Patents

Literature

68results about How to "Improve the on-site operating environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

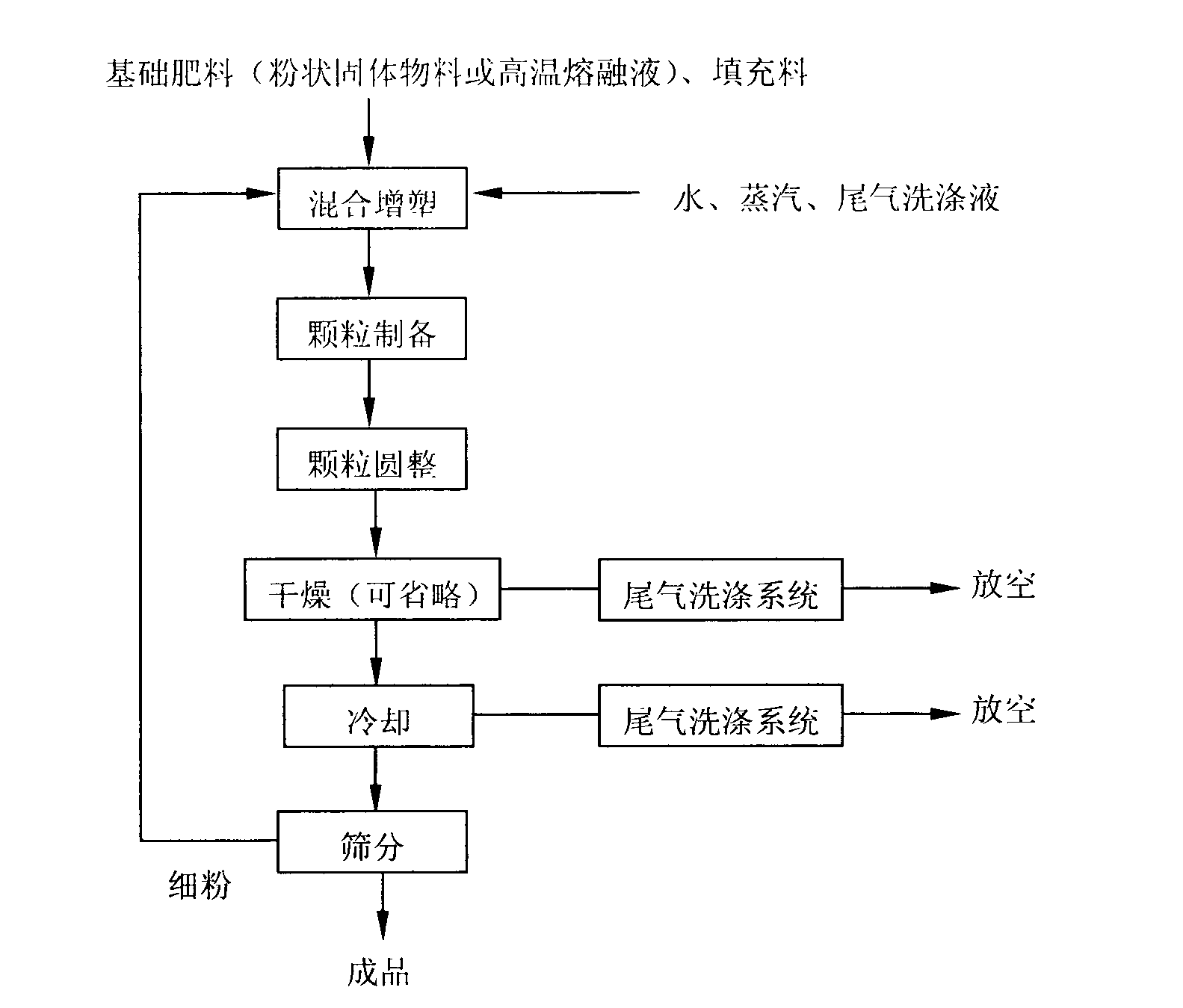

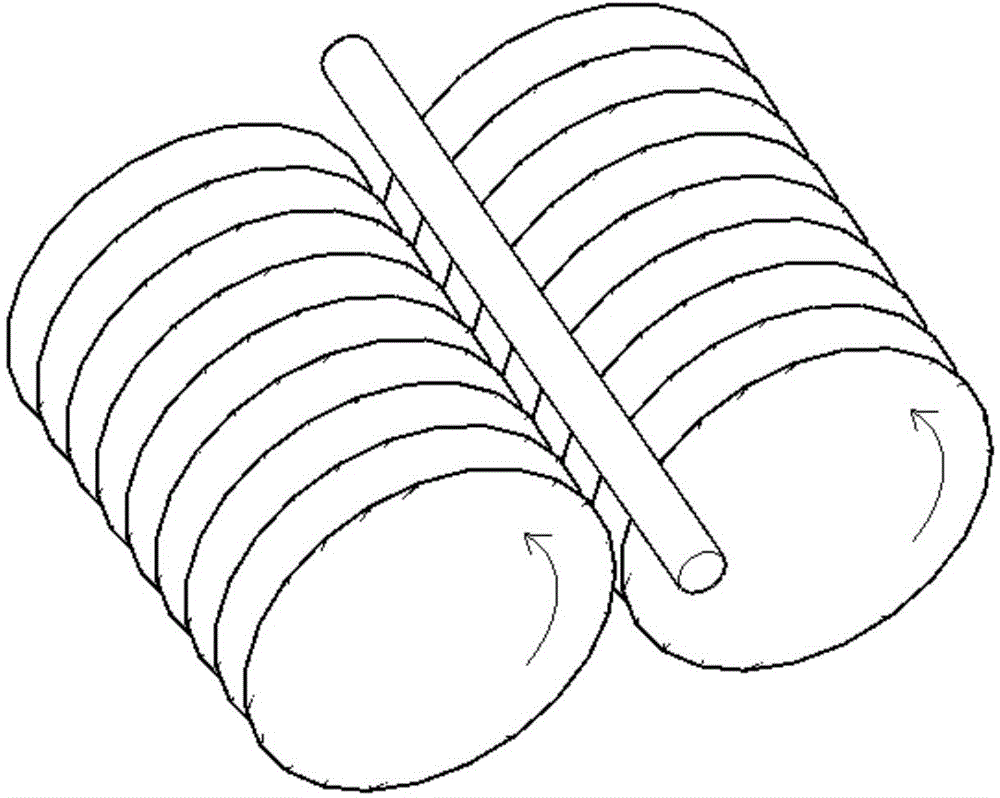

Preparation method for particle compound fertilizer

The invention relates to a preparation method for a particle compound fertilizer. The method comprises the following steps of: wetting or heating and mixing a basic fertilizer and a filler to obtain a plastically-enhanced material with high moisture content or high temperature; preparing a mixed material into uniform particles through extruding machinery; rounding the surfaces of particle materials; drying (e.g., the step can be eliminated when the temperature for preparing the particle materials is high); and cooling and sieving to obtain the particle compound fertilizer. Compared with the conventional extruding method, the method has the advantage that: abrasion on extruding equipment is reduced. Compared with the conventional agglomerating method, the method has the advantages that: material returning multiple in a production process can be reduced, and production energy consumption and production cost are lowered. Product particles are uniform, are round in appearance, and have high pressure resistance and agglomeration resistance. In production process, waste emission is reduced, and the field operation environment is remarkably improved.

Owner:SHANGHAI RES INST OF CHEM IND

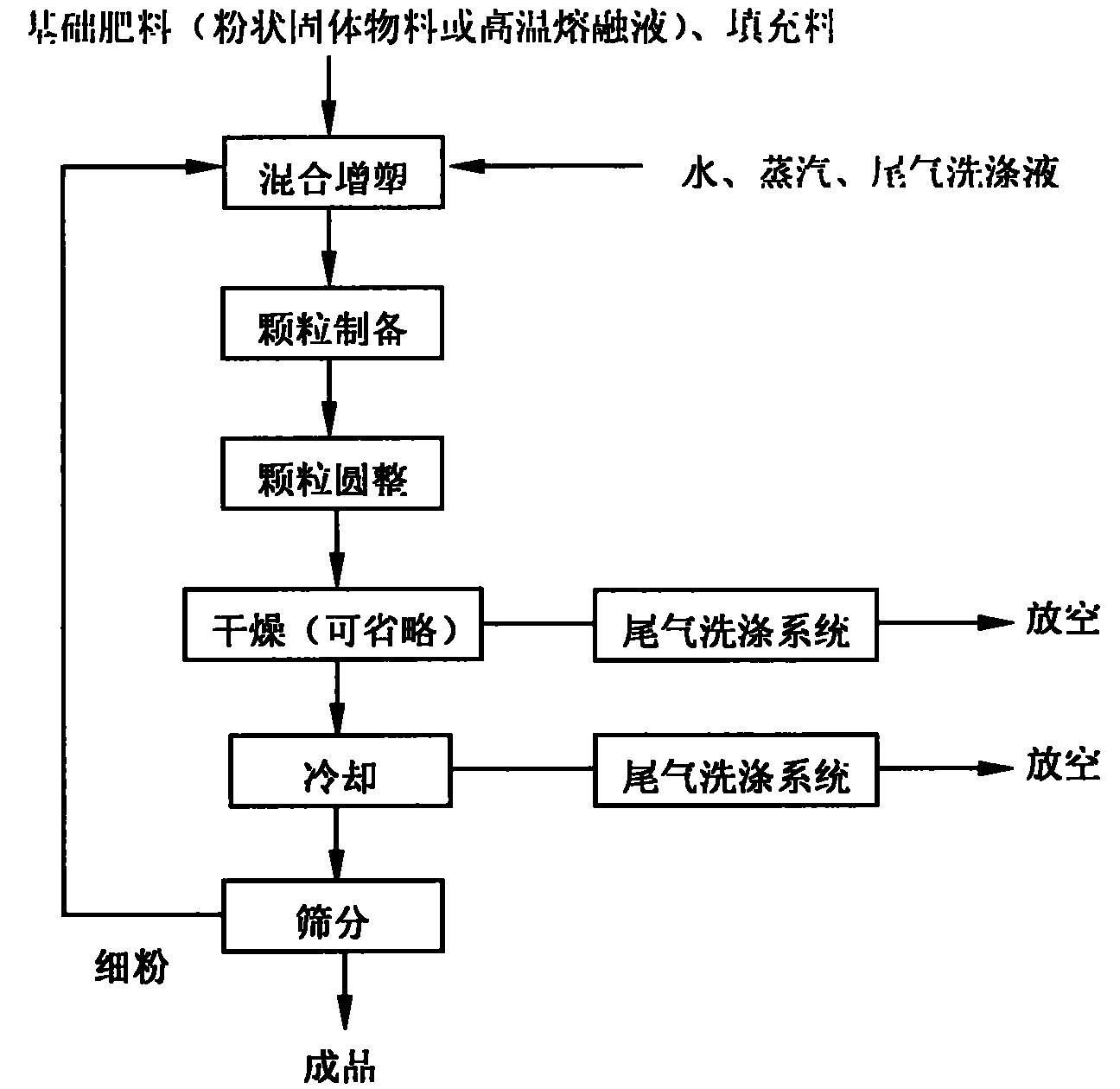

Method for spraying ash and blowing dust in water cooling process of collected stainless steel slag

The invention belongs to the field of steel slag treatment, and in particular relates to a method for spraying ash and blowing dust in water cooling process of collected stainless steel slag. The technical scheme used in the invention relates to a method for spraying ash and blowing dust in water cooling process of collected stainless steel slag. The method comprises the following steps: first, loading steel slag into a slag pot for air cooling in the open air, then putting the slag pot below a dust collection hood for cooling, wherein the cooling water needs to be sprayed in a misty manner to avoid water accumulation on the surface of the steel slag, at the same time a dust collection fan is turned on, so that dust is collected to a deduster along with a dedusting pipe, and when the steel slag is cooled to 70-80 DEG C, the slag pot is sent to a workshop for tipping treatment, and a new slag pot is cooled again. The method has the beneficial effects that dust sprayed in the steel slag water cooling process can be effectively absorbed, and on-site worker operation environment can be obviously improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for preparing high-purity low-chlorine electroplating-grade cupric oxide

InactiveCN103101957AAvoid bringing inGuaranteed purityEnergy inputCopper oxides/halidesDecompositionCarbonization

The invention discloses a method for preparing high-purity low-chlorine electroplating-grade cupric oxide. According to the method, copper, liquid ammonia and high-purity carbon dioxide are taken as raw materials, stronger ammonia water is prepared firstly, carbonated ammonia water is obtained through introducing the high-purity carbon dioxide into the stronger ammonia water and controlling carbonization degree, the carbonated ammonia water reacts with the copper under certain air pressure so as to prepare copper-ammonia complexation liquid, the copper-ammonia complexation liquid is then subjected to heating, ammonia distilling, separating, washing, drying and sieving so as to prepare high-purity heavy basic copper carbonate, and the heavy basic copper carbonate is then subjected to heating calcination and decomposition, thereby preparing the high-purity low-chlorine electroplating-grade cupric oxide. According to the method, the carbon dioxide is directly used as a raw material, so that the problems of the traditional method that impurities, such as heavy metal ions and chloride ions, are introduced by raw materials used in the production of basic copper carbonate are solved, the rate of reaction is increased, the production cycle is shortened, the production efficiency is greatly increased, and products are low in impurity content, high in purity, high in activity and wider in application; and meanwhile, the method is high in yield, low in energy consumption, and low in cost and hardly causes pollution.

