Artificial copper paint for aluminium profile and preparation method thereof

A technology for aluminum profiles and coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as easy paint peeling and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

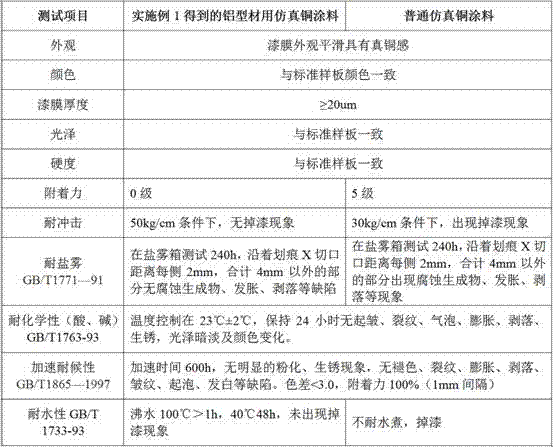

Examples

Embodiment 1

[0039] The simulated copper paint for aluminum profiles is made of the following raw materials in parts by weight:

[0040] 40 parts of electroplating silver resin for baking varnish,

[0041] 6 parts polyester resin,

[0042] 5 parts of mixed solvent,

[0043] 15 parts of cross-linked amino resin,

[0044] 1 part of directional anti-settling agent,

[0045] 8 parts of crystal pearlescent pigment,

[0046] 1 part color palette,

[0047] 1 part of coupling agent,

[0048] The electroplating silver resin for baking varnish is composed of solid electroplating silver resin and a mixed solvent in a ratio of 1:9 to 2:8, and the mixed solvent is methyl isobutyl ketone, n-butanol, ethylene glycol butyl One of ether, butyl acetate, ethyl acetate or any combination thereof.

[0049] Preferably, the polyester resin is one or a combination of E-10 modified polyester resin and saturated polyester resin, and the cross-linked amino resin is modified cyanuric compound cross-linked resi...

Embodiment 2

[0059] The simulated copper paint for aluminum profiles is made of the following raw materials in parts by weight:

[0060] 50 parts of electroplating silver resin for baking varnish,

[0061] 6 parts polyester resin,

[0062] 5 parts of mixed solvent,

[0063] 15 parts of cross-linked amino resin,

[0064] 1 part of directional anti-settling agent,

[0065] Crystal pearlescent pigment 8 parts,

[0066] 1 part color palette,

[0067] 1 part of coupling agent,

[0068] The electroplating silver resin for baking varnish is composed of solid electroplating silver resin and a mixed solvent in a ratio of 1:9 to 2:8, and the mixed solvent is methyl isobutyl ketone, n-butanol, ethylene glycol butyl One of ether, butyl acetate, ethyl acetate or any combination thereof.

[0069] Preferably, the polyester resin is one or a combination of E-10 modified polyester resin and saturated polyester resin, and the cross-linked amino resin is modified cyanuric compound cross-linked resin , ...

Embodiment 3

[0079] The simulated copper paint for aluminum profiles is made of the following raw materials in parts by weight:

[0080] 40 parts of electroplating silver resin for baking varnish,

[0081] 9 parts polyester resin,

[0082] 5 parts of mixed solvent,

[0083] 15 parts of cross-linked amino resin,

[0084] 1 part of directional anti-settling agent,

[0085] 8 parts of crystal pearlescent pigment,

[0086] 1 part color palette,

[0087] 1 part of coupling agent,

[0088] The electroplating silver resin for baking varnish is composed of solid electroplating silver resin and a mixed solvent in a ratio of 1:9 to 2:8, and the mixed solvent is methyl isobutyl ketone, n-butanol, ethylene glycol butyl One of ether, butyl acetate, ethyl acetate or any combination thereof.

[0089] Preferably, the polyester resin is one or a combination of E-10 modified polyester resin and saturated polyester resin, and the cross-linked amino resin is modified cyanuric compound cross-linked resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com