A metal-ceramic composite sintering machine grate bar and its preparation method

A metal-ceramic composite and machine furnace technology, which is applied in the field of metal matrix composite materials, can solve problems such as coating layer damage, and achieve the effects of good impact resistance, multiple comprehensive benefits, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

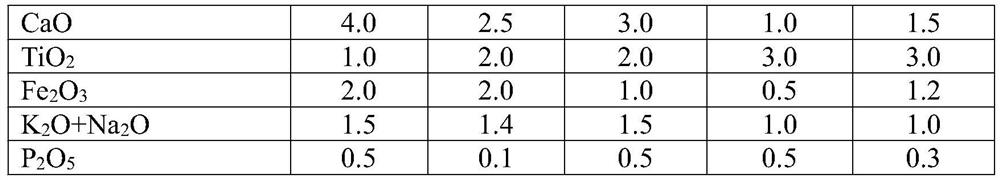

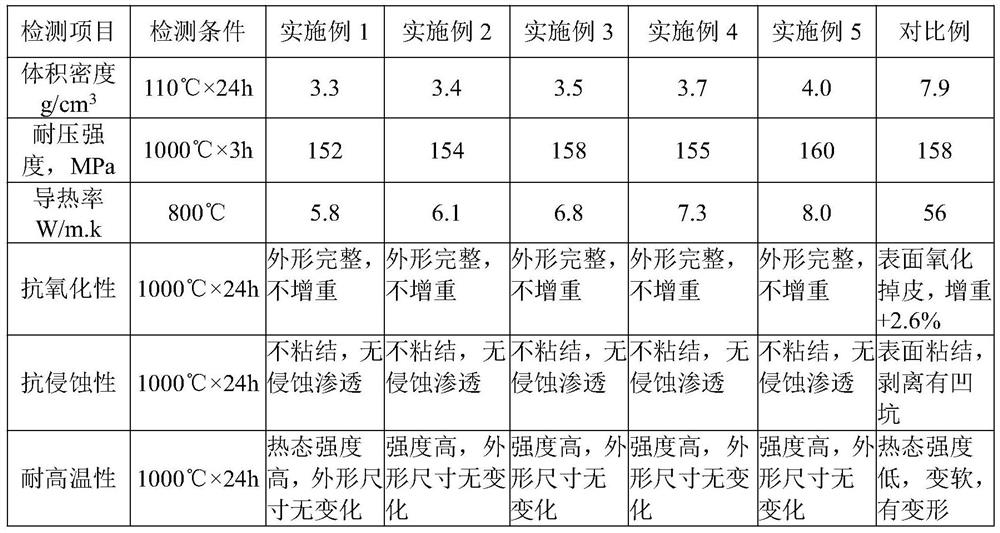

[0025] A kind of preparation method of metal-ceramic composite sintering machine grate bar, it is made of 25wt% heat-resistant steel fiber and 75wt% Al 2 o 3 -SiO 2 prepared from mullite ceramic powder. The preparation method is as follows:

[0026] Place the heat-resistant steel fibers evenly in the grate bar-shaped mold. to Al 2 o 3 -SiO 2 Add water accounting for 10% of its weight to the mullite ceramic powder, stir it into a slurry with good fluidity in a stirring pot, pour the slurry into a mold containing heat-resistant steel fibers, and vibrate on a vibrating table Molding for 30 seconds, so that the ceramic slurry fills each space between the steel fiber and the mold, and tightly wraps each steel fiber. Curing in the mold for 24 hours after forming, demoulding after hardening; curing the structural parts of the composite grate bar after demoulding at room temperature for 24 hours, and then putting them into an oven at 110°C for 20 hours to form a higher strength...

Embodiment 2

[0028] A kind of preparation method of metal-ceramic composite sintering machine grate bar, it is made of 30wt% heat-resistant steel fiber and 70wt% Al 2 o 3 -SiO 2 prepared from mullite ceramic powder. The preparation method is as follows:

[0029] Place the heat-resistant steel fibers evenly in the grate bar-shaped mold. to Al 2 o 3 -SiO 2 The mullite ceramic powder of the series is added with 9.2% of its weight in water, stirred in a stirring pot to form a slurry with good fluidity, poured into a mold containing heat-resistant steel fibers, and formed by vibration on a vibrating table For 35 seconds, the ceramic slurry is filled into each space between the steel fiber and the mold, and tightly wraps each steel fiber. Curing in the mold for 20 hours after forming, demoulding after hardening; curing the structural parts of the composite grate bar after demoulding at room temperature for 20 hours, and then putting them in an oven at 110°C for 18 hours to form a higher s...

Embodiment 3

[0031] A kind of preparation method of metal-ceramic composite sintering machine grate bar, it is made of 35wt% heat-resistant steel fiber and 65wt% Al 2 o 3 -SiO 2 prepared from mullite ceramic powder. The preparation method is as follows:

[0032] Place the heat-resistant steel fibers evenly in the grate bar-shaped mold. to Al 2 o 3 -SiO 2 The mullite ceramic powder of the series is added with 8.5% of its weight in water, stirred in a stirring pot to form a slurry with good fluidity, poured into a mold containing heat-resistant steel fibers, and formed by vibration on a vibrating table For 40 seconds, the ceramic slurry is filled into each space between the steel fiber and the mold, and tightly wraps each steel fiber. Curing in the mold for 16 hours after forming, demoulding after hardening; curing the structural parts of the composite grate bar after demoulding at room temperature for 16 hours, and then drying in an oven at 110°C for 15 hours, the structural parts fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com