Owner:TAIXING SMELTING PLANT

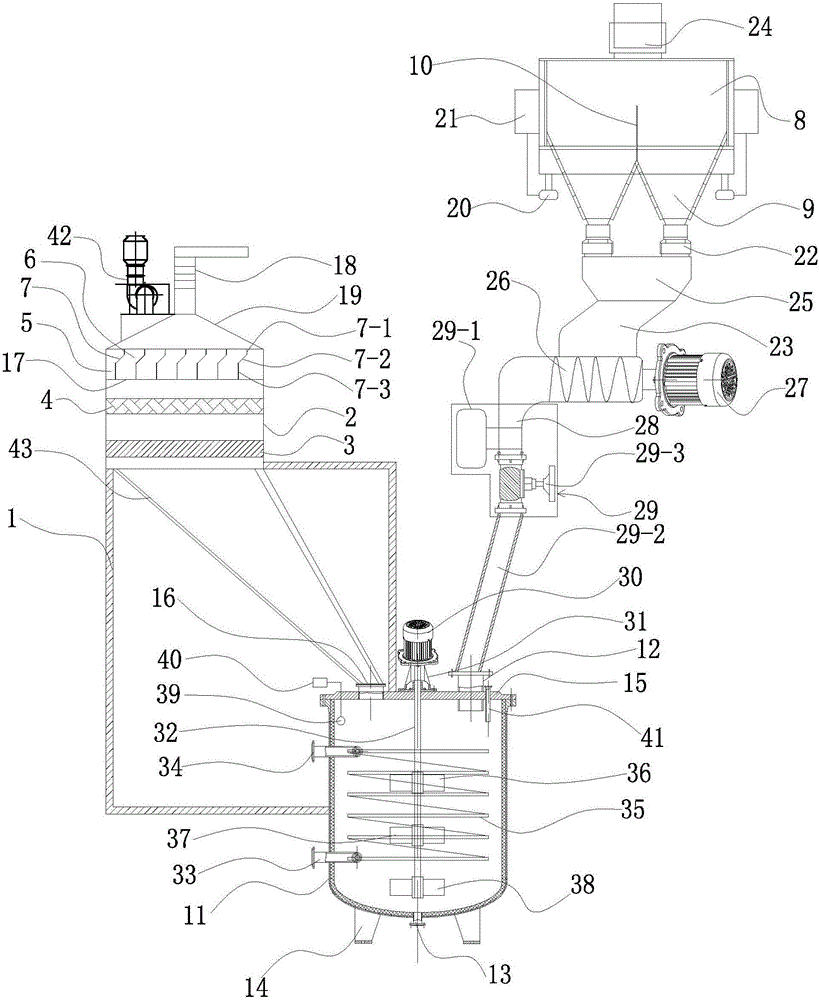

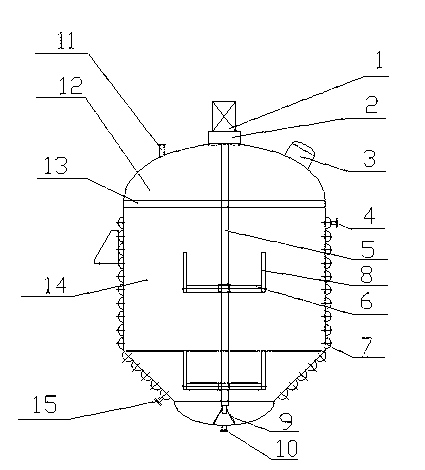

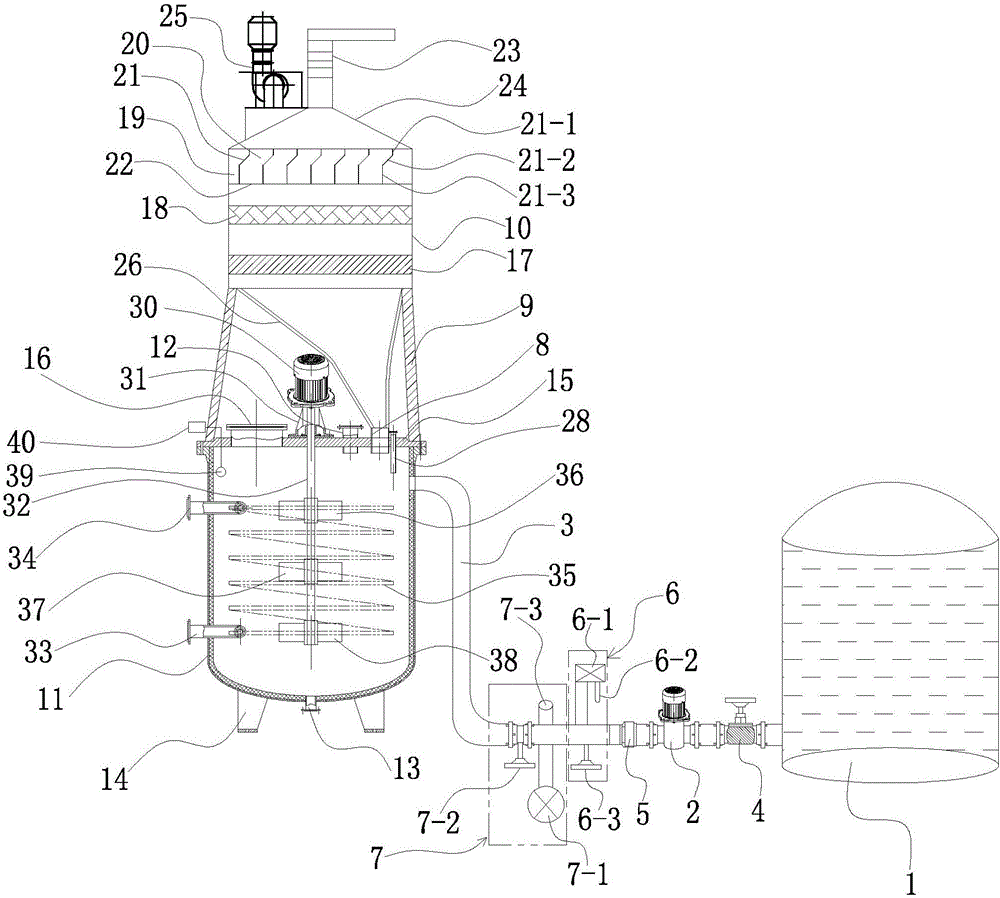

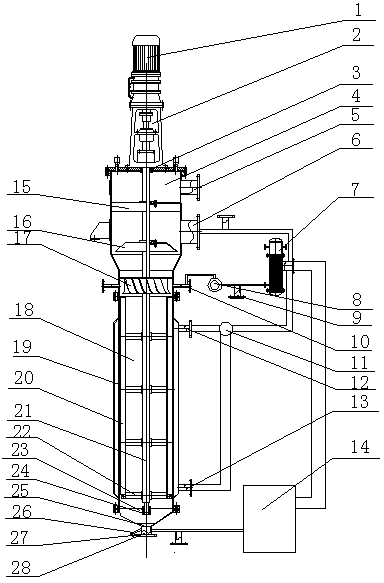

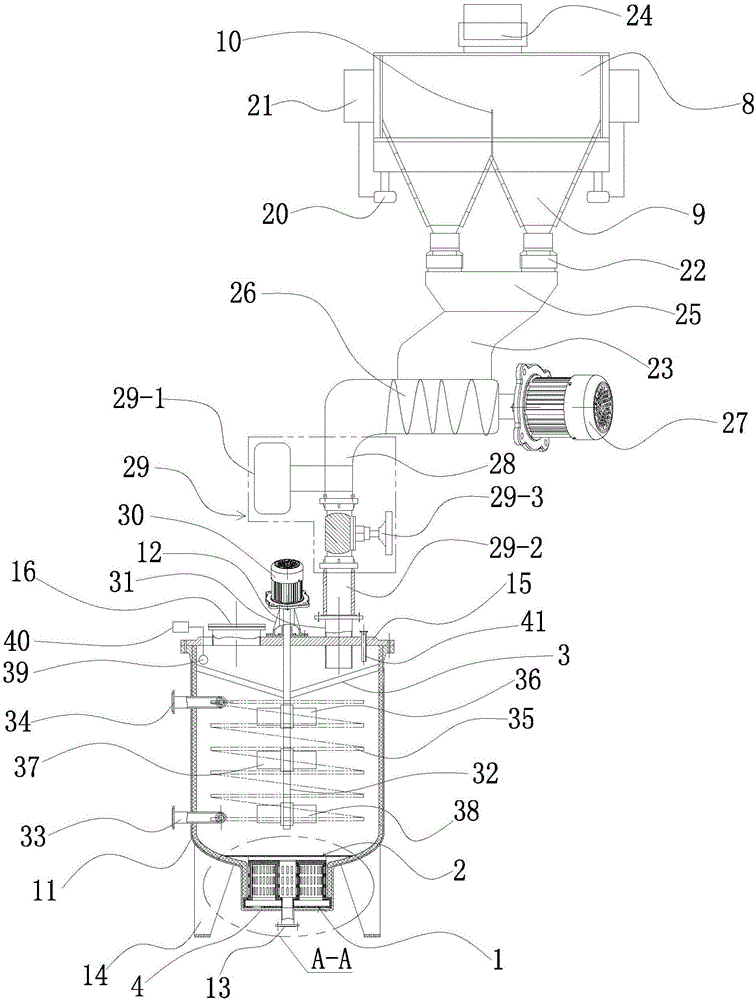

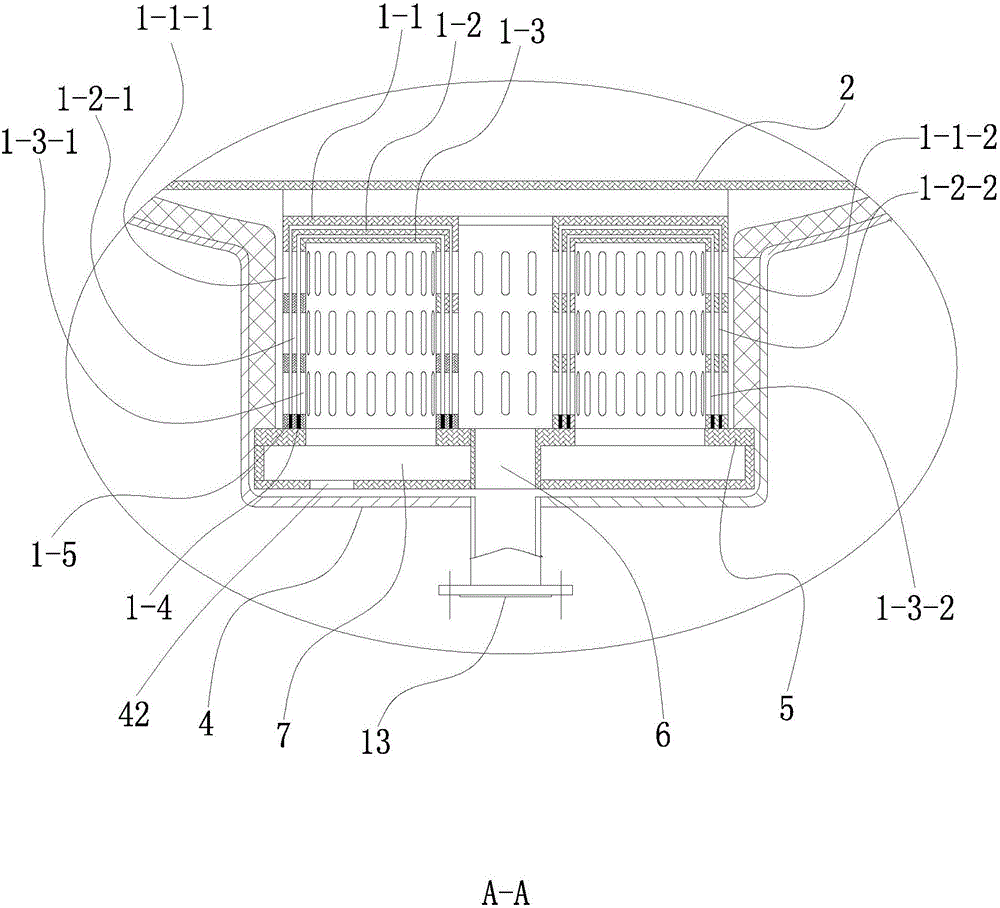

Waste gas purifying and weighing integrated reaction kettle device

InactiveCN106622073AImprove securityImprove heat transfer efficiencyProcess control/regulationDispersed particle filtrationHigh concentrationEmission standard

The invention relates to a waste gas purifying and weighing integrated reaction kettle device which comprises a kettle body, a waste gas treating and purifying device and a weighing device arranged at the top of the kettle body. A kettle cover is arranged at the top of the kettle body, a material inlet, a gas discharging hole and a thermometer sleeve are arranged on the kettle cover, and the waste gas treating and purifying device is positioned at the upper end of the kettle body and fixed through a mounting frame. By arranging a waste gas filtering layer, a waste gas adsorbing layer and a waste gas ventilating layer, a lot of high-concentration organic waste gas generated in the process of reaction for preparing adhesive resin can be treated and absorbed to reach discharging standards; a ventilating wall plate having a certain inclination angle is arranged, so that noise in the process when a fan runs can be lowered. The waste gas purifying and weighing integrated reaction kettle device is compact in structure, high in automation level and convenient and simple to operate.

Owner:YASUSA CHEM CO LTD

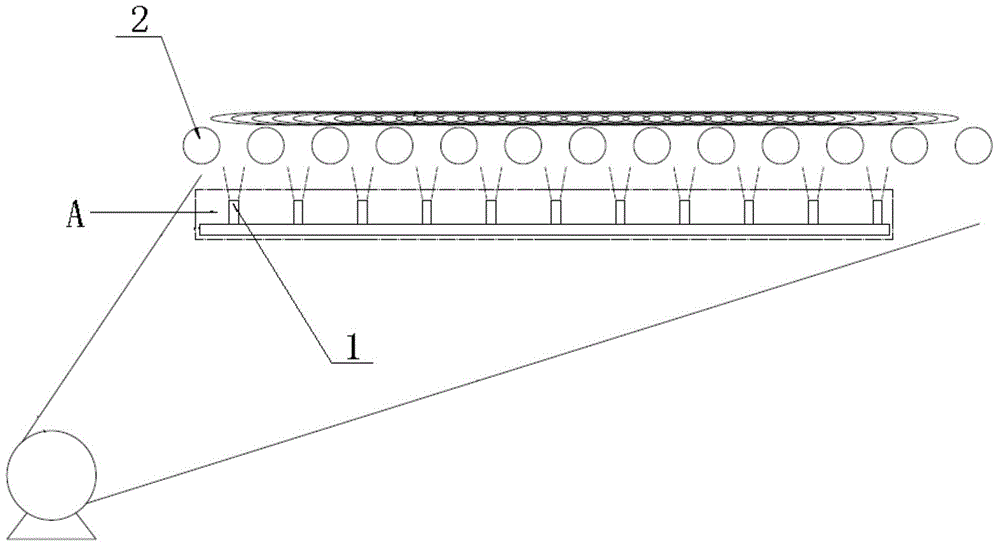

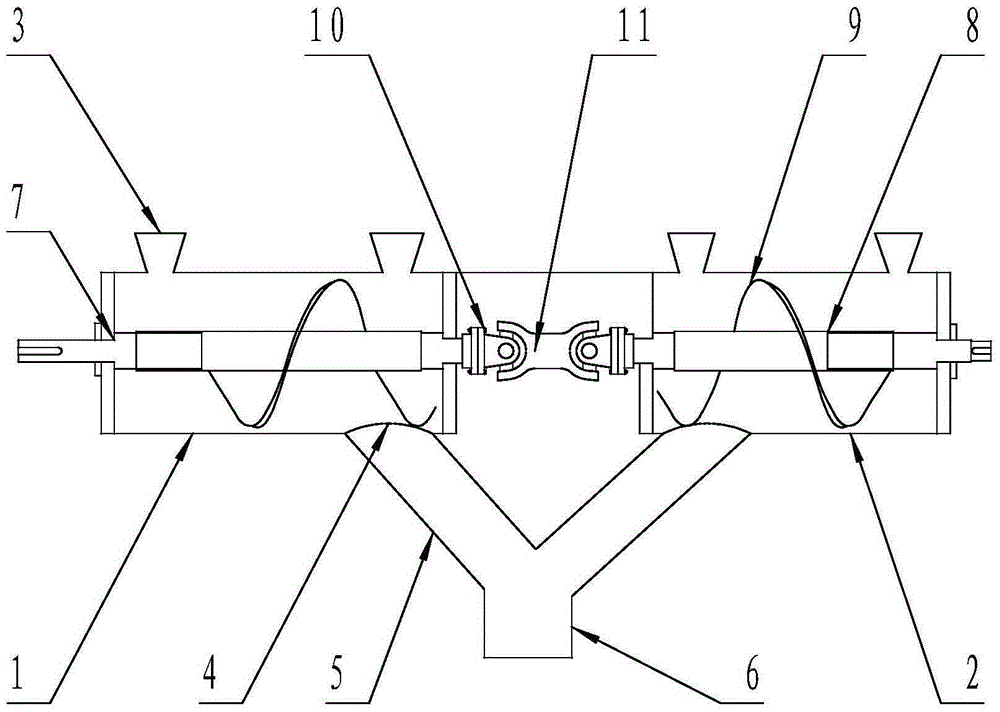

Wire rod edge cooling device and wire rod edge cooling method

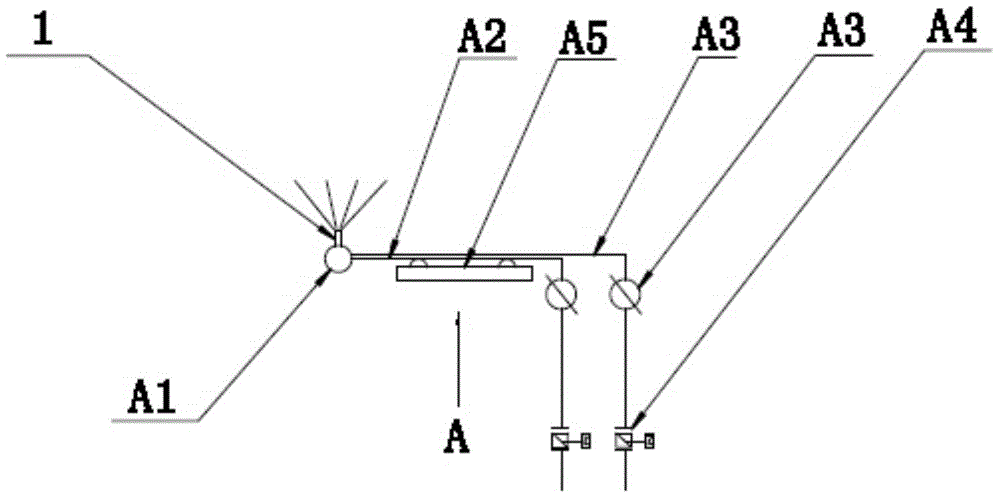

ActiveCN105436214AUniform temperatureUniform tissueTemperature control deviceWork treatment devicesWire rodLap joint

