Patents

Literature

59results about How to "Avoid powder leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

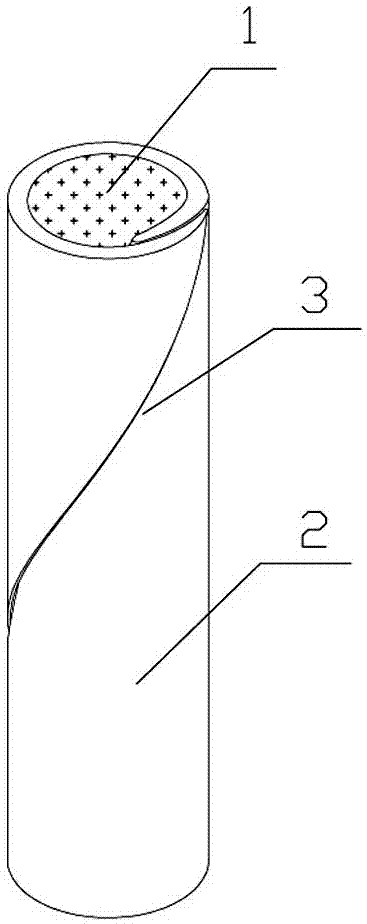

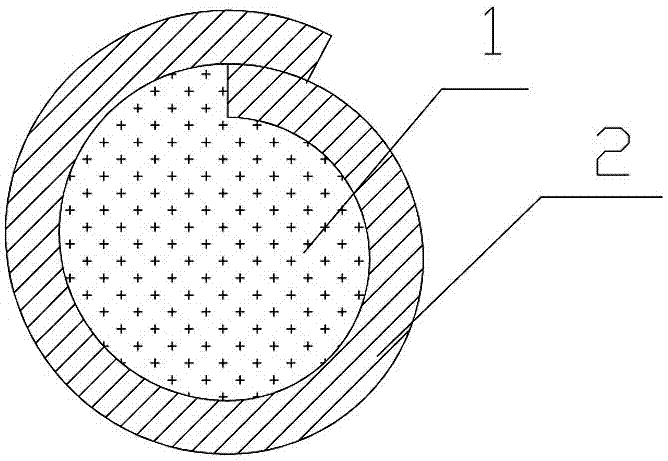

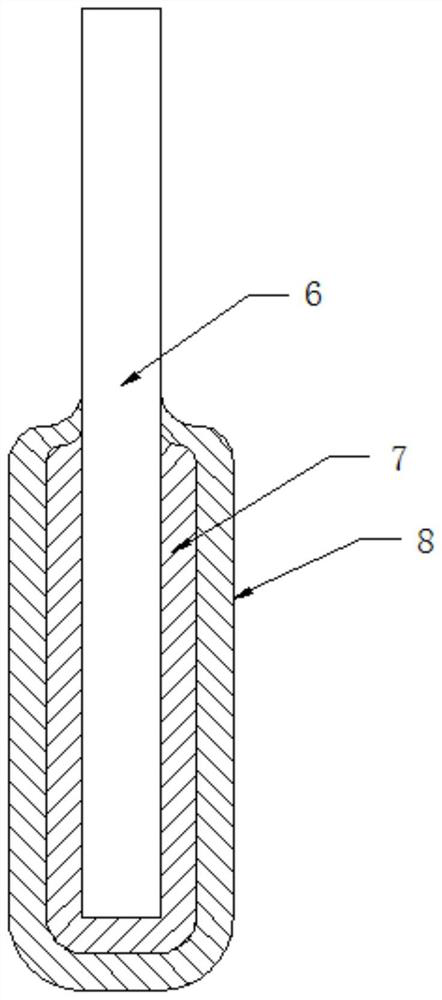

Flux-cored silver solder and preparation method thereof

ActiveCN104907727AEasy to assembleStop the flowWelding/cutting media/materialsSoldering mediaBand shapeMetallurgy

The invention discloses flux-cored silver solder. The silver solder comprises a silver-based solder outer layer and a silver brazing flux core placed inside the silver-based solder outer layer in a padded mode, and the silver-based solder outer layer is formed by rotating and rolling strip-shaped solder and is of a tubular structure provided with spiral lapped seams. The preparation method comprises the steps of smelting and producing out the strip-shaped silver-based solder according to a conventional method, and conducting roughening treatment on the inner surface; then rotating and rolling the strip-shaped solder into the tubular structure in a spiral shape, and adding silver brazing flux into the tube in the rolling process so that the flux core can be formed; producing out the flux-cored silver solder which meets the requirements through the rolling or drawing process. The flux-cored silver solder and the preparation method thereof have the advantages that the brazing flux can be added in advance conveniently and efficiently, the brazing process has the advantages of being convenient to assemble, easy to achieve automatized production, low in cost and the like, and it is facilitated to apply and promote the automatized brazing technique.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

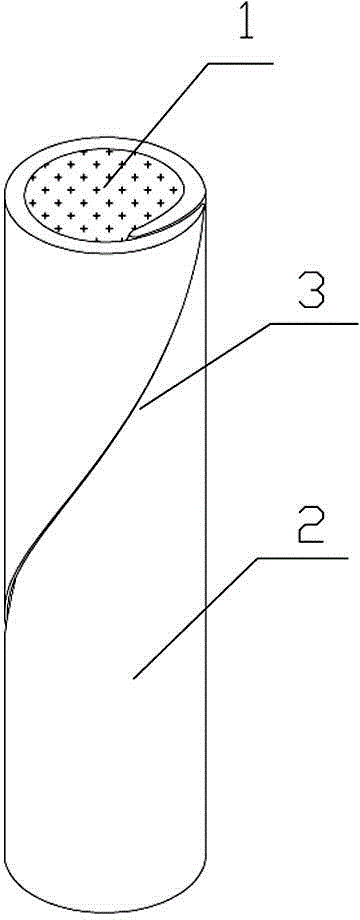

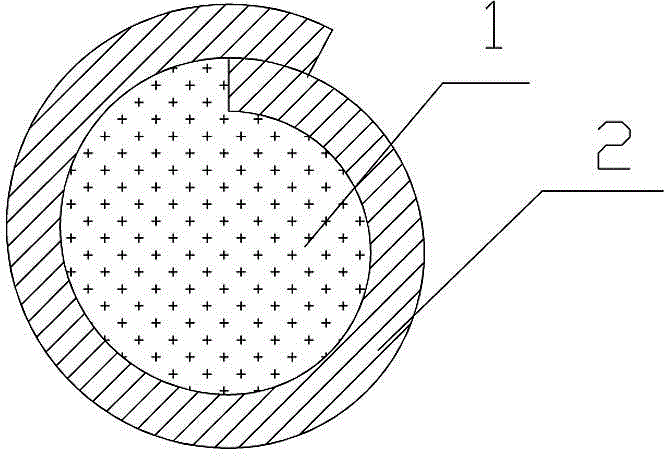

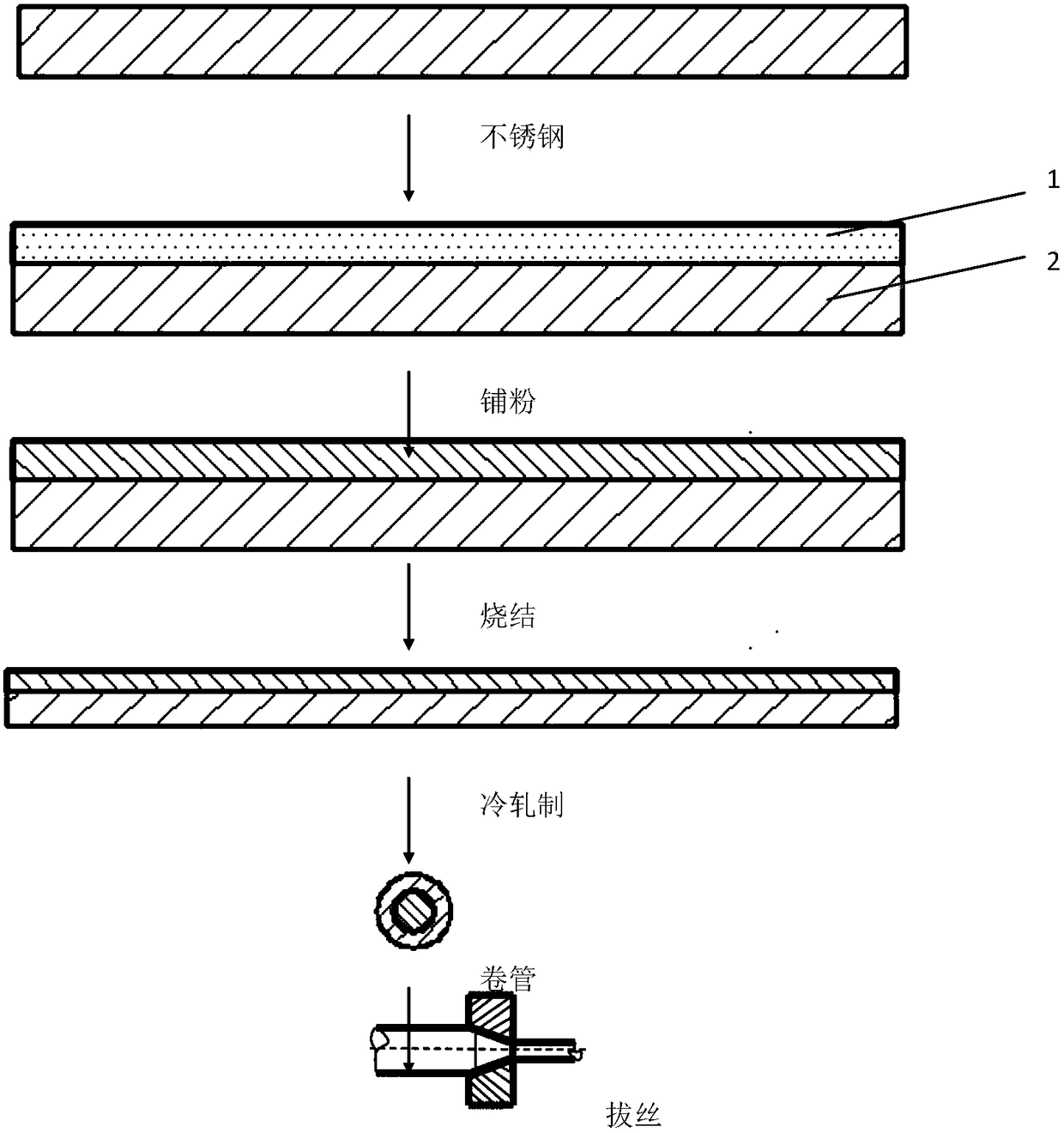

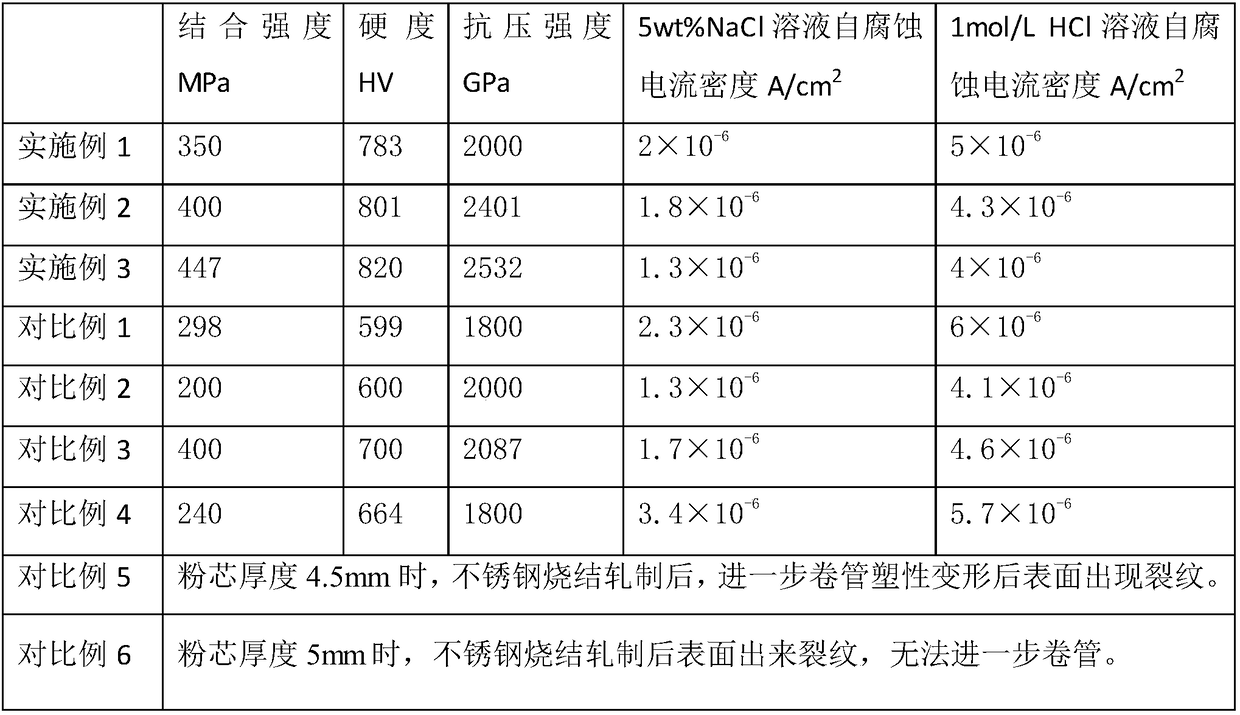

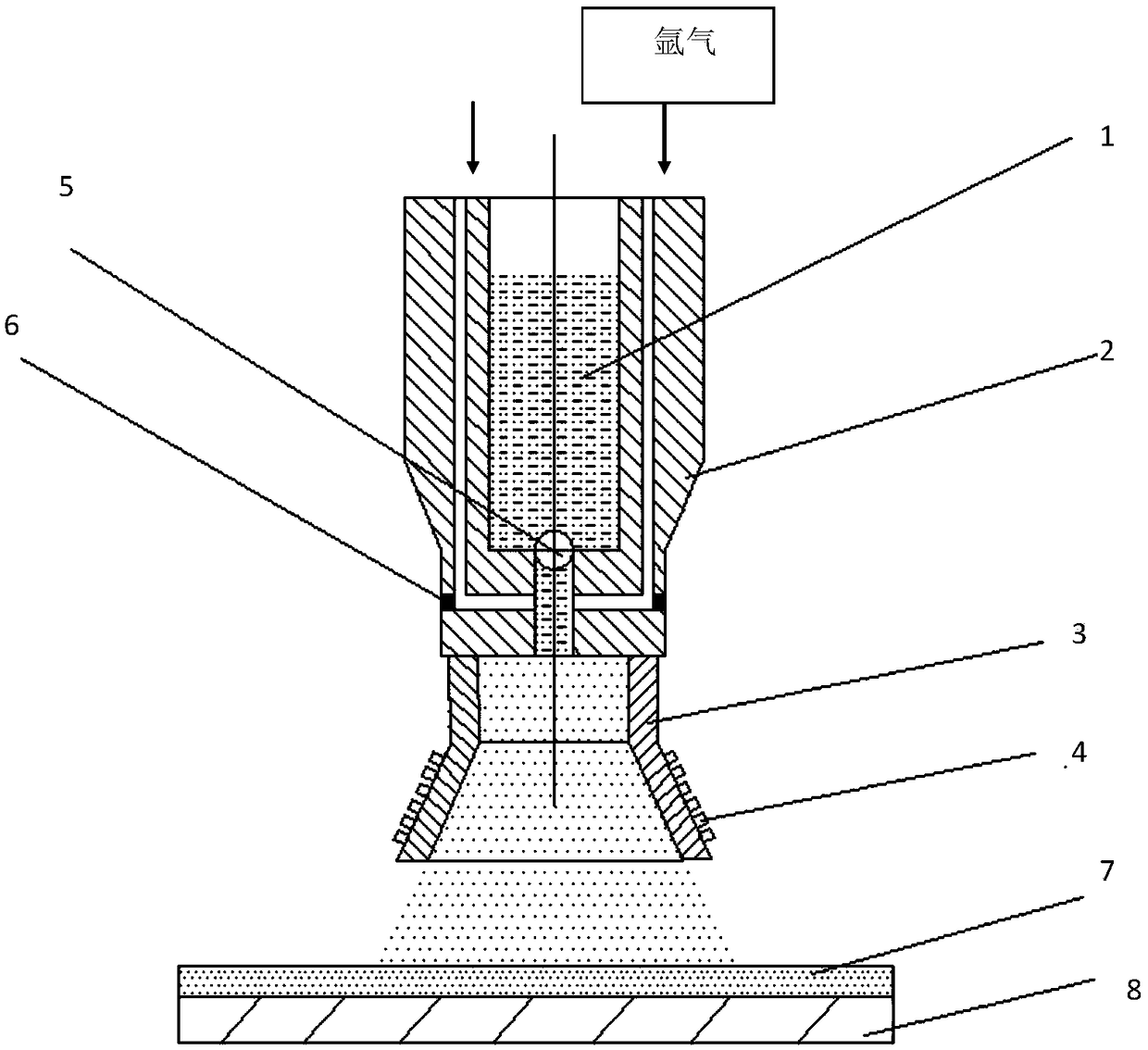

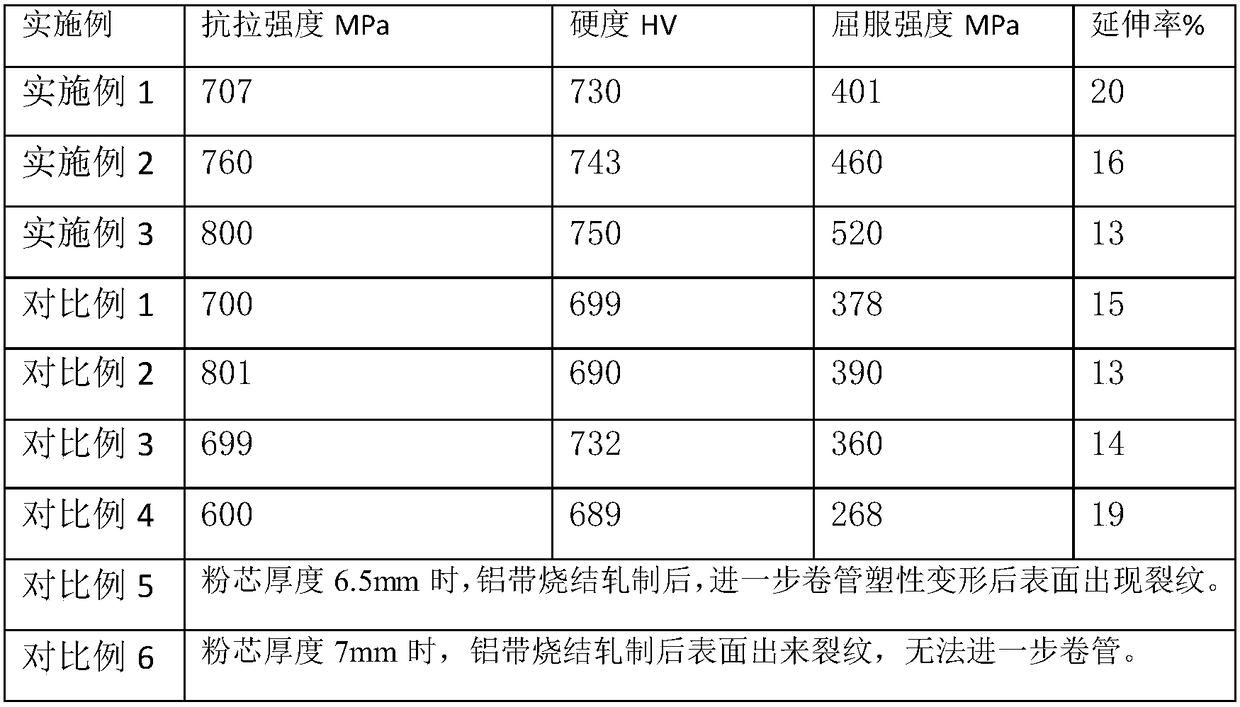

Electric-arc fusion-cladding powder core wire, and preparation method of high-entropy alloy coating

ActiveCN108998716AAvoid powder leakageLarge processing areaMolten spray coatingPower flowHigh entropy alloys

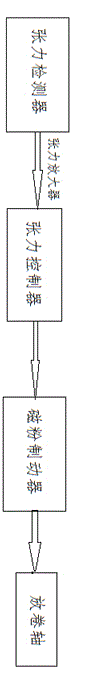

The invention provides an electric-arc fusion-cladding powder core wire, and a preparation method of a high-entropy alloy coating. The powder core wire is composed of a stainless steel strip and a powder core, wherein the thickness of the stainless steel strip is 0.8mm, and the powder core is powder of Mn, Cr, Fe, Ni, and Cu in a molar ratio of 2:2:2:2:1. A preparation method of the powder core wire comprises the following steps: (1) preparing the powder core; (2) paving powder and sintering; (3) performing cold rolling; and (4) coiling, drawing wires, reeling, installing coiled wires on a wire feeder, and spraying-deposing fused core wires on the surfaces of base materials by setting the electric-arc welding voltage to be 14 V, current to be 150A, and speed to be 8cm2 / min under the actionof 0.9MP high-pressure argon to form the high-entropy alloy coating.

