Method for preparing neodymium iron boron permanent magnet material by using associated mixed rare earth

A technology of mixing rare earth and permanent magnetic materials, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve problems such as backlog and environmental pollution, improve microstructure, reduce pollution, improve comprehensive magnetic properties and coercive force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

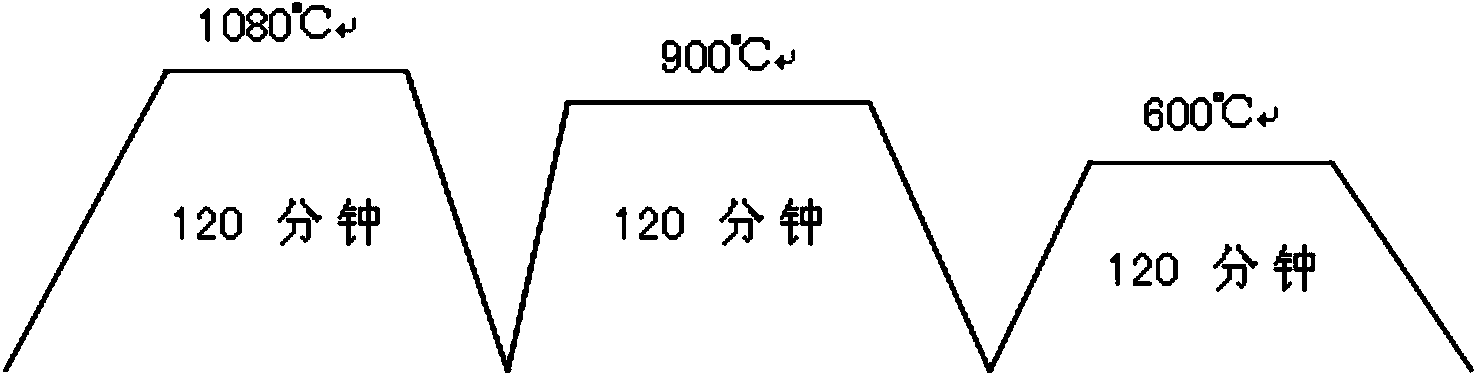

Image

Examples

Embodiment 1

[0032] (1) The raw material is the co-associated mixed rare earths of Baiyun Obo Mine, whose composition is La: 25.87%, Ce: 53.56%, Pr: 6.59%, Nd: 13.98%, and the composition of the main alloy (by weight): MM: 33% , Fe: 64.95%, B: 1.05%, Al: 1%, auxiliary alloys are PrNd: 0.2%, NdCu: 0.2%, AlCu: 0.1%.

[0033] (2) Surface treatment of raw materials: Remove the oxides on the surface of the prepared waste and metal materials by mechanical or chemical methods.

[0034] (3) Smelting: The main alloy MMFeB is prepared into quick-setting sheets through the quick-setting process, the rotation speed is about 1-3m / s, the thickness is 0.01-2mm, and the crystallization state is controlled to be columnar.

[0035] (4) Milling: Use hydrogen explosion plus high-pressure nitrogen jet mill to grind the main alloy quick-setting sheet alloy into 3-5μm more uniform particles, and the auxiliary alloys PrNd, NdCu, AlCu, etc. through hydrogen explosion, jet mill, high-energy ball mill , Grinding in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com