Method for producing compound fertilizer by extrusion-kneading process

A compound fertilizer and compound fertilizer technology, which is applied in the direction of inorganic fertilizers, ammonium salt fertilizers, urea compound fertilizers, etc., can solve the problems of high replacement frequency of extrusion equipment, large one-time investment, and restrictions on popularization and application, and achieve a one-time investment And the effects of reduced floor area, reduced production energy consumption, and improved operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

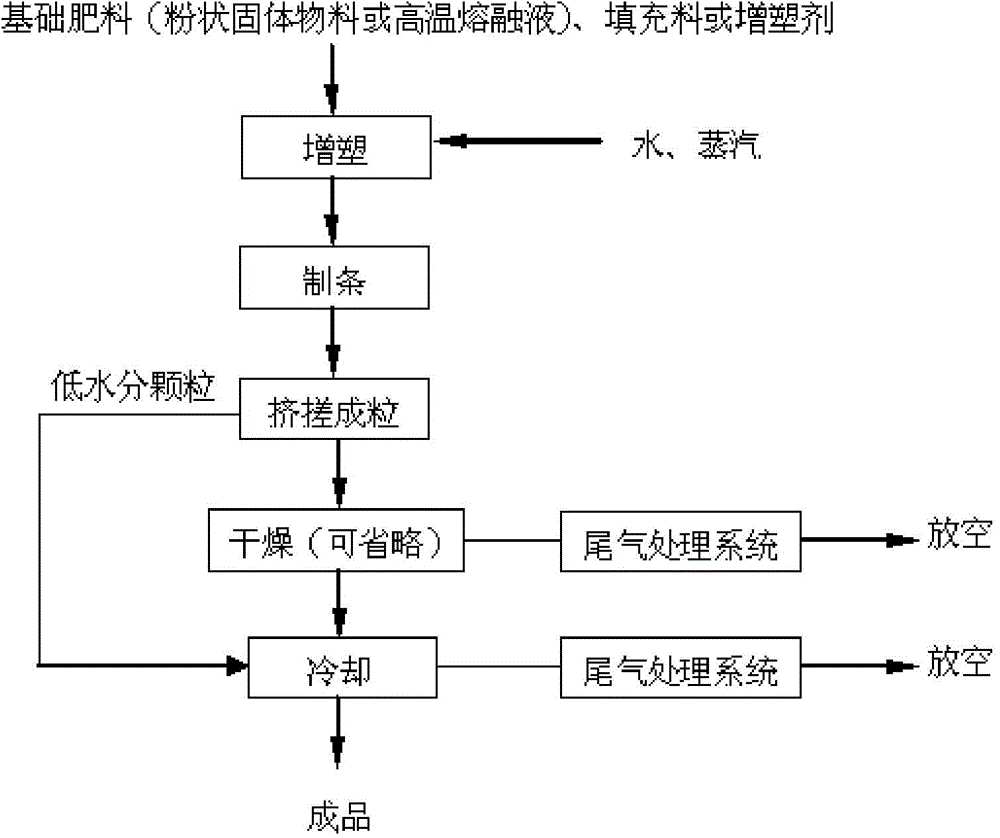

[0044] refer to figure 1 As shown in the process flow of the preparation method of the compound fertilizer in this embodiment, the method in this embodiment is to mix and humidify the basic fertilizer and filling material after batching to make a material with high moisture content and enhanced plasticity, and pass through the extrusion equipment Obtain a cylindrical material strip with a diameter of about 3.5mm, and then obtain spherical particles with a diameter of about 4.5mm through extrusion and granulation equipment. The moisture content of the material after granulation is 3% to 8%, and then the granular material is dried and cooled. Granular compound fertilizer products.

[0045] The raw material composition of entering device is as follows:

[0046] serial number

Types of basic fertilizers and fillers

Raw material addition per ton of product (kg)

1

Urea (N: 46%)

100

2

282

3

Monoammon...

Embodiment 2

[0055] The preparation method of the compound fertilizer refers to Example 1, but the composition of the raw materials used and the extrusion and granulation equipment are changed.

[0056] The composition of raw materials into the system is as follows:

[0057] serial number

Types of basic fertilizers and fillers

Raw material addition per ton of product (kg)

1

Urea (N: 46%)

384

2

Monoammonium Phosphate (N: 11%P 2 o 5 : 44%)

230

3

Potassium Chloride (K 2 O>60%)