The invention provides a wire rod edge cooling device and a wire rod edge cooling method thereof. The device comprises nozzles, each nozzle is connected with a cooling device assembly, and the cooling device assemblies are arranged in air ducts located on the lower portions of the two sides of a roller bed. The cooling device assemblies can move left and right through guiding parts of the cooling device assemblies, and therefore the whole cooling device assemblies can be adjusted in position to be aligned with coil lap-joint points so as to carry out cooling operation. By means of the device and the method, the temperature differences of coils can be adjusted in any position, especially the temperature of a phase change area can be adjusted, so that uniformity of the temperature of the phase change area is guaranteed, structure uniformity is directly guaranteed, and product performance is consistent. According to the device and the method, air mist sprayed from edge cooling equipment can be better blown to wire rods, and water mist which is not gasified is blown to the position above the roller bed and does not drop, so that the air ducts, fans and the like are not influenced. In addition, the device is arranged in the length direction of the Stelmor line and can be lengthened or shortened, the number of switch sets is adjustable, and the sufficient temperature difference adjusting capacity is achieved. In addition, the carbon and oxidation problems in the lap-joint point positions can be solved, and the site operation environment is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

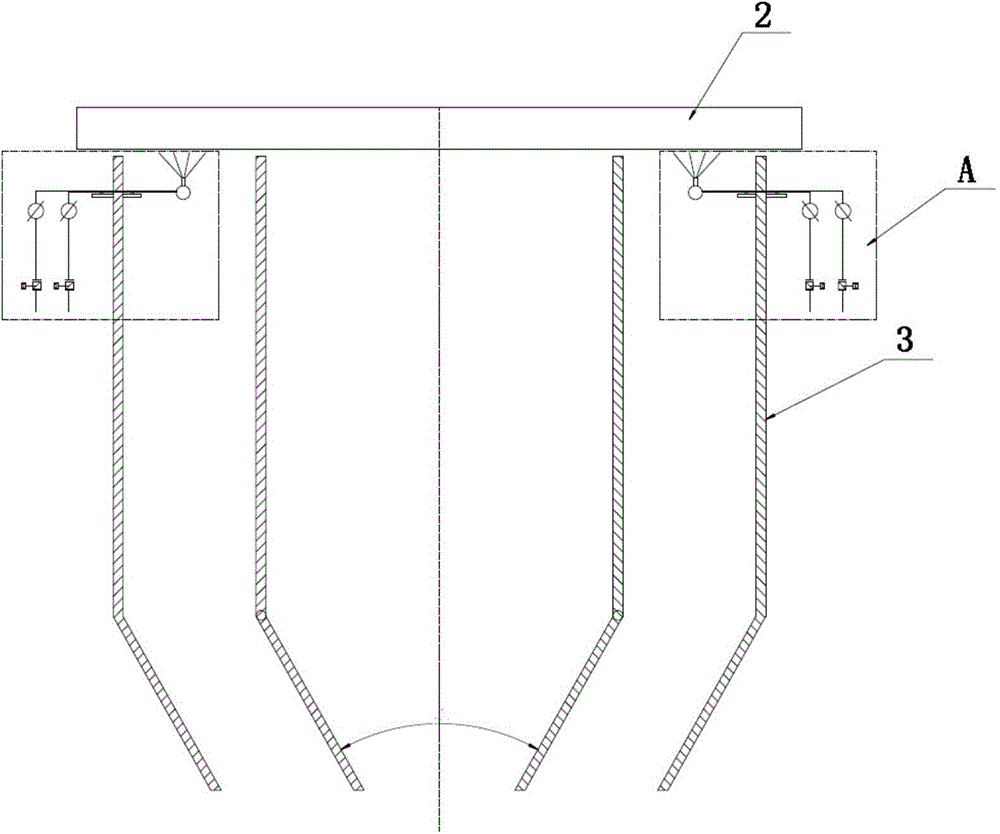

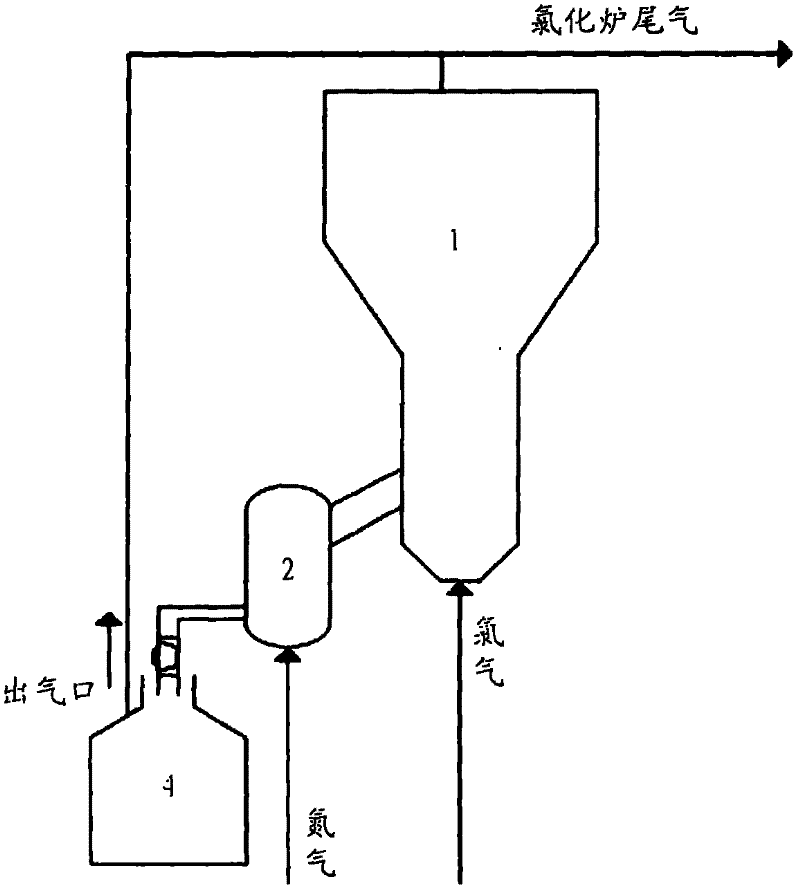

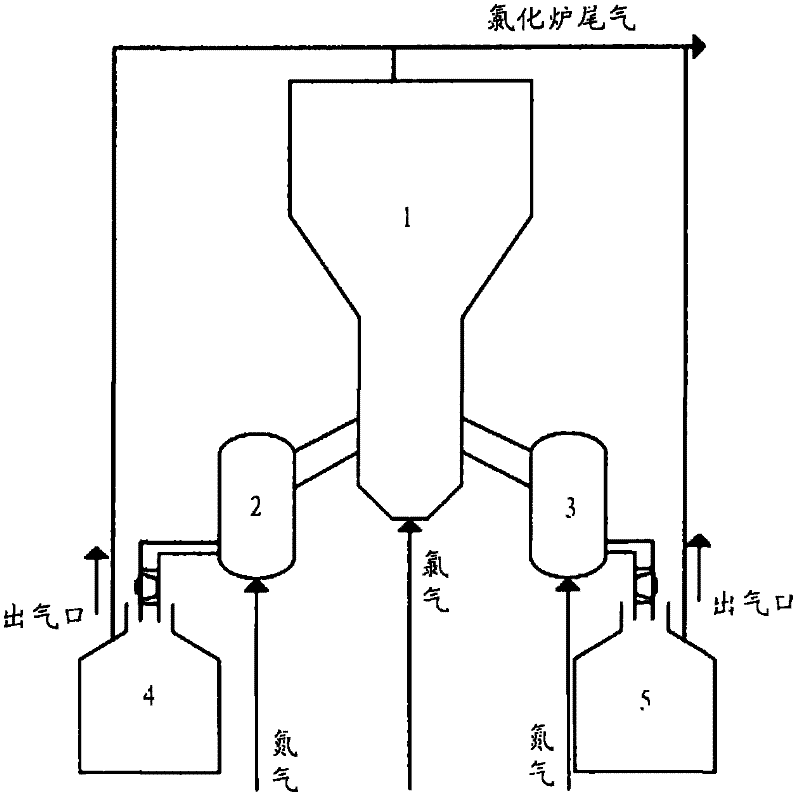

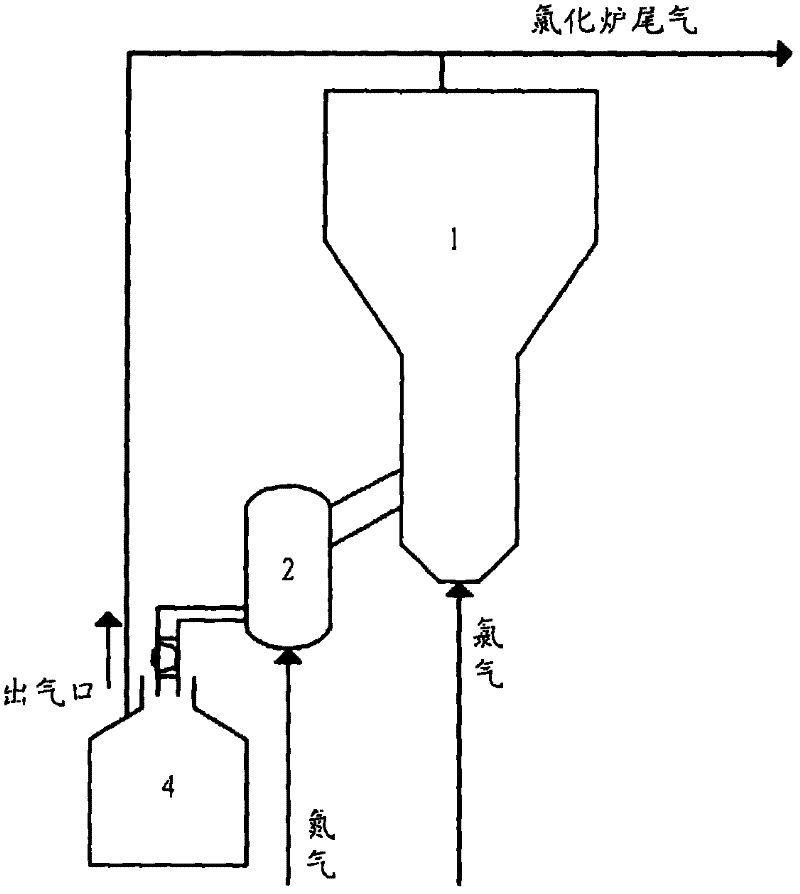

Sealed deslagging method of fluidizing chlorination furnace

InactiveCN102399977ASolve environmental problemsSolve corrosiveFluidised-bed furnacesSlagProduct gas

The invention provides a sealed deslagging method of a fluidizing chlorination furnace. The sealed deslagging method comprises the following steps of: discharging slag generated in the fluidizing chlorination furnace to a sealed deslagging intermediate tank; purifying the slag by using a purge gas in the deslagging intermediate tank to obtain purified slag and mixed gases; discharging the purified slag and at least one part of mixed gases to a slag receiving tank; and enabling at least one part of mixed gases to be discharged to a tail gas system through a negative pressure pipeline connected to the tail gas system in the slag receiving tank and obtaining the purified slag from the slag receiving tank. The sealed deslagging method disclosed by the invention can be used for effectively purifying harmful gasses mingled in the slag, realizes the purpose of sealed deslagging, effectively solves the environment-friendly problem and the gas corrosion problem in the field deslagging process, is beneficial to improvement of field operation environments and has the capability of effectively prolonging the service life of equipment.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

Method for preparing high-purity low-chloride electroplated copper oxide

InactiveCN103011250AAvoid bringing inGuaranteed purityCopper oxides/halidesDistillationCarbonization

The invention discloses a method for preparing high-purity low-chloride electroplated copper oxide. The method comprises the following steps: taking copper, liquid ammonia and high-purity carbon dioxide as raw materials; preparing stronger ammonia water at first; then pumping high-purity carbon dioxide into the stronger ammonia water; preparing and obtaining carbonated ammonia water through controlling the carbonization degree; achieving reaction between the carbonated ammonia water and copper under a certain air pressure to obtain a copper and ammonia complexing solution; preparing heavy high-purity cupric subcarbonate through heating, ammonia distillation, separation, washing, drying and screening; and heating, calcining and decomposing the heavy cupric subcarbonate to obtain high-purity low-chloride electroplated copper oxide. According to the invention, as carbon dioxide serves as the raw material, the problem that the raw material for producing cupric subcarbonate by adopting a traditional method carries heavy metal ions, chloride ion and other impurities is solved, the reaction speed is increased, the production period is shortened, the production efficiency is greatly improved, the impurity content is low, high purity and activity are realized, and the product can be applied more widely. The method has the advantages of high yield, low energy consumption, little pollution and low cost.