Owner:JIANGSU UNIV OF TECH

Automatic powder feeding device of 3D printer

InactiveCN110341185AAvoid powder leakageImprove powder feeding accuracyManufacturing enclosures3D object support structuresLevel sensorEngineering

The invention belongs to the technical field of 3D printing, and particularly relates to an automatic powder feeding device of a 3D printer. The automatic powder feeding device comprises a powder box,a powder blocking cover, a bracket, a transmission mechanism, a L-shaped plate, an eccentric shaft, a sealing pad, a powder feeding mechanism, a forming chamber, a material level sensor and a controller. According to the automatic powder feeding device, the eccentric shaft is arranged, so when the eccentric shaft does periodic motion, power periodically leaks at the lower side of the powder box,in this way, the amount of powder leakage can be controlled, and the structure can be simplified; and meanwhile, through the design of the material level sensor, the controller and the powder feedingmechanism, automatic powder feeding can be achieved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

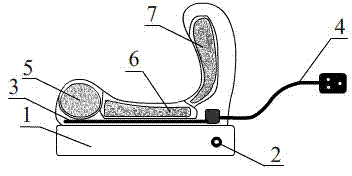

Hair and cervical vertebrae health-care pillow

InactiveCN102920253AImprove sleep qualityIncreased warmth and comfortPillowsThermal insulationCervical vertebral body

The invention relates to a hair and cervical vertebrae health-care pillow. The pillow comprises an air cushion, a pillow cushion connected to the upper surface of the air cushion, and a back cushion, wherein the air cushion is used for regulating the height of the pillow through inflation according to the user requirements, and the sleep comfortability is also improved; the pillow cushion comprises a cervical vertebrae health-care region and a hair health-care region; medicines in the back cushion are directly dissipated to the head to achieve health-care function on the head; and a positive temperature coefficient (PTC) ceramic heating element and a temperature switch have heating and thermal insulation control functions are introduced to make the medicines dissipate well and warm the head and neck, thereby promoting blood circulation to effectively absorbing the medicines in the pillow under the head and neck, and the actual usage effect is improved. The inventive pillow has health-care effect on hair and cervical vertebrae, simultaneously has the effects of relieving anxiety, promoting sleep, and improving sleep quality, and has multiple health-care functions.

Owner:蒋亚飞

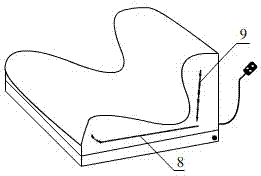

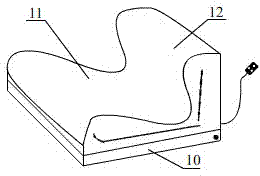

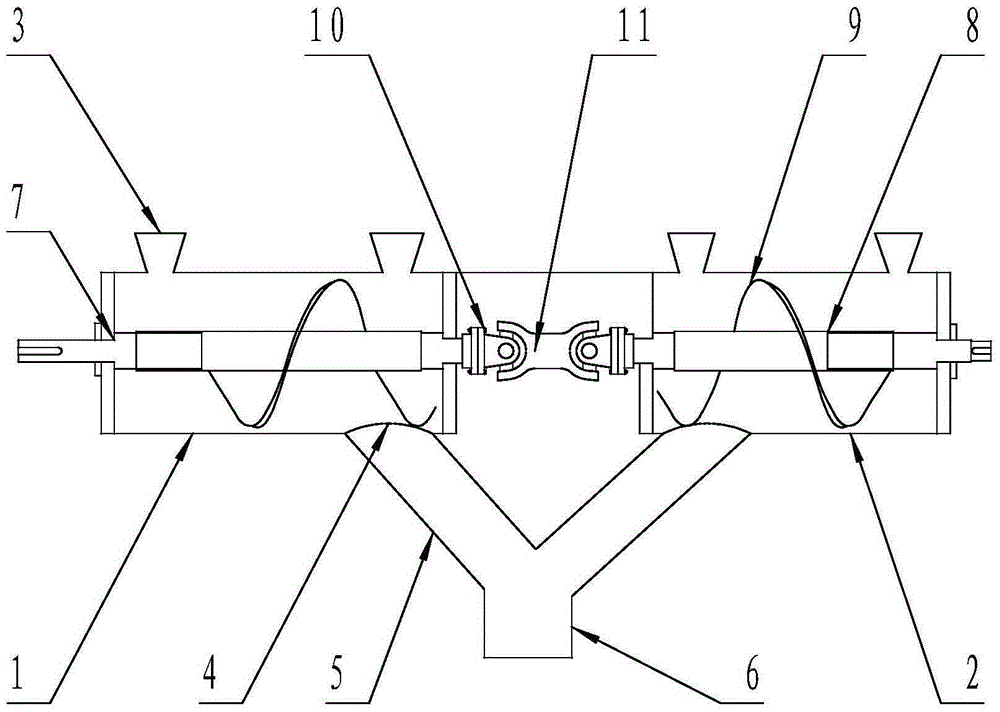

Spiral discharging device for dust collector

InactiveCN105383875AGuarantee continuous and stable operationAvoid powder leakageConveyorsPackagingEngineeringOperating environment

The invention discloses a spiral discharging device for a dust collector. The spiral discharging device for the dust collector is provided with a first discharging shell and a second discharging shell. Dust conveying devices are further arranged in the first discharging shell and the second discharging shell respectively. Each dust conveying device comprises a spiral shaft and a spiral fixedly connected to the spiral shaft. The ends, stretching out of two adjacent side plates, of the spiral shafts installed on bearing seats on the side plates of the first discharging shell and the second discharging shell are connected with a universal rotary shaft through universal rotary shaft connecting flanges respectively. According to the spiral discharging device for the dust collector, the phenomenon that the discharging shells are swept and abraded due to falling and bending of the spiral shafts, and consequently dust leakage is caused is prevented, and checking and maintenance of the spiral shafts are facilitated; the field operating environment is improved, the equipment maintenance cost and workload are reduced, and continuous and stable operation of the spiral discharging device for the dust collector is achieved.

Owner:JINAN AOHAI CARBON PROD

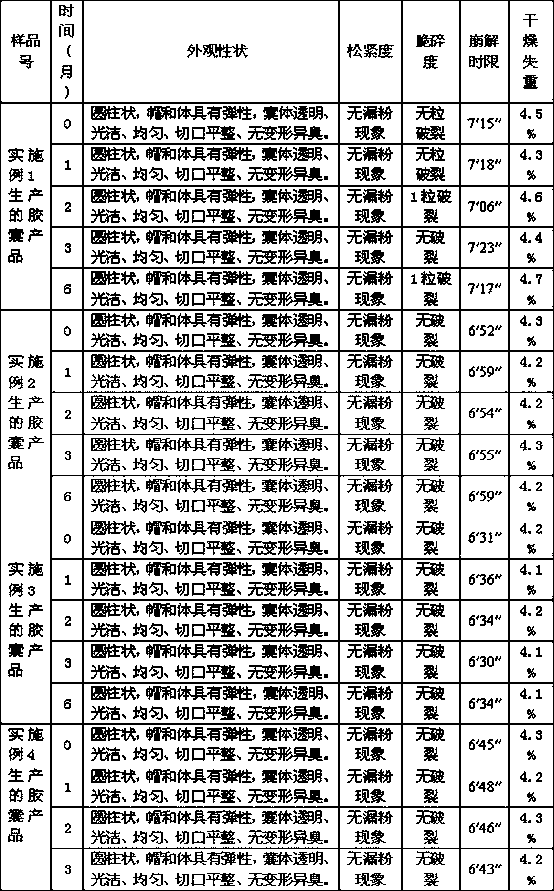

Plant hollow capsule and preparation method thereof

ActiveCN109846850AFast disintegrationSpeed up disintegrationPharmaceutical non-active ingredientsCapsule deliveryPlasticizerMoisture absorption

The invention provides a plant hollow capsule and a preparation method thereof, and belongs to the technical field of hollow capsule production. The plant hollow capsule is prepared from modified hydroxypropyl methylcellulose, gel, coagulant aid, plasticizer, surfactant and the balance of water, wherein the modified hydroxypropyl methylcellulose is prepared by adding a proper amount of microcrystalline cellulose into hydroxypropyl methylcellulose and performing uniform mixing. The plant hollow capsule has the beneficial effects that the capsule as certain moisturizing property besides the molding performance of a hydroxypropyl methylcellulose gel solution can be kept, moisture loss due to dryness and moisture absorption can be avoided in the storing process, shrinkage or expansion of a capsule shell can be avoided, occurrence of powder leakage can be effectively avoided, and the disintegrating speed of a capsule can be accelerated; the ductility and plasticization of the capsule can beimproved by properly adding the plasticizer, uniform wall thickness of the capsule can be guaranteed by combining with the gel; the disintegrating speed can be accelerated by properly adding the surfactant with the microcrystalline cellulose; and the friability can be effectively improved by properly adding the gel and the coagulant aid with the plasticizer.

Owner:CHONGQING HENGSHENG MEDICINAL CAPSULE

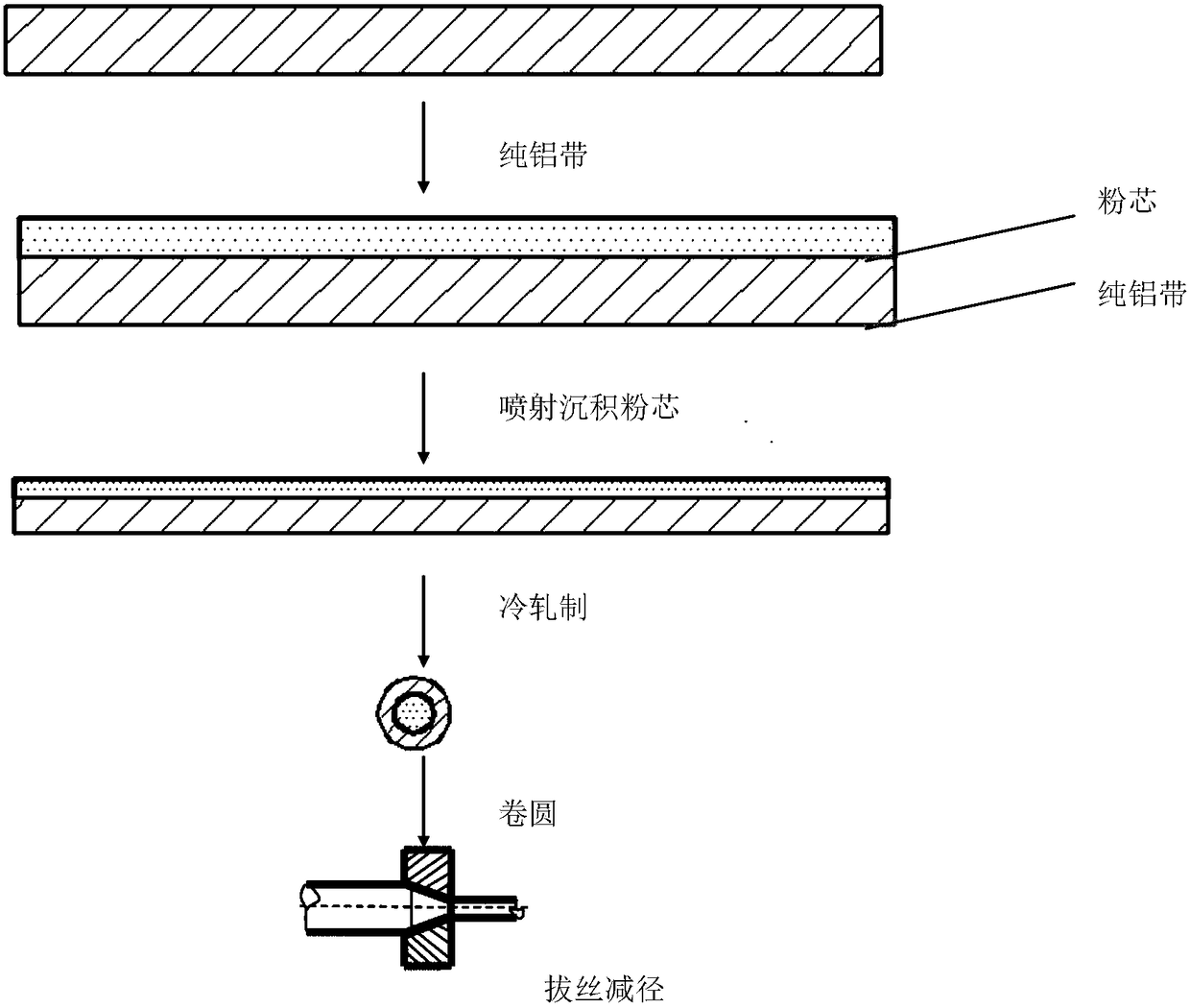

Powder core wire and low-temperature-resistant high-entropy alloy prepared by electric-arc deposition of powder core wire

ActiveCN108950352AHigh low temperature strengthHigh and low temperature hardnessMolten spray coatingHigh entropy alloysDuctility

The invention provides a powder core wire and a low-temperature-resistant high-entropy alloy prepared by electric-arc deposition of the powder core. The powder core wire comprises an aluminum belt anda powder core, wherein each of the aluminum belt and the powder core consists of Co, Cr, Fe, Ni and Cu in an equal atomic ratio being 1 to 1 to 1 to 1 to 1 to 1; and the thickness of the aluminum belt is 0.5 mm. The preparation method for the wire comprises the following steps of: (1) preparing the powder core; (2) spraying a deposited powder core; (3) performing cold-rolling; and (4) performingtube coiling and wire drawing. A prepared high-entropy alloy coating has high low-temperature-resistant strength, high low-temperature hardness and high low-temperature ductility.

Owner:JIANGSU UNIV OF TECH

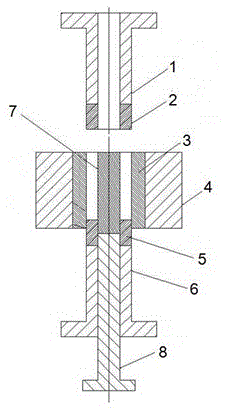

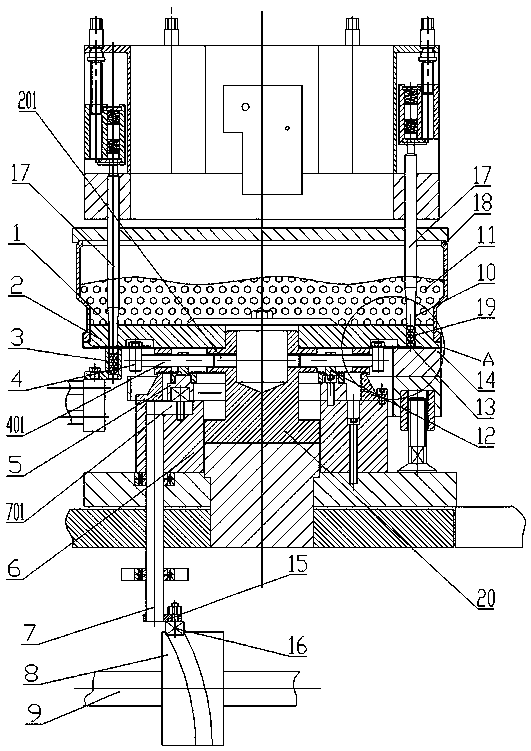

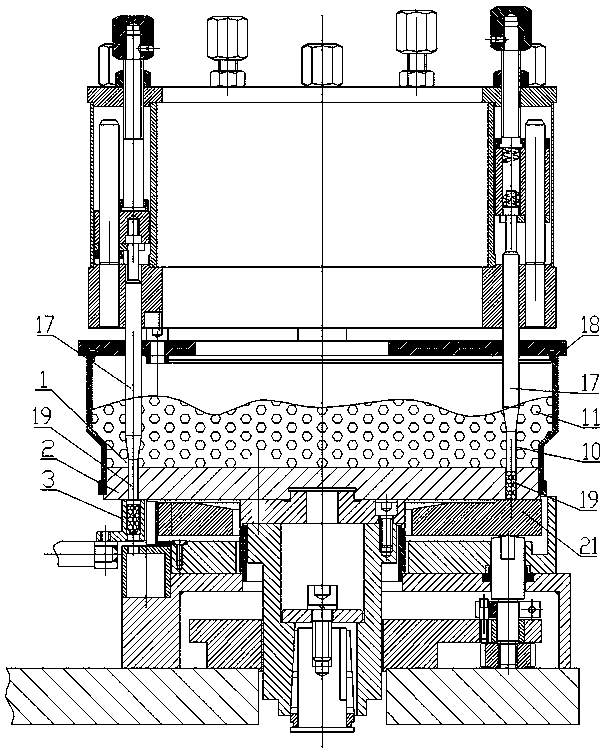

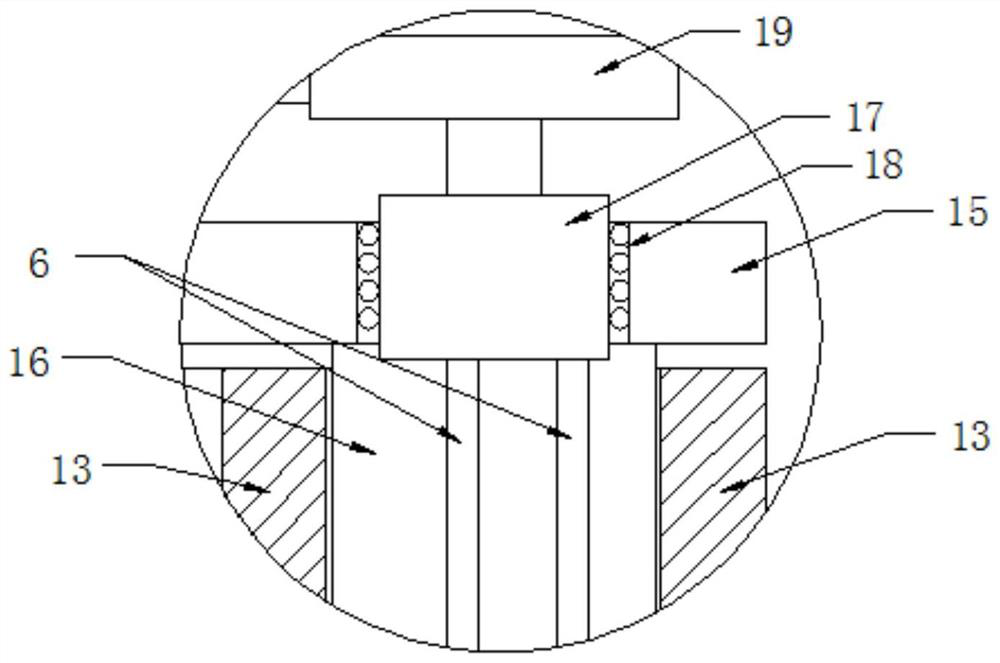

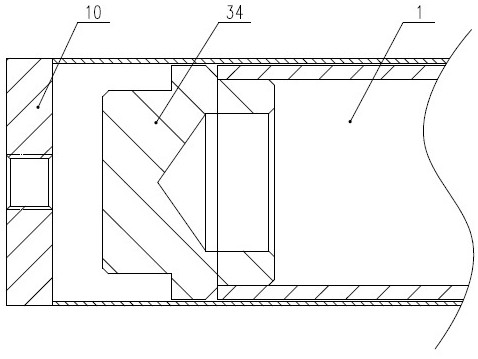

Pressing die for bonded neodymium-iron-boron magnetic body

The invention discloses a pressing die for a bonded neodymium-iron-boron magnetic body. The pressing die comprises an upper punching die, a middle die, a lower punching die and a core rod. A tubular upper punching die punch and a tubular lower punching die punch are bonded to the front end of the hollow upper punching die with a T-shaped cross section and the front end of the hollow lower punching die with a T-shaped cross section respectively. A matching rod is bonded to the front end of the core rod. A middle die core is arranged at the wall of a center hole of the middle die through an embedded opening in an interference fit mode. The matching rod is inserted into the middle die core and located at the axis of the middle die core. The matching rod is sleeved with the upper punching die punch and the lower punching die punch in a spaced mode. The upper punching die punch and the lower punching die punch are both in clearance fit with the inner wall of the middle die core. The pressing die is simple in structure and convenient to operate, is used for molding the bonded neodymium-iron-boron magnetic body and can bear pressure of more than 400 t; since release agents are not needed, it can be guaranteed that holding-on caused by heating expansion in the pressing process will not happen, powder leakage and powder blockage are avoided, the service life is long, and the productivity is high.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