168

4

242

[0058] Product specification: N-P 2 o 5 -K 2 O=20-10-10

[0059] Extrusion equipment used: screw, extrusion hole diameter 3.5mm

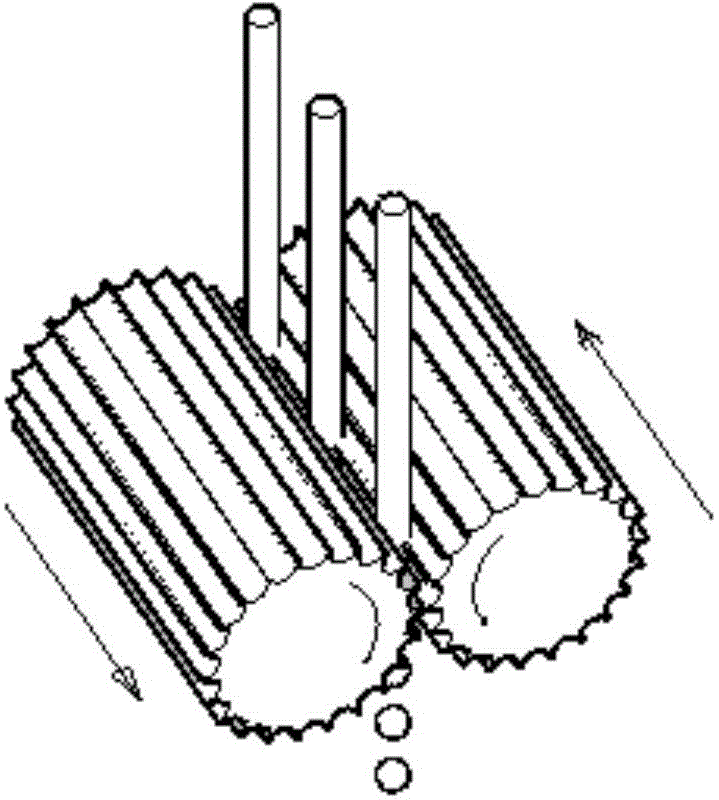

[0060] use Figure 4 The extrusion granulation equipment shown, the granulation aperture is 4.5mm

[0061] The moisture content of the material entering the extruder: ~4%, using a twin-shaft mixer to mix and humidify

[0062] Material temperature into the extruder: room tempe...

Embodiment 3

[0066] The preparation method of the compound fertilizer refers to Example 1, but the composition of the raw materials used and the extrusion and granulation equipment are changed.

[0067] The composition of raw materials into the system is as follows:

[0068] serial number

Types of basic fertilizers and fillers

Raw material addition per ton of product (kg)

1

Phosphorous ammonium nitrate (N: 32%P 2 o 5 : 4%)

242

2

Diammonium Phosphate (N: 18%P 2 o 5 : 46%)

242

3

485

4

Attapulgite

45

[0069] Product specification: N-P 2 o 5 -K 2 O=12-12-24

[0070] Extrusion equipment used: First, the rollers are extruded into a sheet with a thickness of 3.5mm, and then cut into strips of 3.5mm×3.5mm in thickness, and the strips fall directly into the feed port of the extrusion granulator

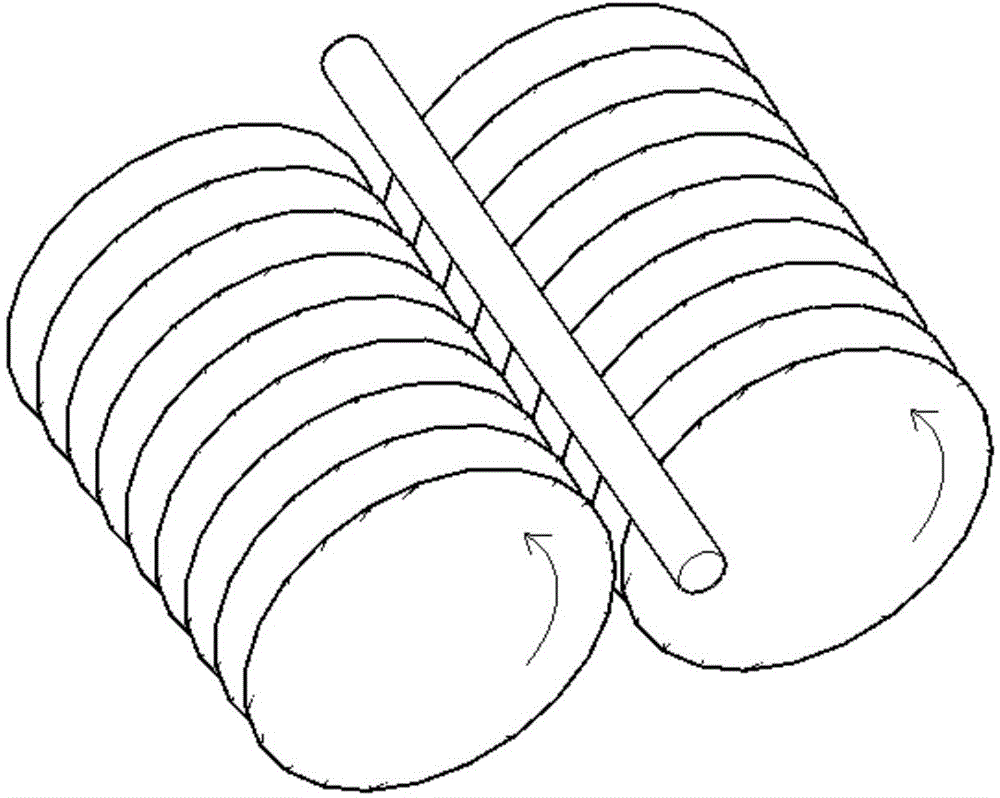

[0071] use figure 2 Extrusion and granulation equipment shown, granulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com