Novel filling device of capsule filling machine

A filling device and capsule technology, which is applied in capsule delivery, drug delivery, household components, etc., can solve problems such as contamination between drugs and increased frictional resistance of drug powder, and achieve the effects of avoiding powder leakage, accurate measurement, and solving cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The above-mentioned and other technical features and advantages of the present invention are clearly and completely described below in conjunction with the embodiments given in the accompanying drawings.

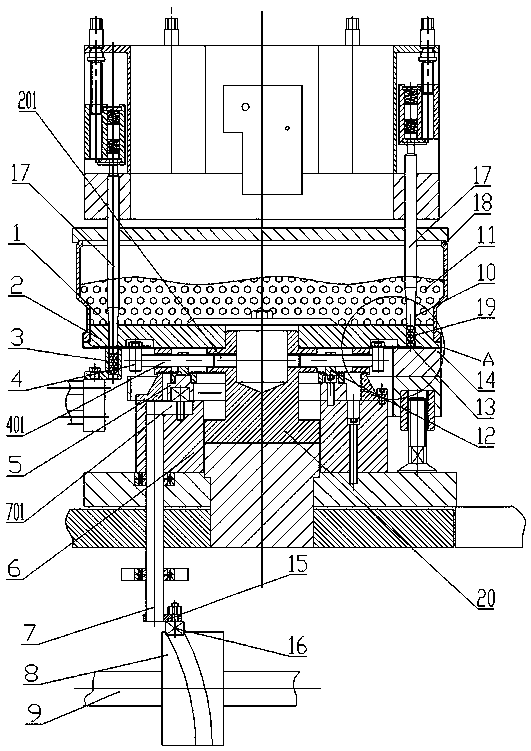

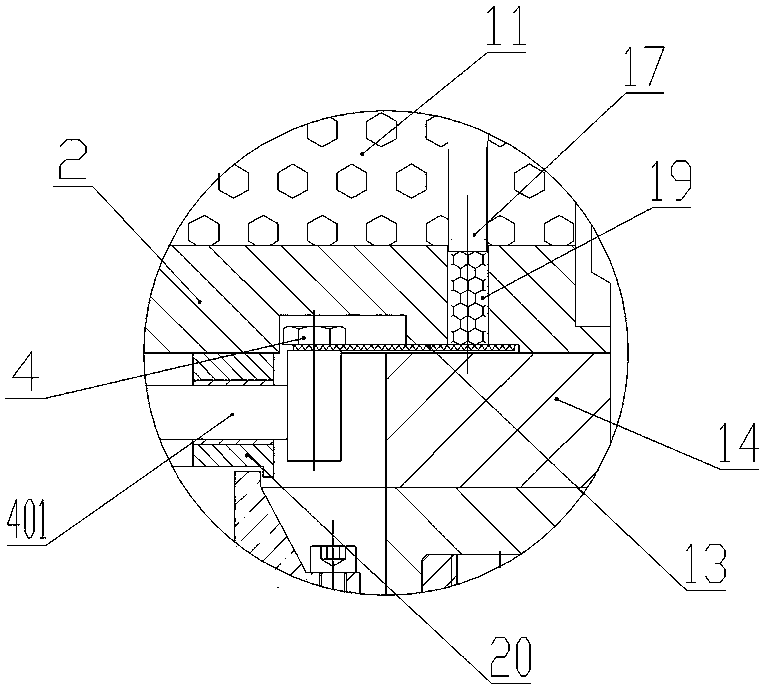

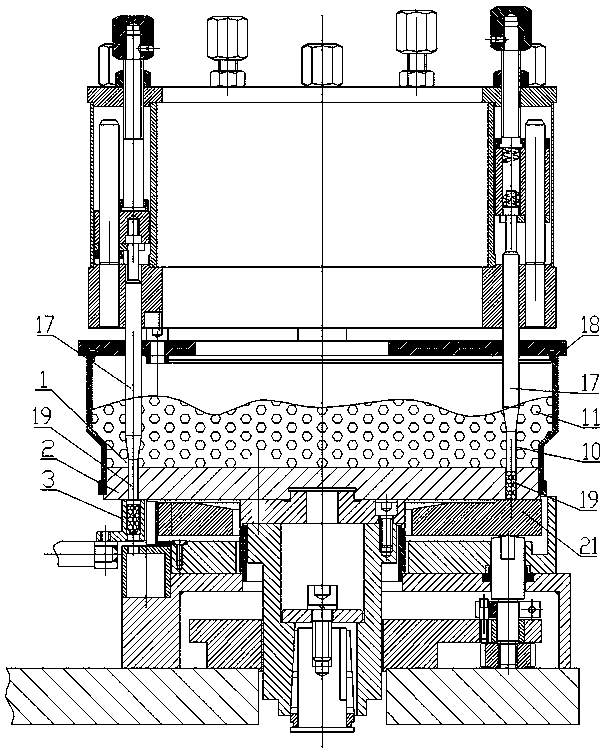

[0014] refer to figure 1 with figure 2 As shown, a new type of capsule filling machine filling device includes a filling station 1 and a compacting station 10 arranged along the circumference. Both the filling station 1 and the compacting station 10 are equipped with a filling rod 17. The metering hole 19 of 2 is adapted, the metering disc 2 is set at the bottom of the powder cartridge 18, the powder cartridge 18 is filled with the powder 11, the lower end of the metering disc 2 is fixedly connected with the support body 20, and the filling station 1 is directly below the filling station. In the lower module 3, the lower end surface of the metering disc 2 located at the metering hole 19 is movable with a slide 13, and the slide 13 is installed on the slide seat 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com