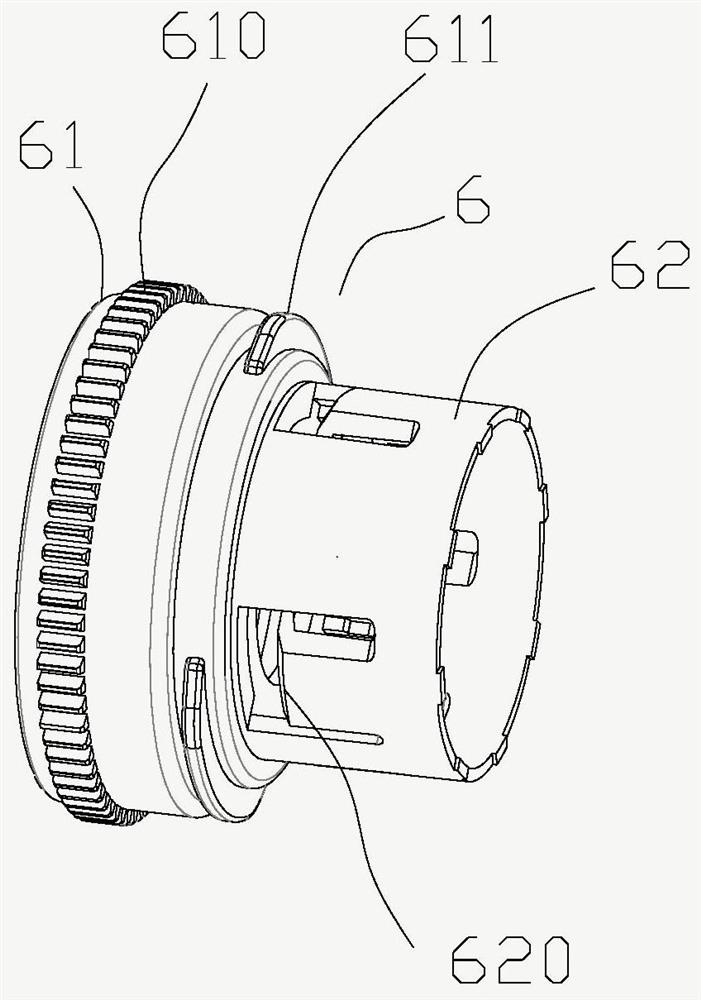

High-tightness toner cartridge

InactiveCN105717766ASimple structureIngenious designElectrographic process apparatusWaste management

The invention discloses a highly sealed toner cartridge, which comprises a developing frame, a photosensitive drum, an auxiliary waste toner collecting box and a toner frame, the toner frame is installed on the developing frame, a toner container is installed in the toner frame, and A developing sleeve is installed, both ends of the developing sleeve can be rotatably set on the developing frame, both ends of the photosensitive drum can be rotatably set on the waste toner frame, and a waste toner container is installed in the waste toner frame . The high-seal toner cartridge is equipped with a cleaning sponge and an auxiliary waste toner collection box on the waste toner frame of the toner cartridge to prevent leakage of toner, because the distance from the auxiliary waste toner collection box to the central axis of the photosensitive drum is smaller than that from the cleaning scraper to the photosensitive drum. The distance from the central axis of the drum, so the toner falling out of the waste toner container is collected by the auxiliary waste toner collection box. In this way, toner leakage is well avoided. promote.

