Compound fermentation strain formula, fermentation technology and compounding device

A technology of composite fermentation and fermented strains, which is applied in the direction of bacteria, fungi, and microbial-based methods, can solve the problems of easy leakage of powder, difficulty in completion, and errors, so as to keep the production environment clean, avoid material waste, Avoid the effect of easy powder leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

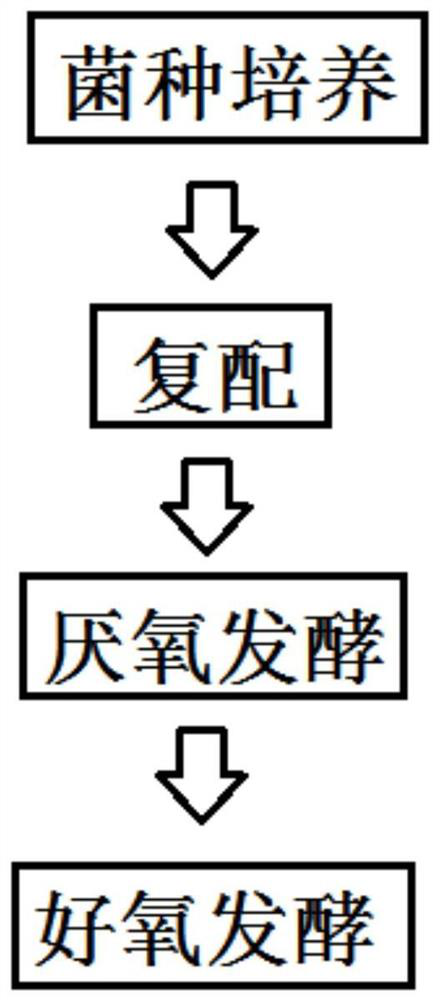

[0027] The invention relates to a fermented strain. The culture medium of the fermented strain in the present invention is nicotine treatment solution, and the fermented strain is Thermophilic Bacillus Geobacillus kaustophilus.

[0028] Further, the compound fermentation strain formula of the present invention includes Candida tropicalis, Bacillus thermophiles, Aspergillus oryzae, and Lactobacillus.

[0029] Further, the compound fermentation strain formula of the present invention also includes cellulose flora and humic acid flora.

[0030] Further, the component parameters of the composite fermentation strain formula of the present invention are, by weight: 0.5-1 part of Saccharomyces cerevisiae, 0.5-1.5 parts of Candida tropicalis, 1.5-2 parts of thermophilic bacillus, 2-4 parts of cellulose flora, 2.5-3.5 parts of humic acid flora, 1-2 parts of Aspergillus oryzae, 0.5-1 part of lactobacillus.

[0031] Further, the component parameters of the compound fermentation strain f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com