A kind of automobile interior trim coating with electroplating effect and preparation method thereof

A technology for automotive interior parts and coatings, applied in the direction of cellulose derivative coatings, coatings, etc., can solve the problems of electroplating plastic parts with many production processes, industrial wastewater, environmental pollution, etc., to achieve realistic imitation electroplating effects and save costs , strong metallic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

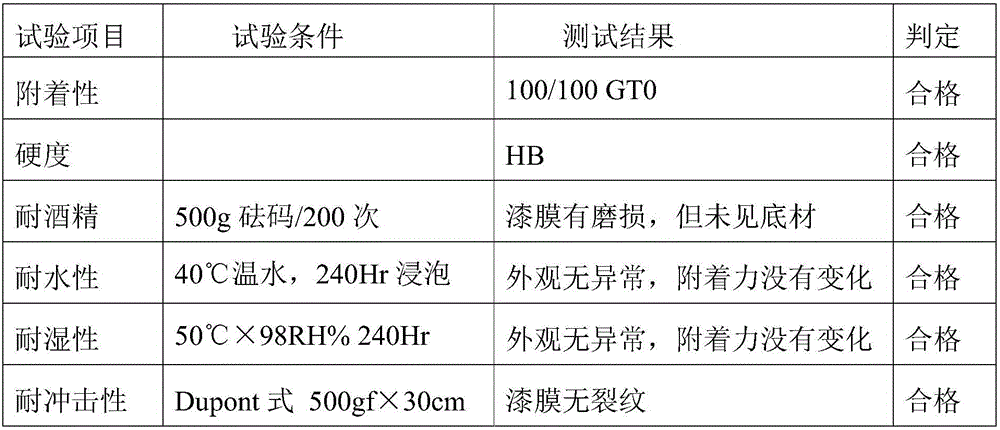

Examples

Embodiment 1

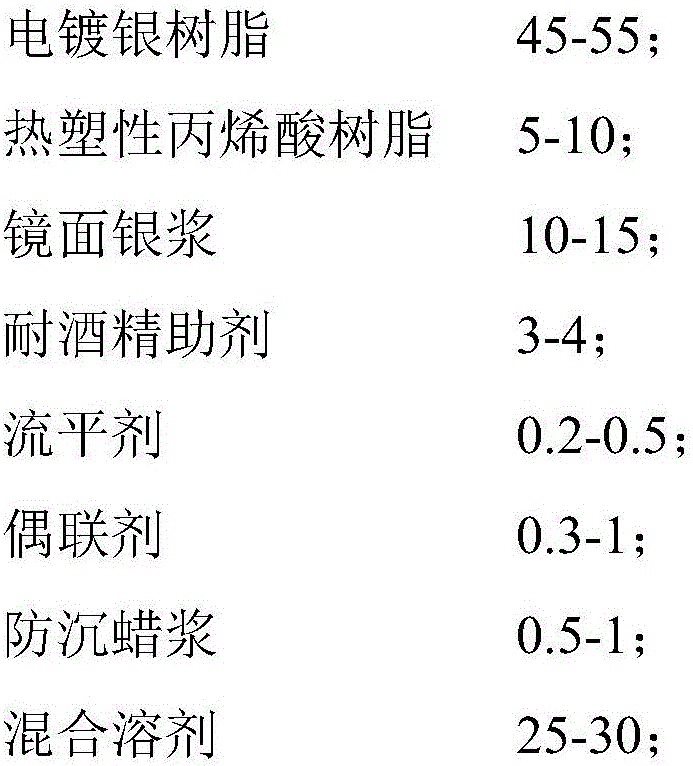

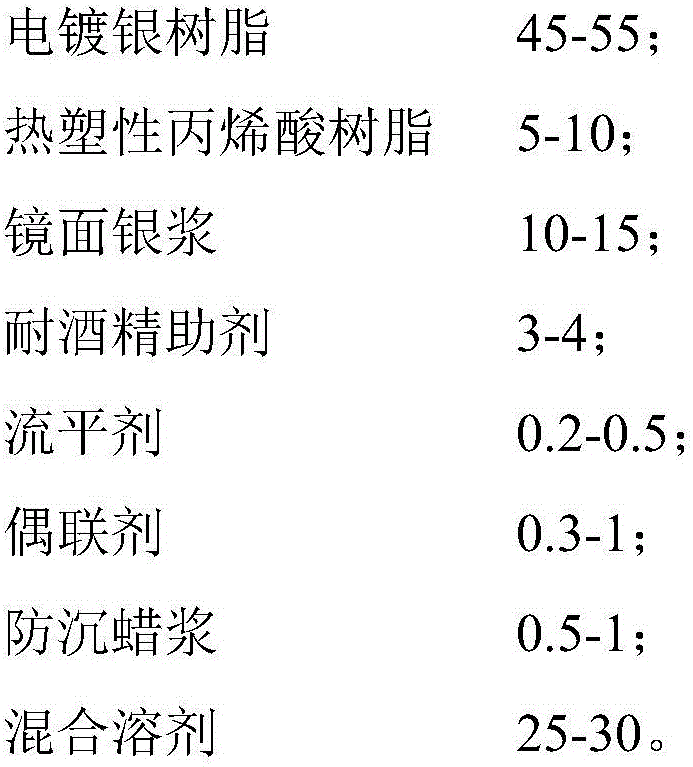

[0027] A coating for automotive interior parts with an electroplating effect and a preparation method thereof, the method comprising the following process steps

[0028] (1) Schlenk Decomet401010 mirror silver paste 10% as component A;

[0029] (2) The mixed solvent is component B, which is composed of the following solvents mixed in parts by weight: white electric oil 20, methyl isobutyl ketone 25, ethyl acetate 22, isopropanol 25, ethylene glycol monobutyl ether 8.

[0030] (3) 48% allyl ether thermoplastic acrylic modified electroplating silver resin BSK A-810P, 8% thermoplastic acrylic resin Lihua 56-1155, 3% alcohol resistance additive K-900, 0.3% leveling agent BYK306 , 0.5% titanate coupling agent | TYZOR-AA75, 29.2% mixed solvent B, 1% anti-settling wax slurry DeuRheo 556 were added in turn, stirred on the disperser, the stirring speed was 800-1000r / min, and the stirring time was 10min stop. Made into component C.

[0031] (4) Add component A to component C, and st...

Embodiment 2

[0036] A coating for automotive interior parts with an electroplating effect and a preparation method thereof, the method comprising the following process steps