Owner:TAIXING SMELTING PLANT

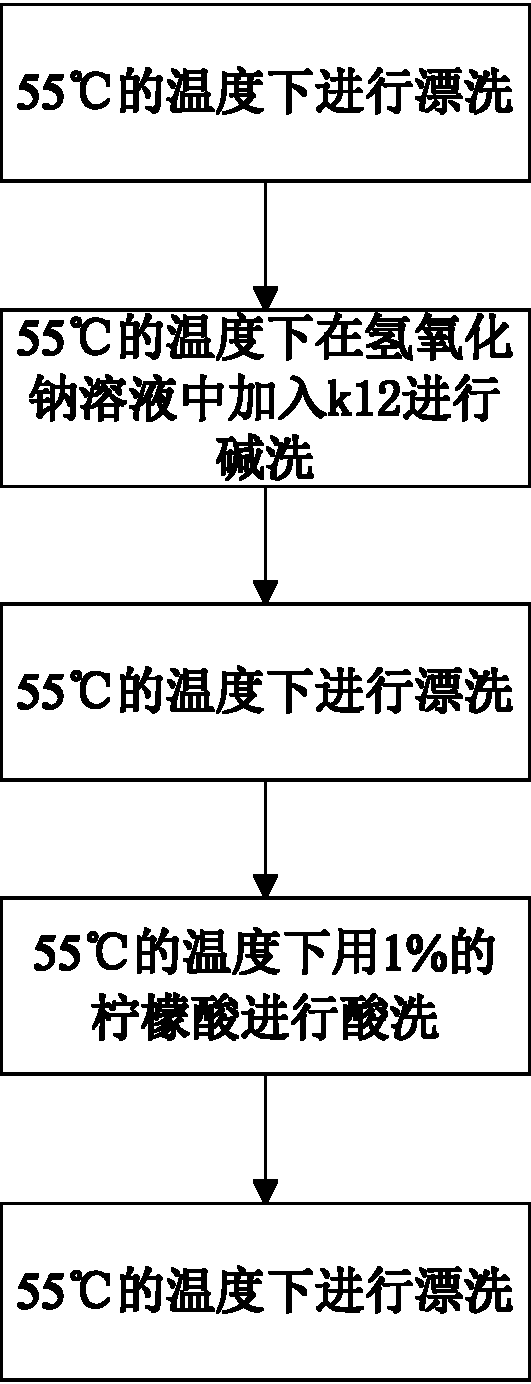

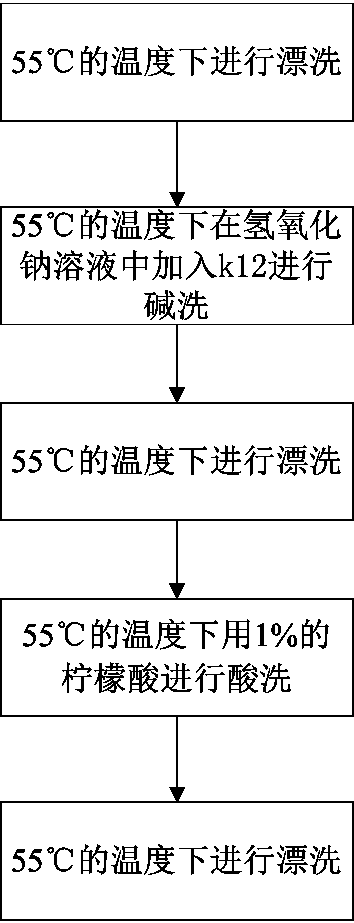

Inorganic ceramic membrane washing method

InactiveCN102512967APrevent eutrophicationImprove the on-site operating environmentSemi-permeable membranesEutrophicationAcid washing

The invention discloses an inorganic ceramic membrane washing method comprising the following steps: considering citric acid as an acid washing agent to carry out the acid-washing on an inorganic ceramic membrane, and adding sodium dodecyl sulfate in an alkaline washing agent to carry out the alkaline-washing on the inorganic ceramic membrane. Through the use of the inorganic ceramic membrane washing method, the difficulty in purchase and transportation caused by that nitric acid is used as an acid washing agent is solved, the eutrophication of the water body caused by that nitric acid is used as the acid washing agent is avoided, the field operation environment is improved, the production safety risk is reduced, and the alkaline-washing effect is enhanced greatly since an assistant washing agent (namely, sodium dodecyl sulfate) is added at the alkaline-washing stage.

Owner:WISDRI ENG & RES INC LTD

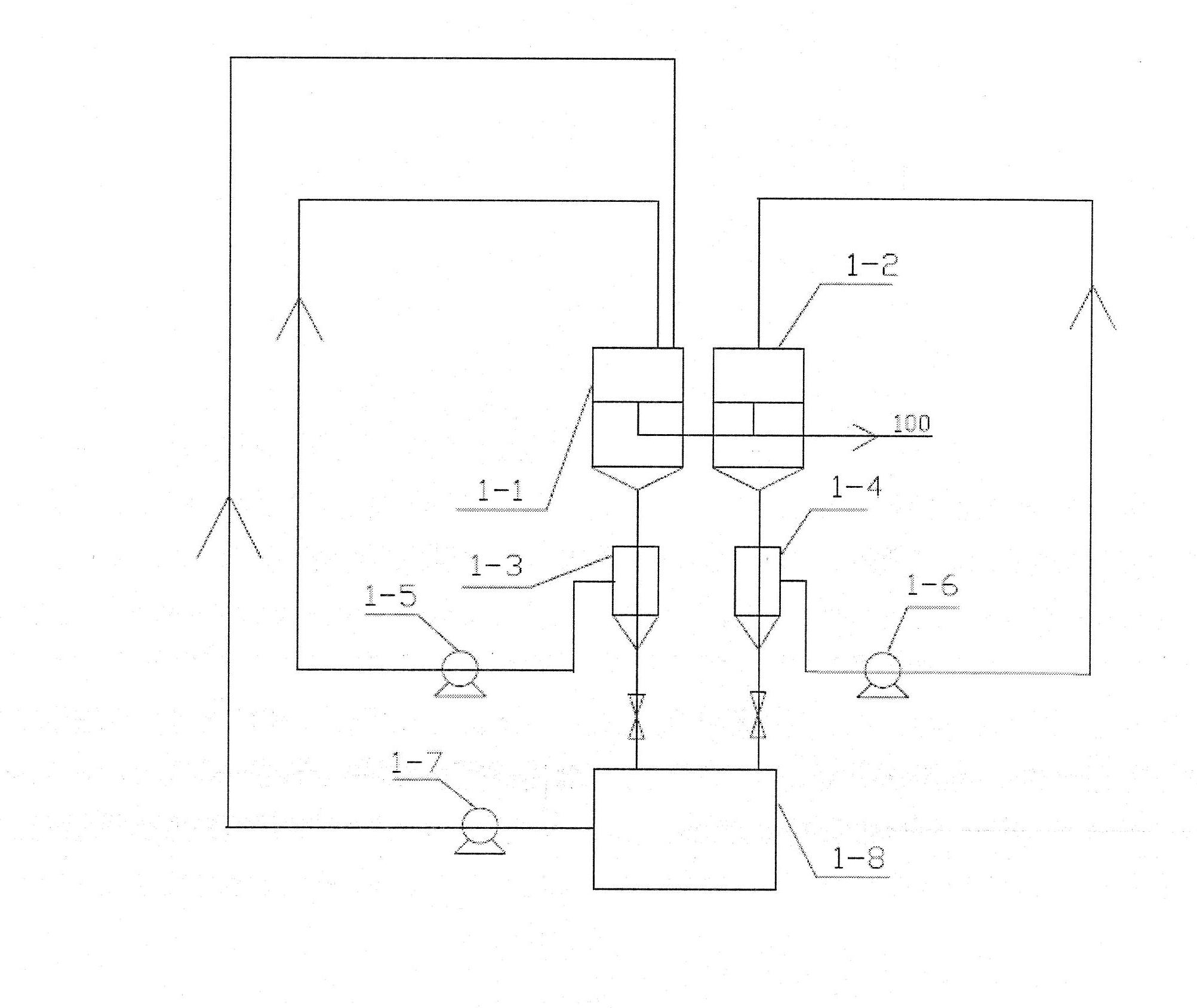

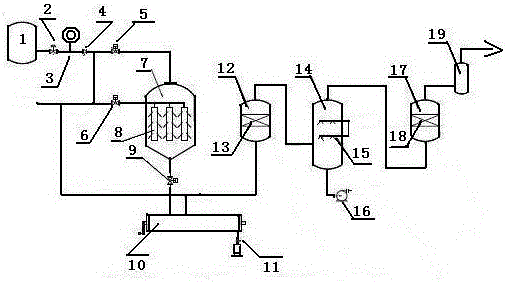

Tar residue pre-separation and removal process and system in coke oven ammonia water system

ActiveCN102657961AEasy to separateGood removal effectSettling tanks feed/dischargeLiquid separationTarCoke oven

The invention discloses a tar residue pre-separation and removal process and a tar residue pre-separation and removal system in a coke oven ammonia water system. The system mainly comprises a tar residue pre-separator, an accommodating tank, a mechanical clarifying tank, a tar residue adding device and the like. The process comprises the following steps of: preliminarily separating a mixture of tar, ammonia water and tar residue through the tar residue pre-separator, introducing the tar / ammonia water mixed solution into the next process, inputting the tar residue and mixture of residual tar and ammonia water into the mechanical clarifying tank for performing gravity separation, discharging the obtained mixed solution into the accommodating tank, and inputting the solution into the tar residue pre-separator through a submerged pump and the like; and scraping the tar residue from the mechanical clarifying tank, and transferring the tar residue to the tar residue adding device for blending coal. The effect of pre-separating and removing tar residue in the ammonia water can be greatly improved, the tar residue is separated in the mechanical clarifying tank, the link of depositing the tar residue in an underground emptying tank can be saved, the field operating environment is greatly improved, and the labor intensity of a worker is reduced.

Owner:SHAGANG GROUP

Method for preparing high-purity basic cupric carbonate by outer-coil internal-stirring type reaction kettle

InactiveCN103011245AEasy to separateQuick responseCopper compoundsBASIC CUPRIC CARBONATEBasic copper carbonate

Owner:TAIXING SMELTING PLANT

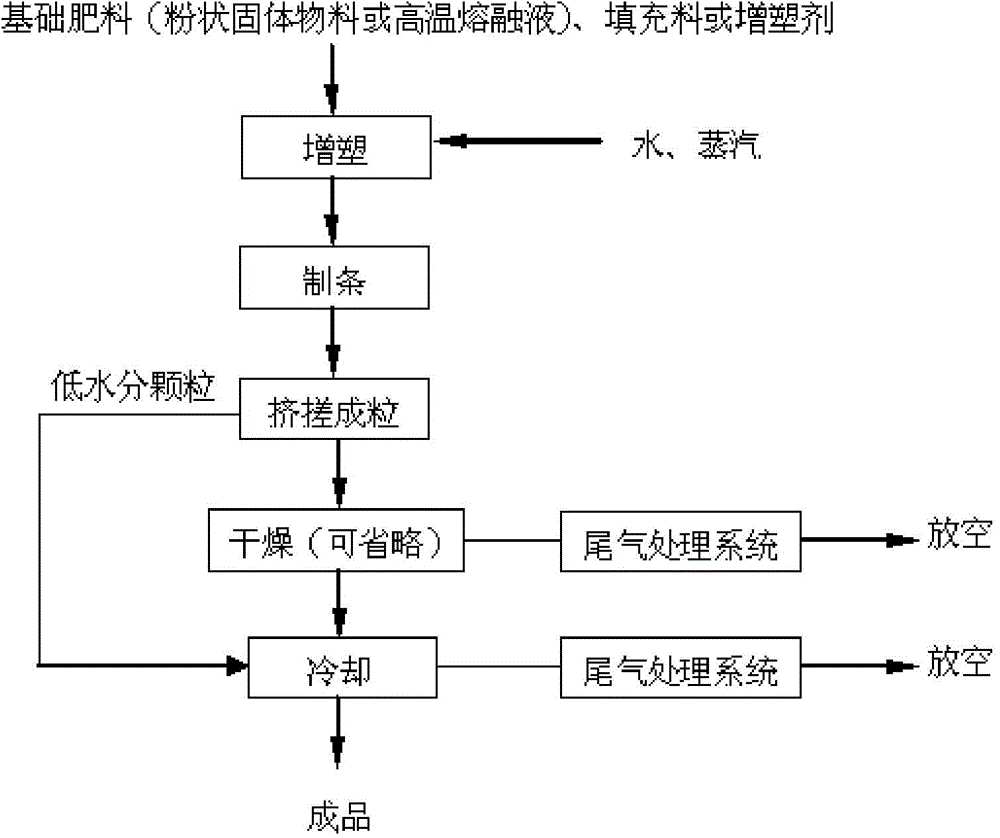

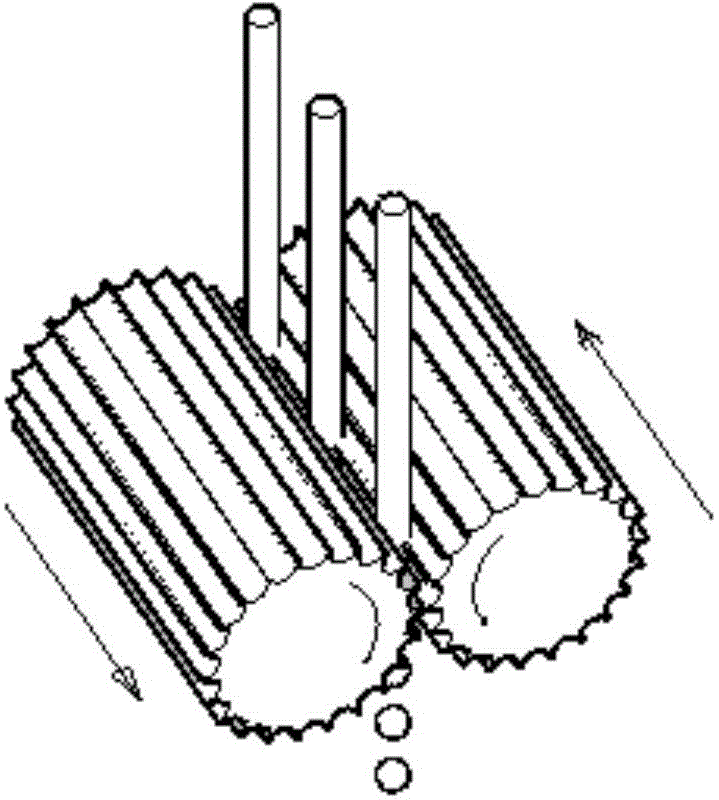

Method for producing compound fertilizer by extrusion-kneading process

ActiveCN104529597AUniform sizeRound appearanceSuperphosphatesAlkali orthophosphate fertiliserEngineeringTableting

The invention relates to a method for producing a compound fertilizer by an extrusion-kneading process, which comprises the following steps: (1) plasticizing a raw material mixture; (2) extruding the plasticized raw material mixture into strips, or pressing into sheets and cutting into strips; and (3) sending the strips into an extrusion-kneading granulation device to form compound fertilizer granules. Compared with the prior art, the product obtained by the method has the advantages of uniform granular size, smooth appearance, more accurate nutrients and improved storage quality. Compared with the traditional pellet process, the method provided by the invention further simplifies the production process, can save the steps of drying, screening, large granule crushing and the like, obviously reduces the exhaust emission, obviously improves the production shop environment and greatly lowers the comprehensive energy consumption.

