Industrial sulfanilamide production system

A production system and technology for industrial sulfonamides, which are applied in the preparation of sulfonic acid amides, sulfonic acid, organic chemistry, etc., can solve the problems of unguaranteed product yield and quality, low automation level, and heavy dependence on operator experience, and achieve product quality. The effect of quality improvement, improved automation control and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

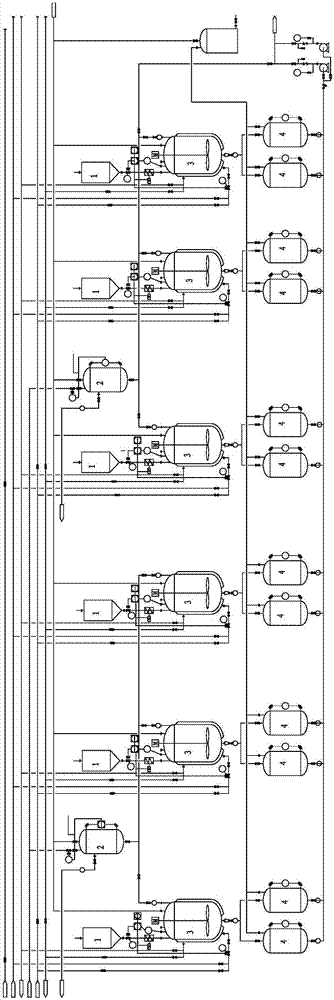

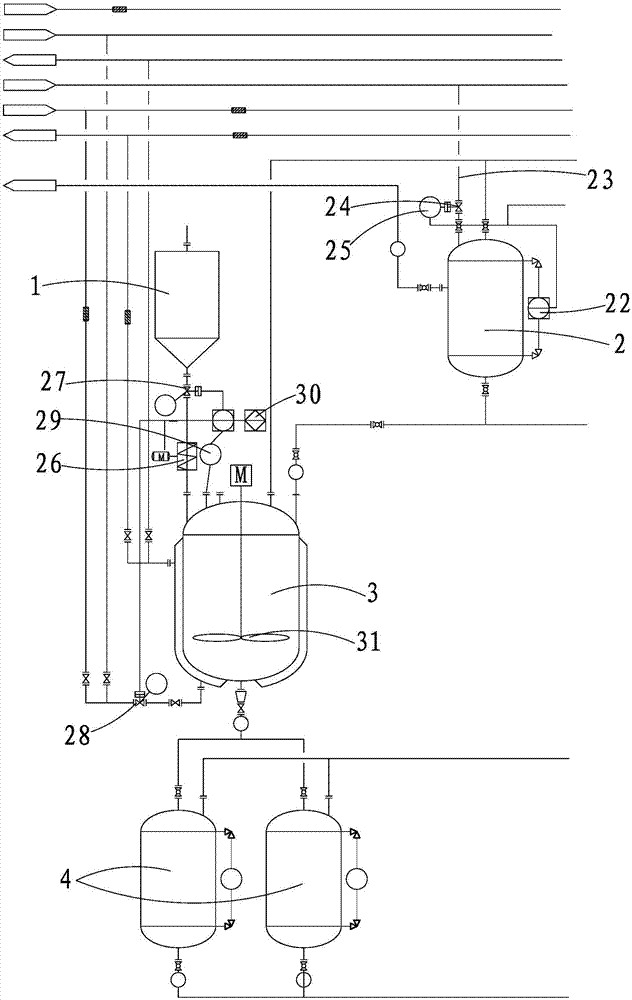

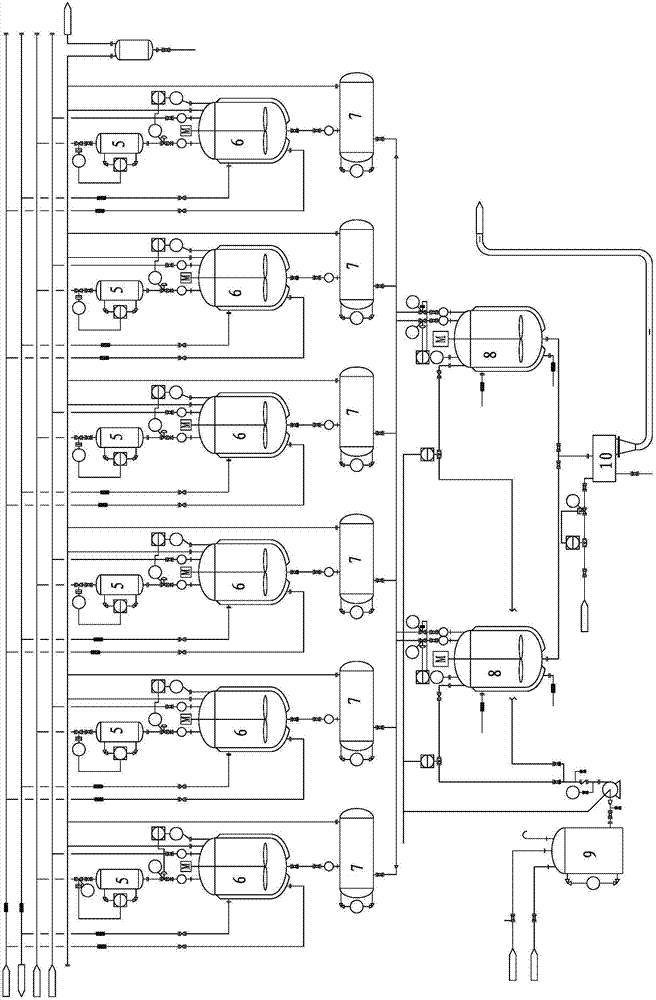

[0042] This embodiment provides an industrial sulfonamide production system, including 5 to 7 acetanilide feeding tanks 1, 1 to 3 chlorosulfonic acid metering tanks 2, 5 to 7 sulfonation tanks 3, and 10 to 14 sulfonated oil metering tanks Tank 4, 5-7 water metering tanks 5, 5-7 one-separation tanks 6, 5-7 one-separation tanks 7, 1-3 two-separation tanks 8, 1-2 recycling acid tanks 9 , 1 to 2 belt centrifuges 10, 1 to 3 beating kettles 11, 1 to 2 vacuum buffer tanks 12, 2 to 4 ammoniation kettles 13, 1 to 3 liquid ammonia metering tanks 14, 5 to 7 15 hydrolysis tanks, 1 to 3 liquid alkali metering tanks 16, 5 to 7 ammonia separation tanks 17, 8 to 10 crystallization tanks 18, 1 to 2 hydrochloric acid metering tanks 19, 1 to 3 centrifuges 20, 1 ~2 cyclone dryers 21, circulating water cooling devices connected with sulfonation kettle 3, one-part kettle 6, two-part kettle 8, beating kettle 11, ammoniation kettle 13, hydrolysis kettle 15 and crystallization kettle 18 respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com