Flux-cored silver solder and preparation method thereof

A technology of silver solder and silver-based solder, used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problem that the solder cannot normally wet the welding base material, affect the quality of the flux core solder, and the forming process is complicated. problems, to achieve the effect of reducing labor intensity and environmental pollution, low cost and good craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of flux-cored silver solder of the present invention comprises the following steps:

[0028] In the first step, carry out the smelting of the silver-based solder ingot according to the conventional method, and prepare a strip-shaped solder;

[0029] The second step is to roughen the inner surface of the strip-shaped solder. The specific method can be sandblasting, mechanical friction or directly processed into an uneven surface with grooves to avoid flux flow during processing;

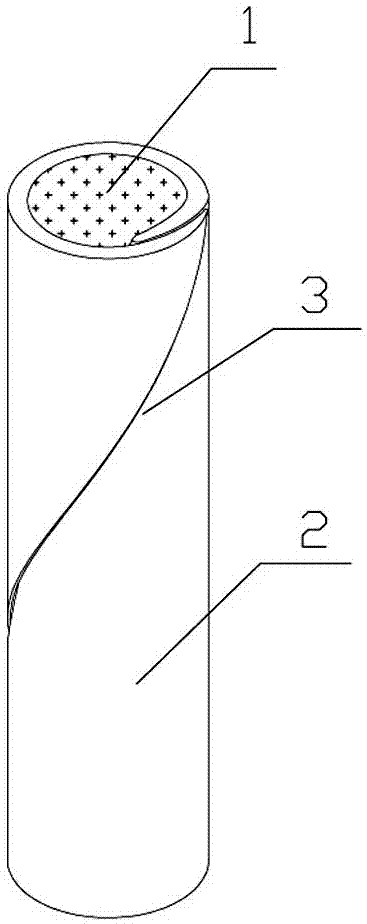

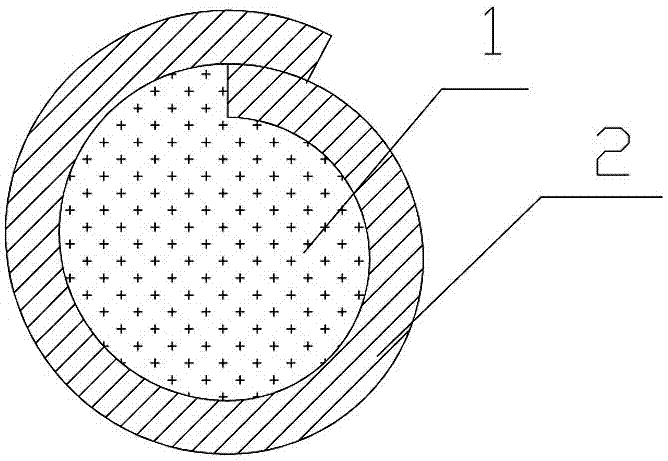

[0030] In the third step, the strip-shaped solder is rotated and rolled into a spiral tubular structure with the lap joint 3, and silver solder (in powder, paste or block) is added into the tube during the rolling process to form a solder joint. core 2;

[0031] The fourth step is to manufacture a flux-cored silver solder that meets the requirements through a conventional rolling or drawing process. The obtained finished flux-cored silver solder can be further processed...

Embodiment 1

[0034] Flux core silver solder of the present invention, its preparation method is as follows:

[0035] a) Silver, copper, and zinc are mixed in proportion and smelted, and cast into a Φ50 mm rod-shaped BAg45Cu30Zn25 solder ingot, cut off the riser, and then turn the ingot to remove the scale for use;

[0036] b) Raise the temperature of the solder extrusion equipment to 460 °C, place the turned ingot in the muffle furnace for preheating, the preheating temperature is 470 °C, put the preheated ingot into the mold of the extrusion equipment Inside, extrude into a strip-shaped solder with a thickness of 5.0 mm and a width of 8.5 mm, and make a strip of solder with a thickness of 0.2 mm and a width of 7.5 mm;

[0037] c) Sandblasting and roughening one side of the strip-shaped solder;

[0038] d) Evenly mix silver brazing flux containing 15% borax, 10% potassium fluoride, 20% potassium fluoroborate, and 55% boric acid, dry in a low-vacuum drying oven at 100°C~130°C for 200min, a...

Embodiment 2

[0042] Flux core silver solder of the present invention, its preparation method is as follows:

[0043]a) Silver, copper, zinc, and tin are prepared in proportion and smelted, and cast into a Φ50 mm rod-shaped BAg34Cu36Zn27.5Sn2.5 solder ingot, cut off the riser, and then turn the ingot to remove the scale for use;

[0044] b) Raise the temperature of the solder extrusion equipment to 460 °C, place the turned ingot in the muffle furnace for preheating, the preheating temperature is 470 °C, put the preheated ingot into the mold of the extrusion equipment Inside, extrude into a strip-shaped solder with a thickness of 5.5 mm and a width of 8.6 mm, and make a strip of solder with a thickness of 0.2 mm and a width of 7.8 mm;

[0045] c) Process grooves on one side of the strip-shaped solder to form an uneven surface;

[0046] d) Evenly mix silver brazing flux containing 42% potassium fluoride, 23% potassium fluoroborate, and 35% boron anhydride, dry in a low-vacuum drying oven at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com