Owner:SHANGHAI RES INST OF CHEM IND

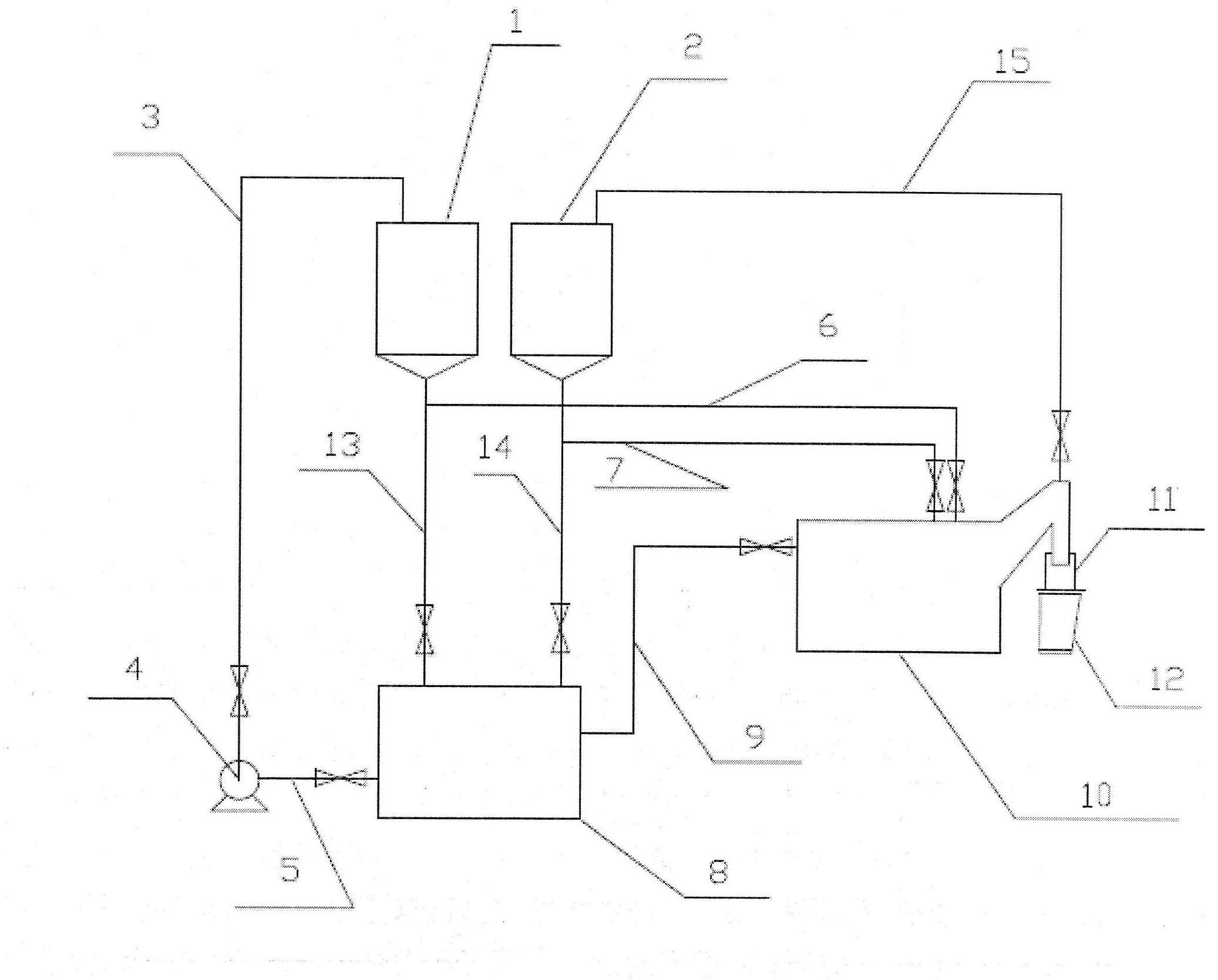

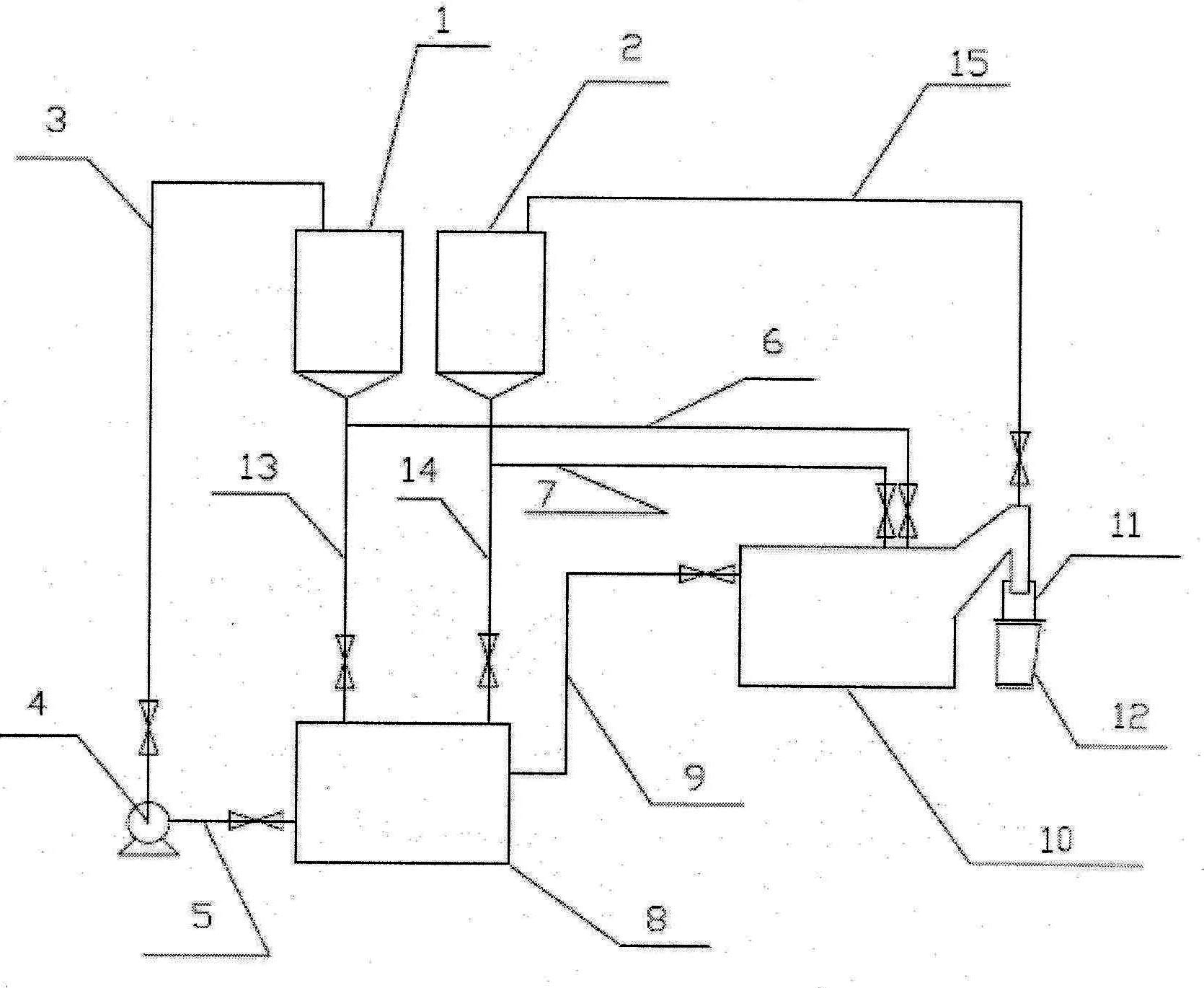

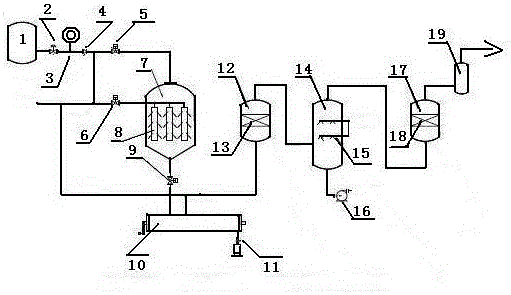

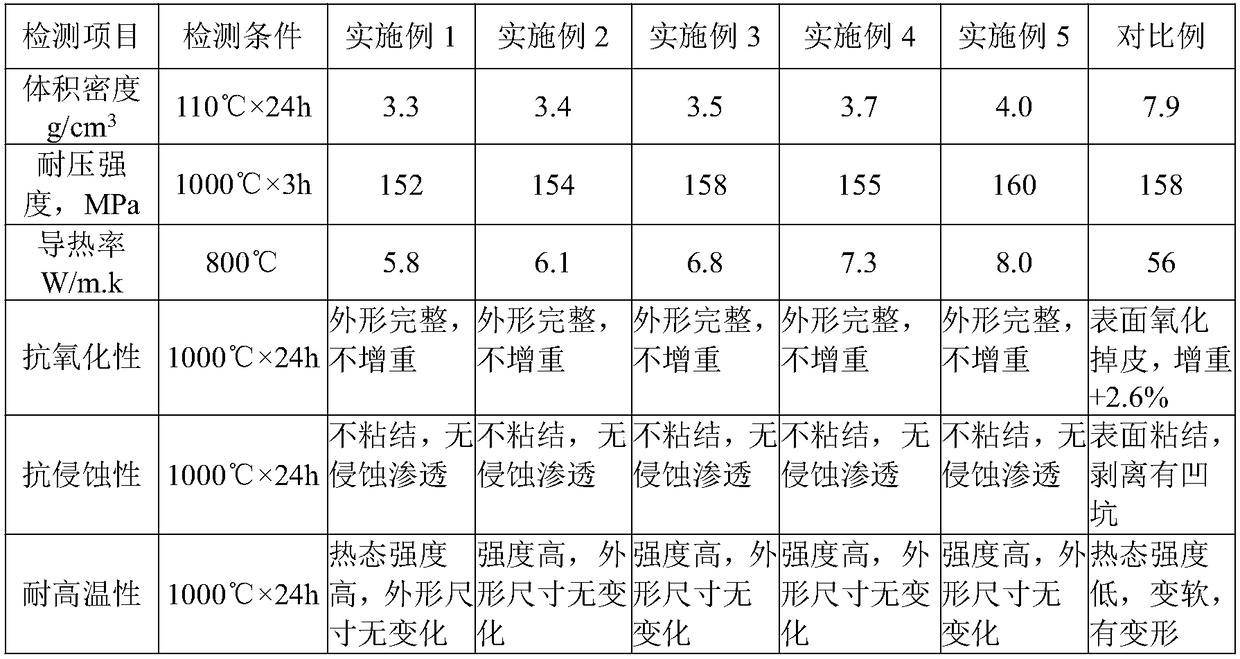

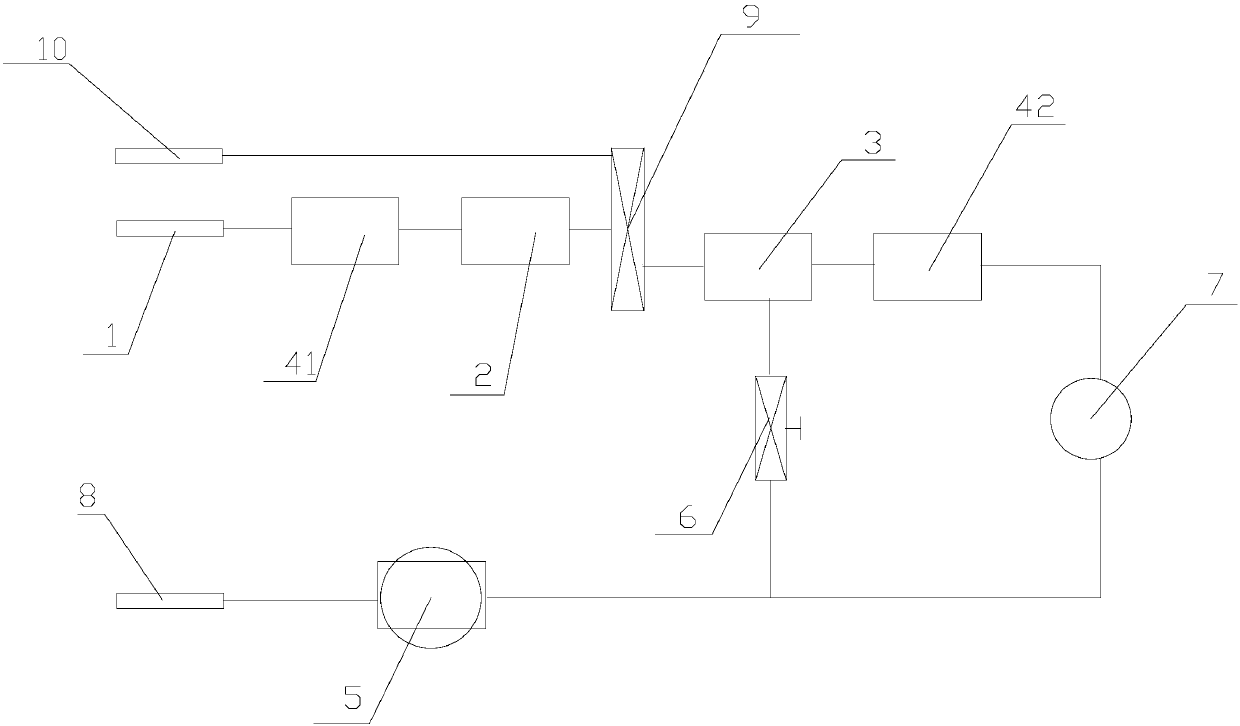

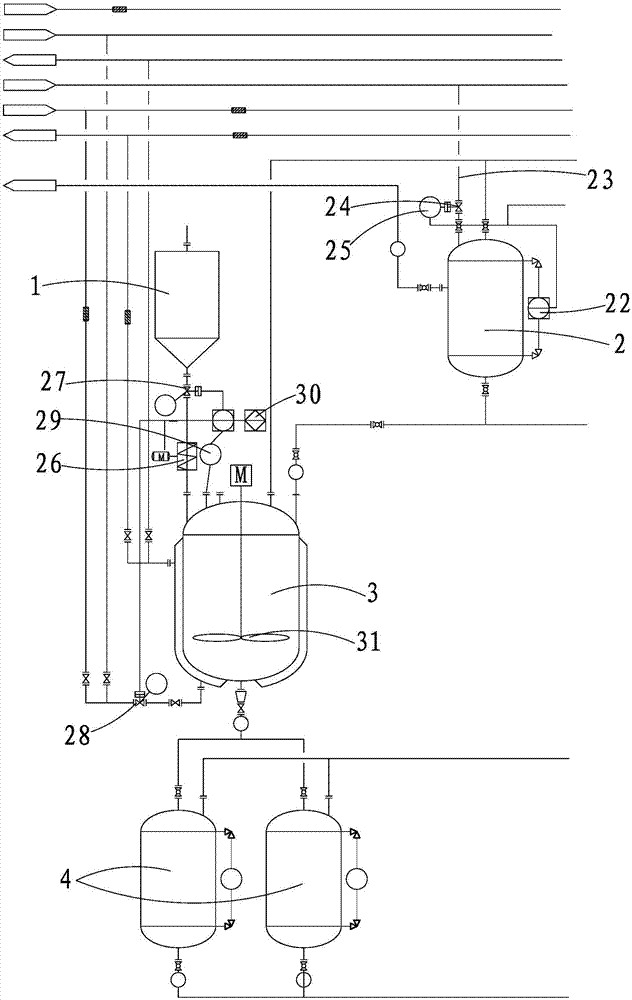

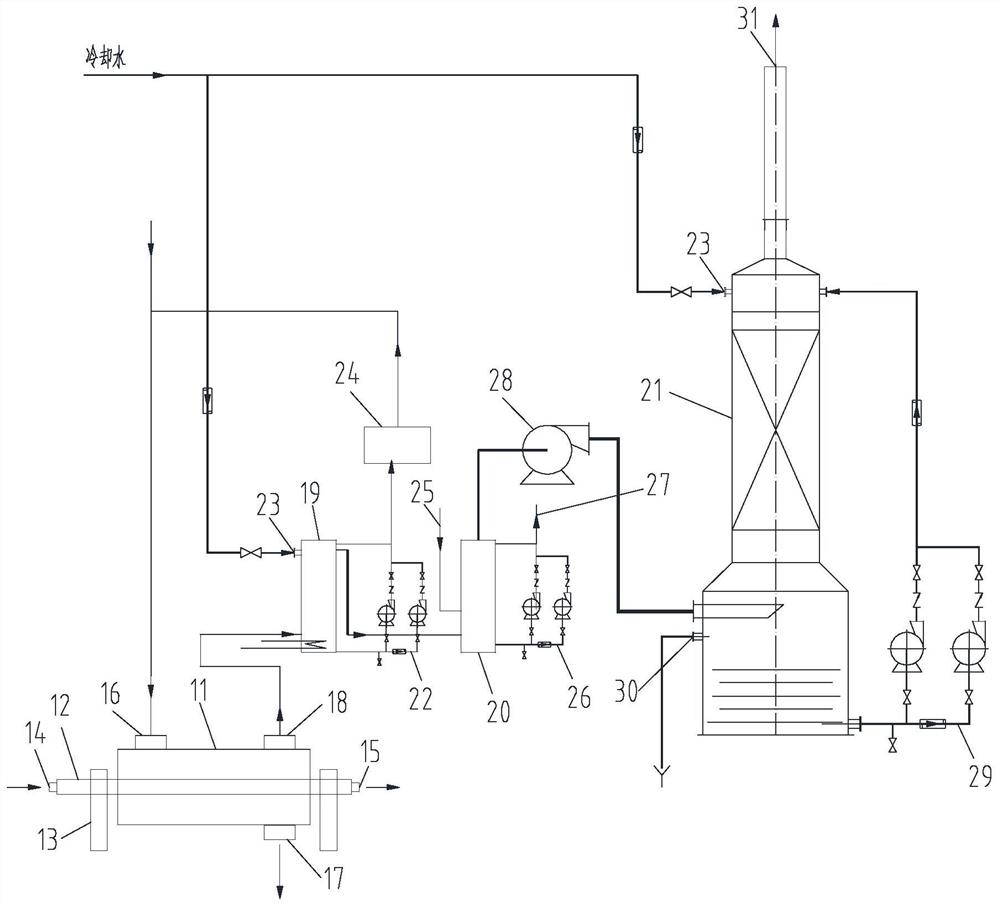

Closed-circuit internal circulation technology for gas collection in solid-liquid separation process