Owner:TIANJIN ZHIJIE TECH CO LTD

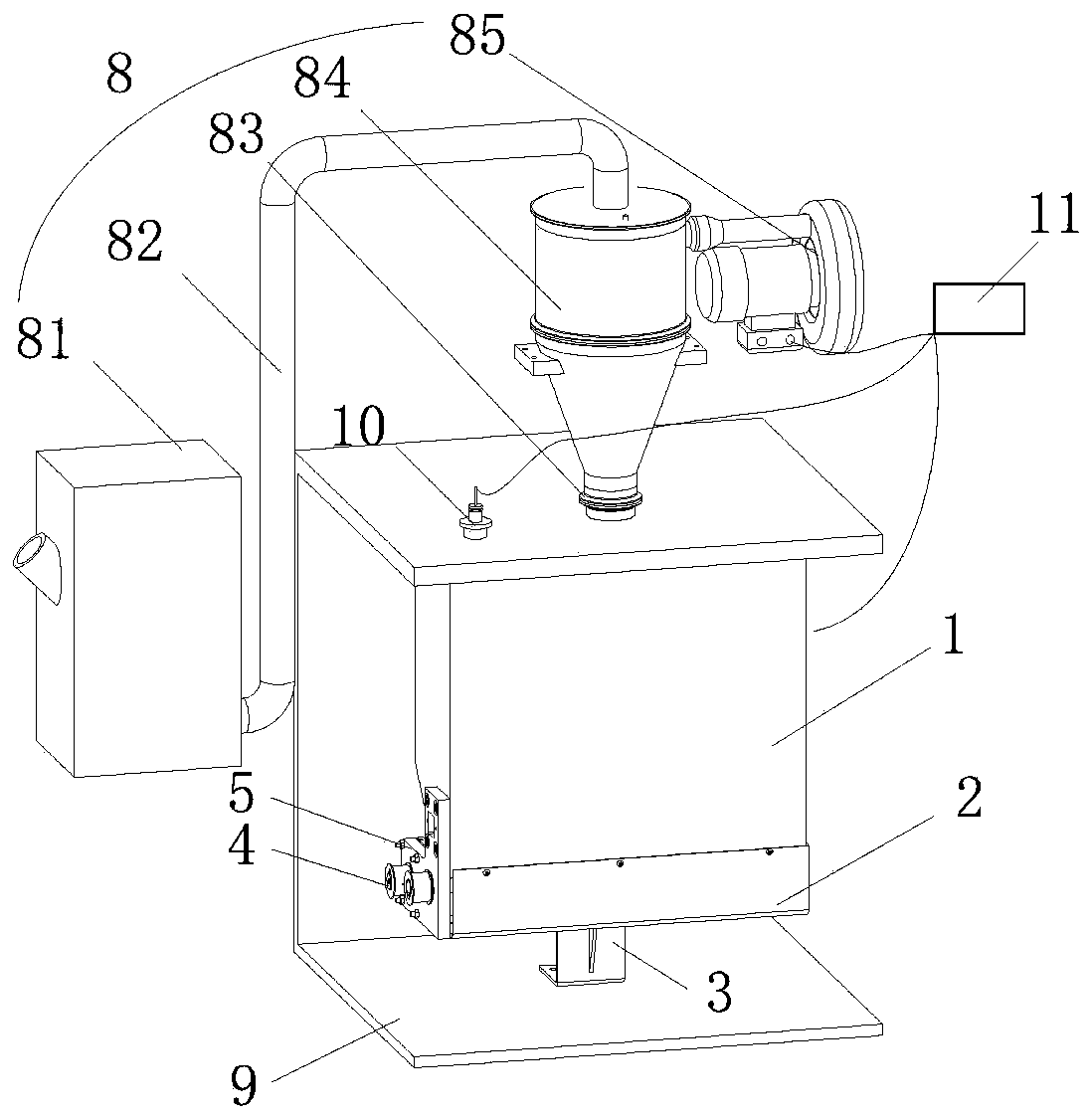

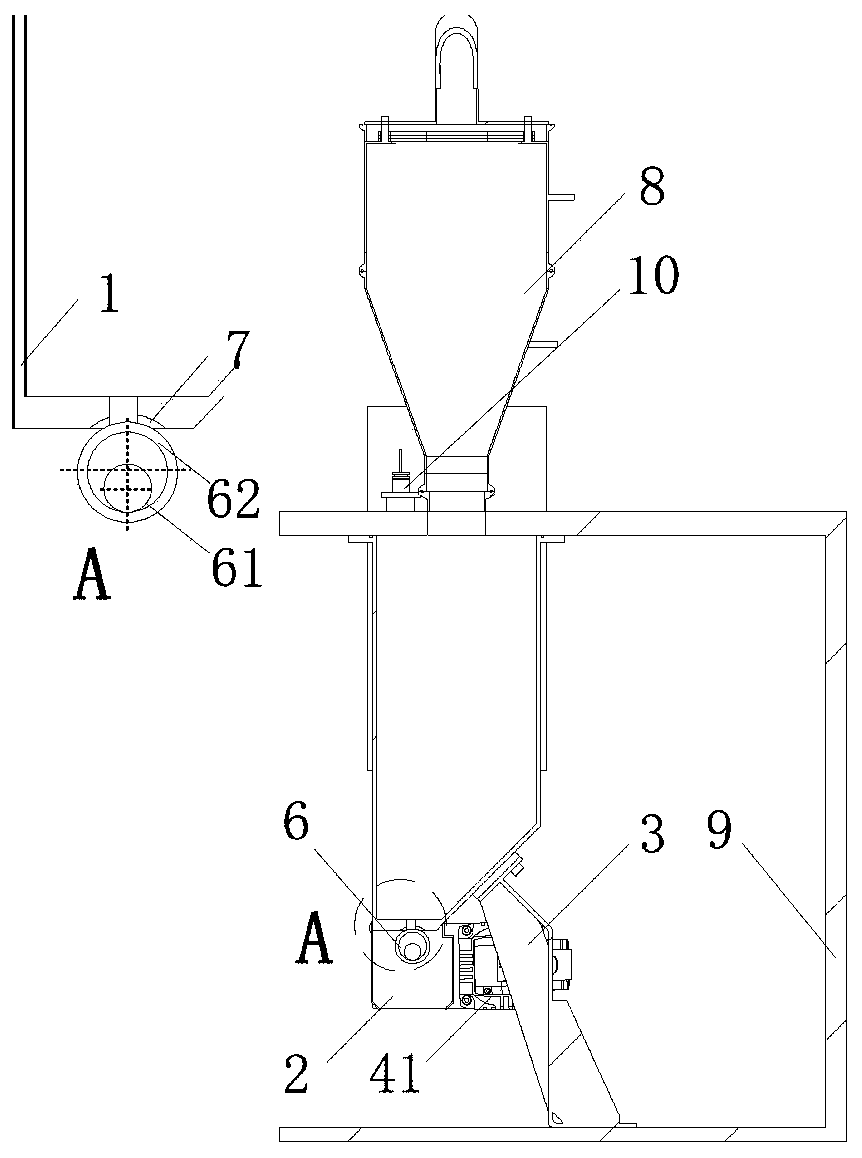

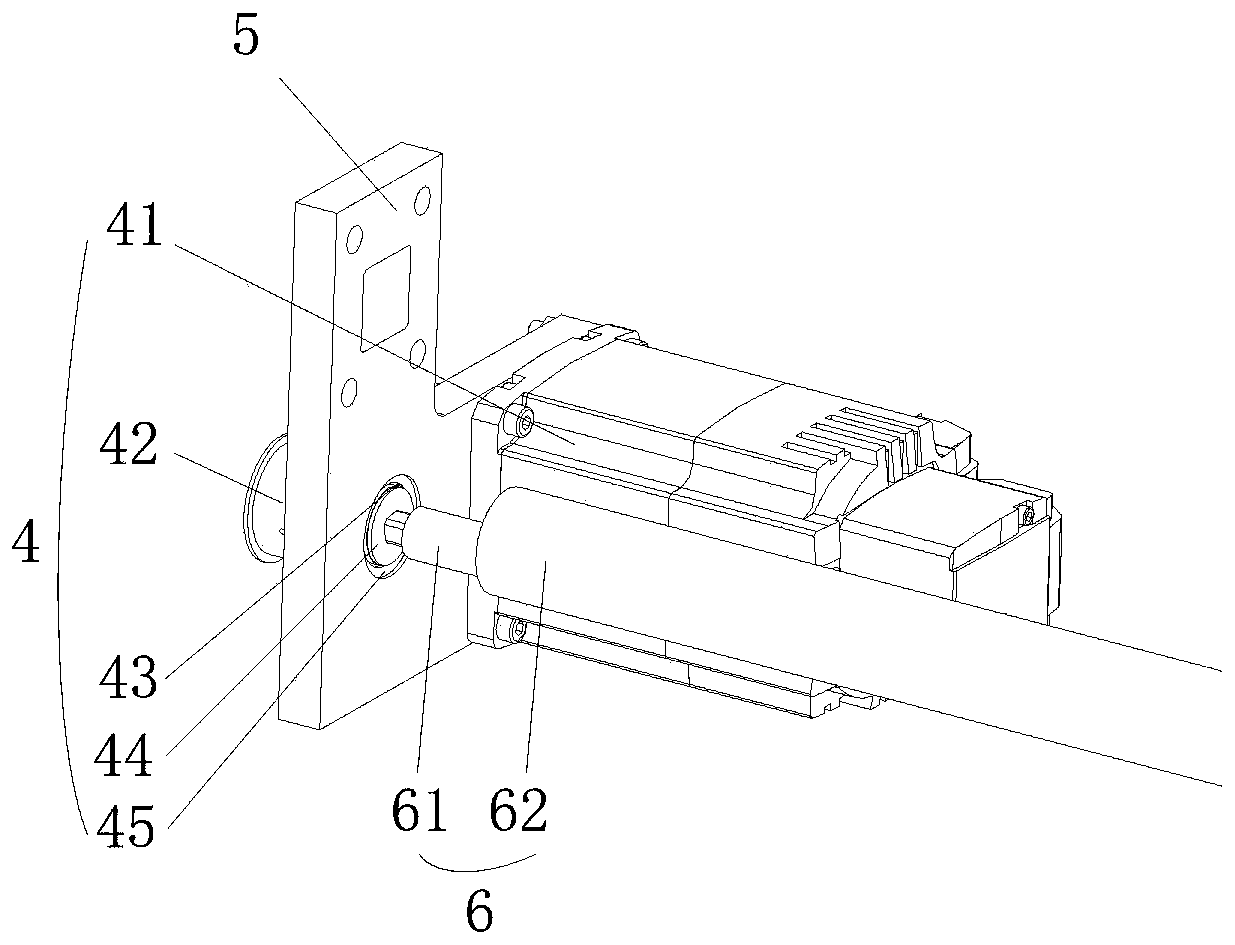

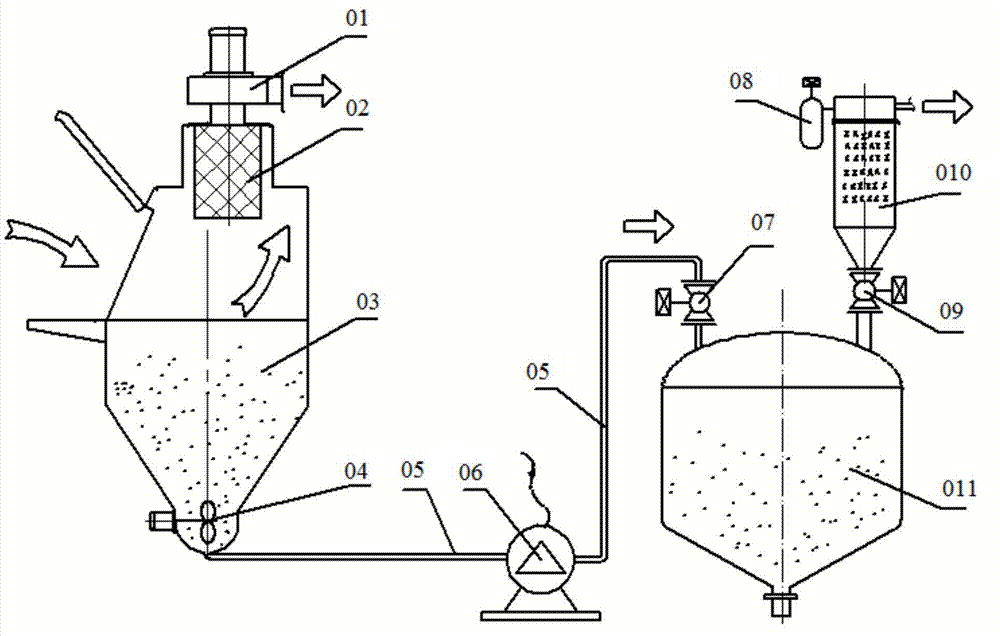

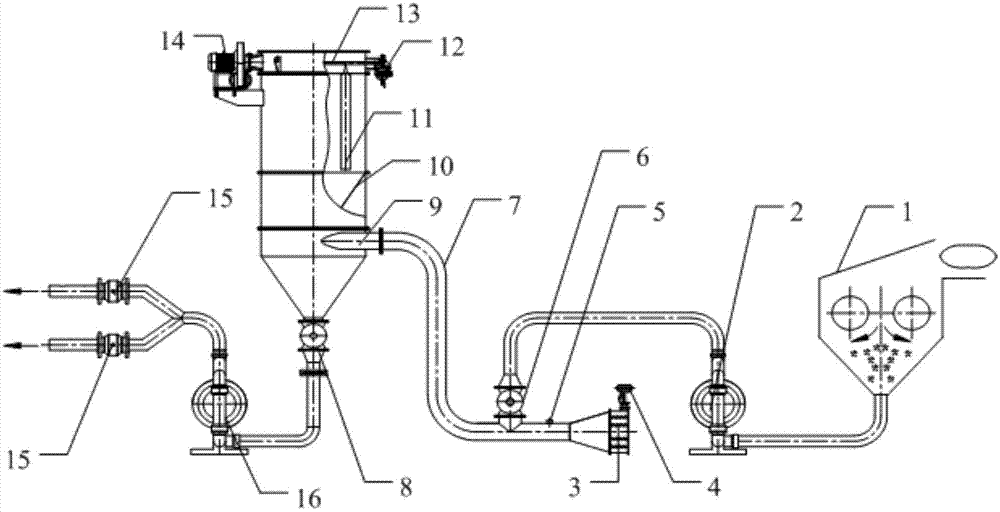

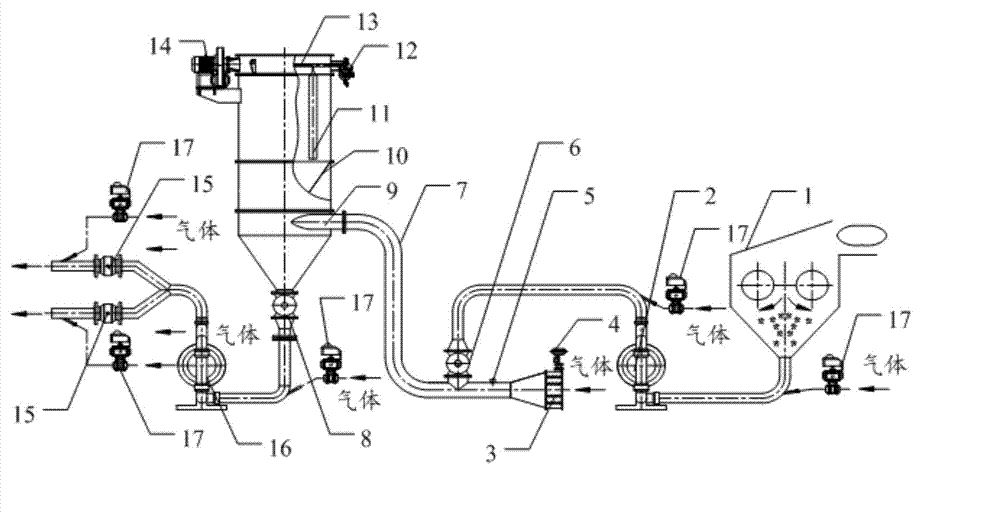

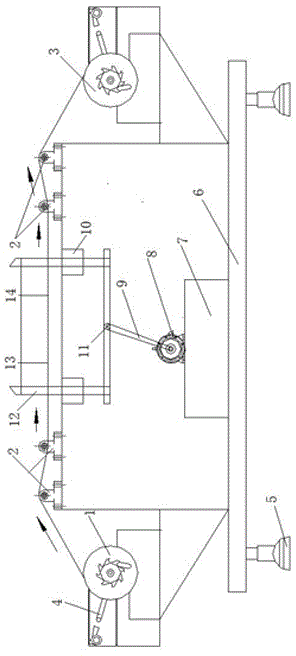

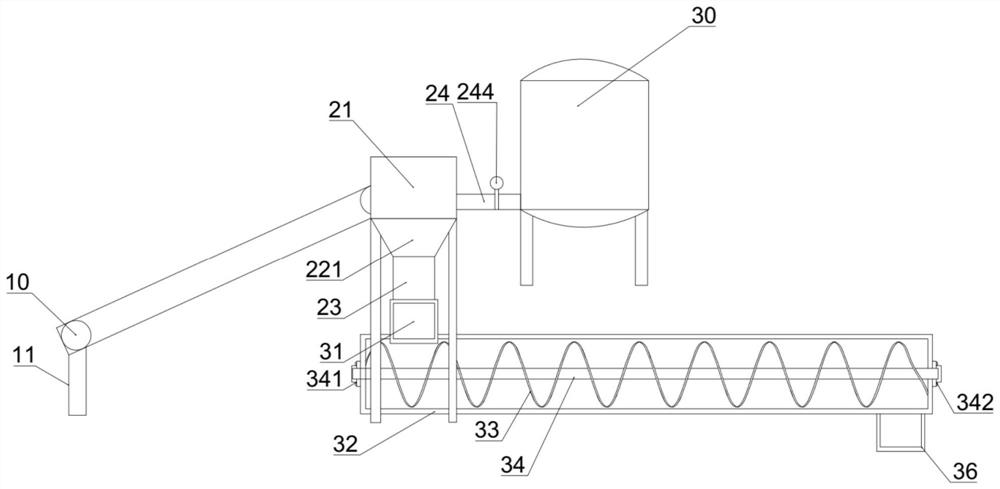

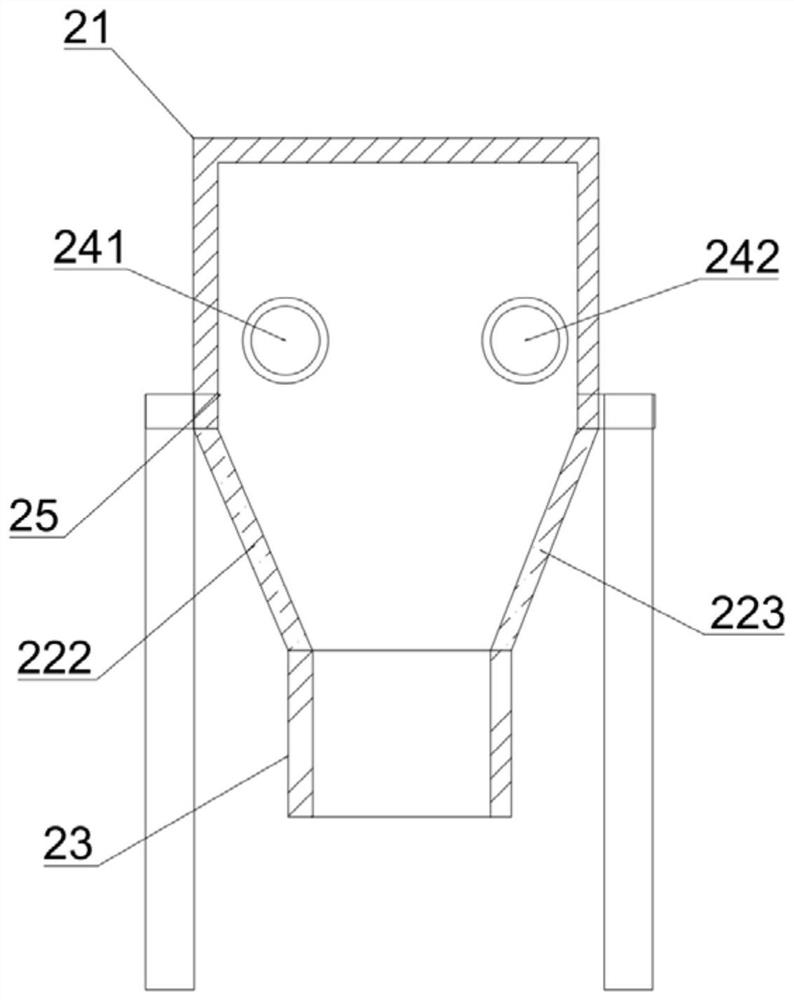

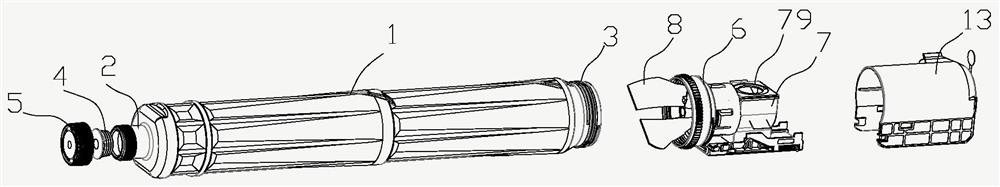

Continuous powder conveying device with drying function

ActiveCN103662222AAvoid powder leakageRealize negative pressure pneumatic conveying and dust removalArticle unpackingBulk conveyorsEngineeringPhencyclone

The invention discloses a continuous powder conveying device with a drying function. The device adopts a full-automatic and full-closed design, integrates the negative pressure pneumatic conveying of a high-pressure centrifugal fan and the conveying of a pneumatic diaphragm pump, and can overcome the defects of the prior art through a fan with lower power. The continuous powder conveying device with the drying function comprises an unpacking mechanism 1, a feeding pneumatic diaphragm pump 2, a heat exchanger 3, a regulating valve 4, a temperature and humidity sensor 5, a feeding gas-lock valve 6, a powder feeding pipeline 7, a discharge gas-lock valve 8, a cyclone separator 9, a collection mechanism 10, a filtering mechanism 11, an air blowing mechanism 12, a spraying and blowing pipe 13, the high-pressure centrifugal fan 14, a control valve 15 and a discharge pneumatic diaphragm pump 16.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

Metal part additive forming system and method

The invention discloses a metal part additive forming system and method.The system comprises a forming chamber, a powder laying platform is arranged in the forming chamber, a forming cylinder and a lower powder box are arranged below the powder laying platform, an upper powder box is arranged above the powder laying platform, and a first driving device is arranged on the powder laying platform; the first driving device drives the scraper to scrape and convey metal powder on the powder laying platform into the forming cylinder, a discharging disc is arranged at the bottom of the upper powder box, a plurality of second through holes are formed in the discharging disc, a rotating disc is arranged below the discharging disc, a plurality of first through holes are formed in the rotating disc, and a stirring piece is arranged on the first driving device. The motor is used for driving the rotating disc to switch between a closed state and an open state; in a closed state, the first through hole is not communicated with the second through hole; in the opening state, the first through hole and the second through hole are communicated to form a discharging channel, and the bottom end of the discharging channel is located between the scraper and the forming cylinder. According to the metal part additive forming system and method, powder falling is smooth, and the metal powder utilization rate is high.

