Processing method for tail gas generated in preparation of ammonium sulfate from phosphogypsum

A treatment method, ammonium sulfate technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as deterioration of the operating environment, increased costs, and treatment of ammonium sulfate tail gas that has not been seen in phosphogypsum production, and achieves improved operations. Environment, effect of reducing ammonia consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

[0011] A phosphate fertilizer factory affiliated to a certain company adopts the method of the present invention to process ammonia-containing gas from a phosphogypsum ammonium sulfate plant.

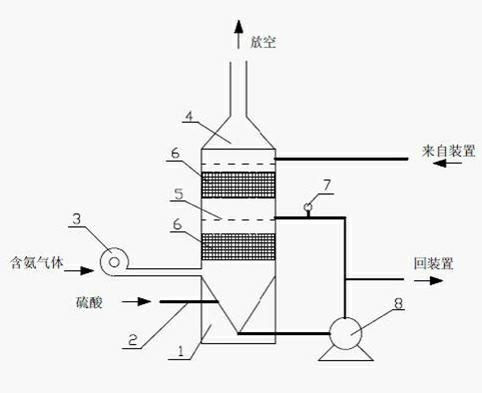

[0012] In the device, an ammonia-containing gas scrubber 1, an exhaust fan 3 and a circulation pump 8 are added, and the circulation pump 8 forms a circulation loop with the scrubber 1 through a pipeline. The washing tower 1 is a packed tower, the packing 6 in the tower is divided into two sections, the liquid separator 5 is in the middle of the two sections, the demister 4 is on the upper part of the tower, and the bottom of the tower is an absorption liquid container; the packing material is Q235, and the packing tower 1 Anti-corrosion with rubber lining. Use the acidic filtrate from the phosphogypsum filtration in the device as the circulating absorption liquid, send it to the washing tower 1 to countercurrently wash the ammonia-containing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com