InactiveCN106166409AAvoid unordered releaseImprove the on-site operating environmentCombination devicesMembrane filtersTreatment burdenVapor–liquid separator

The invention relates to a technology of a closed-circuit internal circulation device for gas collection in a solid-liquid separation process. The closed-circuit internal circulation device consists of a compressed gas storing tank, a pressure adjusting valve, a pressure transmitter, a check valve, a pressure exhaust drying valve, a reverse blowing valve, a bundling type reverse blowing filter, filtering elements, a slag discharging valve, a slurry drying machine, a slag conveyor, a first-stage gas-liquid separator, a first-stage aggregation element, a gas washer, a spraying assembly, a conveying pump, a second-stage gas-liquid separator, a second-stage aggregation element, and a high-efficiency gas filter. The slurry drying machine in closed operation is used for collecting slag discharging filer cakes and slag discharging gas, and drying treatment is further performed on the filter cakes, so that disordered release of gas and dust is avoided; the gas-liquid separator is used for performing gas-liquid aggregation and separation on the gas, so that the direct discharge of atomized gas is avoided, the effective aggregation and collection of liquid mingled in the gas can be realized, and the subsequent treatment burden is reduced; and an inclined corrugated plate silk screen or a filling is used for separating the gas, and the spraying component is used for spraying and absorbing toxic and harmful gas, so that the danger of directly discharging the toxic and harmful gas is avoided.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

Spiral discharging device for dust collector

InactiveCN105383875AGuarantee continuous and stable operationAvoid powder leakageConveyorsPackagingEngineeringOperating environment

The invention discloses a spiral discharging device for a dust collector. The spiral discharging device for the dust collector is provided with a first discharging shell and a second discharging shell. Dust conveying devices are further arranged in the first discharging shell and the second discharging shell respectively. Each dust conveying device comprises a spiral shaft and a spiral fixedly connected to the spiral shaft. The ends, stretching out of two adjacent side plates, of the spiral shafts installed on bearing seats on the side plates of the first discharging shell and the second discharging shell are connected with a universal rotary shaft through universal rotary shaft connecting flanges respectively. According to the spiral discharging device for the dust collector, the phenomenon that the discharging shells are swept and abraded due to falling and bending of the spiral shafts, and consequently dust leakage is caused is prevented, and checking and maintenance of the spiral shafts are facilitated; the field operating environment is improved, the equipment maintenance cost and workload are reduced, and continuous and stable operation of the spiral discharging device for the dust collector is achieved.

Owner:JINAN AOHAI CARBON PROD

Waste gas purification device of multifunctional reaction kettle

InactiveCN106732252AReduce riskReduce labor intensityProcess control/regulationGas treatmentWaste treatmentWall plate

The invention relates to a waste gas purification device of a multifunctional reaction kettle. The waste gas purification device comprises a kettle body, a waste gas treatment and purification device and a liquid weighing device arranged on the side wall of the kettle body, wherein a kettle cover is arranged at the top of the kettle body, and a manhole, a feeding hole, a gas vent and a thermometer sleeve are arranged on the kettle cover; the waste gas treatment and purification device is located at the upper end of the kettle body and fixed through a support seat; a horn type connecting pipe is mounted at the bottom end of the waste gas treatment and purification device, and the bottom of the connecting pipe is connected with the gas vent; with arrangement of a waste gas filtering layer, a waste gas adsorbing layer and a waste gas ventilating layer, a large amount of high-concentration organic waste gas produced in a process of preparing vinyl resin through reaction can be treated and absorbed until reaching emission standard; meanwhile, ventilating wall plates at certain inclined angles are arranged, and noise produced in a fan operating process can be reduced. The device is compact in structure, high in automation degree, and convenient and simple to operate.

Owner:浙江晨诺高分子材料有限公司

Closed-loop internal circulation device for gas collection in solid-liquid separation process

ActiveCN106076068AAvoid unordered releaseImprove the on-site operating environmentCombination devicesTreatment burdenSlag

Provided is a closed-loop internal circulation device for gas collection in the solid-liquid separation process. The closed-loop internal circulation device is composed of a compressed gas storage tank, a pressure regulating valve, a pressure transmitter, a check valve, a pressure exhaust drying valve, a reverse blowing valve, a clustered type reverse blowing filter, filter elements, a slagging valve, a slurry drying machine, a slag conveyor, a first-stage gas-liquid separator, a first-stage coalescence element, a gas scrubber, a spray assembly, a conveying pump, a second-stage gas-liquid separator, a second-stage coalescence element and an efficient gas filter. The slurry drying machine which operates in a sealed mode collects slagging filter cake and slagging gas, further drying treatment is conducted on the filter cake, and disorderly release of the gas and dust is avoided; gas-liquid coalescence separation is conducted on the gas through the gas-liquid separators, direct exhaust of atomized gas is avoided, effective coalescence collection of liquid mixed in the gas is achieved, and subsequent treatment burden is reduced; the gas is separated through inclined type corrugated plate screens or filler, spraying absorption is conducted on poisonous and harmful gas through the spray assembly, and damage caused by direct exhaust of the poisonous and harmful gas is avoided.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

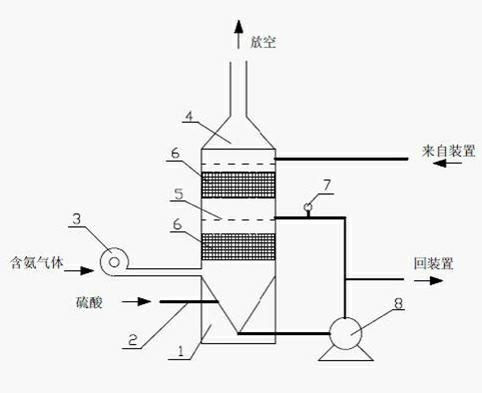

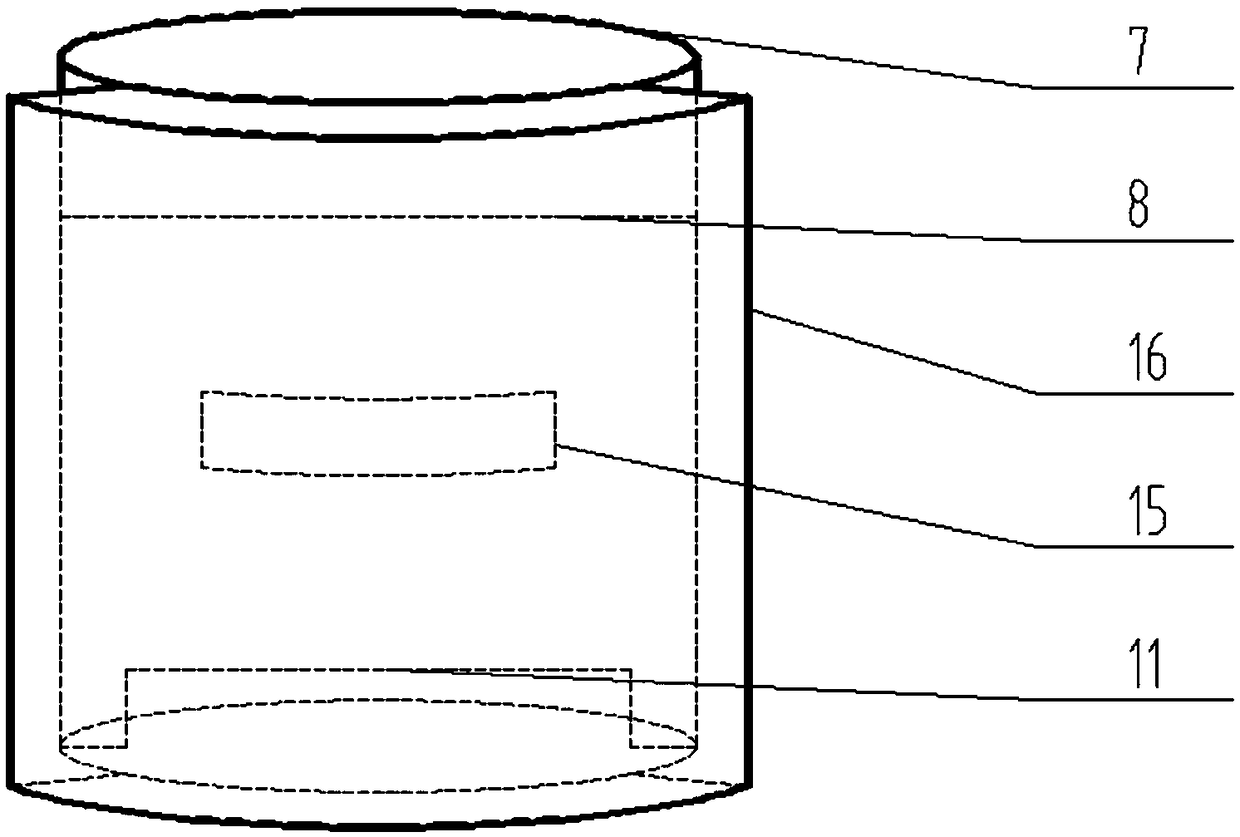

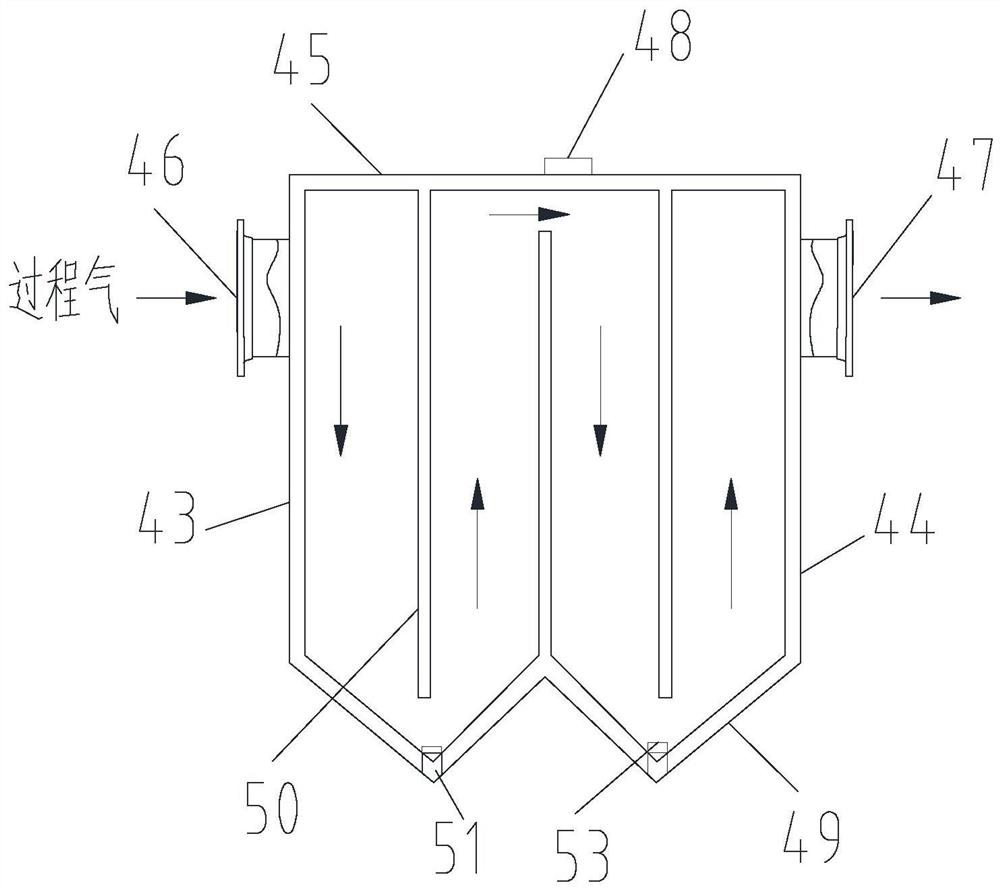

Processing method for tail gas generated in preparation of ammonium sulfate from phosphogypsum

InactiveCN102631825AImprove the on-site operating environmentReduce ammonia consumptionDispersed particle separationEconomic benefitsPhosphogypsum

The invention discloses a processing method for tail gas generated in preparation of ammonium sulfate from phosphogypsum, and the method comprises the following steps: additionally arranging a washing tower, an exhaust fan and a circulating pump in a device for preparing ammonium sulfate from phosphogypsum.; connecting the circulating pump and the washing tower to form a circulating loop by virtue of a pipeline; feeding acid filtered fluid, utilized as circulating absorption liquid, from the device into the washing tower to backflush gas containing ammonia and absorb the ammonia in the gas, enabling the acid filtered fluid to flow to the bottom of the tower, then pumping out the acid filtered fluid by virtue of the circulating pump so as to be used as absorption liquid, and recycling and absorbing; returning part of the absorption liquid back into the device so as to be used as a reaction replenisher, wherein the ammonia in the liquid can be used for producing the ammonium sulfate; feeding the tail gas in the device for preparing ammonium sulfate from phosphogypsum and the volatized gas containing ammonia into the washing tower by virtue of the exhaust fan; and when the pH value of the circulating absorption liquid is overhigh, adding sulfuric acid from the bottom of the tower. The processing method can be used for sufficiently absorbing the tail gas in the device for preparing ammonium sulfate from phosphogypsum and the volatized gas containing ammonia, improving a field operation environment, recovering the ammonia for producing ammonium sulfate and reducing the ammonia consumption of products, and has economic benefits, thus being applicable to manufacturers for producing ammonium sulfate from phosphogypsum.