Owner:SICHUAN ENG TECHN COLLEGE

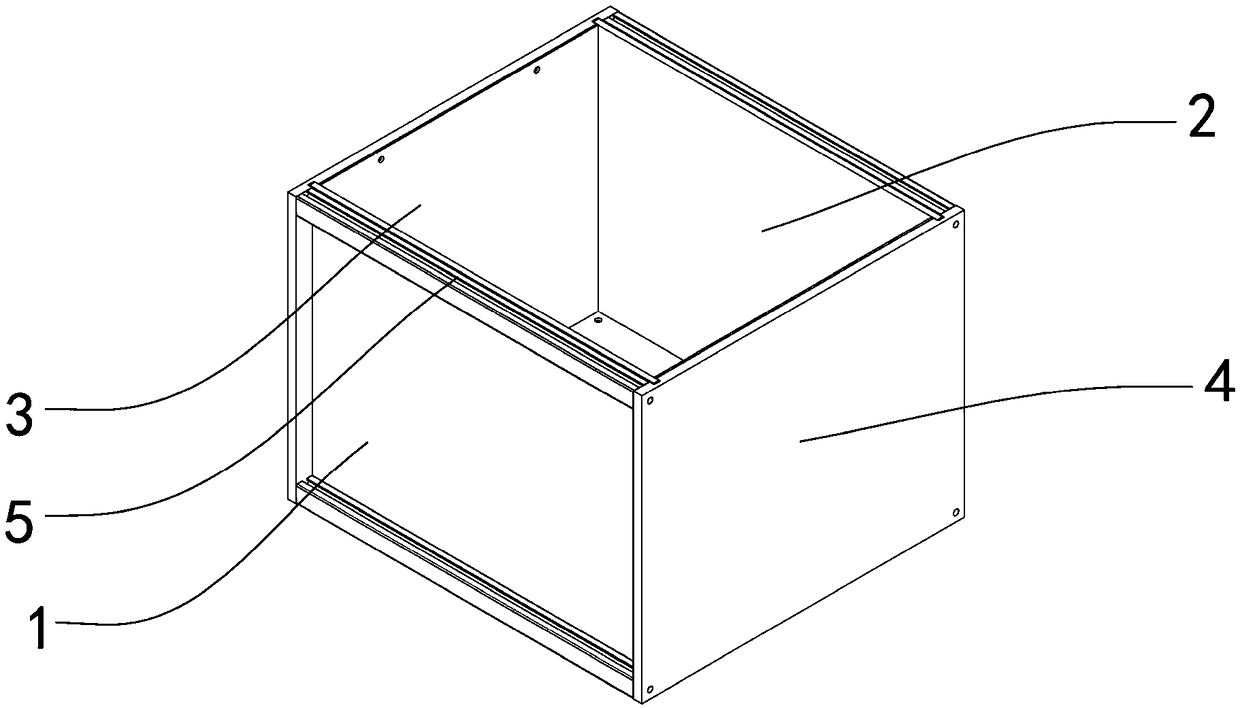

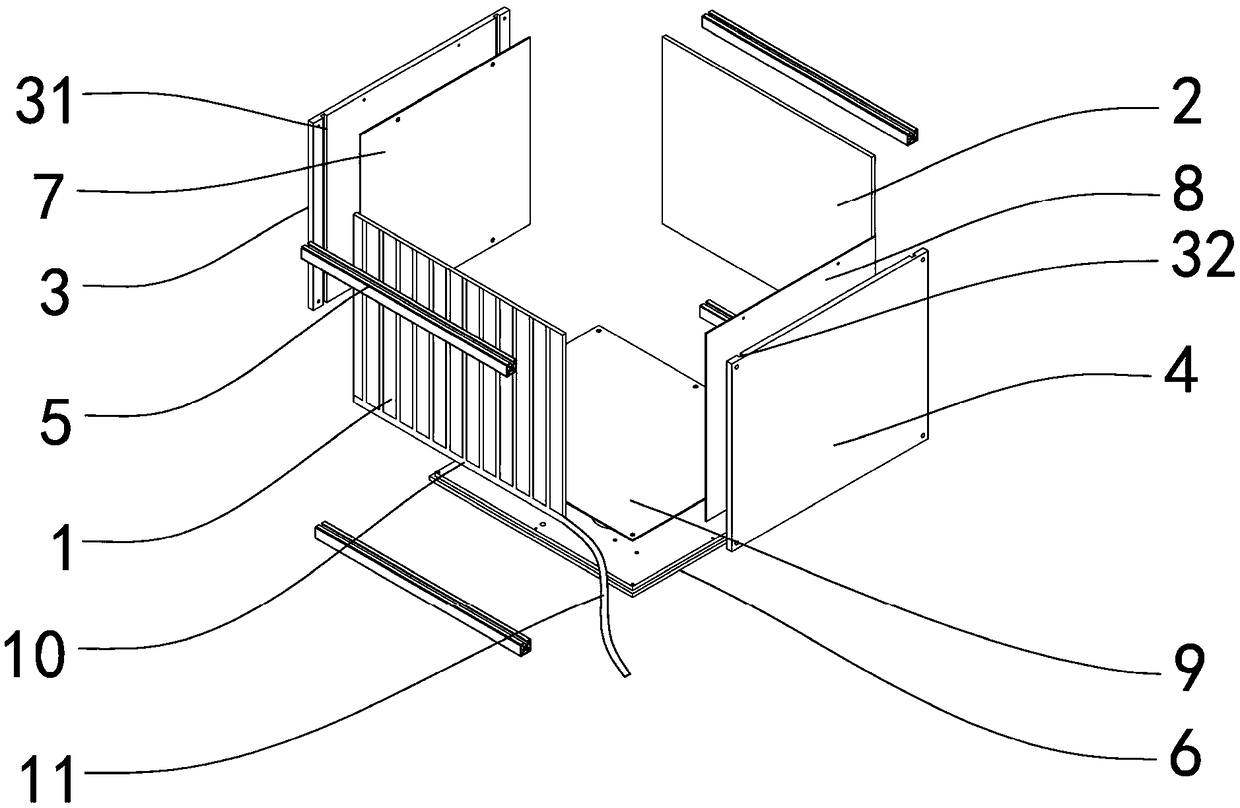

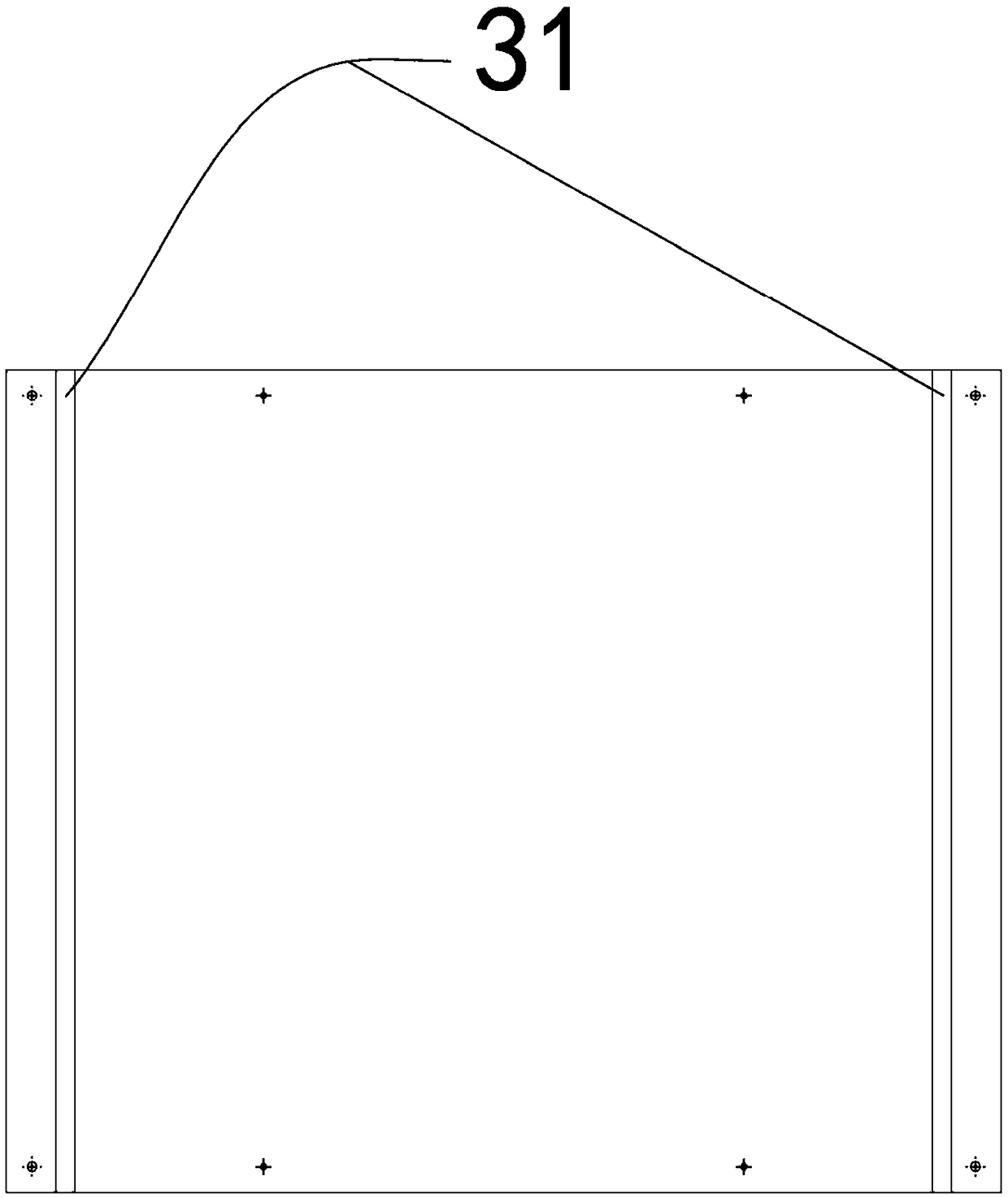

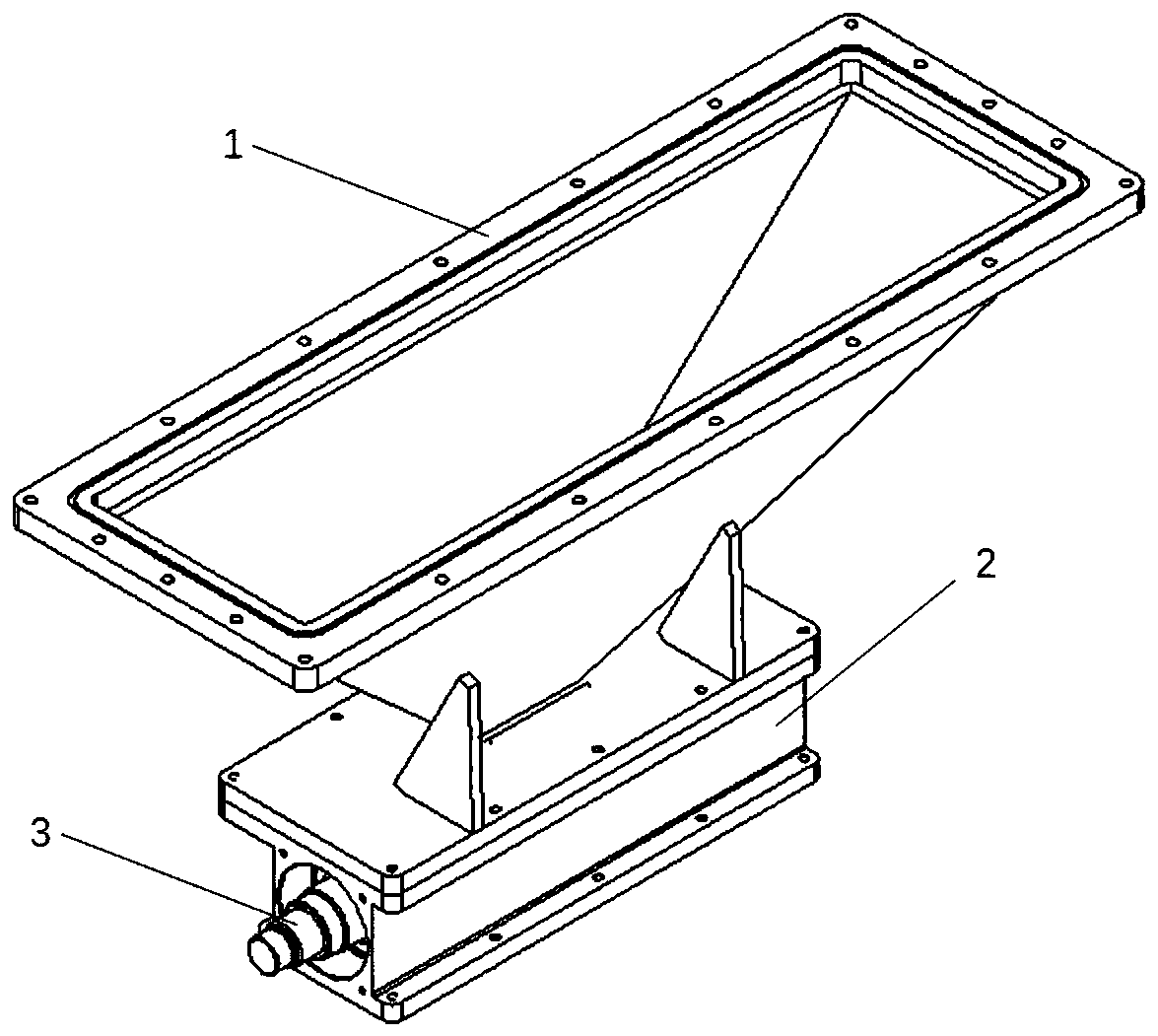

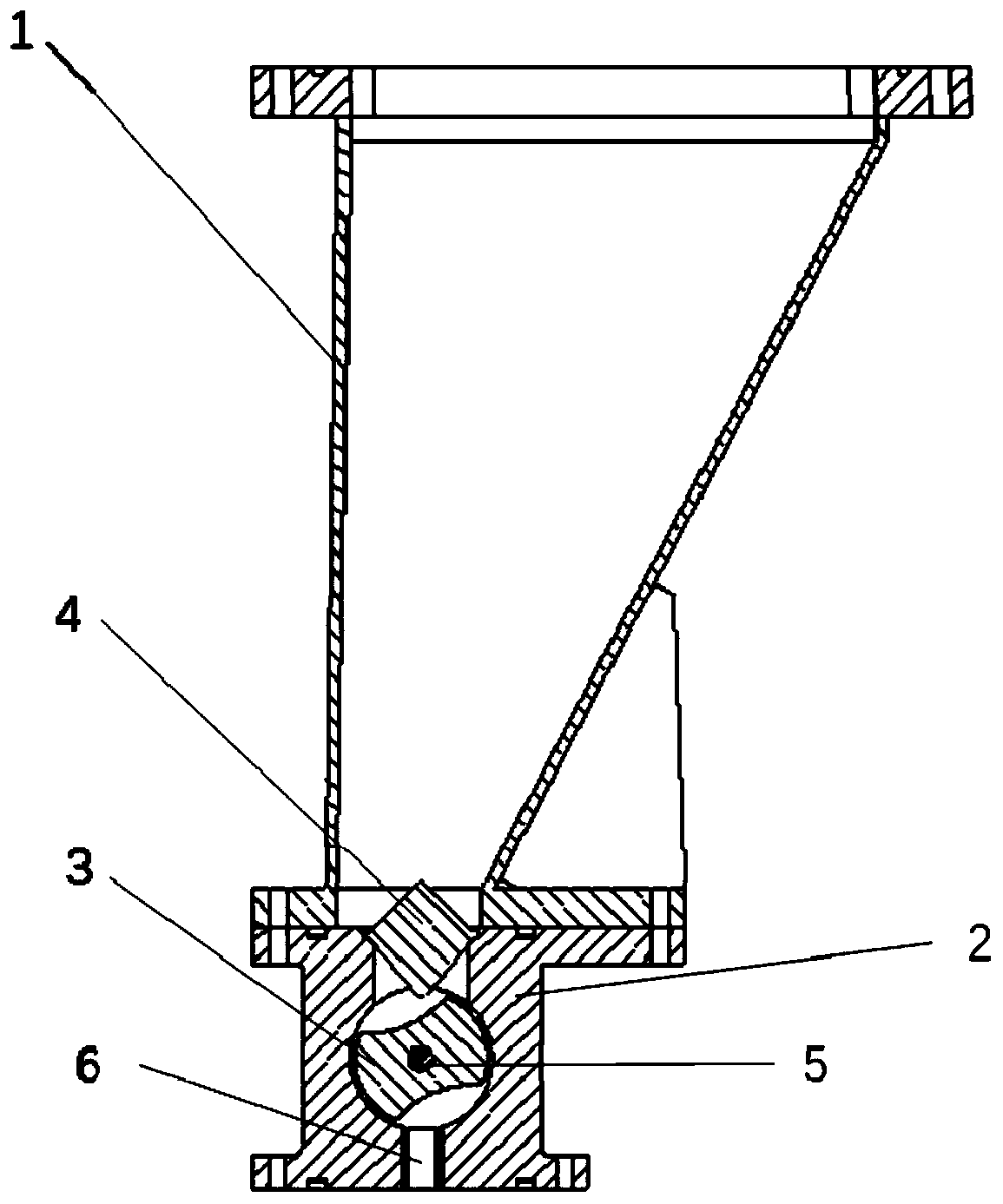

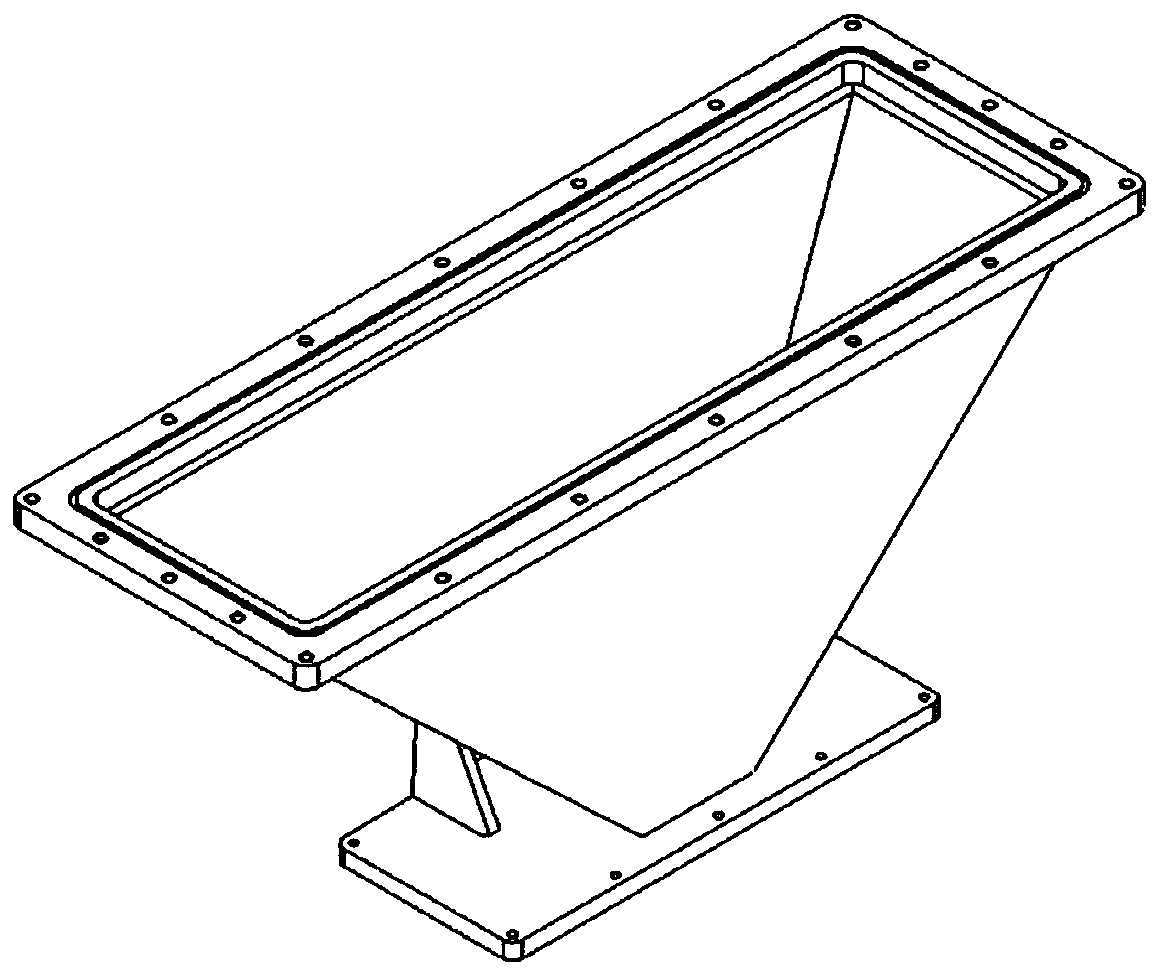

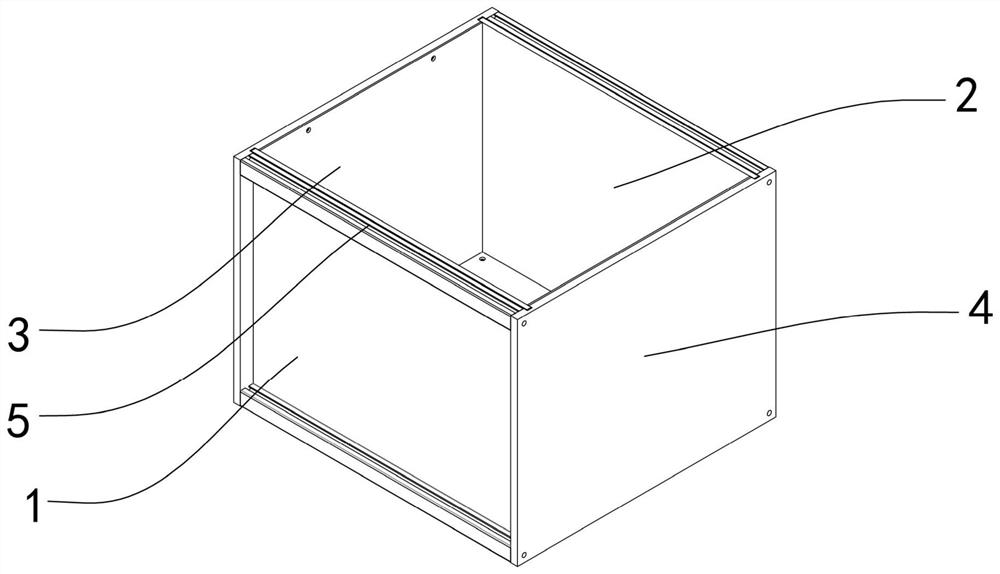

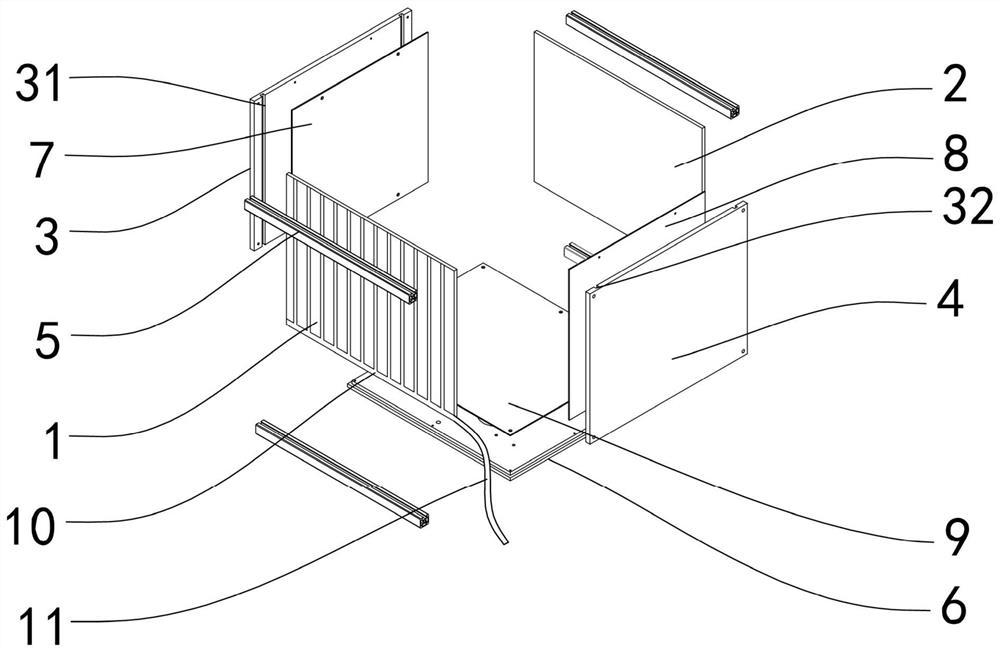

3D printer leakproof working cylinder

ActiveCN109049691AAvoid deformationAvoid corrosionManufacturing enclosuresAdditive manufacturing with solidsEngineeringUltimate tensile strength

The invention provides a 3D printer leakproof working cylinder. The 3D printer leakproof working cylinder comprises a first cylinder wall, a second cylinder wall, a first side plate, a second side plate, positioning rods and a piston plate; a rectangular channel structure is jointly defined by the first cylinder wall, the second cylinder wall, the first side plate and the second side plate; the first cylinder wall and the second cylinder wall are cooperatively connected through grooves in the first side plate and the second side plate; the first side plate and the second side plate are fastened and connected through the positioning rods; the piston plate slides in the rectangular channel; and the first cylinder wall and the second cylinder wall are made of glass or resin. The problems that3D printer working cylinders are insufficient in strength, and sand is prone to leaking are solved, the 3D printer leakproof working cylinder is convenient to dismount, mount and maintain and has good application prospects, on the basis of superior performance than original metal cutting machining, the cost is greatly reduced, the corrosion resistance is significantly improved, the especially inapplication of a large-sized piston cylinder blocks, the flatness of a whole board cannot be ensured by metal cutting machining easily, and the 3D printer leakproof working cylinder can be widely popularized in similar application.

