Externally expanding, assembling, converting and lifting method for medium/small span steel structure roof net rack

A technology of steel structure and net frame, which is applied in the direction of building structure, construction, and building material processing, etc., to achieve the effects of reducing construction costs, improving safety, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

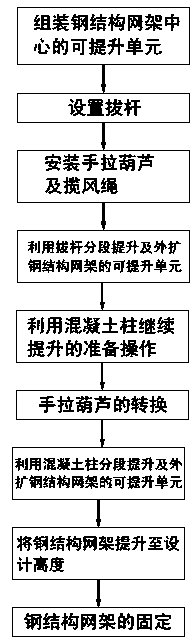

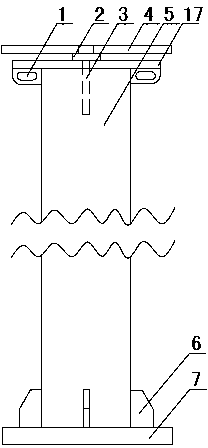

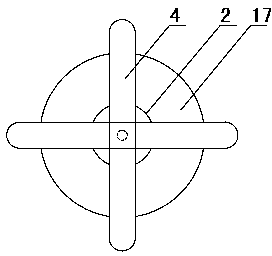

[0041] Figure 1~7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0042] In the prior art, the steel grid structure is a relatively common structural form, and is often used as a roof of a building. Under normal circumstances, when the lifting construction of the steel structure grid is carried out, the overall concrete construction of the building has been completed, and the actual construction site conditions cannot be changed. In large-span buildings, large-scale lifting devices such as cranes can be used to lift steel structure grids, while in buildings with medium / small spans, due to the relatively small indoor area, large-scale lifting devices such as cranes cannot enter. In the prior art, lifting by pulling rods or synchronous hydraulic lifters has its own shortcomings, thereby increasing the difficulty of construction.

[0043] The medium / small-span steel structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com