A plane servo punching machine for wrapping paper roll film

A plane and paper roll technology, applied in the field of packaging paper roll film plane servo piercing machine, to achieve the effect of saving personnel, maximizing production, increasing stability, and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically described below in conjunction with the accompanying drawings. The following examples are further illustrations of the present invention, but do not constitute a limitation of the present invention.

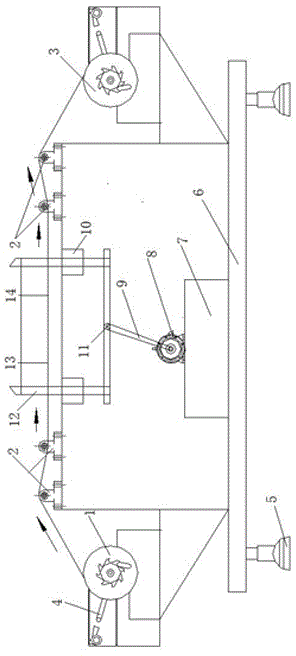

[0015] Such as figure 1 As shown, a plane servo piercing machine for wrapping paper film includes: constant tension unwinding mechanism 1, paper film guide shaft 2, servo constant speed rewinding mechanism 3, tension spring 4, support seat 5, mounting plate 6, Drive box 7, driving wheel 8, connecting rod 9, electrostatic absorption device 10, movable hinge 11, needle plate installation box 12, needle upper mold 13, needle plate lower mold 14, and the described support base 5 is fixed on the ground, A mounting plate 6 is fixed on the support base 5, a constant tension unwinding mechanism 1 is installed on one side of the mounting plate 6, a servo constant speed rewinding mechanism 3 is installed on the other side of the mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com