Owner:武汉阿尔法激光有限公司

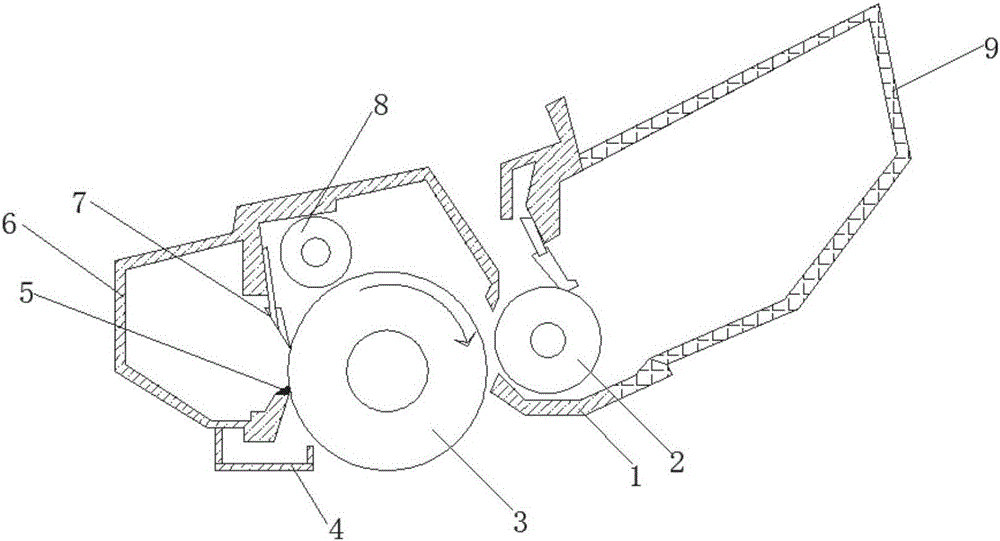

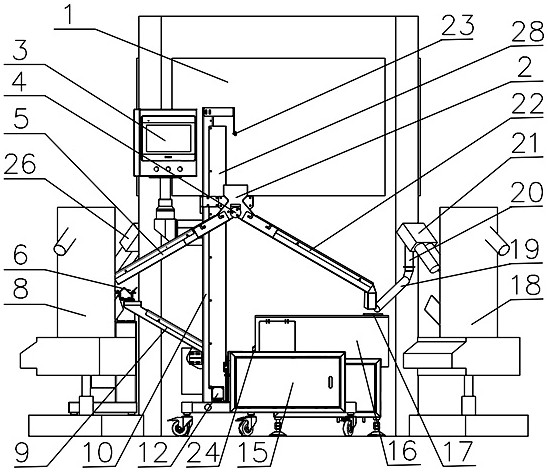

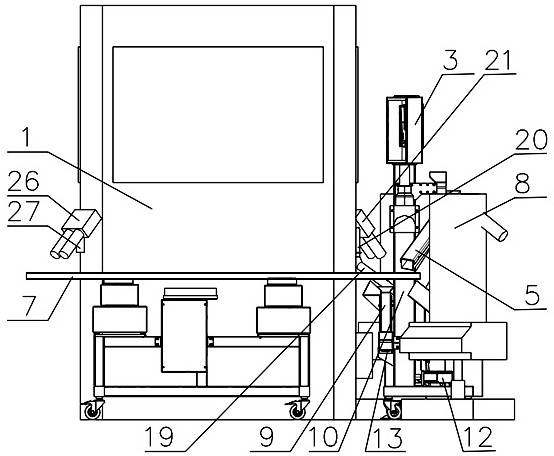

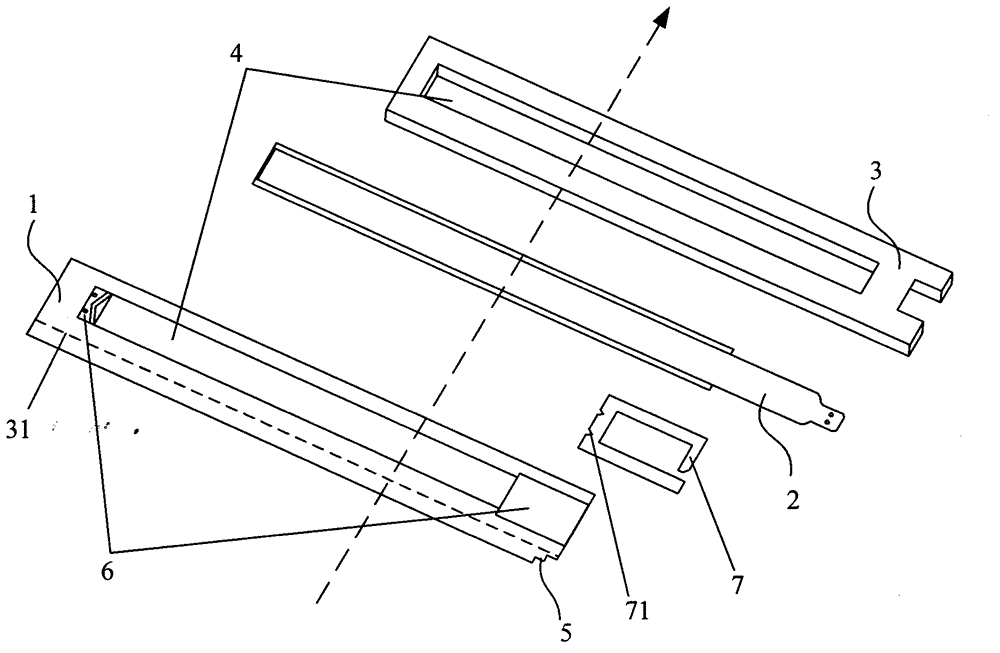

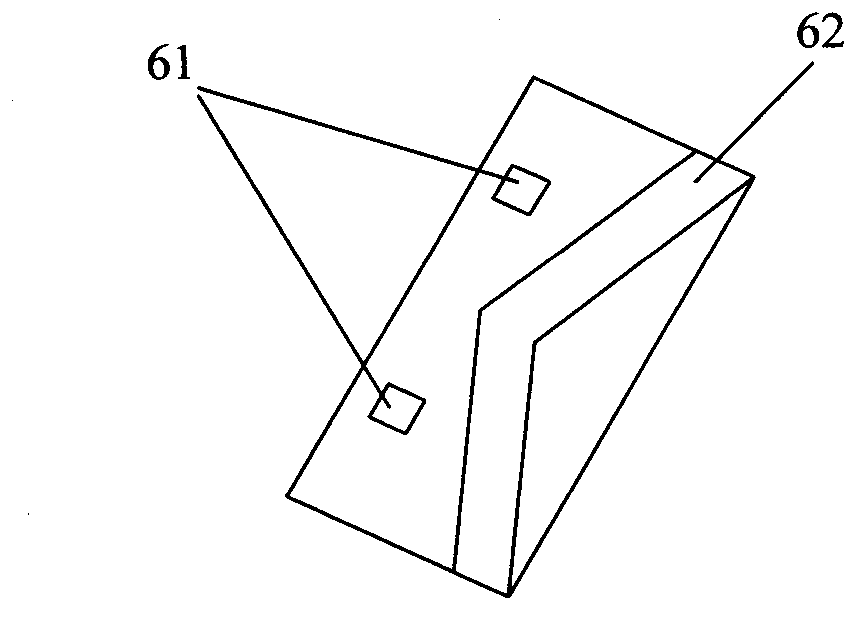

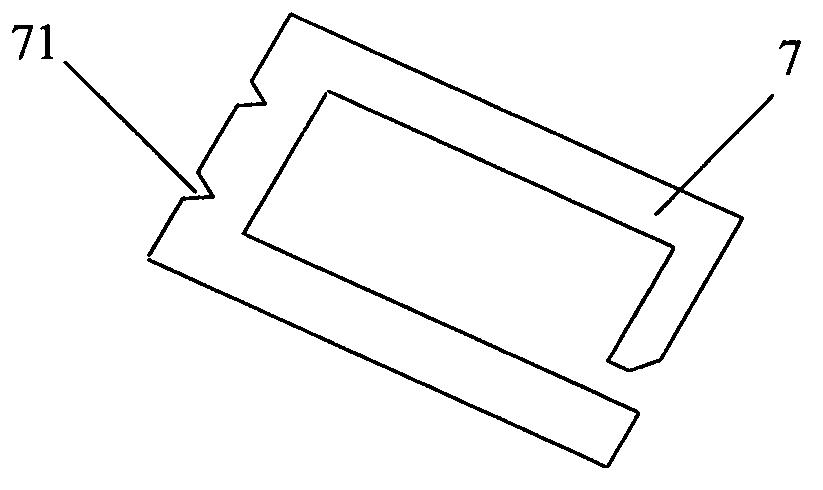

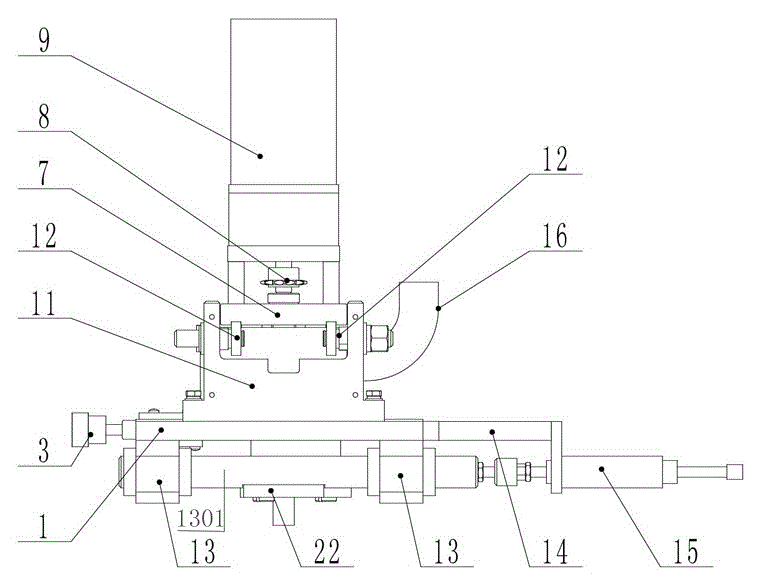

A plane servo punching machine for wrapping paper roll film

ActiveCN103991100BSolve the problem of uneven punching and scratching the paper filmRapid productionMetal working apparatusWebs handlingDrive wheelRoll film

The invention discloses a packaging paper roll film plane servo hole puncher. A supporting base is fixed to the ground. An installation plate is fixed to the supporting base. A constant tension unwinding mechanism is installed on one side of the installation plate. A servo constant speed winding mechanism is installed on the other side of the installation plate. Four paper film guiding shafts are installed between the constant tension unwinding mechanism and the servo constant speed winding mechanism. A driving box is arranged at the central position of the installation plate and connected with a driving wheel. A connecting rod is installed on the driving wheel and connected with a pin plate installation box through a movable hinge. A pin plate upper mold and a pin plate lower mold are installed inside the pin plate installation box. According to the packaging paper roll film plane servo hole puncher, the design of the constant tension unwinding mechanism, the paper film guiding shafts, the pin plate upper mold and the pin plate lower mold is adopted, the problems that holes are unevenly formed in packaging paper and paper films are scratched are solved, the phenomenon that powder is leaked or pollution is caused by a broken bag during packaging is avoided, efficiency is high, production is safe, the number of workers is saved, maximum production is achieved, and maximum benefits are brought to an enterprise.

Owner:青岛力海药用包装科技有限公司

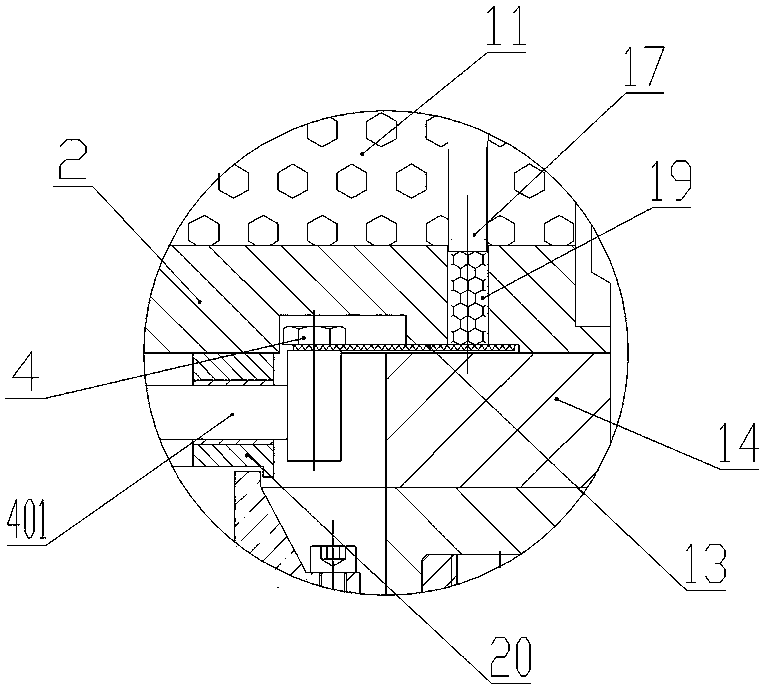

Selective laser melting forming powder falling device

ActiveCN110181047AReduce volumeImprove utilization efficiencyAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMetallurgy

The invention discloses a selective laser melting forming powder falling device. The device comprises a powder cylinder, a powder falling chamber, a quantitative powder falling shaft, a rhombic sliding block and a servo motor, wherein a cylindrical cavity is formed in the powder falling chamber; a powder inlet and a powder outlet are respectively formed in the upper surface and the lower surface of the powder falling chamber; the powder cylinder is arranged on the upper surface of the powder falling chamber and communicates with the powder inlet; the quantitative powder falling shaft is arranged in the cylindrical cavity of the powder falling chamber; two symmetrical outer circular arcs and circular arc grooves are arranged at the periphery of the middle part of the quantitative powder falling shaft and located at the powder inlet of the powder falling chamber; the rhombic sliding block is placed at the powder inlet of the powder falling chamber by virtue of self gravity; the lower part of the rhombic sliding block extends into the arc grooves; a gap is reserved between the outer circular arcs of the middle part of the quantitative powder falling shaft and the cylindrical cavity ofthe powder falling chamber; and the servo motor is used for driving the quantitative powder falling shaft to rotate. The device effectively avoids the powder leakage and the powder falling shaft blocking existing in powder falling in the process of laser selective melting forming; and quantitative powder falling is achieved, so that the powder utilization efficiency is increased.

Owner:XI AN JIAOTONG UNIV

Tabletting machine capable of preventing fragmentation

InactiveCN104309151AImprove plasticityImprove integrityShaping pressEngineeringMechanical engineering

The invention discloses a tabletting machine capable of preventing fragmentation. The machine comprises a machine frame, wherein an upper stamping die, a middle die and a lower stamping die are arranged on the machine frame from top to bottom, the upper stamping die is connected with an upper driving mechanism for driving the upper stamping die to move up and down, the lower stamping die is connected with a lower driving mechanism for driving the lower stamping die to mode up and down, and a die hole is formed in the middle die; a die head of the upper stamping die and a die head of the lower stamping die are both matched with the hole diameter of the die hole; the axes of the upper stamping die, the lower stamping die and the die hole coincide; a feed hopper is arranged on the right side of the machine frame; a time relay which is connected with the upper driving mechanism to control stay time when the upper stamping die is downwards pressed on a tablet is also arranged above the machine frame. The tabletting machine is simple in structure and convenient to operate, can increase the rate of finished tablet products, improve the production efficiency, can also reduce generated dust, and can reduce a mixing rate of impurities in the tablet in a manufacturing process.

Owner:博凯药业有限公司

Novel filling device of capsule filling machine

PendingCN107714479ASolve problems such as cross contaminationAchieve sealingCapsule deliveryDomestic articlesEngineeringMechanical engineering

The invention discloses a novel filling device of a capsule filling machine. The novel filling device comprises a filling position and a tamping position which are arranged along the circumference, wherein filling rods adaptively arranged in the filling position and the tamping position and matched with metering holes of metering panels arranged at the bottom end of a drug powder cylinder, the drug powder cylinder is filled with drug powder, the lower ends of the metering panels are fixedly connected with a support, a lower module for storing capsules is arranged under the filling position, slide sheets are arranged movably on the lower end surfaces, located at the metering holes, of the metering panels and are mounted in slide sheet bases provided with slide rods which are in slide fit with a guide hole in the support, the slide rods are fixedly connected with a support frame which is linked with a movable guide rail plate, the movable guide rail plate is inked with an upper swing armconnected with the upper end of a swing shaft, the lower end of the swing shaft is connected with a lower swing arm, the lower swing arm is linked with a groove-shaped cam through a bearing, and thegroove-shaped cam is driven by a spindle. Powder leakage is avoided, so that the drug powder is metered precisely, and cross contamination of the drug powder can be avoided in work.

Owner:瑞安市意佳机械有限公司

A 3D printer leak-proof working cylinder

ActiveCN109049691BImprove acid resistanceEliminates finishing stepsManufacturing enclosuresAdditive manufacturing with solidsComputer printingStructural engineering

The invention provides a 3D printer leakproof working cylinder. The 3D printer leakproof working cylinder comprises a first cylinder wall, a second cylinder wall, a first side plate, a second side plate, positioning rods and a piston plate; a rectangular channel structure is jointly defined by the first cylinder wall, the second cylinder wall, the first side plate and the second side plate; the first cylinder wall and the second cylinder wall are cooperatively connected through grooves in the first side plate and the second side plate; the first side plate and the second side plate are fastened and connected through the positioning rods; the piston plate slides in the rectangular channel; and the first cylinder wall and the second cylinder wall are made of glass or resin. The problems that3D printer working cylinders are insufficient in strength, and sand is prone to leaking are solved, the 3D printer leakproof working cylinder is convenient to dismount, mount and maintain and has good application prospects, on the basis of superior performance than original metal cutting machining, the cost is greatly reduced, the corrosion resistance is significantly improved, the especially inapplication of a large-sized piston cylinder blocks, the flatness of a whole board cannot be ensured by metal cutting machining easily, and the 3D printer leakproof working cylinder can be widely popularized in similar application.

Owner:武汉阿尔法激光有限公司

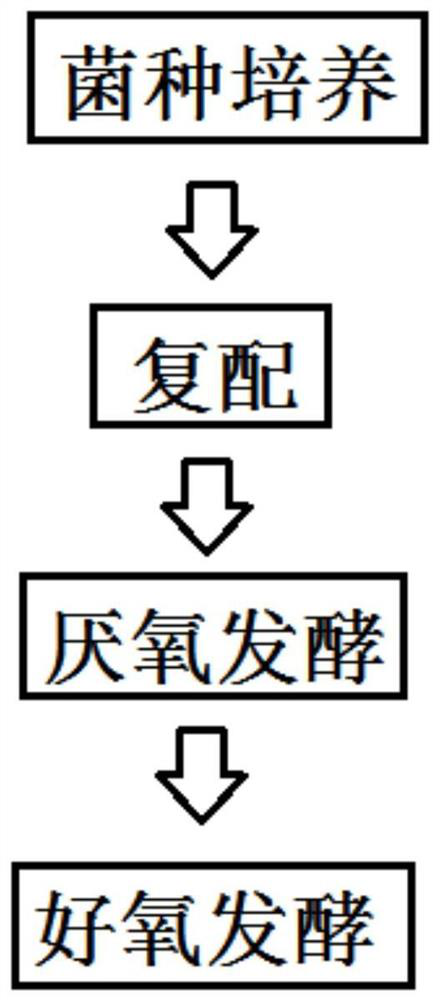

Compound fermentation strain formula, fermentation technology and compounding device

PendingCN111778189AQuick resultsAvoid wastingBio-organic fraction processingFungiBiotechnologyCandida tropicalis

The invention relates to a compound fermentation strain formula, a fermentation technology and a compounding device. A strain medium of a fermentation strain is a nicotine treatment solution, and thefermented strain is Geobacillus kaustophilus; and the compound fermentation strain formula includes candida tropicalis, geobacillus kaustophilus, aspergillus oryzae and lactobacillus. The organic fertilizer production method is fast in macromolecular material decomposition, high in fertilizer efficiency, small in nutrient loss and fast in effect taking, can form a large amount of water-soluble small molecule activated carbon and has the advantages of being lasting in fertilizer efficiency of organic fertilizer and fast in effect taking of chemical fertilizer.

Owner:曲靖凯美冠有机肥生产有限公司

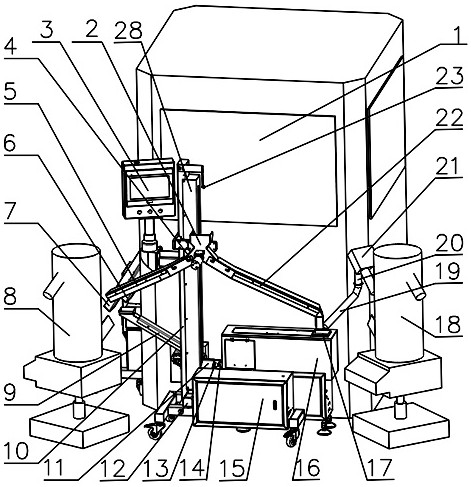

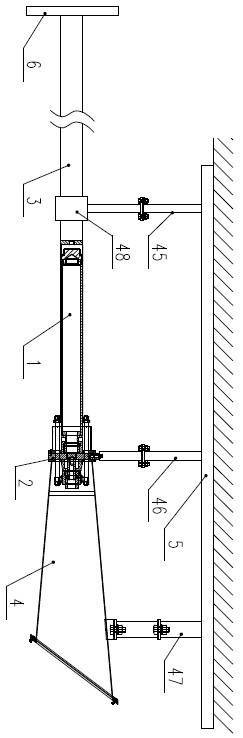

Backflow device for automatic sampling inspection

PendingCN113752618AReduce manufacturing costReduce labor costsSortingPressesControl engineeringControl theory

A backflow device for automatic sampling inspection comprises an elevator, a flow dividing mechanism and a detection device, wherein the elevator comprises a stand column, a lifting driving device installed on the stand column, a transmission mechanism and a transfer hopper, and a taking sliding groove and the flow dividing mechanism are arranged on the stand column; the flow dividing mechanism comprises an inclined slide way inlet, a switching driving device, a left sliding groove inclining towards the left lower portion and a right sliding groove inclining towards the right lower portion, the inclined slide way inlet communicates with the left sliding groove and the right sliding groove through the switching driving device, an outlet of the left sliding groove is in butt joint with an inlet of a subsequent left processing device, and an outlet of the right sliding groove is in butt joint with a feeding port of the detection device; when the transfer hopper is positioned at the bottom of the elevator, the inlet of the transfer hopper is butted with the taking sliding groove and a discharge port of the detection device; and when the transfer hopper is positioned at the top of the elevator, an outlet of the transfer hopper is butted with the inclined slideway inlet.

Owner:SHANDONG SETAQ INSTR

Flux-cored silver solder and preparation method thereof

ActiveCN104907727BEasy to assembleStop the flowWelding/cutting media/materialsSoldering mediaMetallurgyBrazing

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Laser printer selenium drum sealing strip

InactiveCN104062868APrecise positioningAvoid powder leakageElectrographic process apparatusNotchingLaser

The invention discloses a laser printer selenium drum sealing strip, which comprises a base plate, the sealing strip and a stretching strap, a stretching strap groove adaptable to the stretching strap are arranged on the base plate and the sealing strip, a bonding structure is provided between the base plate and the sealing strip, the stretching strap bonds between the base plate and the sealing strip, and a positioning gap is arranged on the base plate. The laser printer selenium drum sealing strip employed with the above structure, can accurately position while installing, can avoid powder leakage phenomenon generated by the selenium drum, and can simultaneously simplify the installation step for the installation operators.

Owner:保定莱盛办公设备有限公司

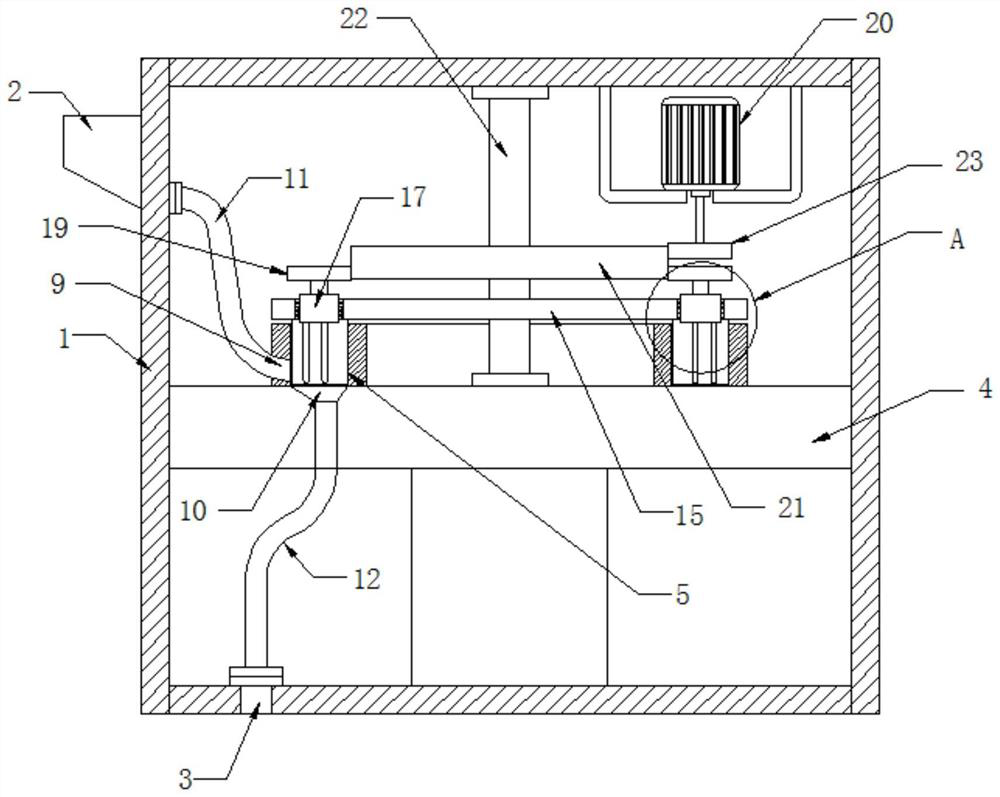

Special intelligent hard capsule polishing machine for laboratory

ActiveCN114505775AImprove adsorption capacityAvoid pokingPlastic recyclingGrinding machinesHard CapsuleEngineering

The intelligent hard capsule polishing machine special for the laboratory comprises a box body and a cleaning assembly arranged in the box body, a feeding port is formed in the top of the box body, a discharging port is formed in the bottom of the box body, the cleaning assembly is arranged between the feeding port and the discharging port, and the cleaning assembly communicates with the feeding port and the discharging port; the cleaning assembly comprises a supporting platform and a rotating assembly arranged above the supporting platform, the supporting platform is provided with a movement channel distributed in the circumferential direction, a cleaning rod extending towards the interior of the movement channel is arranged below the rotating assembly, and the cleaning head of the cleaning rod is sequentially wrapped with a sponge layer and a lint strip layer from inside to outside. Optionally, the moving channel is provided with a first port and a second port, the first port is communicated with the feeding port, the second port is communicated with the discharging port, and the axis of the first port and the axis of the second port intersect at the axis of the supporting platform. According to the capsule cleaning device, powder leakage, deformation and scratches of capsules can be prevented in the cleaning process, and meanwhile the cleaning quality can be improved.

