Low-temperature distillation and liquefying separation recovery system and method for coal bed gas high in nitrogen content, oxygen content and hydrogen content

A low-temperature rectification, liquefaction separation technology, applied in liquefaction, cold treatment separation, refrigeration and liquefaction, etc., can solve the problems of reduced separation and liquefaction device processing capacity, no disclosure of liquefaction process, low refrigeration efficiency, etc., to achieve strong operability and process adaptability, high level of process automation control, and the effect of improving liquefaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

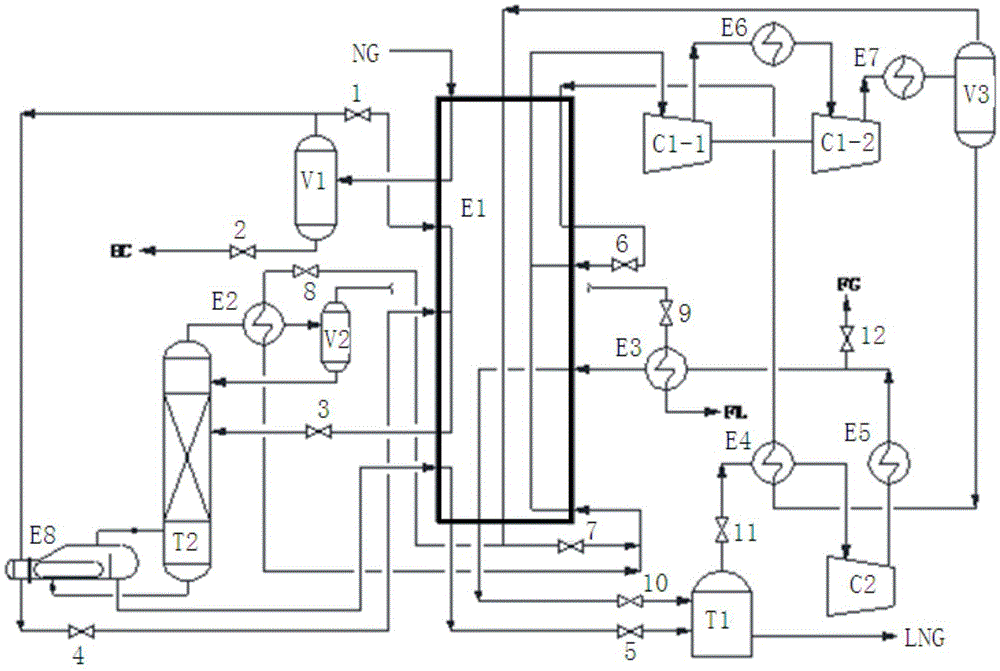

[0017] Such as figure 1 As shown, the present invention provides a low-temperature rectification liquefaction separation and recovery system for coalbed methane containing high nitrogen and oxygen hydrogen, which includes cold box E1, rectification tower T2, denitrification, hydrogen, oxygen system, refrigerant circulation system, vent Gas treatment system and flash gas utilization system; Among them, the refrigerant circulation system provides cooling capacity for the cold box E1 and the rectification tower T2.

[0018] The denitrification, hydrogen, and oxygen systems include feed gas pipelines, rectification tower T2, heavy hydrocarbon separation tank V1, condenser E2, reboiler E8, and valves 1 to 5; among them, condenser E2 is set in the rectification tower T2 tower At the top, the reboiler E8 is set at the bottom of the rectification column T2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com