Owner:WENGFU (GRP) CO LTD

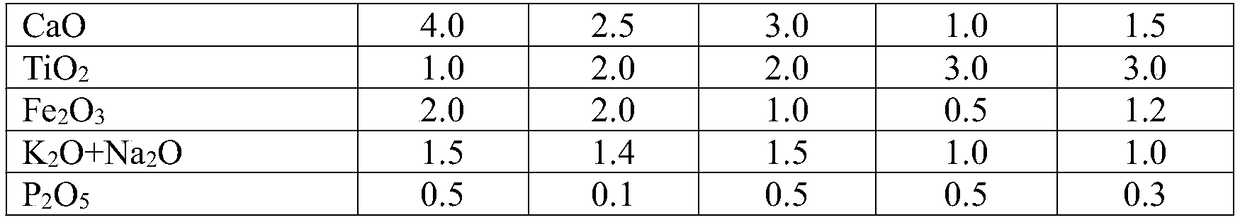

Metal ceramic compound sintering machine fire grate and preparation method thereof

The invention provides a metal ceramic compound sintering machine fire grate and a corresponding preparation method thereof. The metal ceramic compound sintering machine fire grate is prepared from 25to 50 wt% of heat-resisting steel fiber and 75 to 50 wt% of Al2O3-SiO2 series mullite-based ceramic powder. The invention further provides the preparation method of the metal ceramic compound sintering machine fire grate. The fire grate has the advantages of wear resistance, corrosion resistance, oxidization resistance and high temperature resistance of a ceramic material and advantages of good toughness of a metal material. The fire grate further has special characteristics of lower heat conductivity and lighter than a metal fire grate; furthermore, a sintering machine trolley wholly achieves more energy conservation, environmental friendliness, light weight and long service life; sintering energy consumption is reduced, field operation environment is improved, and more economic benefitsare generated.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing high soda ash type copper carbonate by adopting duplex centrifugal film evaporator

The invention discloses a method for preparing high soda ash type copper carbonate by adopting a duplex centrifugal film evaporator. The method comprises the following steps: using copper, liquid ammonia and high-purity carbon dioxide as the raw materials; firstly, preparing stronger ammonia water; secondly introducing the high-purity carbon dioxide into the stronger ammonia water so as to prepare carbonized ammonia water; reacting the carbonized ammonia water with pure copper under a certain air pressure so as to prepare a copper-ammino complexing solution; further evaporating by using the duplex centrifugal film evaporator, rotationally separating and scrapping so as to prepare the high soda ash type copper carbonate. By utilizing the method, the reaction speed is increased, the production period is shortened, the product is higher in purity, the production efficiency is greatly improved, the production cost is lower, the quality is significantly improved, and the product application is wider; and meanwhile by adopting the duplex centrifugal film evaporator, the method is high in yield, small in heat radiation and short in reaction time, the coal resource is saved, and the requirements on environmental-friendliness are met better and at the same time the production cost is greatly reduced.

Owner:TAIXING SMELTING PLANT

Method for preparing heavy high-purity basic cupric carbonate

InactiveCN103011246AAvoid bringing inHigh purityProductsReagentsBASIC CUPRIC CARBONATEBasic copper carbonate

The invention discloses a method for preparing heavy high-purity basic cupric carbonate. The method comprises the steps that copper, liquid ammonia and high-purity carbon dioxide are used as raw materials, stronger ammonia water is firstly prepared, then high-purity carbon dioxide is fed into the stronger ammonia water to form carbonized ammonia water, carbonized ammonia water is reacted with copper at a certain air pressure to form a copper ammonia complexation solution, the copper ammonia complexation solution is subjected to heating, ammonia stilling, separating, washing, drying and sieving to prepare the heavy high-purity basic cupric carbonate. According to the method for preparing the heavy high-purity basic cupric carbonate, carbon dioxide is directly used as a raw material, so that heavy metal ions and chloride ions are prevented from being brought in, the reaction speed is improved, the production cycle is shortened, the production efficiency is substantially improved, the product purity is higher, the quality is remarkably improved, the product application is wider, and simultaneously the method is high in yield, small in heat dissipation and low in energy consumption, so that the method further meets the environment-friendly requirement and simultaneously reduces the production cost.

Owner:TAIXING SMELTING PLANT

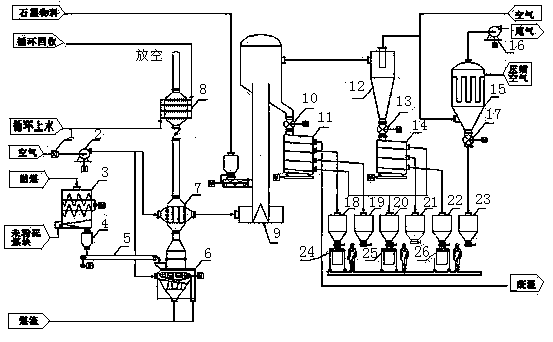

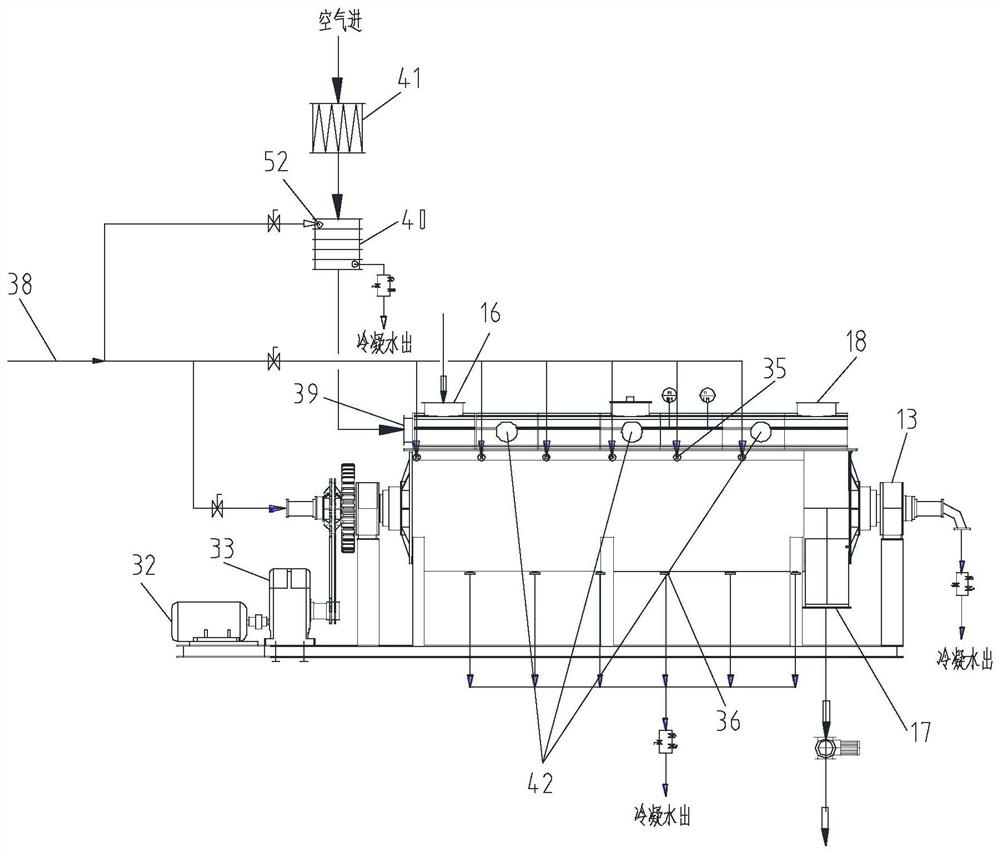

Method for drying, screening and collecting graphite powder

ActiveCN103673508AImprove heat transfer coefficientShorten drying timeDrying solid materials with heatSolid separationSocial benefitsEnvironmental resistance

The invention relates to a method for drying, screening and collecting graphite powder. The method comprises the steps that firstly, the graphite powder is dried through the differential dying technology, then, the graphite powder is screened and collected through airflow classification, and finally graphite products at different levels are obtained. The method for drying, screening and collecting the graphite powder has the advantages that the whole system continuously operates in a sealing mode, energy is saved, consumption is reduced, safety and environmental friendliness are achieved, operation is continuous, the mesh number of the graphite products is increased, and the economic benefits and social benefits of an enterprise are increased. Compared with the prior art, the method for drying, screening and collecting the graphite powder further has the advantages of reducing the labor intensity of workers, reducing contact between the operation workers and the graphite powder, preventing the harm of the graphite powder to the respiratory systems of the workers, greatly improving an operation site, and achieving cleanness and tidiness of the environment of the whole production site.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Method for preparing heavy high-purity basic cupric carbonate

InactiveCN103011248AAvoid bringing inHigh purityCopper compoundsBASIC CUPRIC CARBONATEBasic copper carbonate

The invention discloses a method for preparing heavy high-purity basic cupric carbonate. According to the method, copper, liquid ammonia and high-purity carbon dioxide are taken as the raw materials; high-purity carbon dioxide is blown into stronger ammonia water, and carbonized ammonia water is obtained through controlling the carbonization degree; the carbonized ammonia water reacts with copper under certain air pressure to obtain a copper-ammonia complex solution; and finally heavy high-purity basic cupric carbonate is obtained through heating, ammonia distilling, separating, washing, drying and screening. According to the method, carbon dioxide is directly taken as the raw material, so that heavy metal ions and chloride ions are prevented from entering, as a result, the reaction speed is improved, the production period is shortened, the production efficiency is greatly improved, the product purity becomes higher, the impurity is less, the quality is significantly improved, the product is more widely applied, meanwhile, the yield by adopting the method is high, the heat dissipation is less, the energy consumption is lower, the environment protection requirement is met more satisfactorily and the production cost is greatly reduced at the same time.

Owner:TAIXING SMELTING PLANT

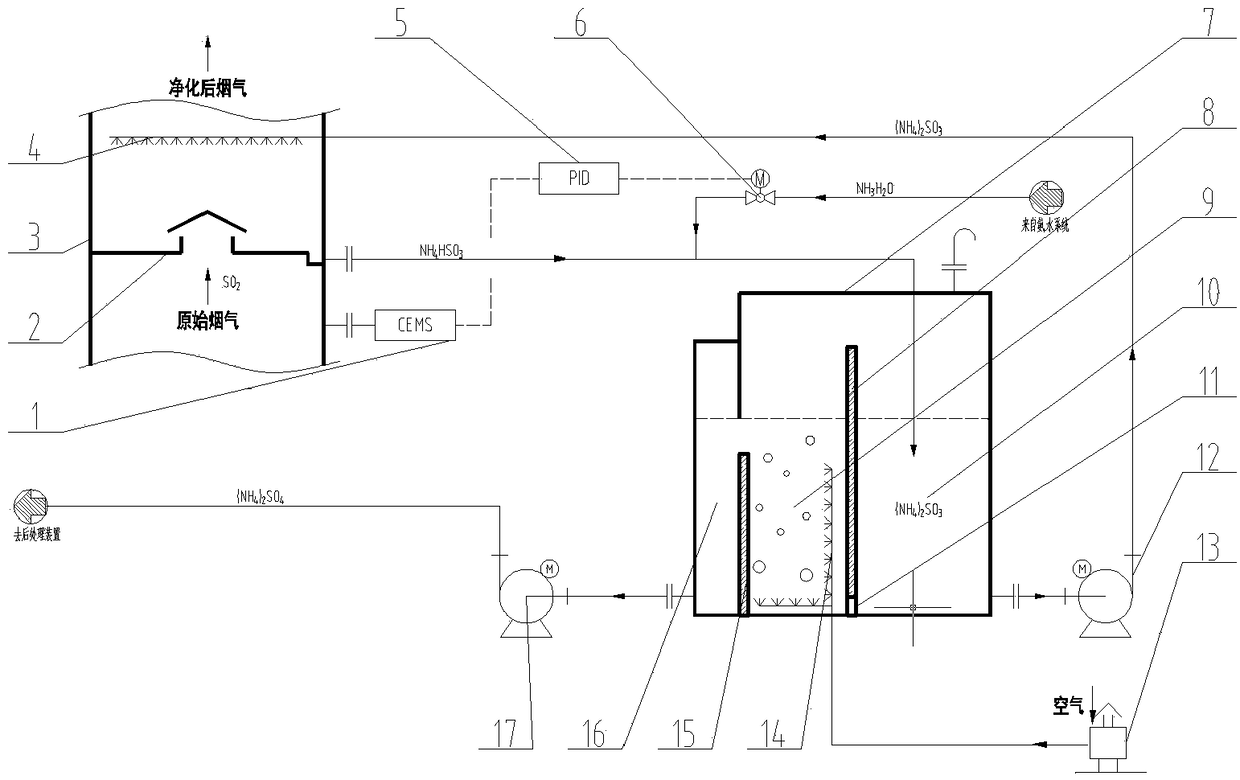

Function guidance product partition ammonia process desulfurization oxidation circulation tank device and method

PendingCN109260895AImprove desulfurization effectWon't happenGas treatmentDispersed particle separationOxidation zoneSlurry

The invention belongs to the technical field of ammonia process smoke gas desulfurization, and particularly relates to a function guidance product partition ammonia process desulfurization oxidation circulation tank device and method. The device comprises a desulfurization tower absorption section and an oxidation circulation tank, wherein the desulfurization tower absorption section and the oxidation circulation tank are connected through a pipeline; the oxidation circulation tank is separated into three regions including a single phase liquid region, an oxidation region and a reduction region by tank wall plates and separation plates; one side of the reduction region is communicated with the oxidation region; the other side of the reduction region is communicated with a desulfurization circulation pump through a pipeline; the oxidation region is communicated with the single phase liquid region; the single phase liquid region is communicated with an ammonium sulfate material transferpump through a pipeline; an oxidation aeration layer is arranged inside the oxidation region, and is communicated with an oxidation fan through a pipeline. The absorbing capacity of absorption slurryon SO2 is greatly improved; the smoke gas desulfurization effect is enhanced; the field operation environment is greatly improved; the continuous and stable discharging of ammonium sulfate by-productsis ensured.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

Device for on-line detection of die casting argon protection effect and detection method

InactiveCN107812899ANovel structureEasy to makeCasting parameters measurement/indication devicesAir pumpDie casting

The invention provides a device for on-line detection of a die casting argon protection effect and a detection method. The device comprises a sampling pipe, a cooling device, a dehumidifying device, an adjusting valve, an air extracting pump and a tail gas pipe which are sequentially connected in series through pipelines; a first dust filter is arranged between the sampling pipe and the cooling device; an instrument is further arranged between the dehumidifying device and the air extracting pump; and the instrument and the adjusting valve are connected in parallel. The detection method includes the steps that before die casting pouring, the sampling pipe and a sample taking pipe of an argon protecting cover are communicated, a selection valve is opened, and the adjusting valve is closed; apower source is started, and argon in the argon protecting cover is discharged out of the tail gas pipe sequentially through the sampling pipe, the first dust filter, the cooling device, the dehumidifying device, the instrument and the air extracting pump; and oxygen content data in the argon protecting cover are displayed on the instrument. The device has the beneficial effects that the device is novel in structure and easy to manufacture, and the automation level of field operation is improved.

Owner:宝钢特钢有限公司

Method for preparing heavy highly-pure basic cupric carbonate

InactiveCN103011247AAvoid bringing inHigh purityCopper compoundsEnvironmental resistanceCarbonization

The invention discloses a method for preparing heavy highly-pure basic cupric carbonate. The method takes copper, liquid ammonia and high-purity carbon dioxide as raw materials and includes the following steps: preparing stronger ammonia water firstly, then introducing high-purity carbon dioxide into the stronger ammonia water, controlling the carbonization degree to prepare and obtain carbonated aqueous ammonia; performing the reaction of the carbonated aqueous ammonia and copper under a certain air pressure to obtain a copper ammonia complex solution; and then obtaining the heavy highly-pure basic cupric carbonate through heating, ammonia stilling, separation, washing, drying and sieving. According to the invention, carbon dioxide is directly used and taken as a raw material, heavy metal ions and chloride ions are prevented from being brought in, the reaction speed is improved, the production cycle is shortened, the production efficiency is greatly improved, the product purity is higher, few impurities can be generated, the quality is greatly improved, and the application range of the product is wider. Besides, through the adoption of the method, the yield is high, less heat is emitted, the energy consumption is lower, and the environmental requirement can be better met while the production cost is greatly reduced.

Owner:TAIXING SMELTING PLANT

Filtering and weighing integrated reaction kettle

InactiveCN106732253APrecise weight controlNo splashProcess control/regulationChemical/physical/physico-chemical stationary reactorsFiltrationProcess engineering

The invention relates to a filtering and weighing integrated reaction kettle. The filtering and weighing integrated reaction kettle comprises a kettle body and a weighing device arranged at the top of the kettle body, wherein a kettle cover is arranged at the top of the kettle body, and a manhole, a feed port and a thermometer well are arranged on the kettle cover; the thermometer well extends into the kettle body, the upper end is fixed on the kettle cover, a thermometer is arranged in the thermometer well, and a discharge port is formed in the bottom of the kettle body; a stirring device is arranged in the kettle body; a mounting support frame is arranged at the bottom of the kettle body. According to the filtering and weighing integrated reaction kettle, weight of fed materials can be accurately controlled when the materials are fed into the reaction kettle, the structure is simple, and the cost is low; meanwhile, with the arrangement of a filtrate sieve plate and a filtering device, the reaction kettle is completely sealed for filtering, no liquid is splashed, the filtration is thorough, and the safety of an operating worker is guaranteed.