Owner:HEFEI CAREER TECHNICAL COLLEGE

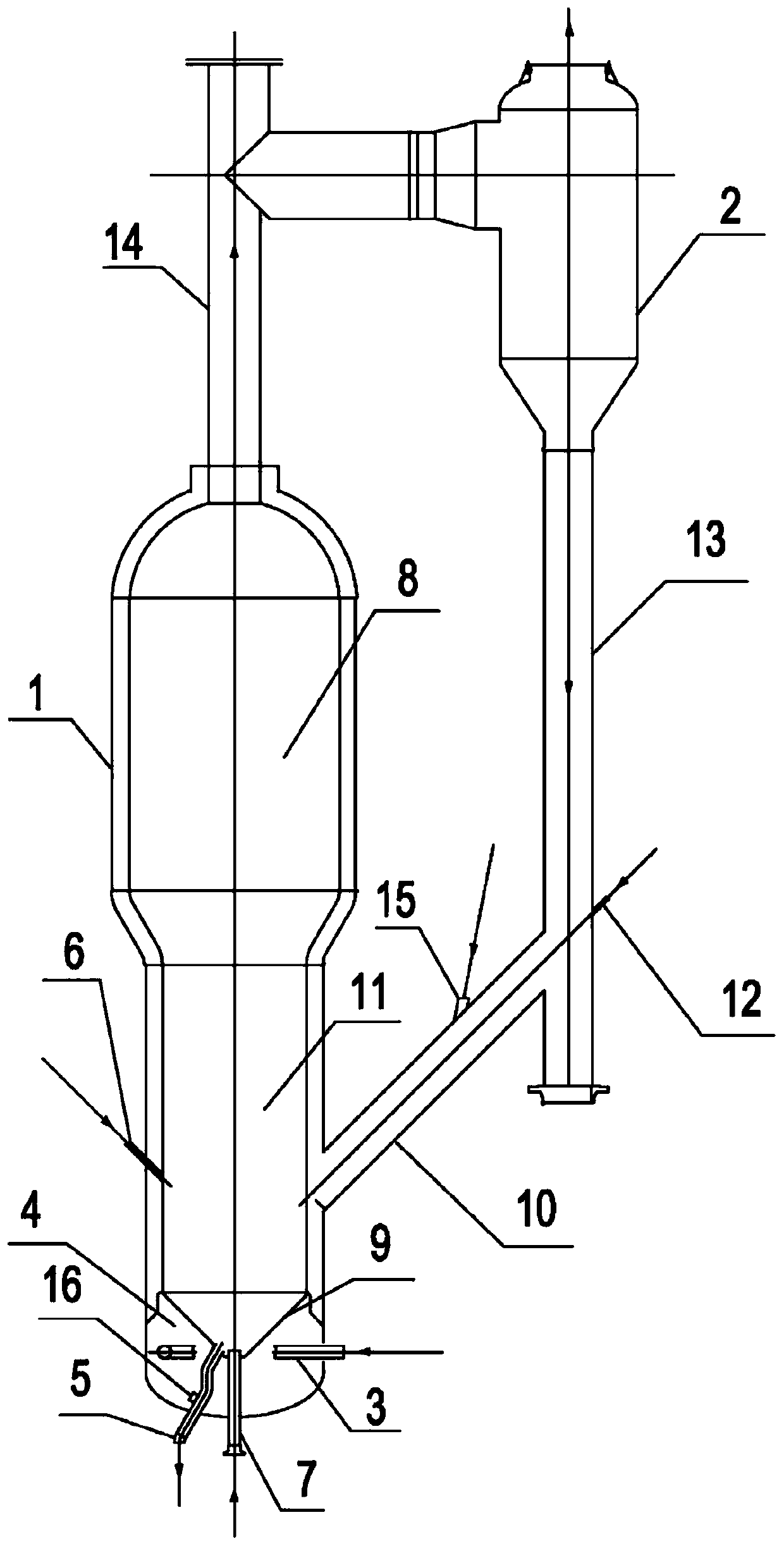

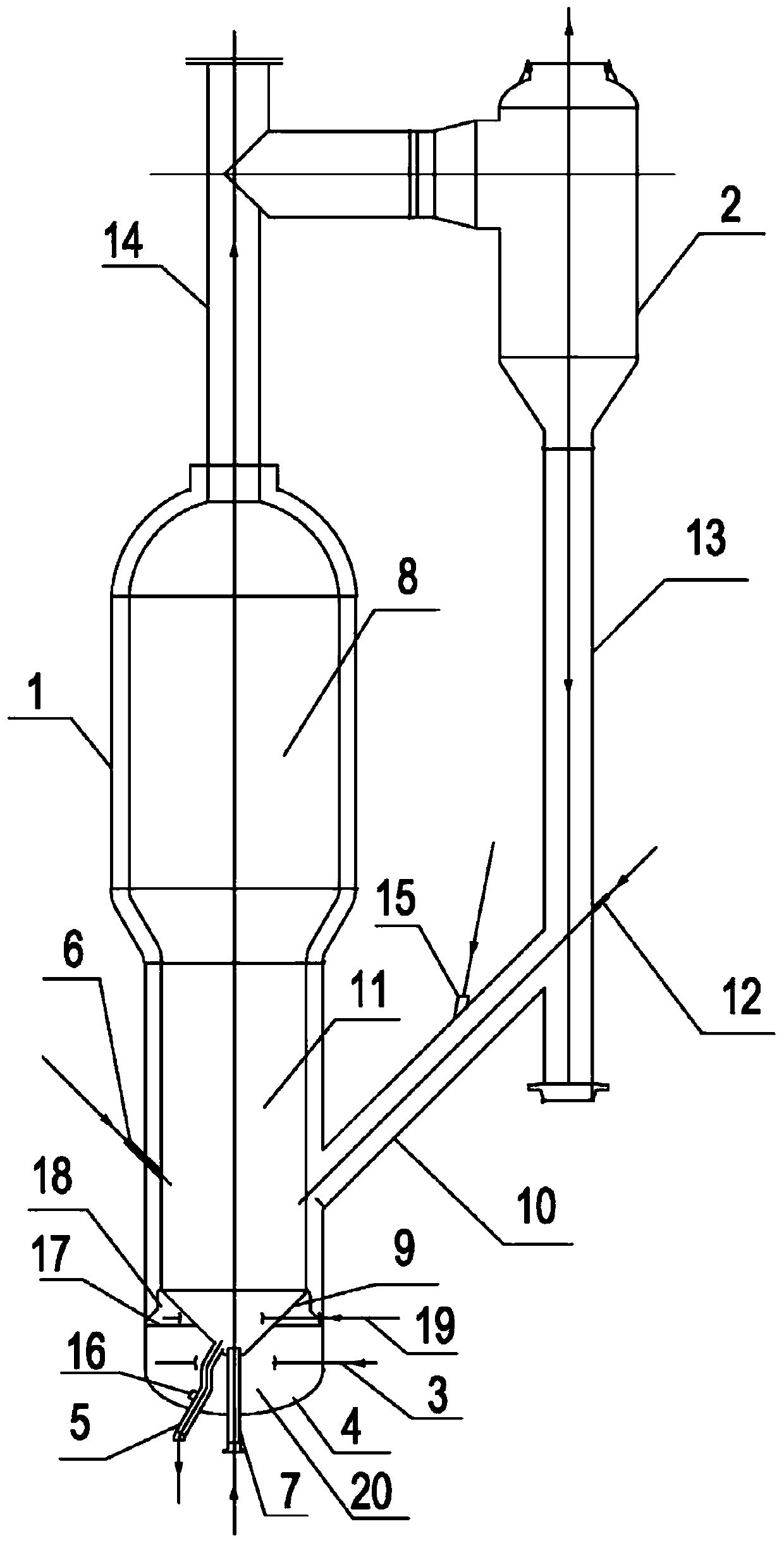

Fluidized bed reactor for gasifying inferior coal with high ash content and low activity

PendingCN110894428AExtended service lifeImprove adaptabilityGasification processes detailsGranular/pulverulent flues gasificationCombustionFluidized bed

The invention discloses a fluidized bed reactor for gasifying inferior coal with high ash content and low activity. The fluidized bed reactor comprises a reactor main body, which is internally provided with a gas distribution plate, wherein the gas distribution plate divides the reactor main body into a dense phase zone and a gas chamber, a gasifying agent jet pipe and a residue discharge pipe arealso arranged on the gas distribution plate, and a powder coal inlet is formed in one position of the dense phase zone. According to the invention, by independently arranging the gasifying agent jetpipe and the residue discharge pipe, the adaptability to high-ash coal is improved; and by arranging the residual carbon combustion burner for discharging residue and circulating coke powder, the carbon conversion rate of low-activity inferior coal is greatly improved, and the efficient gasification of low-activity inferior coal is realized.

Owner:上海浦名能源科技有限公司

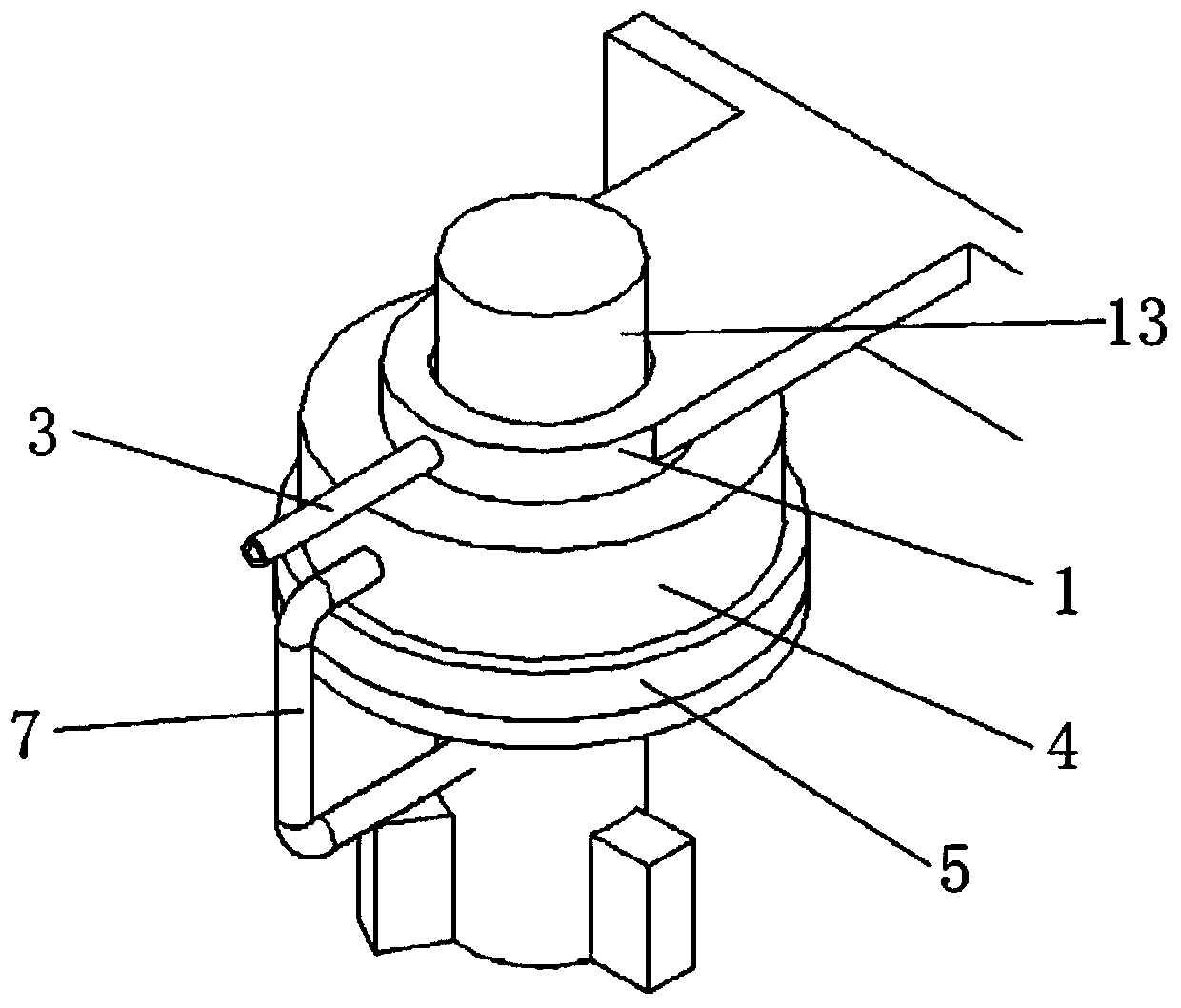

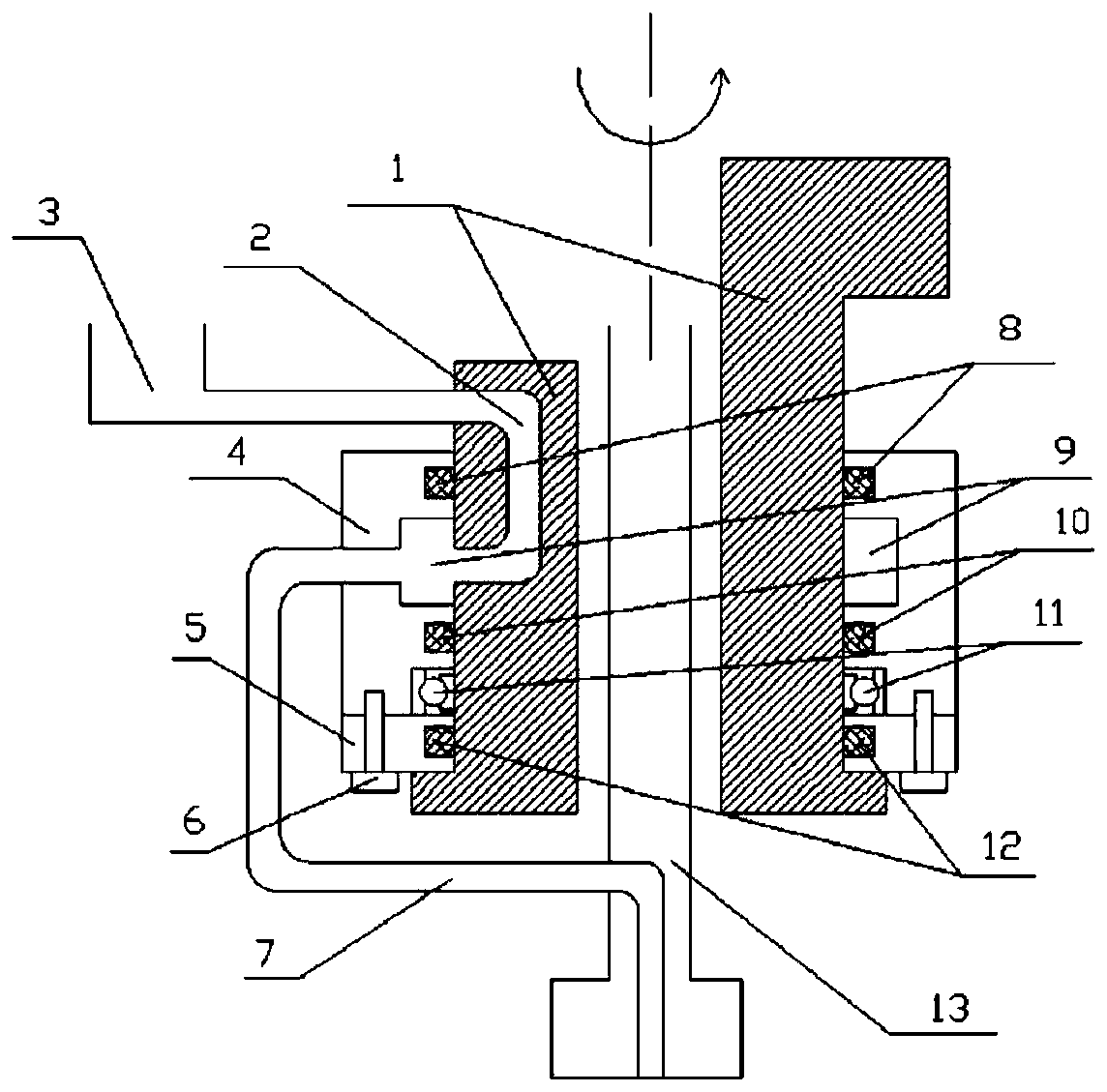

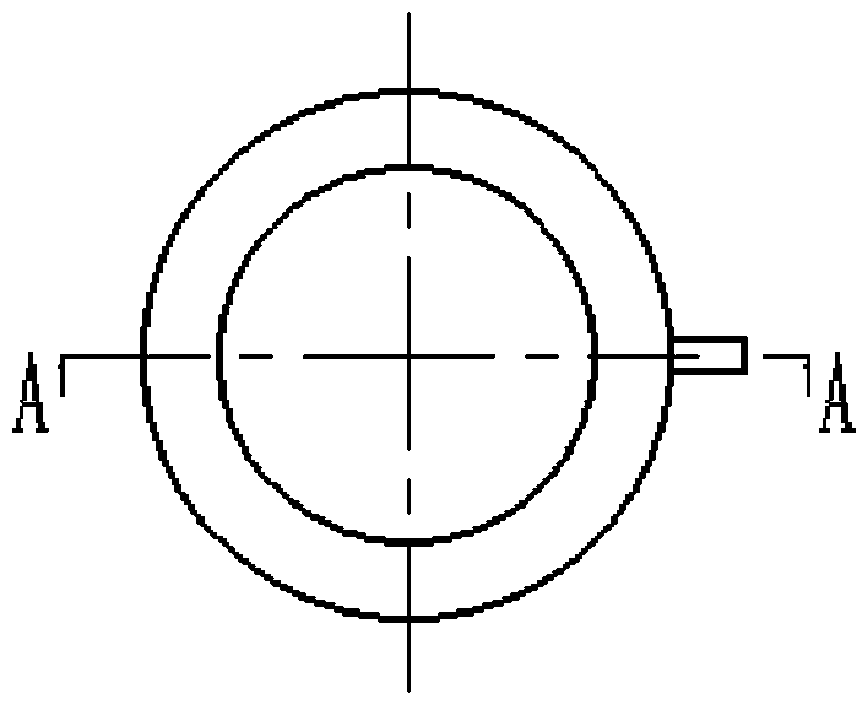

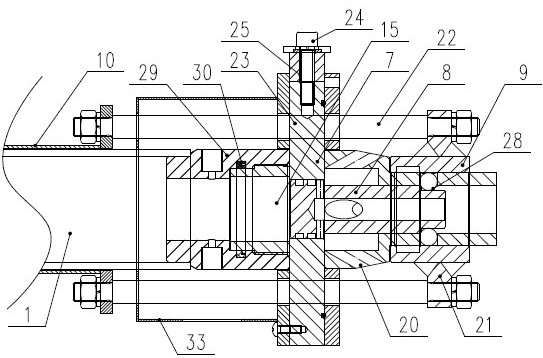

Sealed follow-up type powder conveying device

The invention discloses a sealed follow-up type powder conveying device. The device comprises a fixed inner cylinder, a rotating shell, a bearing and a follow-up air pipe, wherein a stirring hole is formed in the center of the fixed inner cylinder, and a stirring shaft penetrates through the stirring hole; the lower part of the fixed inner cylinder is matched with the inner ring of the bearing; the rotating shell is arranged outside the fixed inner cylinder, the upper part of the inner wall of the rotating shell is matched with the outer wall of the fixed inner cylinder, and the lower part ofthe inner wall of the rotating shell is matched with the outer ring of the bearing; a powder gas channel is formed in the fixed inner cylinder, the inlet of the powder gas channel communicates with the inlet of a peripheral desulfurizing agent powder supplying pipeline; a powder bin is arranged on the inner wall of the rotating shell, and the outlet of the powder gas channel communicates with thepowder bin; and the powder bin communicates with the follow-up air pipe, the inlet of the follow-up air pipe penetrates through the rotating shell, the follow-up air pipe is radially inserted into thestirring shaft, and the outlet of the follow-up air pipe communicates with the outside. The device has the beneficial effects that desulfurizing agent powder and molten steel can be fully contacted and uniformly mixed under the stirring effect of the stirring shaft, and safety and reliability are achieved.

