Tar residue pre-separation and removal process and system in coke oven ammonia water system

A tar residue and pre-separation technology, applied in liquid separation, separation methods, settling tanks, etc., can solve problems such as difficult maintenance, labor and material resources, and volume reduction of underground tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

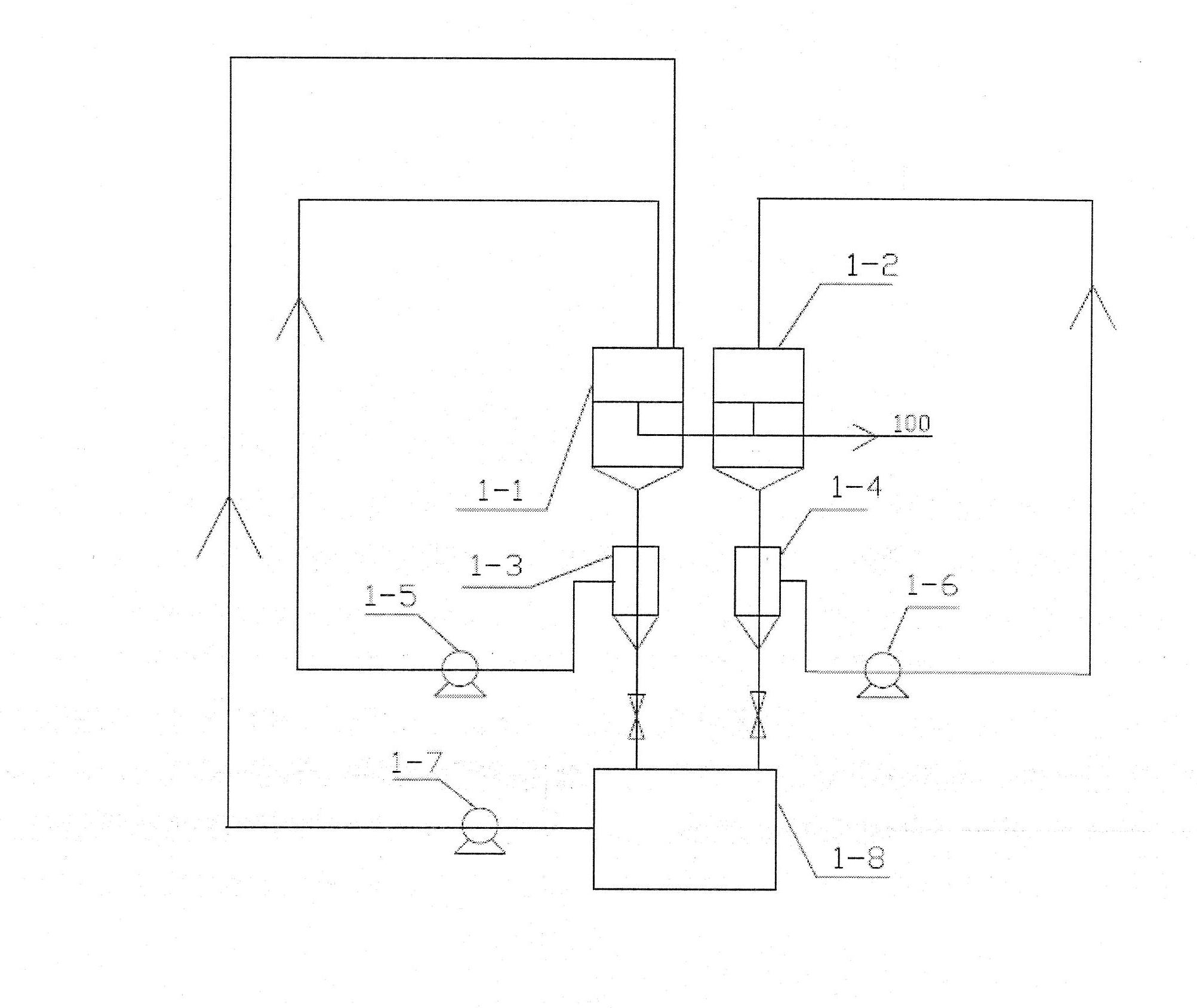

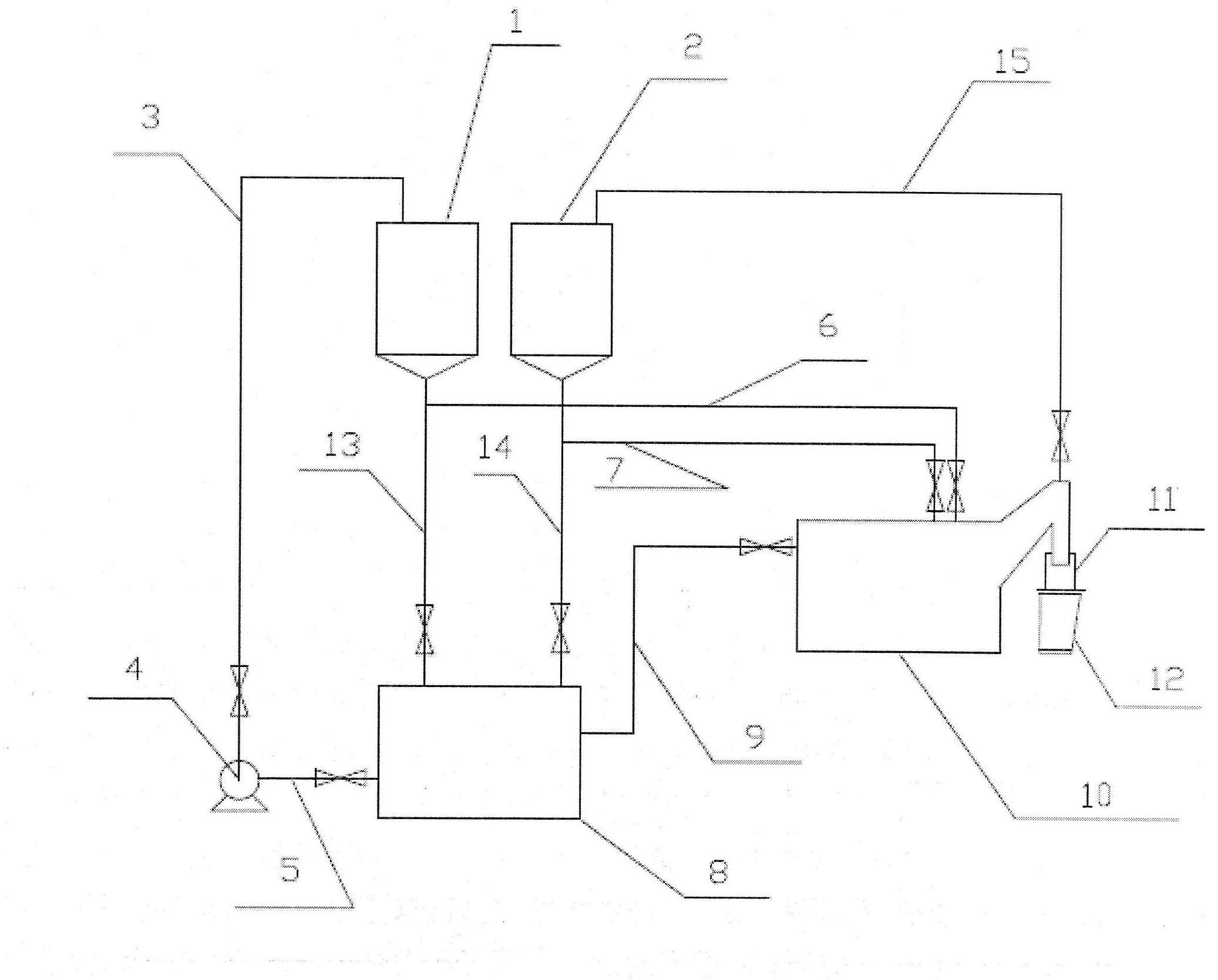

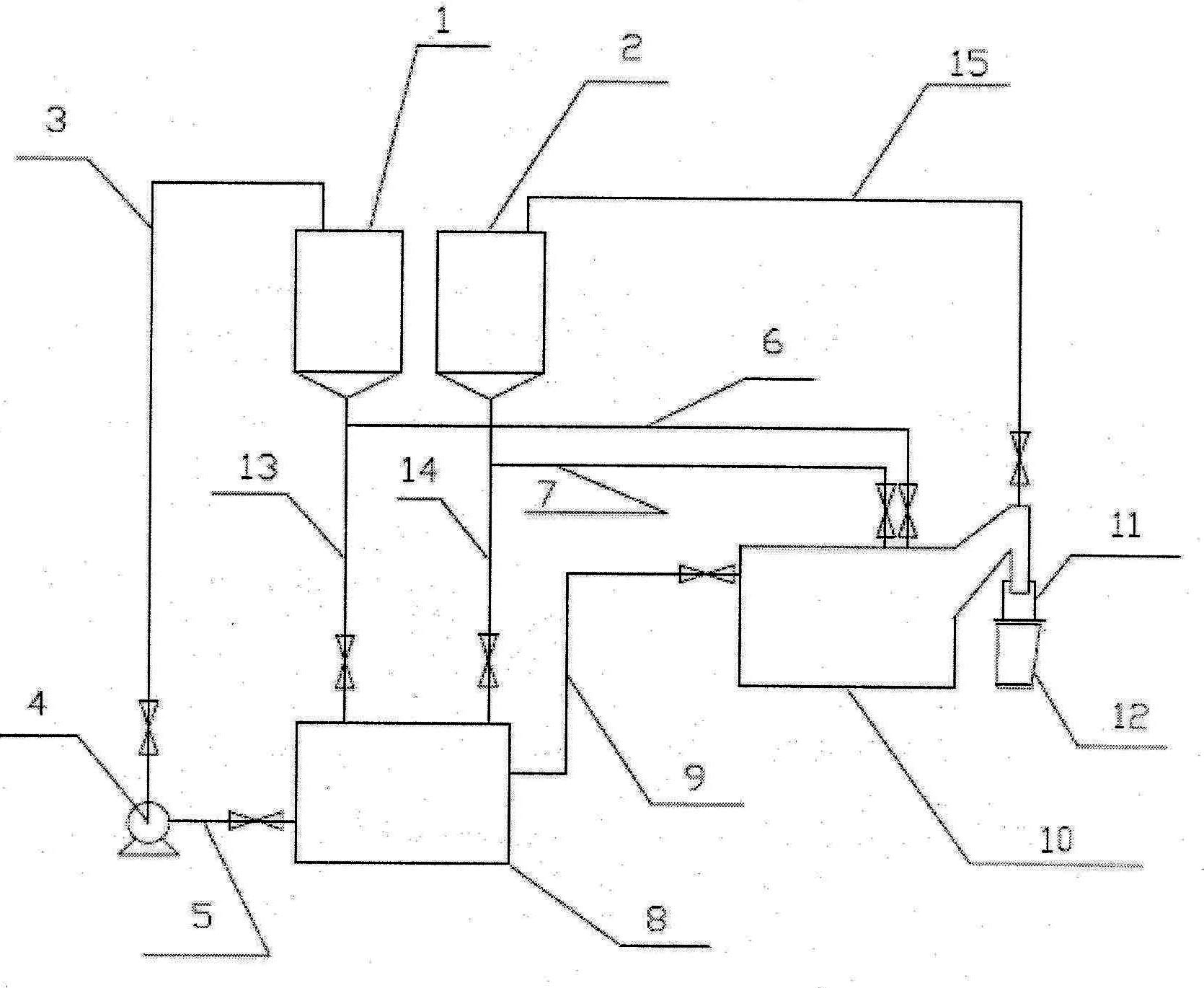

[0028] refer to figure 2 , the coke oven ammonia water system tar residue pre-separation and removal system includes: tar residue pre-separator 1, 2, mechanized clarification tank 10, tar sealing device 11, tar residue tank 12, underground vent tank 8, submerged pump 4, pipeline 3,5,6,7,9,13,14, centralized release pipe 15. Wherein, the tar residue pre-separators 1 and 2 are communicated with the mechanized clarifier 10 through pipelines 6 and 7 respectively; the mechanized clarifier 10 is connected with the tar residue tank 12 through a tar sealing device 11; the mechanized clarifier 10 is connected with the underground empty tank through a pipeline 9 8 is connected; the underground empty tank 8 is connected with the submerged pump 4 through the pipeline 5; the submerged pump 4 is connected with the tar residue pre-separator 1 and 2 through the pipeline 3 respectively. The aforementioned mechanized clarification tank 10 is preferably connected with the tar residue tank 12 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com