Method for spraying ash and blowing dust in water cooling process of collected stainless steel slag

A stainless steel slag and water cooling technology, which is applied to chemical instruments and methods, cleaning methods and utensils, and smoke and dust removal, can solve environmental pollution, affect the environment of the job site, and float into the air, etc., to achieve the effect of improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

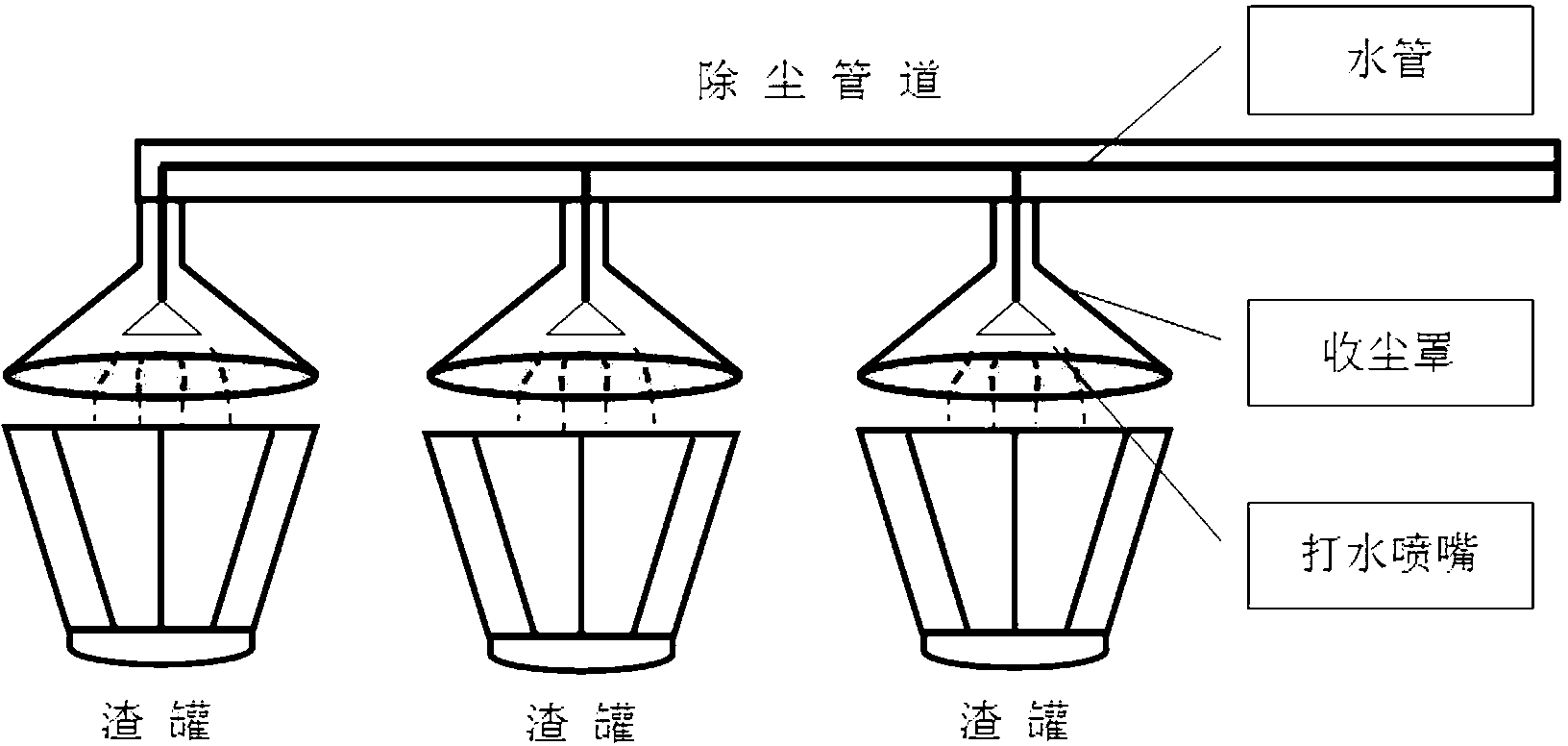

[0007] First put the steel slag into the slag tank for air cooling in the open air, and then figure 1 As shown, put it under the dust collection hood to draw water for cooling. The cooling water should be sprayed in a mist shape to avoid water accumulation on the surface of the steel slag. At the same time, turn on the dust collection fan to let the dust be collected into the dust collector with the dust removal pipe. After the steel slag is cooled to 70-80 ℃, send the slag pot to the workshop for overturning treatment, and then re-cool the new slag pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com