Owner:武汉钢铁有限公司

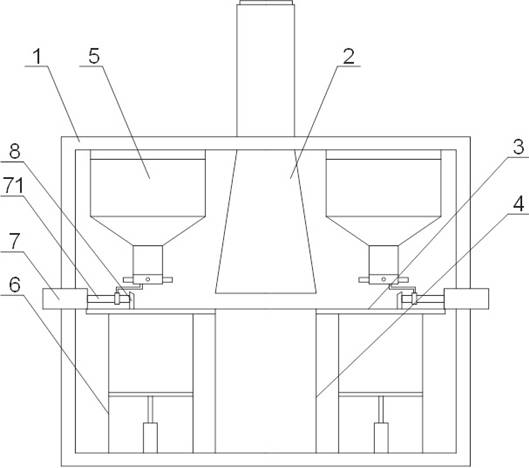

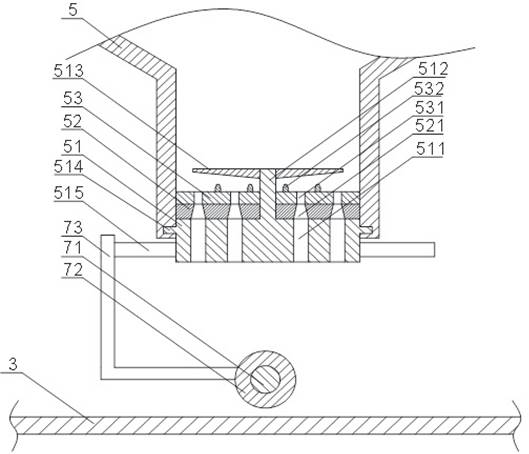

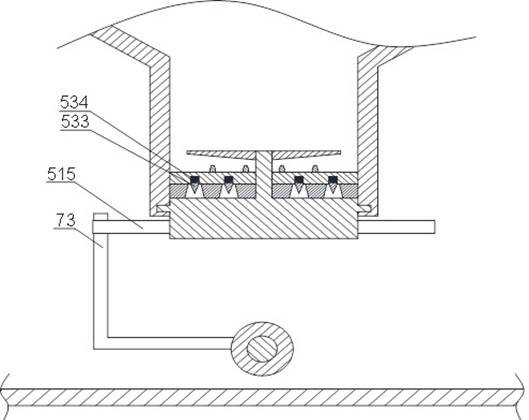

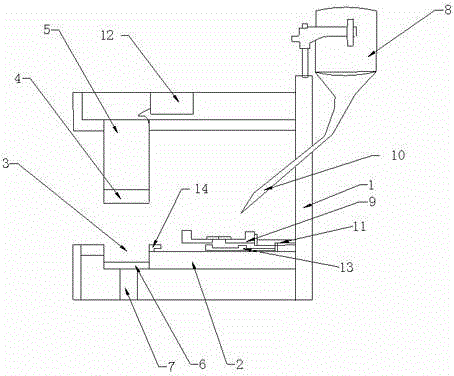

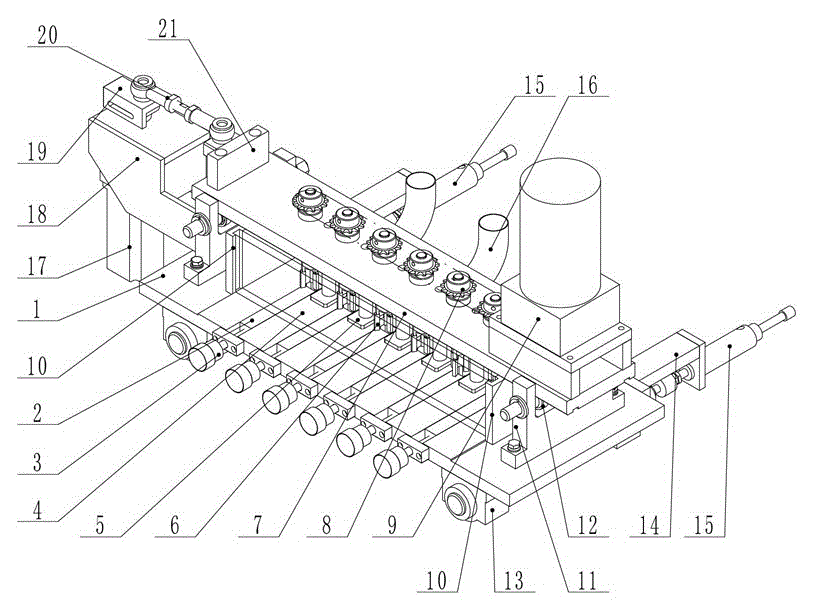

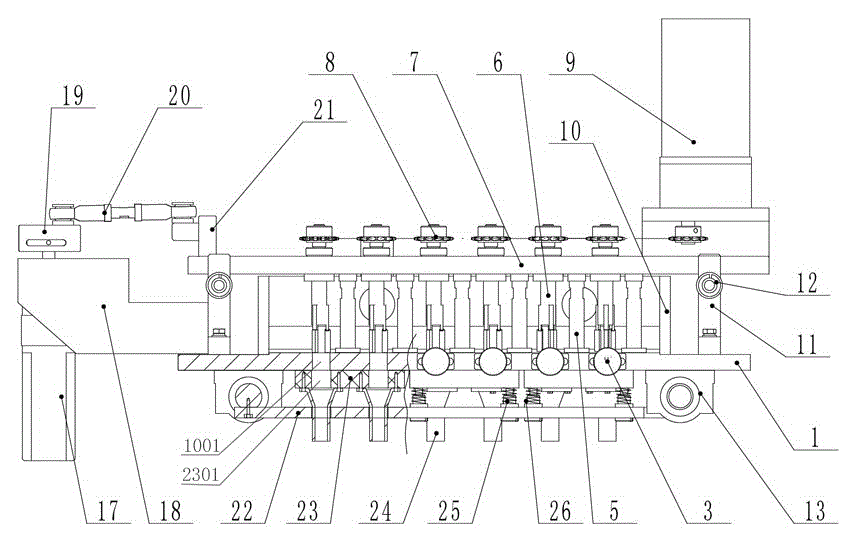

Special feeding device for dry suspension

ActiveCN103662131BMeet the requirements of precise meteringAvoid powder leakageSolid materialEngineeringMicromotor

The invention relates to a feeding device special for dry suspensions. The feeding device special for the dry suspensions is characterized in that a box body is composed of a metering plate with a metering tank, a left vertical plate, a right vertical plate, a rear vertical plate and a transparent front baffle, wherein supports with track idler wheels are installed at the left end and the right end of the upper surface of the metering plate respectively, an upper movable plate is supported on the top of the box body through the track idler wheels, a plurality of rotary shifting forks and a plurality of material blocking blocks are installed on the upper movable plate, and are inserted into the box body, the rotary shifting forks are connected with a micromotor through a chain drive mechanism, one end of the upper movable plate is connected with an output shaft of a servo motor through a left-and-right transmission mechanism, sliding unit bases are installed at the left end and the right end of the lower surface of the metering plate respectively, sliding rods are arranged in the sliding unit bases respectively, a lower movable plate is fixedly connected between the two sliding rods, feeding valves are arranged above the lower movable plate, and are connected with the lower movable plate through feeding hoppers, the upper surfaces of the feeding valves are closely attached to the lower surface of the metering plate, feeding ports are formed in the feeding valves, the feeding hoppers are communicated with the metering tank through the feeding ports, and the other ends of the sliding rods are connected with air cylinders. The feeding device special for the dry suspensions has the advantages of being accurate in feeding metering and free of powder leakage.

Owner:JINZHOU IDEAL PACKAGING MACHINERY

Deoxidizing agent packaging film and preparation method thereof

PendingCN111923550AStay in shapeGuarantee product qualityFlexible coversWrappersPaper sheetComposite material

The invention discloses a deoxidizing agent packaging film and a preparation method thereof. The deoxidizing agent packaging film comprises oil-resistant waterproof paper, and the two opposite sides of the oil-resistant waterproof paper are coated with a layer of perforated PE film and a layer of perforated PET film respectively. The thickness of the perforated PE film is 25-50 [mu] m, and the thickness of the perforated PET film is 10-15 [mu] m. The perforated holes in the step 2 and the step 3 do not break through the oil-resistant waterproof paper so that the powder leakage phenomenon of the deoxidizing agent package is avoided, the package can be in direct contact with inclusions, and no dust leaks out. Meanwhile, the oil-resistant waterproof paper can prevent moisture and oil in the inclusions from eroding the deoxidizing agent, and potential safety hazards and hazards such as inclusion pollution caused by leakage of the deoxidizing agent are avoided. The deoxidizing agent packaging film is simple in preparation process and structure, convenient to use, good in transparency and particularly suitable for deoxidizing agent packaging containing indication marks.

Owner:KAIDA GRP CO LTD FJ

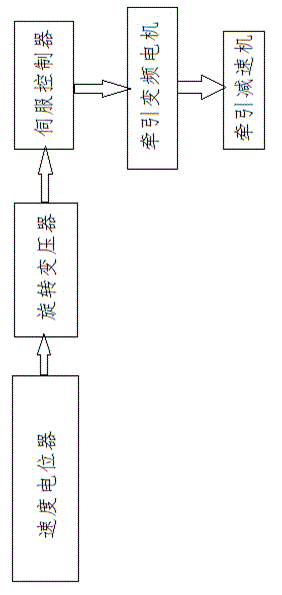

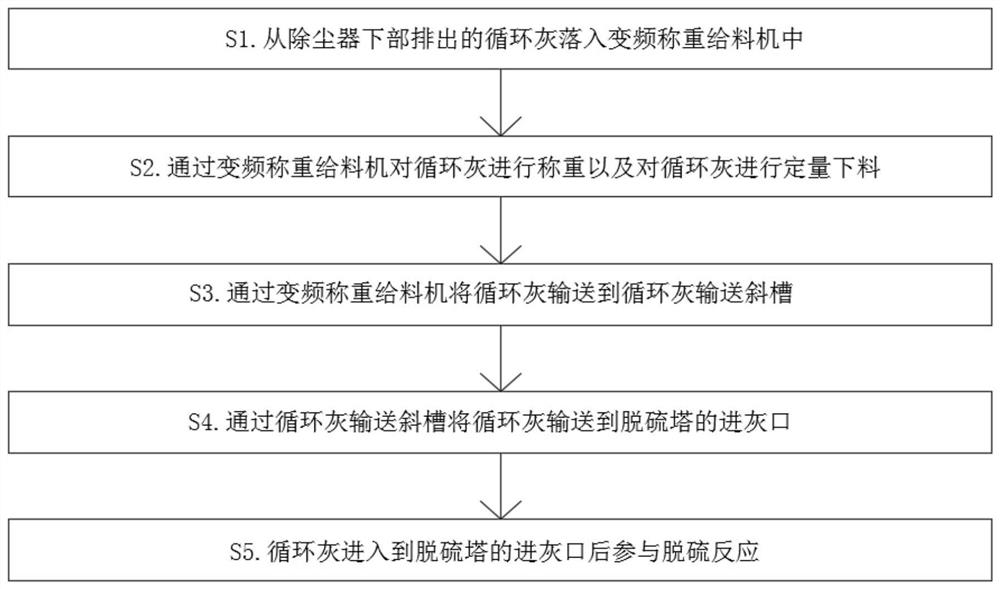

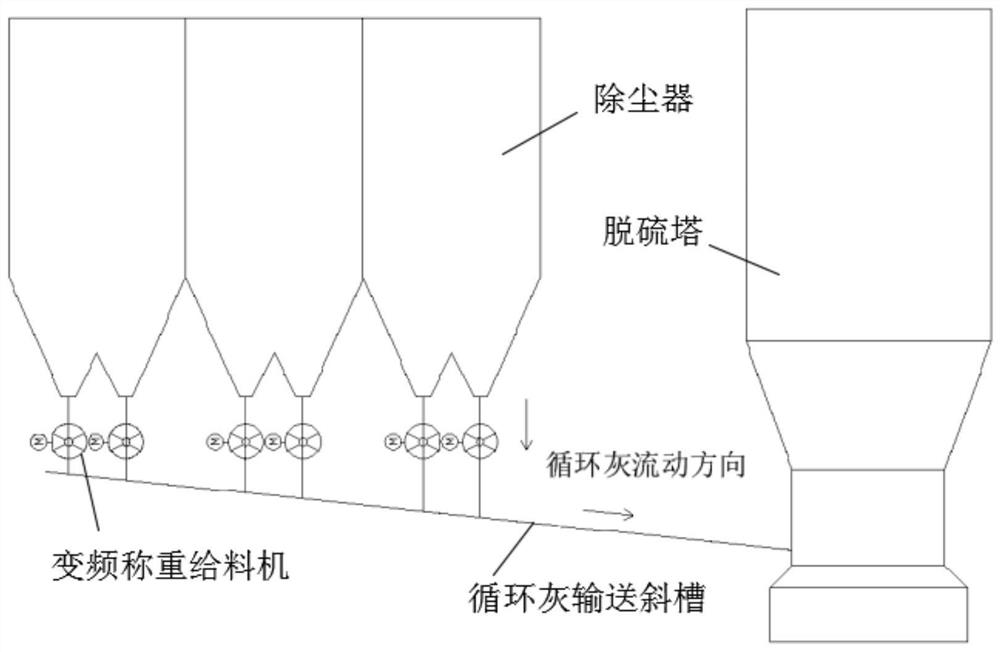

Process for returning circulating ash to tower during semi-dry desulfurization of electrolytic flue gas

PendingCN113230872AAvoid energy consumptionAvoid powder leakageGas treatmentDispersed particle filtrationElectrolysisFlue gas

The invention discloses a process for returning circulating ash to a tower during semi-dry desulfurization of electrolytic flue gas. The process comprises the steps that: S1, the circulating ash discharged from the lower part of a dust remover falls into a variable-frequency weighing feeder; S2, the circulating ash is weighed through a frequency conversion weighing feeder, and quantitative discharging is conducted on the circulating ash; S3, the circulating ash is conveyed to a circulating ash conveying chute through the variable-frequency weighing feeder; S4, circulating ash is conveyed to an ash inlet of the desulfurization tower through a circulating ash conveying chute; and S5, circulating ash enters the ash inlet of the desulfurization tower and then participates in desulfurization reaction. According to the invention, the overall position of the dust remover is lifted, and the circulating ash is directly conveyed to the ash inlet of the desulfurizing tower through the circulating ash conveying chute under the action of gravity, so that the problems of high energy consumption, powder leakage, material blockage, hardening and the like caused by long-distance conveying are avoided, the system is simpler and more integrated, and the investment and operation cost is saved.

Owner:北京铝能清新环境技术有限公司

Storage device, thermal insulation material for storage device and bundling and sealing method of thermal insulation material

PendingCN111816223AAffects protectionGuaranteed stability and securityReducing temperature influence on carrierSynthetic resin layered productsInsulation layerThermal insulation

The invention discloses a memory, a thermal insulation material for the memory and a bundling and sealing method of the thermal insulation material, and belongs to the technical field of memories. Thethermal insulation material comprises a thermal insulation layer, the thermal insulation layer is coated with a barrier layer, and the barrier layer is formed by thermal shrinkage of a thermal shrinkage film. The thermal insulation material for the memory is arranged among the memory, the storage medium and the protective shell. According to the bundle sealing method for the thermal insulation material for the memory, the thermal insulation layer is put into a thermal shrinkage bag with the thickness of 10-25 microns and sealed, and a full-automatic thermal shrinkage film packaging machine isused for carrying out thermal shrinkage packaging on the thermal insulation layer so as to coat the surface of the thermal insulation layer with a barrier layer. The defect that a heat insulation material is prone to breakage and powder leakage is overcome, the heat insulation material for the storage is provided, the blocking layer can effectively separate the heat insulation layer from the outside, and the powder leakage phenomenon caused by vibration of the heat insulation layer is avoided. The memory provided by the invention has good safety stability and protection performance. Accordingto the heat insulation material bundle sealing method, heat insulation material bundle sealing can be quickly achieved, and the operation process is easy and convenient to control.

Owner:JIANGSU DU WAN ELECTRONICS TECH CO LTD

Printer toner cartridge

PendingCN113093495AEasy to concentrate powderImprove powder output efficiencyElectrographic process apparatusComputer printingMechanical engineering

The invention discloses a printer toner cartridge which comprises a toner cartridge main body, wherein two ends of the toner cartridge main body are respectively a toner feeding part and a toner discharging part; an end cover which is of a hollow structure and is rotationally connected to a toner discharging part end; a powder stirring bin which is provided with a funnel bin body, wherein a toner outlet is formed in the bottom of the funnel bin body; an outer cover which is clamped on the powder stirring bin and covers the powder stirring bin and a clamping part; and a powder stirring group which comprises a stirring blade and a scraping blade, the stirring blade is rotatably arranged in the toner cartridge main body, and when the stirring blade drives the scraping blade to perform sweeping action in the funnel bin body, the toner is beat out from the toner outlet. A new toner discharging mode is achieved, continuous and uninterrupted toner supply is achieved, the toner supply efficiency is improved, smooth toner feeding is kept, interruption is avoided, and the efficiency and the printing quality are greatly improved; the communication end of the outer side of a toner outlet seat outside the powder stirring bin is redesigned to be a multi-stage climbing small step, and an arc-shaped rib is formed at the highest position of the step, so that the arc-shaped rib is in butt joint with an image developing device in a tighter matching position, and the phenomenon of powder leakage is prevented.

Owner:中山万拓电子有限公司

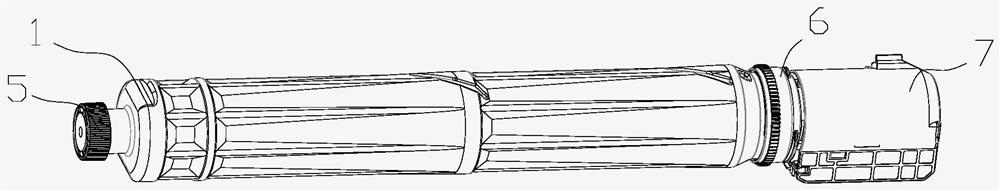

Coal mine flame-retardant and explosion-proof device

ActiveCN112761710AEvenly distributedFast releaseDust removalFire preventionMining engineeringMechanical engineering

The invention relates to the technical field of coal mine flame-retardant devices, in particular to a coal mine flame-retardant explosion-proof device. The coal mine flame-retardant explosion-proof device comprises a high-pressure gun, a trigger device, a trigger rod and an spraying device, the high-pressure gun is arranged on one side of the trigger device, the spraying device is arranged on the other side of the trigger device, the explosive-proof device is installed at the top in a coal mine tunnel through a hanging device, fire extinguishing powder is arranged in the spraying device, the trigger rod is installed at the top in the coal mine tunnel through the hanging device, a trigger plate is arranged at one end of the trigger rod, and the other end of the trigger rod is installed on the trigger device. According to the device, the high-pressure gun is arranged outside the spraying device, more fire extinguishing powder can be stored in the spraying device, and compared with the prior art, no cavity is generated in the center when the fire extinguishing powder is sprayed out, so that the fire extinguishing powder is uniformly distributed in a tunnel, the high-pressure gun does not occupy the space in the spraying device, sealing of the fire extinguishing powder is facilitated, powder leakage or damp is prevented, and regular replacement of the fire extinguishing powder is facilitated.

Owner:山东宸兴重工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com