Spiral discharging device for dust collector

A technology of screw unloading and dust collector, applied in the field of unloading devices, can solve the problems of harsh on-site environment, increased material processing cost, inconvenient inspection and maintenance, etc., to improve the operating environment, facilitate inspection and maintenance, and reduce equipment maintenance. Effects of cost and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

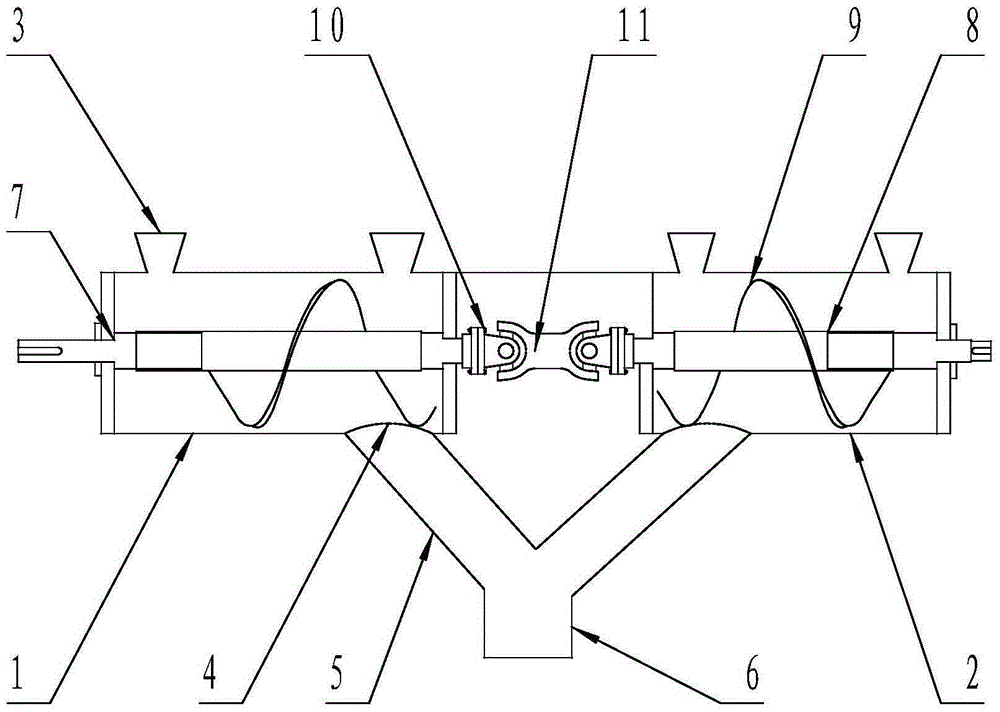

[0012] Such as figure 1 As shown, a dust collector spiral discharge device is characterized in that: the dust collector spiral discharge device has a first discharge housing 1 and a second discharge housing 2, the first discharge housing 1 and the second discharge shell 2 respectively have a cylinder and two opposite side plates sealing the cylinder. The tops of the first discharge shell 1 and the second discharge shell 2 are respectively arranged in sequence There are two feeding ports 3, and a discharging port 4 is respectively provided at the bottom. The discharging port 4 is sleeved with a powder output branch pipe 5. The first discharging shell 1 and the second discharging shell 2 barrel out The outlet 4 is sleeved and then the output end of the powder output branch pipe 5 is hermetically connected to the powder output pipe 6; the first discharge housing 1 and the second discharge housing 2 are also provided with powder conveying devices, respectively, The powder conveyin...

Embodiment 2

[0015] Such as figure 1 As shown, a dust collector spiral discharge device is characterized in that: the dust collector spiral discharge device has a first discharge housing 1 and a second discharge housing 2, the first discharge housing 1 and the second discharge shell 2 respectively have a cylinder and two opposite side plates sealing the cylinder. The tops of the first discharge shell 1 and the second discharge shell 2 are respectively arranged in sequence There are two feeding ports 3, and a discharging port 4 is respectively provided at the bottom. The discharging port 4 is sleeved with a powder output branch pipe 5. The first discharging shell 1 and the second discharging shell 2 barrel out The outlet 4 is sleeved and then the output end of the powder output branch pipe 5 is hermetically connected to the powder output pipe 6; the first discharge housing 1 and the second discharge housing 2 are also provided with powder conveying devices, respectively, The powder conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com