Open-type drying furnace for automobile parts

An auto parts, open technology, applied in drying, dryer, progressive dryer and other directions, can solve the problem of slow opening of isolation door, lower temperature of drying room, affecting drying, etc., to achieve high utilization rate , the effect of speeding up drying and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

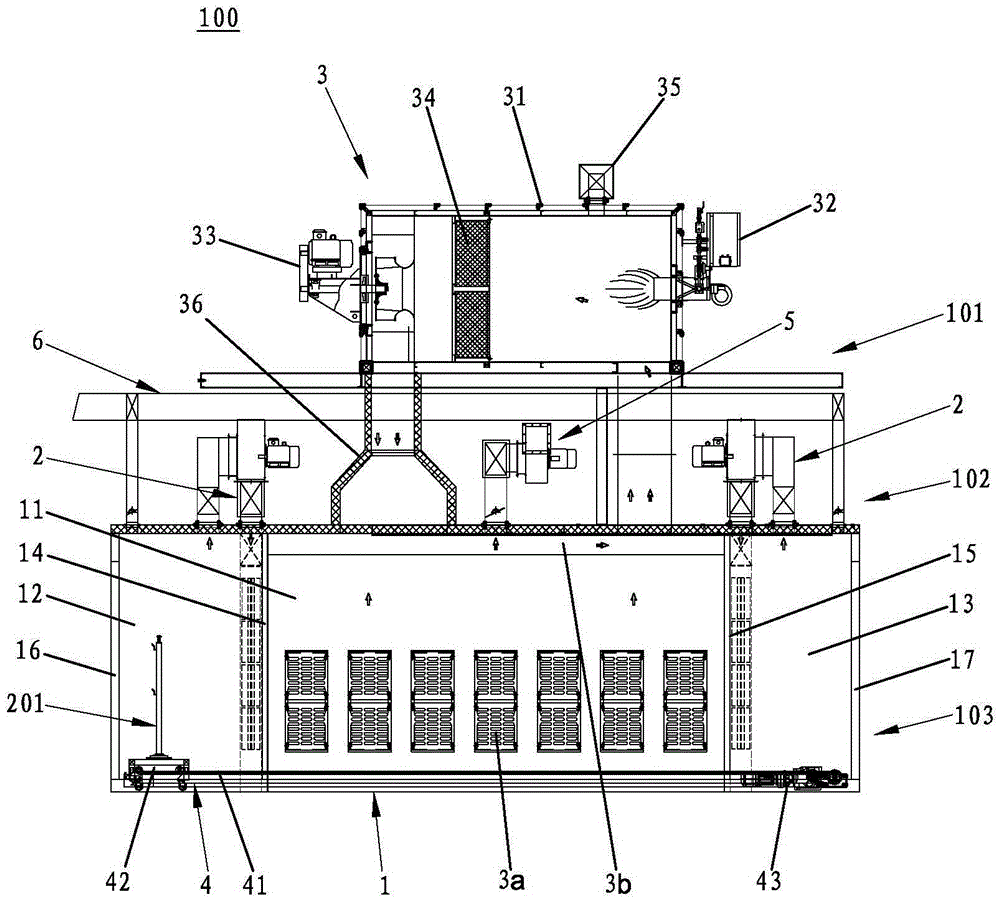

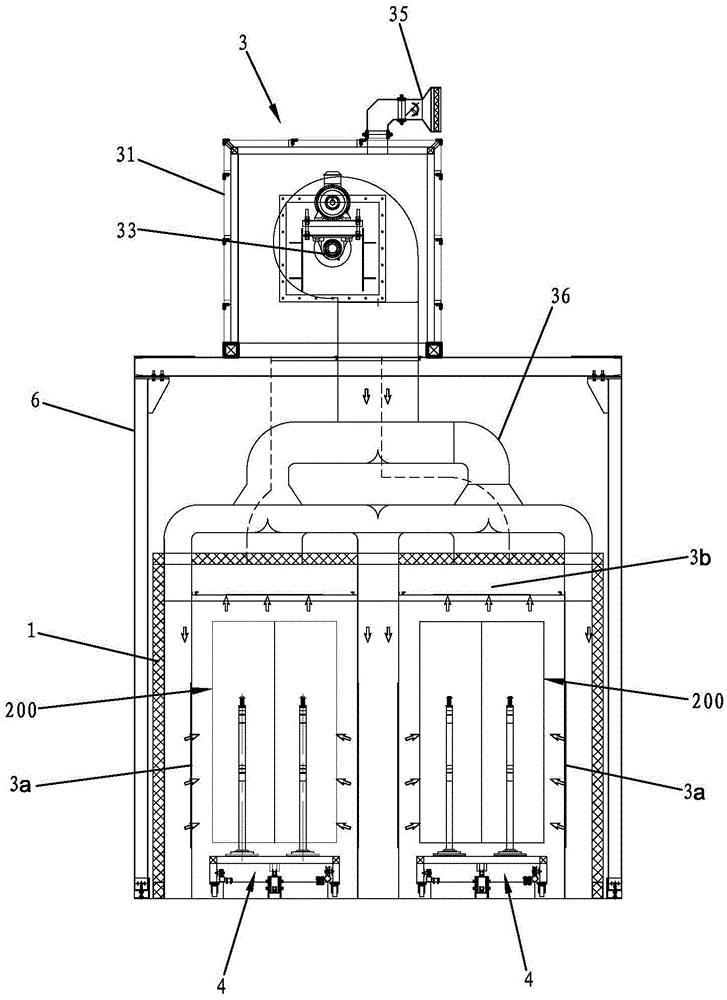

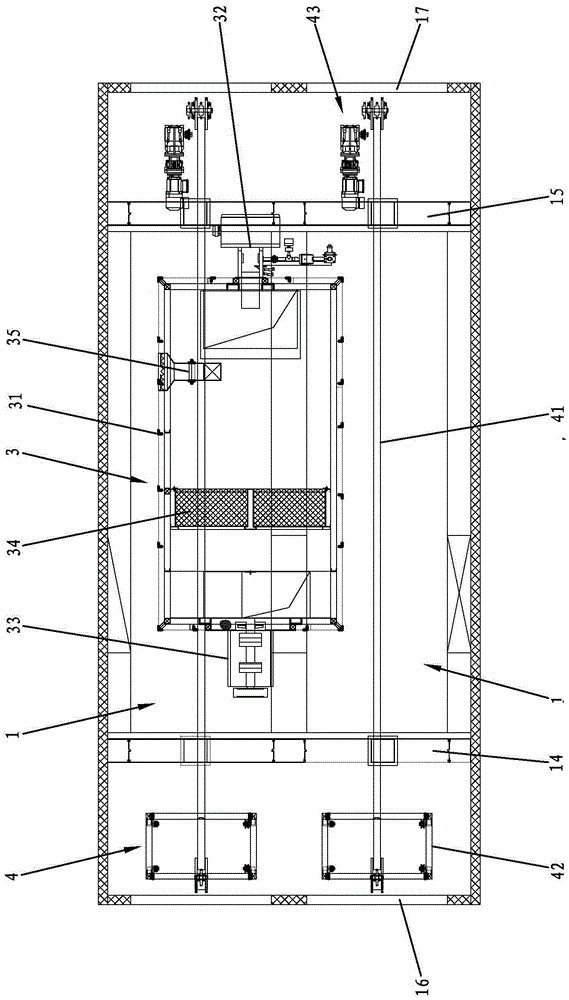

[0020] Such as figure 1 As shown, the open drying furnace 100 for auto parts of the present invention includes a furnace body main body 1, two air curtain machines 2, a hot air circulation system 3, a conveying chain 4 and an exhaust fan 5; The steel structure platform 6 makes the open drying furnace 100 for auto parts divided into an upper layer 101, a middle layer 102 and a lower layer 103, the furnace main body 1 is located in the lower layer 103, the two air curtain machines 2 and the Exhaust gas blower 5 is positioned at described middle layer 102, and described hot air circulation system 3 is positioned at upper layer 101; By being divided into three layers, make the drying oven of the present application utilize the space of upper layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com