of derailment of open wheel-rail structure, wear of wheel bearings, high energy consumption of suspension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] The present invention is described in further detail now in conjunction with accompanying drawing.

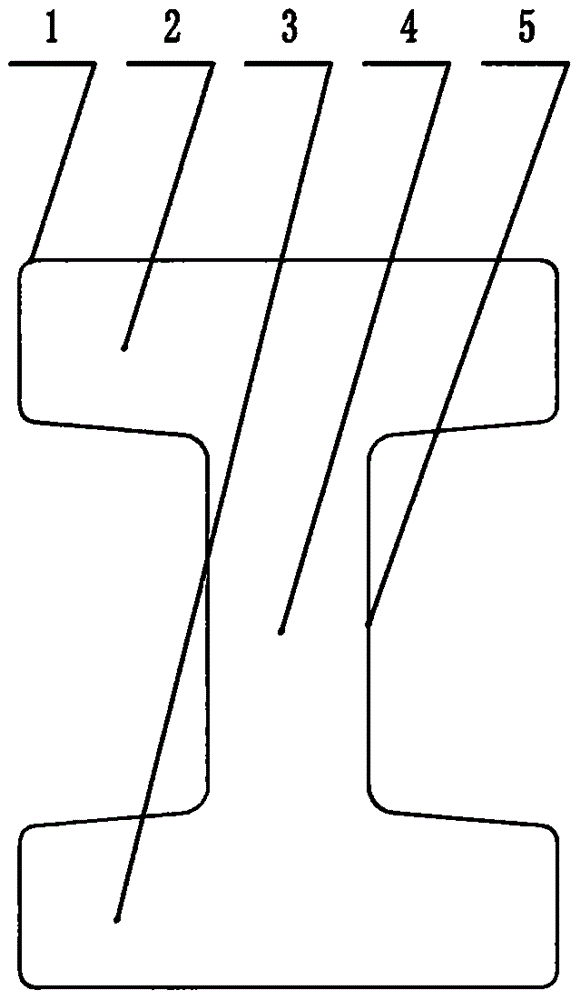

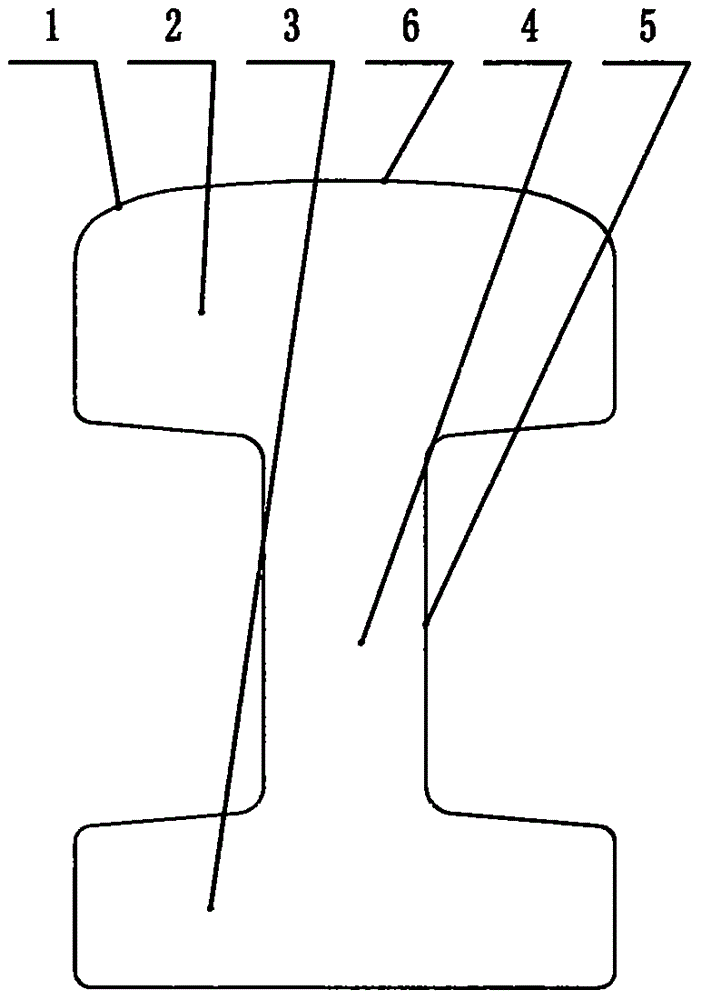

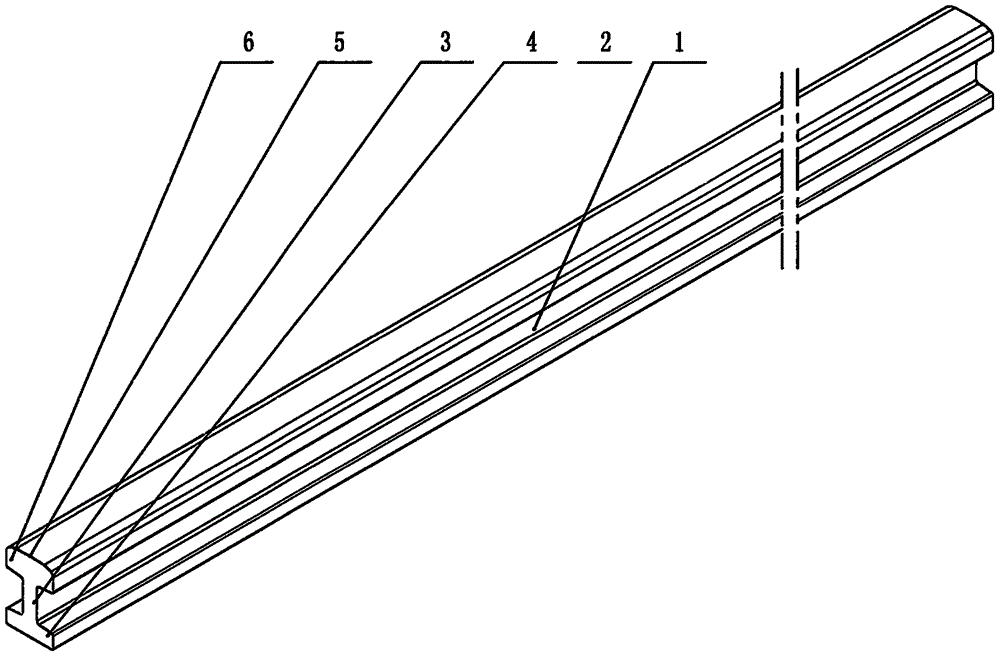

[0119] like figure 1 and image 3 As shown, a kind of I-shaped suspension rail 1, the overall section is I-shaped, and its material is a magnetic material, such as industrial pure iron or steel, and the I-shaped suspension rail 1 is composed of an upper yoke plate 2 and a lower yoke plate 3 The waist plate 4 vertically arranged in the middle is composed of the waist plate 4, which connects the upper yoke plate 2 and the lower yoke plate 3 in the middle. The left and right width and thickness are basically equal, and the section is extended along a straight line or a curve.

[0120] The left and right widths of the upper yoke plate 2 and the lower yoke plate 3 can also be unequal widths, and the thicknesses can also be unequal thicknesses.

[0121] The horizontal upper yoke plate 2 and the lower yoke plate 3 can be provided with a slope for ease of manufacture, prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com