Environmentally-friendly and high-performance aluminium alloy cutting fluid

A high-performance, aluminum alloy technology, applied in the field of high-performance aluminum alloy cutting fluid, environmental protection, aluminum alloy cutting fluid, can solve problems such as environmental protection, human comfort, etc., to ensure emulsification stability, improve operating environment, and reduce dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

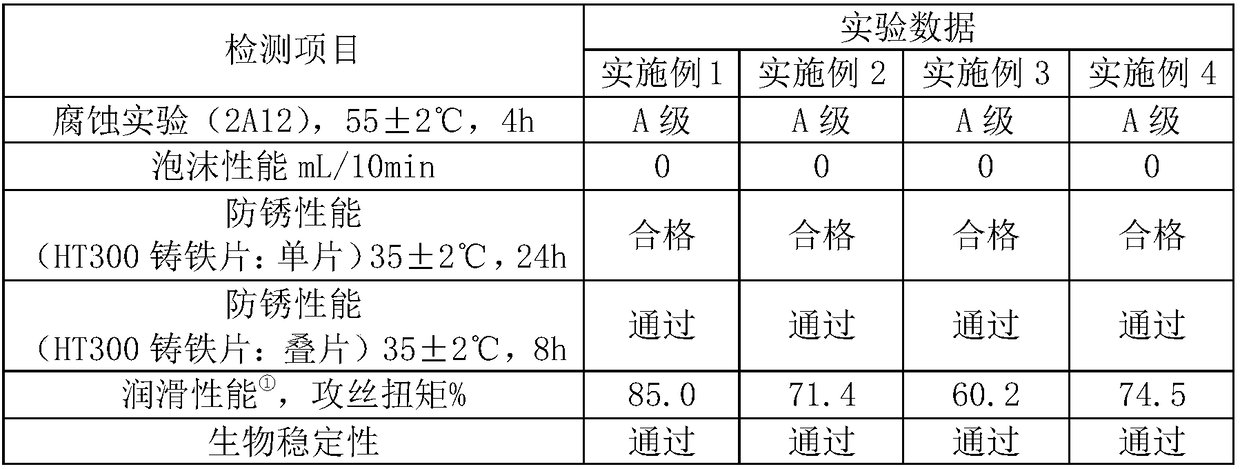

Examples

Embodiment 1

[0019] An environment-friendly, high-performance aluminum alloy cutting fluid provided in Example 1 is prepared from the following components by weight percentage: 40% vegetable oil; 4% isopropanolamine, 6% N-methyldiethanolamine; self-emulsifying Esters 6%; Organic dibasic acids 3%; Polyisobutylene succinic anhydride 3%, Neodecanoic acid 1.5%, C16-C18 fatty alcohol alkoxylate 4%, C16-C20 fatty alcohol polyethoxypropoxylate 2 %; dodecylamine 1.5%, 1,2-benzisothiazolin-3-one 2%, 3-iodo-2-propynyl butylcarbamate 0.3%; diethylene glycol butyl ether 3% ; Polyether defoamer 0.5%; water balance.

Embodiment 2

[0021] An environment-friendly, high-performance aluminum alloy cutting fluid provided in Example 2 is prepared from the following components by weight percentage: 30% synthetic ester; 3% diglycolamine, 6% triethanolamine; 4% self-emulsifying ester , polyester 4%; water-based polymer corrosion inhibitor 1%; organic dibasic acid 2%, organic tribasic acid 2%; dodecenyl succinic acid 1.5%, isononanoic acid 2.5%, C16-C18 fatty alcohol Alkoxylate 4%, C16-C20 fatty alcohol polyethoxypropoxylate 2%, C14-C20 fatty alcohol polyethoxylate 3%; 1,2-Benzisothiazolin-3-one 2 %, 2-methyl-4-isothiazolin-3-one 2%, 3-iodo-2-propynyl butyl carbamate 0.3%; triethylene glycol butyl ether 2%; polyetheramine 0.5 % water balance.

Embodiment 3

[0023] An environment-friendly, high-performance aluminum alloy cutting fluid provided in Example 3 is formulated from the following components by weight percentage: 45% trimethylolpropane oleate; 3% diglycolamine, N-methyl Diethanolamine 6%; self-emulsifying ester 4%, polymer ester 10%; organic dibasic acid 2%, fatty acid amide 2%; dodecenyl succinic acid 2%, polyisobutylene succinic anhydride 1.5%, isononanoic acid 2.5% , C16-C20 fatty alcohol polyethoxypropoxylate 3%, C14-C20 fatty alcohol polyethoxylate 4%; 1,2-benzisothiazolin-3-one 2%, 2-butyl -1,2-benzisothiazolin-3-one 0.5%; dipropylene glycol butyl ether 4%; polyetheramine 1% water balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com