Owner:浙江晨诺高分子材料有限公司

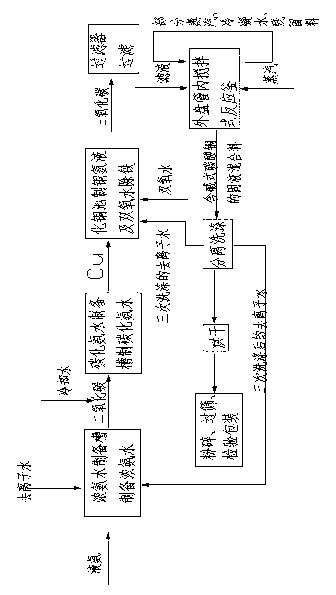

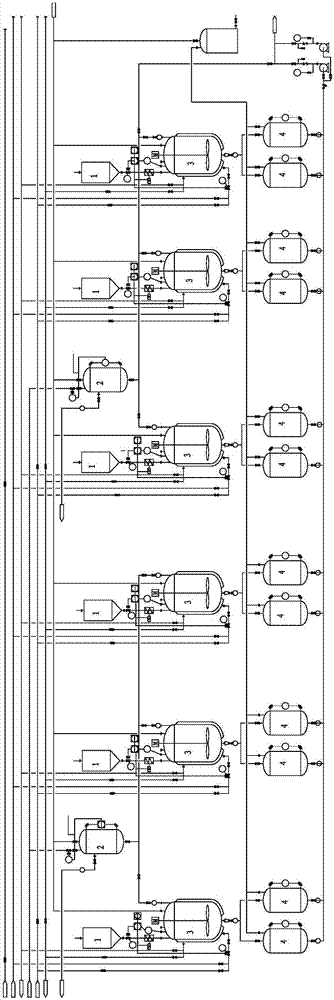

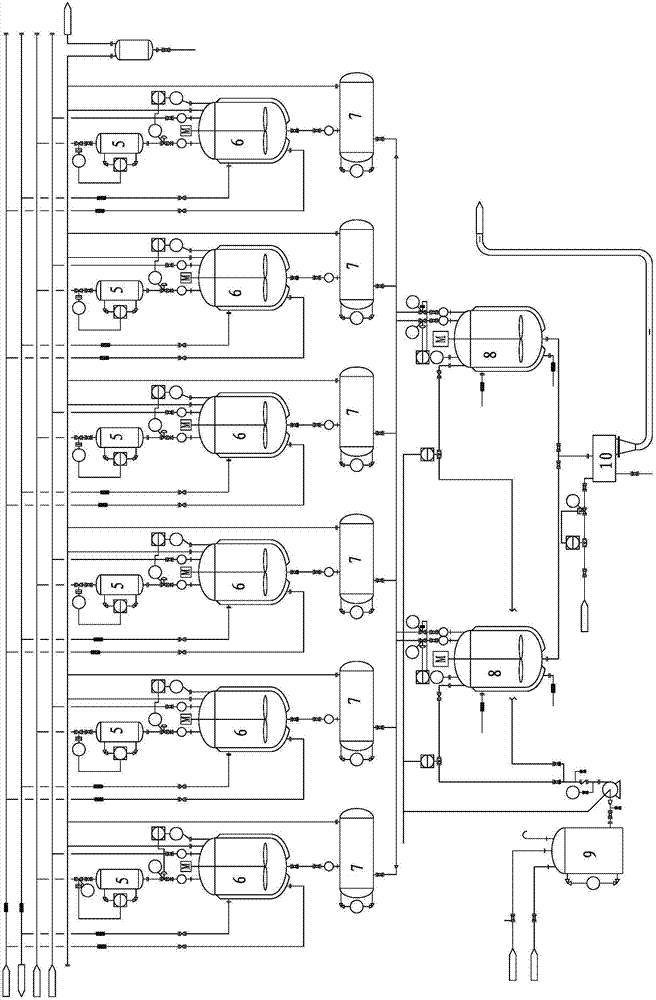

Industrial sulfanilamide production system

PendingCN107266342AImprove automation control levelImprove securitySulfonic acid amide preparationSulfonic acid preparationChlorosulfuric acidAutomatic control

The invention relates to an industrial sulfanilamide production system, which includes a sulfonation kettle, an acetanilide feed pot, a chlorosulfonic acid metering tank, a sulfonated oil metering tank, a first kettle, a water metering tank, a first oil standing tank, a second kettle, a recycling acid tank, a belt type centrifuge, a pulping kettle, an air supply device, a vacuum buffer tank, an ammoniation kettle, a liquid ammonia metering tank, a steam supply device, a hydrolysis kettle, a liquid caustic soda metering tank, an ammonia separation tank, a crystallization kettle, a hydrochloric acid metering tank, a centrifuge, a cyclone dryer, a circulating water cooling device, and a distributed control system. Through overall transformation of the production system, the industrial sulfanilamide production system provided by the invention can be controlled by the distributed control system, improves the automatic control level and safety performance, improves product quality and makes the product quality stable, reduces the operation intensity of workers, improves the on-site operation environment, saves energy and reduces emission, downsizes staff and improves efficiency.

Owner:吴赣药业(苏州)有限公司

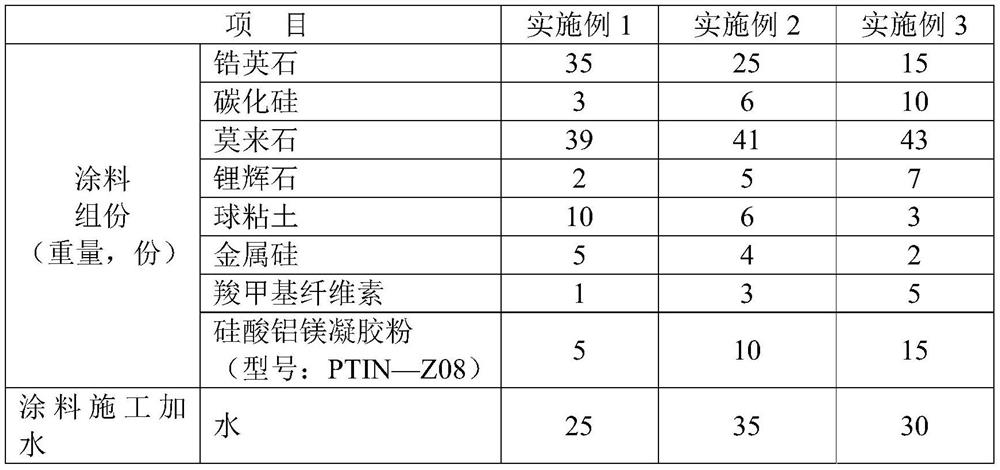

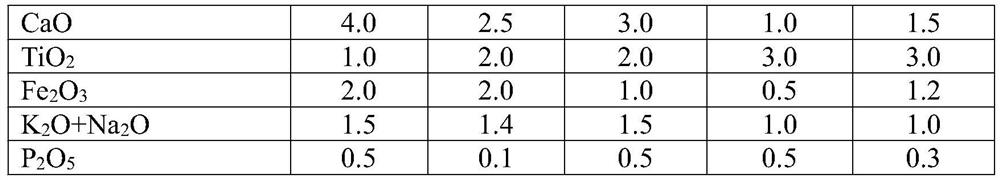

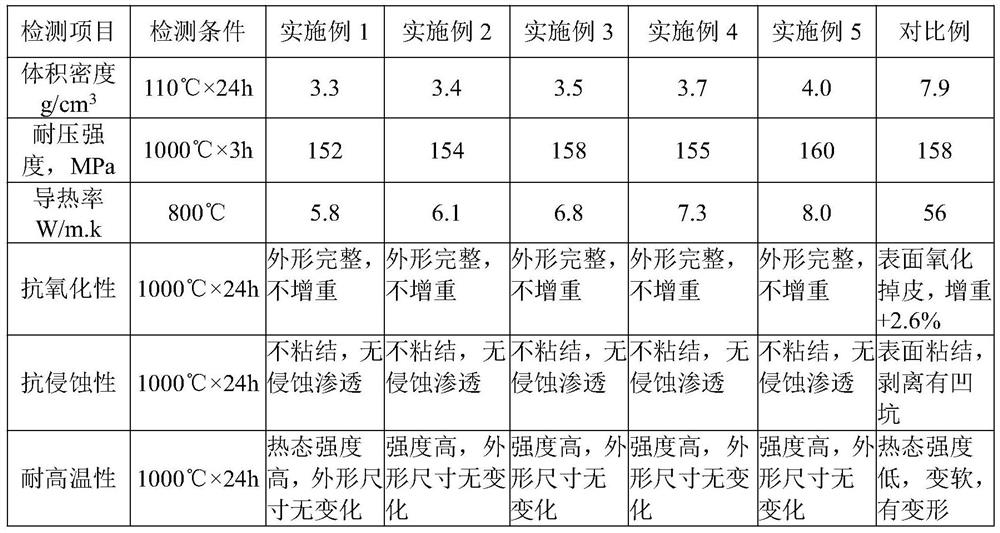

A kind of high-temperature energy-saving anti-corrosion coating for metal baffle of sintering trolley and its application

ActiveCN110628244BExtended service lifeReduce consumptionFireproof paintsAnti-corrosive paintsCarbide siliconAluminum magnesium silicate

The invention relates to a high-temperature energy-saving anti-corrosion paint for a metal baffle of a sintering trolley and an application method thereof. The paint contains 15-35 parts by weight of zircon powder, 3-10 parts by weight of silicon carbide powder, 39-43 parts by weight of mullite powder, 3-10 parts by weight of ball clay, 2-7 parts by weight of spodumene, metal silicon 2-5 parts by weight, magnesium aluminum silicate gel powder 5-15 parts by weight. Add water to prepare a fine slurry, spray or smear on the metal surface of the baffle, and after drying and heat treatment, the coating will firmly adhere to the metal surface of the baffle to form a high-temperature resistant, energy-saving and anti-corrosion ceramic coating. It can not only reflect the heat of the material layer, reduce the temperature of the inner wall of the baffle, but also protect the inner wall of the metal baffle from corrosion. This can prolong the life of the baffle plate, and at the same time have the effect of saving energy, which is very beneficial to reducing the production cost of sintered ore.

Owner:BAOSHAN IRON & STEEL CO LTD

A metal-ceramic composite sintering machine grate bar and its preparation method

The invention provides a metal-ceramic composite sintering machine grate bar and a corresponding preparation method thereof. 2 o 3 ‑SiO2 2 Mullite ceramic powder. The invention also provides a preparation method of the grate bar of the cermet composite sintering machine. The grate bar has the advantages of wear resistance, corrosion resistance, oxidation resistance and high temperature resistance of ceramic materials and good toughness of metal materials. It also has the characteristics of lower and lighter thermal conductivity than metal grate bars, which can also make the sintering trolley more energy-saving, environmentally friendly, lightweight, and longer-lived, reduce sintering energy consumption, improve the on-site operating environment, and generate more economic benefits.

Owner:BAOSHAN IRON & STEEL CO LTD

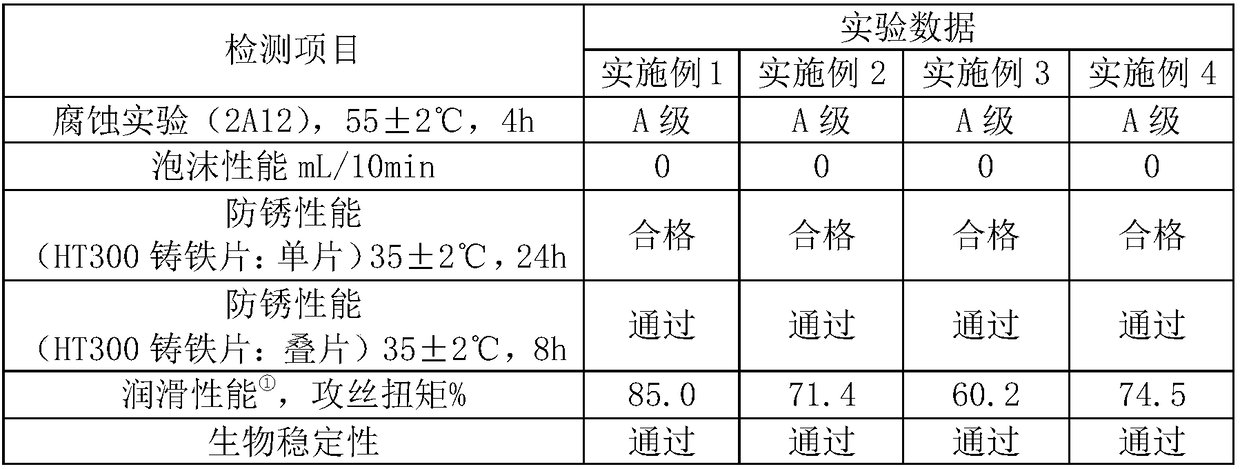

Environmentally-friendly and high-performance aluminium alloy cutting fluid

InactiveCN108587757AAvoid sticking to the machine toolAvoid problems such as sticky chipsLubricant compositionEnvironmental resistanceMetal working fluid

The invention discloses an environmentally-friendly and high-performance aluminium alloy cutting fluid and belongs to the technical field of metal working fluids. The environmentally-friendly and high-performance aluminium alloy cutting fluid is prepared from the following ingredients: base oil, organic alcohol amine, a lubricant, a corrosion inhibitor, an antirust agent, an emulsifier, a bactericide, a coupling agent, an antifoaming agent and water. By the use of plant oil or ester-based oil, addition amount of the lubricant can be reduced and excellent surface smoothness after processing canbe guaranteed. Through reasonable matching with the emulsifier and the coupling agent, the lubricating effect is guaranteed, emulsion particle size is reduced and cleanability of the product is raised. As the lubricant adopts self-emulsifying ester or polymeric ester, use amount of the emulsifier is greatly minimized. As the emulsifier is low-foam type, emulsion stability is greatly guaranteed and foam of the system is effectively controlled. With the non-formaldehyde release type bactericide and plant oil and ester-based oil, comfortableness of human body is raised, customer field operatingenvironment is obviously improved, and allergy is greatly controlled.

Owner:NANJING KERUN NEW MATERIAL TECH

System and method for preparing H2SO4 from sulfur-containing waste

PendingCN112408422AAchieve recyclingReduce escapeSulfur compoundsAmmonia compoundsProcess engineeringEnvironmental engineering

The invention relates to a system for preparing H2SO4 from sulfur-containing waste. The system comprises a pretreatment unit; the pretreatment unit comprises a drying machine and a tail gas washing and recycling system; the drying machine comprises a barrel and a rotating shaft; a heating medium is introduced into at least the barrel or the rotating shaft; the rotating shaft can be driven to rotate to stir the sulfur-containing waste in the barrel; the tail gas washing and recycling system comprises a washing device, a pickling device and a tail gas washing device; the washing device is used for washing and cooling tail gas exhausted by the drying machine, the gas inflow end of the washing device is connected with a tail gas exhaust port of the drying machine, and a part of washing mixed liquid generated by tail gas washing is filtered and then supplied to a feeding port of the drying machine; the pickling device is connected with a gas outlet of the washing device and used for neutralizing ammonia in the washed tail gas to generate ammonium sulfate mother liquor; and the tail gas washing device is connected with a gas outlet of the pickling device and is used for washing and cooling pickled tail gas.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com