Bamboo sheet coloring process and device based on temperature-controlled drying carbonization

A technology of toning device and bamboo chips, which is applied in the direction of humidity control wood, manufacturing tools, charcoal burning/combustion, etc., can solve the problems of non-compliance with environmental protection requirements, huge damage, etc., and achieve fully automatic intelligent control, low energy consumption, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of bamboo chip toning technology based on temperature-controlled drying carbonization, comprises the following steps:

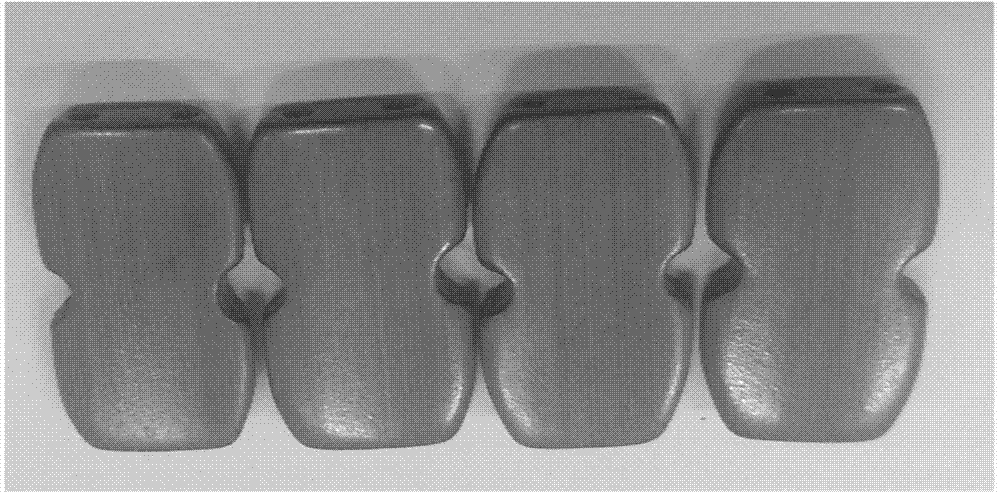

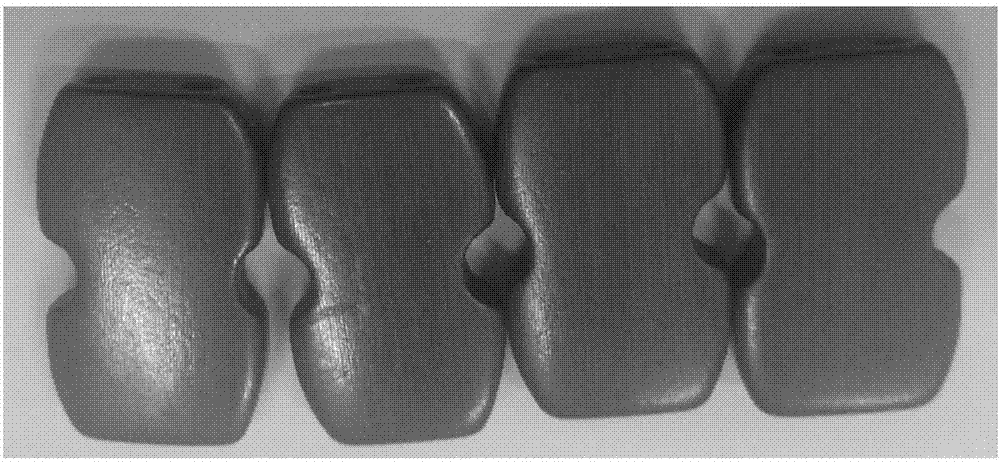

[0037] (1) Under the condition of an ambient temperature of 5 °C, a batch of light yellow bamboo chip blanks (such as figure 1shown) into a heating device, start the heating device to quickly heat up to 120°C, first preheat the bamboo blank, and at the same time keep turning the bamboo blank to make it evenly heated, after the bamboo blank is heated, the contained The water evaporates and escapes into the inner cavity of the heating device. After 1 hour of preheating, the humidity sensor detects that the humidity of the gas inside the heating device is 60%;

[0038] (2) Transfer the measured humidity parameters to the controller of the heating device, and use the three-dimensional working model of "humidity-heating system-color selection" preset in the controller to determine the heating of the heating device in the batch of bamboo blanks. syst...

Embodiment 2

[0044] A kind of bamboo chip toning technology based on temperature-controlled drying carbonization, comprises the following steps:

[0045] (1) Under the condition of an ambient temperature of 5 °C, a batch of light yellow bamboo chip blanks (such as figure 1 shown) into a heating device, start the heating device to quickly heat up to 120°C, preheat the bamboo blanks first, and at the same time keep turning the bamboo blanks to make them evenly heated, after the bamboo blanks are heated, the moisture contained in them The evaporation escapes into the inner cavity of the heating device. After 1 hour of preheating, the humidity sensor detects that the humidity of the gas inside the heating device is 60%;

[0046] (2) Transfer the measured humidity parameters to the controller of the heating device, and use the three-dimensional working model of "humidity-heating system-color selection" preset in the controller to determine the heating of the heating device in the batch of bambo...

Embodiment 3

[0052] like Figure 4 to Figure 11 Shown, a kind of bamboo chip toning device comprises the cylinder 2 that is installed on the frame 1 and the driving assembly 3 that drives the cylinder 2 to rotate, and the circumferential side wall of the cylinder 2 is provided with feed inlet 22 and with feed inlet 22 matched dodge door 21, the dodge door 21 is hinged at the feeding port 22 of the drum 2 and is provided with a lock, which can be opened and closed as required. The inner chamber of the drum 2 is provided with a heating assembly 4, a temperature sensor 5 and a humidity sensor 6. The bamboo chip toning device also includes a peripheral controller (not shown in the figure), the heating component 4, the temperature sensor 5 and the humidity sensor 6 are all connected to the controller, and the heating component 4 is fixed in a non-contact bamboo chip At the axis of rotation of the drum 2, it provides heat at the center of the drum 2, achieving stability and ease of operation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com