Selective laser melting forming powder falling device

A technology of selective laser melting and powder dropping, applied in the field of additive manufacturing, can solve problems such as jamming and inability to perform the forming process, achieve convenient cleaning, increase powder utilization efficiency, and solve the phenomenon of powder leakage and powder drop shaft stuck. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

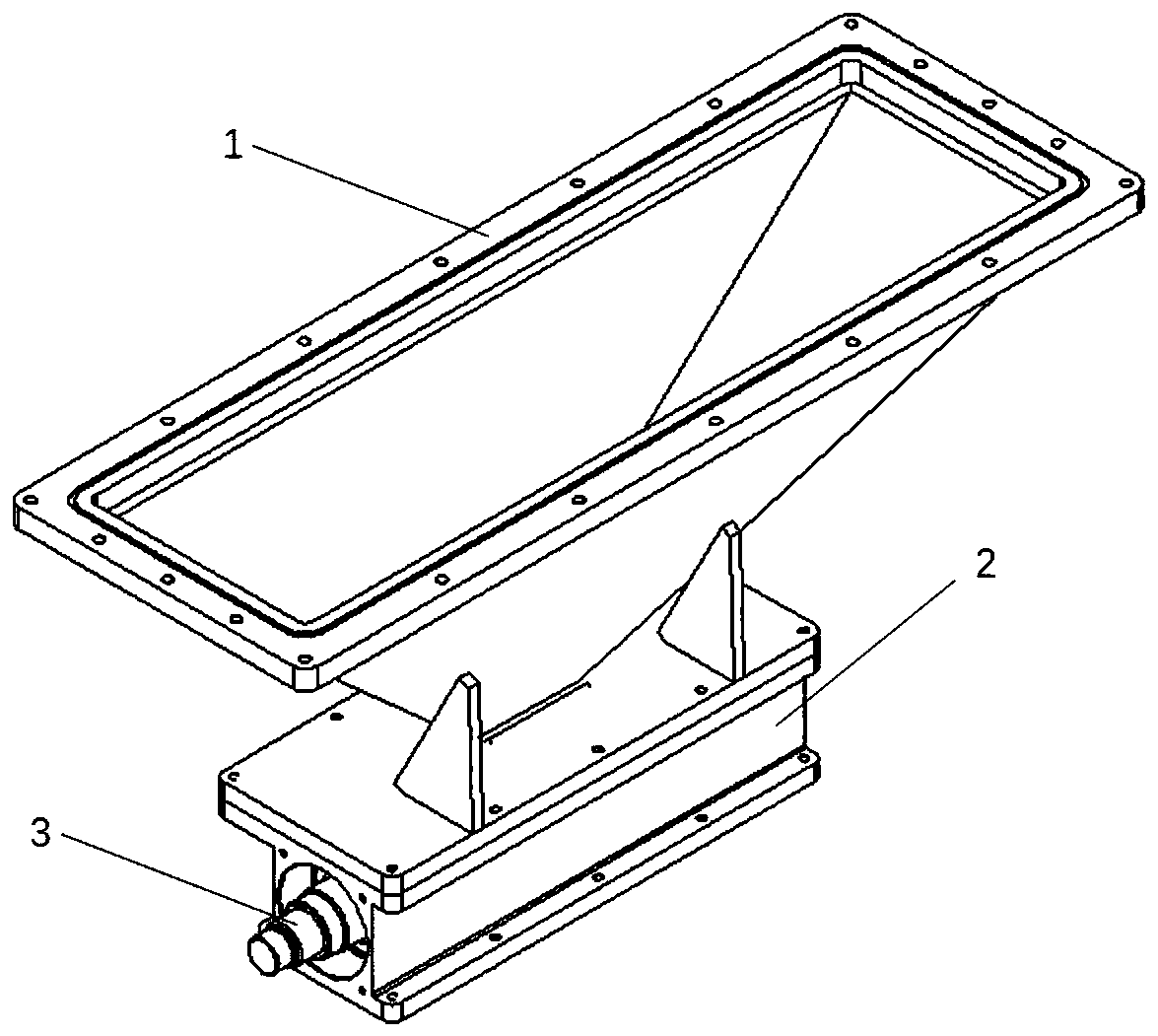