[0037] (1) 10% BASF Merxin 41-0010 mirror silver paste as component A;

[0038] (2) The mixed solvent is component B, which is composed of solvents mixed in proportion: white electric oil 20, methyl isobutyl ketone 25, ethyl acetate 22, isopropanol 25, ethylene glycol monobutyl ether 8.

[0039] (3) 47% cellulose modified electroplating silver resin A-830S, 8% thermoplastic acrylic resin Deqian AC7450, 4% N-sico-7050 Intermediate alcohol-resistant intermediate, 0.3% leveling agent BYK333, 1% titanium Ester coupling agent | TYZOR-AA75, 28.7.% mixed solvent B, 1% anti-settling wax slurry Add 6900-HV in turn, stir on the disperser, the stirring speed is 800-1000r / min, and the stirring time is 10min to stop. Made into component C.

[0040] (4) Add component A to component C, and stir on the disperser, the stirring sp...

Embodiment 3

[0045] A coating for automotive interior parts with an electroplating effect and a preparation method thereof, the method comprising the following process steps

[0046] (1) 15% BASF Merxin 41-0010 mirror silver paste as component A;

[0047] (2) The mixed solvent is component B, which is composed of solvents mixed in proportion: white electric oil 20, methyl isobutyl ketone 25, ethyl acetate 22, isopropanol 25, ethylene glycol monobutyl ether 8.

[0048] (3) 48% aldehyde ketal silver plating resin AA-8315A, 7% thermoplastic acrylic resin AC7450, 3% alcohol resistance additive K-900, 0.3% leveling agent Glide100, 0.5% silane coupling agent KBM- 603, 25.2% mixed solvent B, 1% anti-settling wax slurry Add 4200 in turn, stir on the disperser, the stirring speed is 800-1000r / min, and the stirring time is 10min to stop. Made into component C.

[0049] (4) Add component A to component C, and stir on the disperser, the stirring speed is 500-800r / min, and the stirring time is 5min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com