Fluidized bed reactor for gasifying inferior coal with high ash content and low activity

A fluidized bed reactor and reactor technology are applied in the field of fluidized bed gasification, and can solve problems affecting the long-cycle stable operation time of the fluidized bed reactor, corrosion and wear of slag discharge pipes, jet pipe classifiers, fluidized bed The reactor theory is complex and other problems, to achieve the effect of improving the secondary agglomeration rate and the conversion rate of raw coal, shortening the manufacturing cycle, and wide adaptability of coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

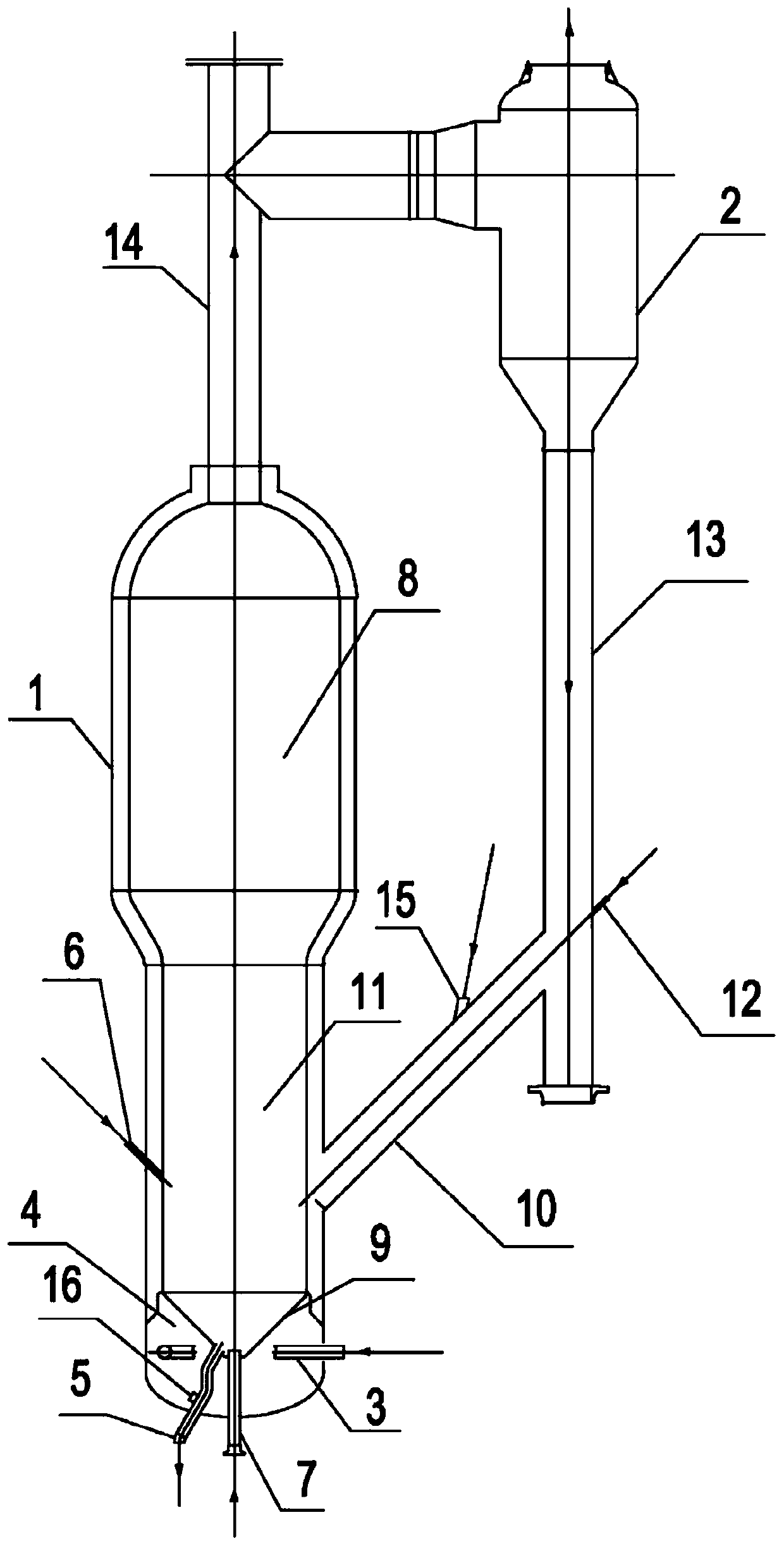

[0041] like figure 1 As shown, the fluidized bed reactor used in this embodiment to gasify high-ash, low-activity low-quality coal includes: a reactor main body 1, a gas distribution plate 9 is arranged inside the reactor main body 1, and the gas distribution plate 9 Divide the reactor main body 1 into two parts: a dense-phase area 11 and a gas chamber 4; wherein, the gasification agent jet pipe 7 and a slag discharge pipe 5 are also provided on the gas distribution plate 9; the dense-phase area 11 One of the positions is provided with pulverized coal inlet 6.

