Process for returning circulating ash to tower during semi-dry desulfurization of electrolytic flue gas

A semi-dry desulfurization and ash recycling technology, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of long conveying process, powder leakage, high energy consumption, etc., save investment and operating costs, and avoid high energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

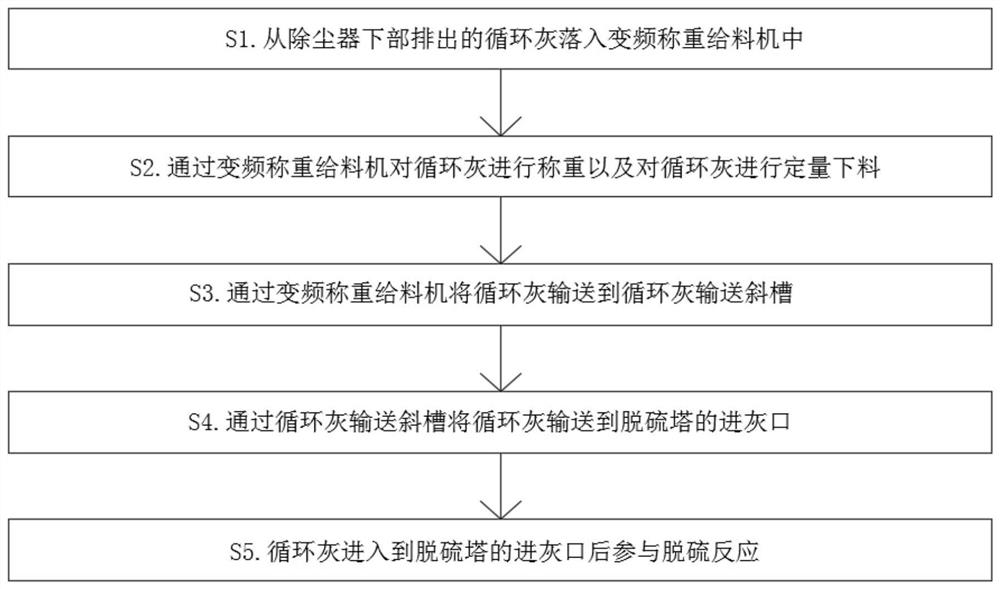

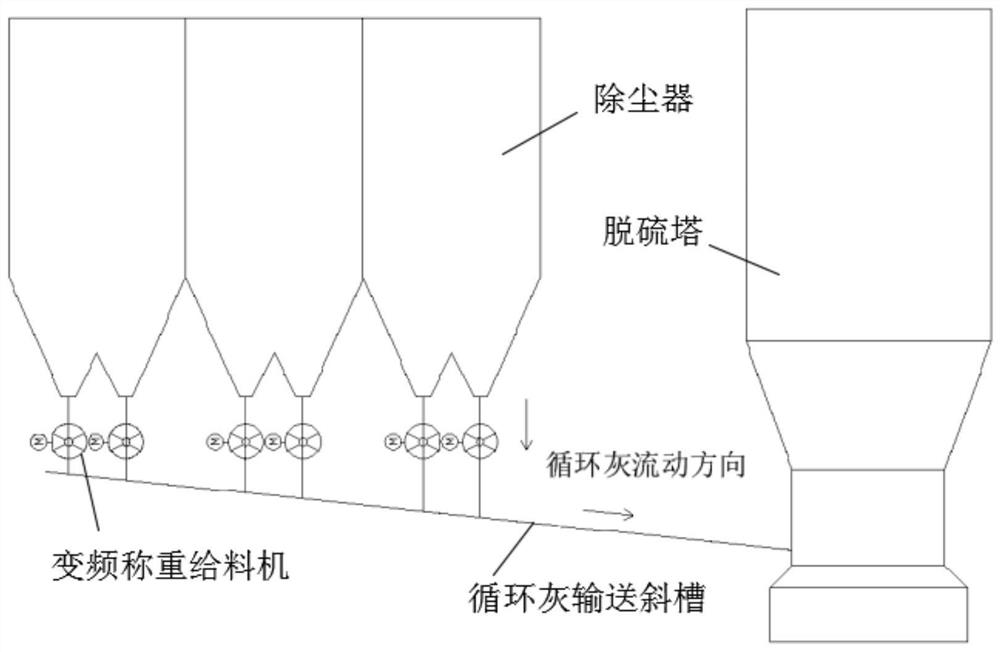

[0023] see figure 1 As shown, the present invention provides an electrolytic flue gas semi-dry desulfurization cycle ash return tower process, comprising the following steps:

[0024] S1. The circulating ash discharged from the lower part of the dust collector falls into the variable frequency weighing feeder;

[0025] S2. Weigh the circulating ash and quantitatively unload the circulating ash through the frequency conversion weighing feeder;

[0026] S3. The circulating ash is transported to the circulating ash conveying chute through the variable frequency weighing feeder;

[0027] S4. The circulating ash is conveyed to the ash inlet of the desulfurization tower through the circulating ash conveying chute;

[0028] S5. The circulating ash enters the ash inlet of the desulfurization tower and participates in the desulfurization reaction.

[0029] In this embodiment, preferably, the dust collector in S1 is a bag filter.

[0030] In this embodiment, preferably, there are se...

Embodiment 2

[0035] see figure 1 As shown, the present invention provides an electrolytic flue gas semi-dry desulfurization cycle ash return tower process, comprising the following steps:

[0036] S1. The circulating ash discharged from the lower part of the dust collector falls into the variable frequency weighing feeder;

[0037] S2. Weigh the circulating ash and quantitatively unload the circulating ash through the frequency conversion weighing feeder;

[0038] S3. The circulating ash is transported to the circulating ash conveying chute through the variable frequency weighing feeder;

[0039] S4. The circulating ash is conveyed to the ash inlet of the desulfurization tower through the circulating ash conveying chute;

[0040] S5. The circulating ash enters the ash inlet of the desulfurization tower and participates in the desulfurization reaction.

[0041] In this embodiment, preferably, the desulfurization reaction in S5 adopts semi-dry desulfurization, and the process of semi-dry ...

Embodiment 3

[0044] see figure 1 As shown, the present invention provides an electrolytic flue gas semi-dry desulfurization cycle ash return tower process, comprising the following steps:

[0045] S1. The circulating ash discharged from the lower part of the dust collector falls into the variable frequency weighing feeder;

[0046] S2. Weigh the circulating ash and quantitatively unload the circulating ash through the frequency conversion weighing feeder;

[0047] S3. The circulating ash is transported to the circulating ash conveying chute through the variable frequency weighing feeder;

[0048] S4. The circulating ash is conveyed to the ash inlet of the desulfurization tower through the circulating ash conveying chute;

[0049] S5. The circulating ash enters the ash inlet of the desulfurization tower and participates in the desulfurization reaction.

[0050] In this embodiment, preferably, the dust collector in S1 is a bag filter.

[0051] In this embodiment, preferably, there are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com