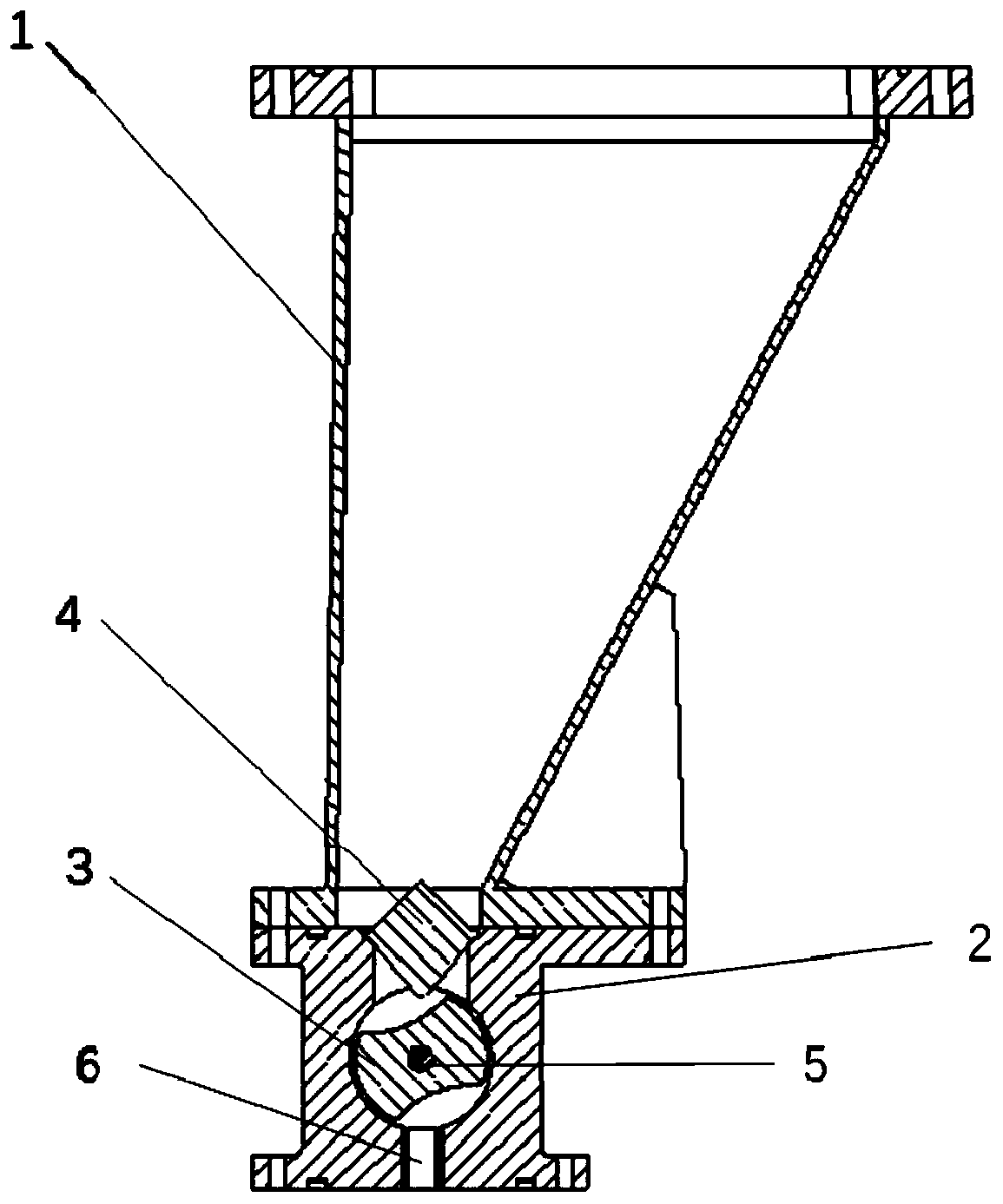

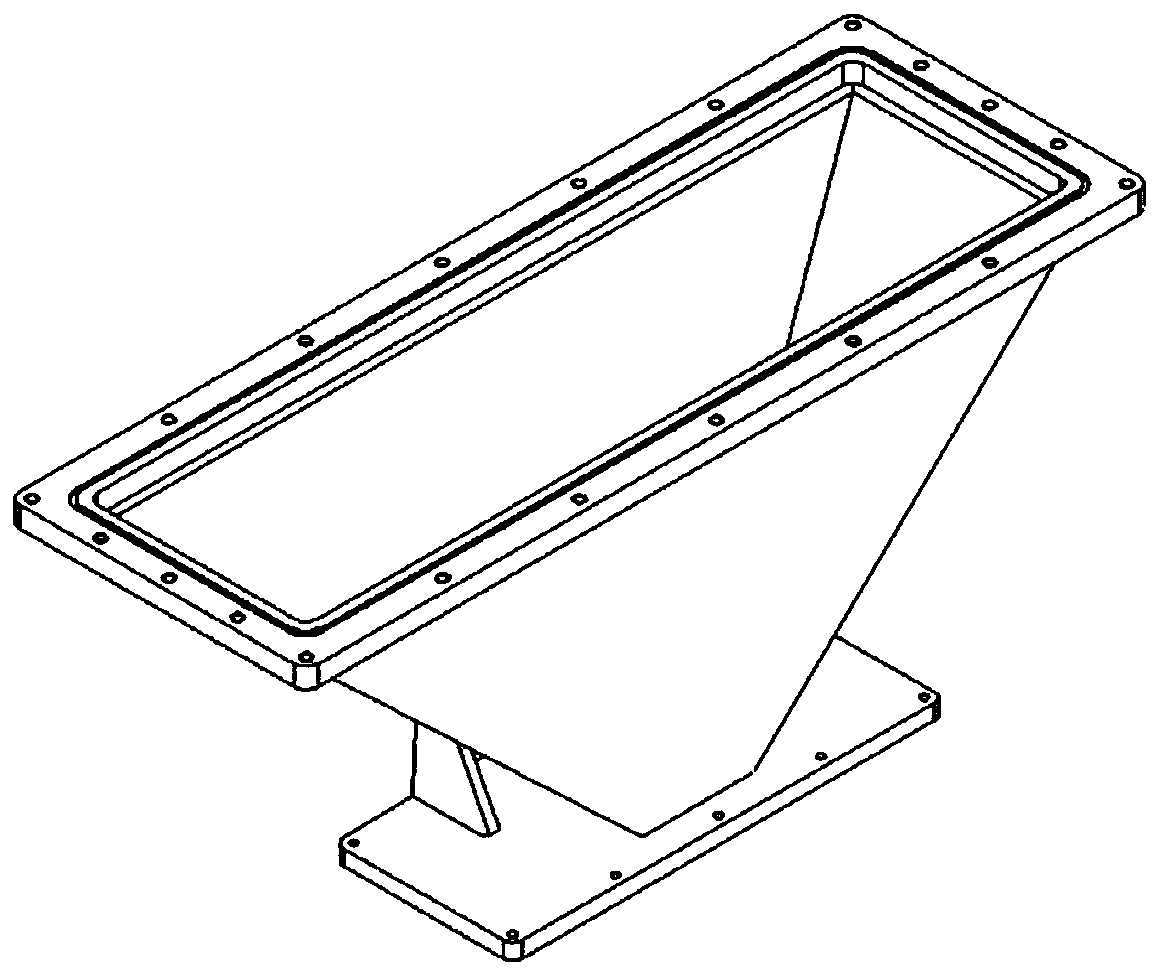

[0028] Such as Figure 1 to Figure 6 As shown, a selective laser melting forming powder dropping device provided by the present invention includes a powder tank 1 , a powder dropping cabin 2 , a quantitative powder dropping shaft 3 , a rhombus slider 4 and a servo motor 5 . The powder cylinder 1 is connected by bolts to the powder drop cabin 2 through the base, and a sealing groove 8 is opened on the contact surface between the powder cylinder 1 and the powder drop cabin 2, and an O-ring is placed to ensure the airtightness inside the powder drop device. Such as figure 2 As shown, the quantitative powder falling shaft 3 is placed in the cylindrical cavity in the middle of the powder falling cabin 2, and the quantitative powder falling shaft 3 rotates with the servo motor 5 during operation. A powder outlet is provided at the bottom of the powder tank 1 to be connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com