Wire edge cooling device and wire edge cooling method

A cooling device and wire rod technology, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of limited temperature drop of coils, small cooling range, and poor strength of the same coil, so as to achieve uniform temperature in the phase change zone and high product quality. The effect of consistent performance and reduced generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

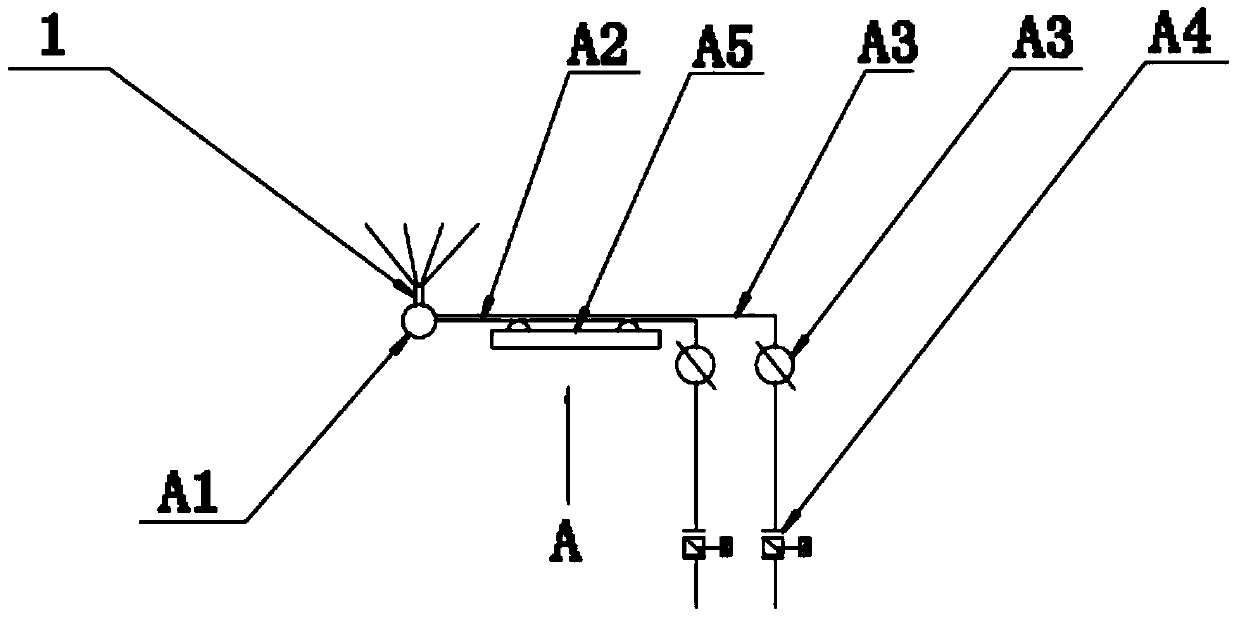

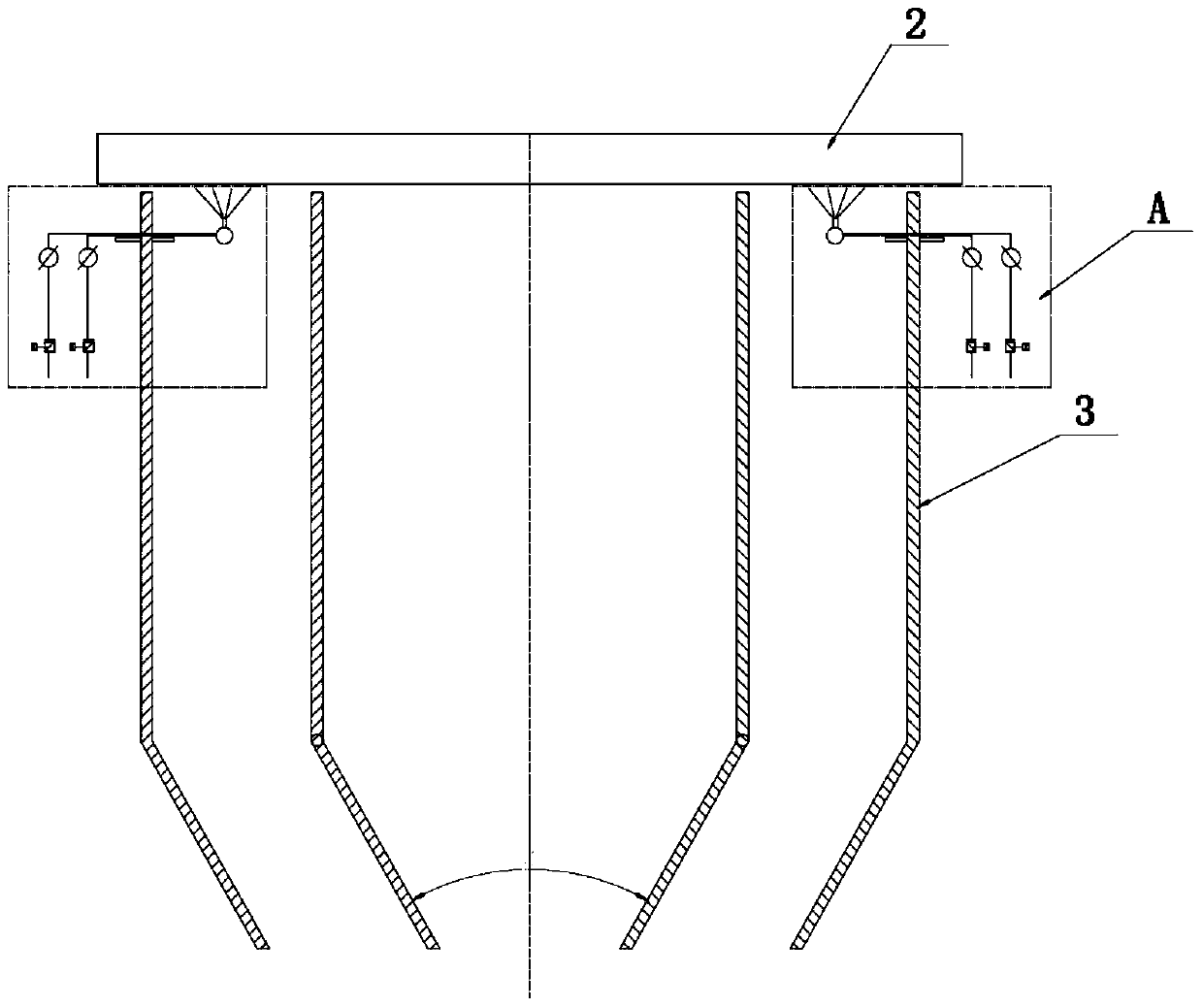

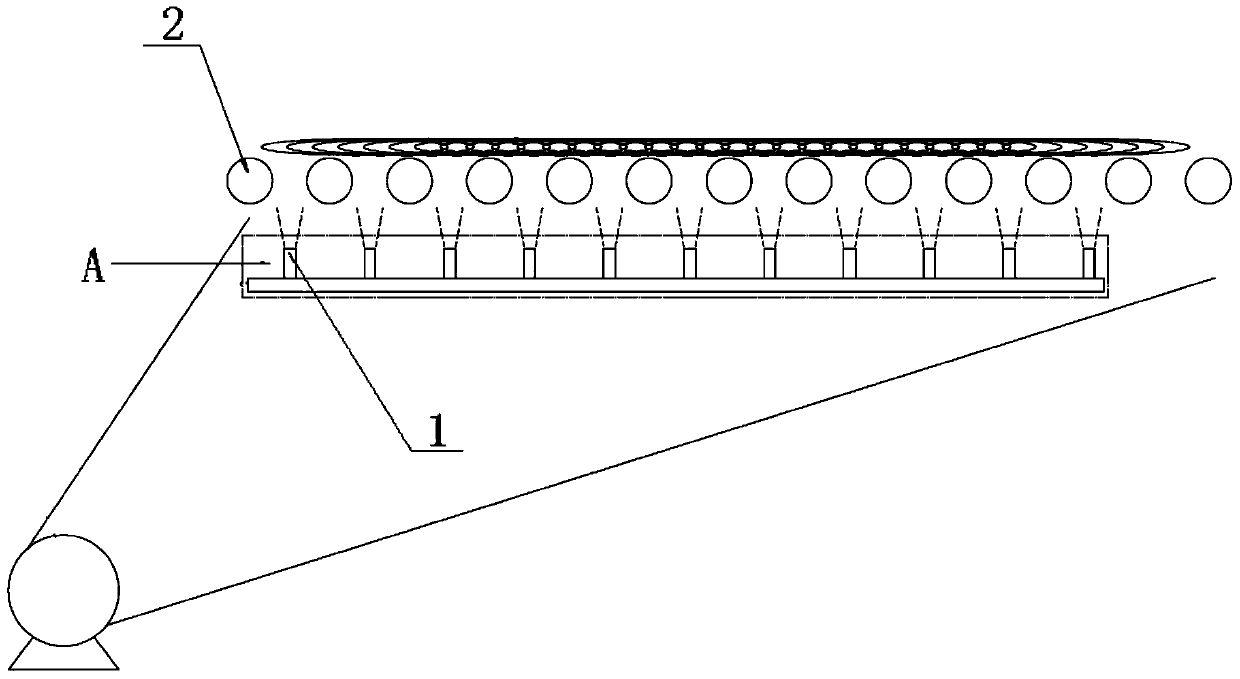

[0051] Example 1: For wire rod, the spinning temperature is 900°C, using 3 sets of edge cooling devices, each set of 30 nozzles on one side, the water pressure is 3bar, the air pressure is 5bar, and the measured temperature difference in the same circle is 47°C;

Embodiment 2

[0052] Example 2: For wire rod, the spinning temperature is 920°C, 5 sets of edge cooling devices are used, each set of 30 nozzles on one side, the water pressure is 1.5 bar, the air pressure is 3 bar, and the measured temperature difference in the same ring is 53°C;

Embodiment 3

[0053] Example 3: For wire rod, the spinning temperature is 880°C, using 5 sets of edge cooling devices, each set of 30 nozzles on one side, the water pressure is 2 bar, the air pressure is 3 bar, and the measured temperature difference in the same circle is 58°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com