[0042] In this embodiment, a suitable position of the dense phase zone 11 is selected to be provided with a pulverized coal inlet 6 (such as figure 1 shown). According to the amount of coal input, preferably, 2 to 3 pulverized coal inlets 6 can be provided. Among them, the pulverized coal can enter the dense phase zone 11 through the pulverized coal inlet 6 by using a pneumatic conveying device.

[0043] Wherein, t...

Embodiment 2

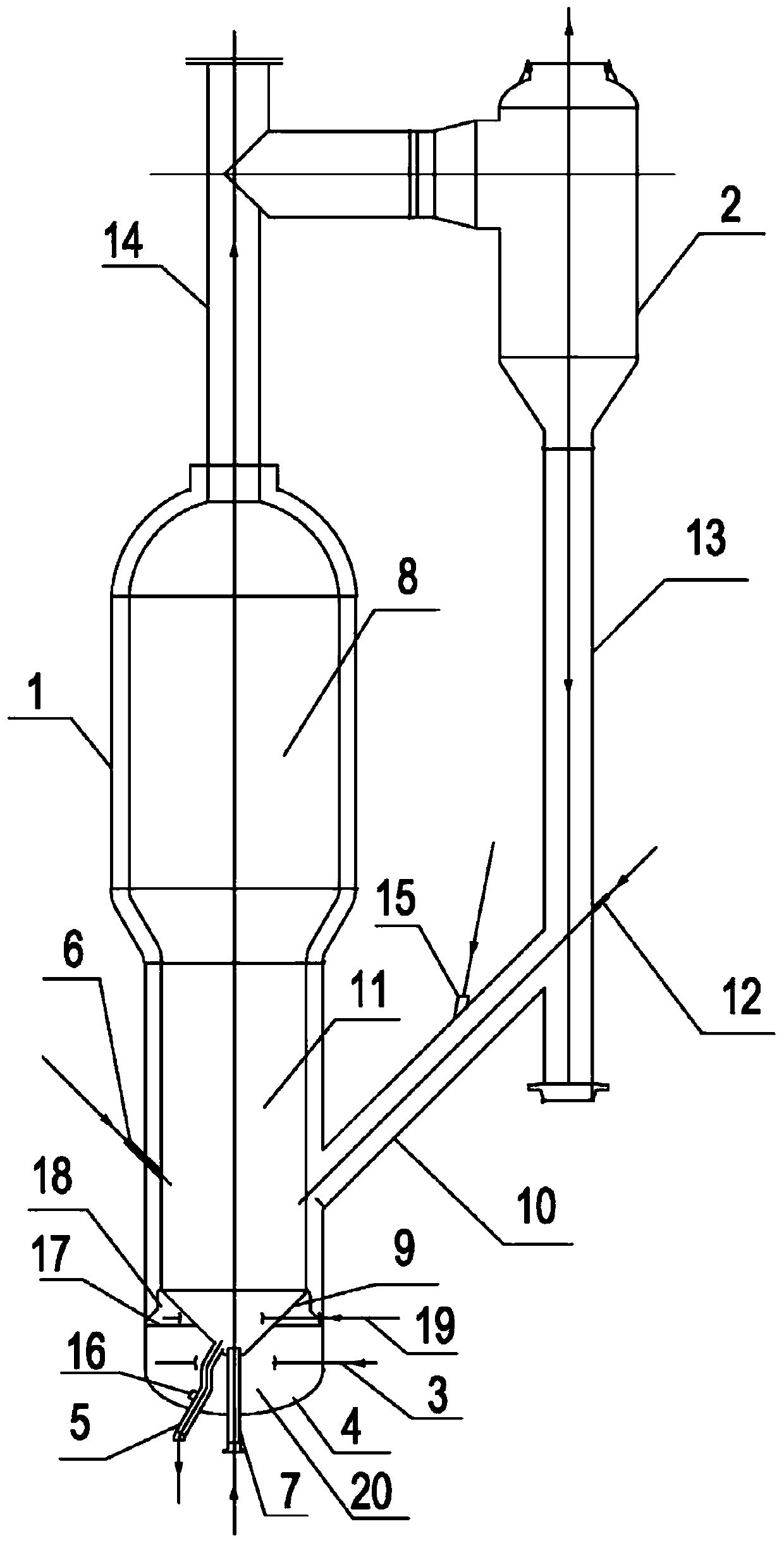

[0059] The difference between this embodiment and Embodiment 1 is that in this embodiment, N partition plates 17 are arranged in the air chamber 4, wherein, N≥1, and the air chamber 4 is surrounded by the partition plates 17 is divided into N+1 sub-air chambers.

[0060] In this embodiment, N=1 is used for further explanation, and those skilled in the art can understand the specific implementation manner of N>1 on the basis of this embodiment.

[0061] like figure 2 As shown, the air chamber 4 is provided with a partition plate 17 , and the air chamber 4 is divided into a first sub-air chamber 20 and a second sub-air chamber 18 by the partition plate 17 . The fluidized bed reactor in this embodiment is provided with two sub-gas chambers according to the up-and-down arrangement. By adjusting the gasification agent flow rate and oxygen concentration in different sub-gas chambers, the strong back-mixing of coal char particles in the upper area of the distribution plate is rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com