A kind of water-based simulated copper coating and preparation method thereof

A water-based and coating technology, applied in the direction of coating, etc., can solve the problems of non-compliance with volatile organic compound emissions, non-compliance with environmental protection requirements, and unfavorable human health, and achieve realistic imitation electroplating effects, realistic imitation copper effects, and good long-term effect The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. Those skilled in the art should understand that the examples are only used to help understand the present invention, and should not be regarded as specific limitations on the present invention. Unless otherwise specified, various raw materials of the present invention can be obtained commercially; or prepared according to conventional methods in the art.

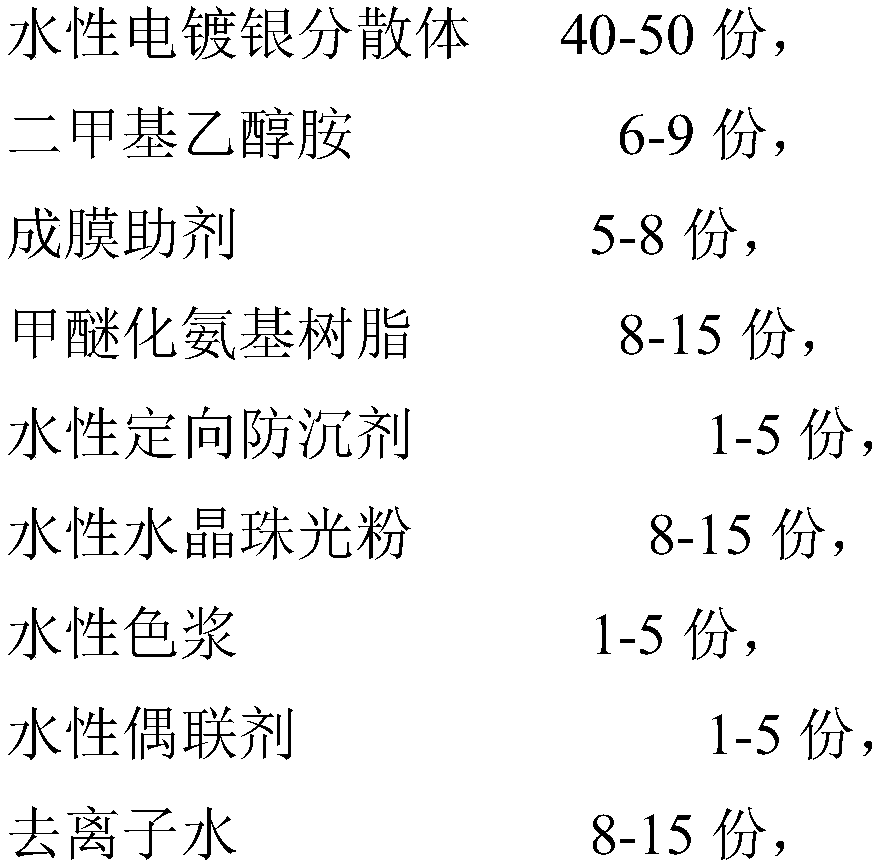

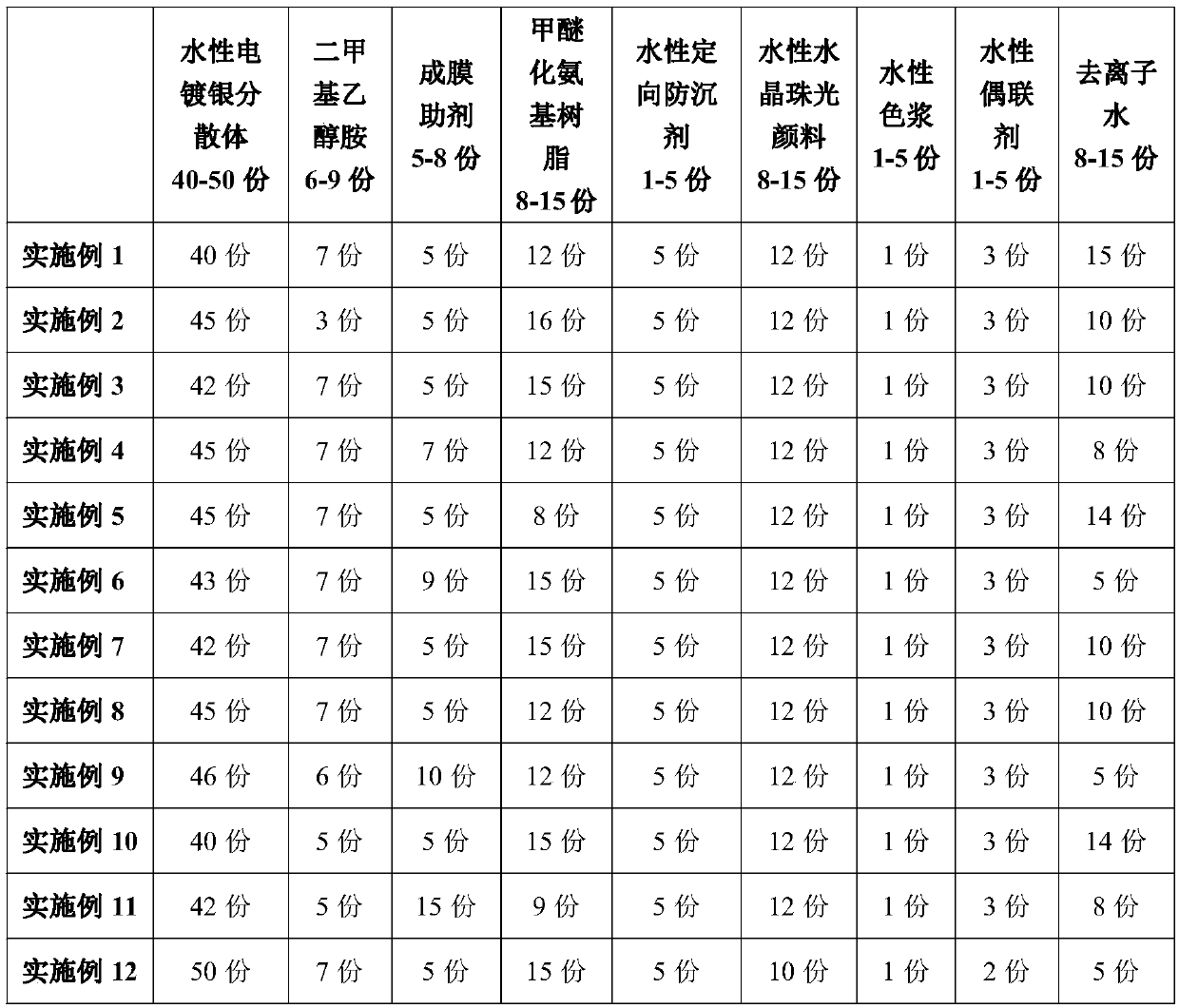

[0026] The formula of each component of water-based simulated copper coating is as shown in table 1 among the embodiment 1~12;

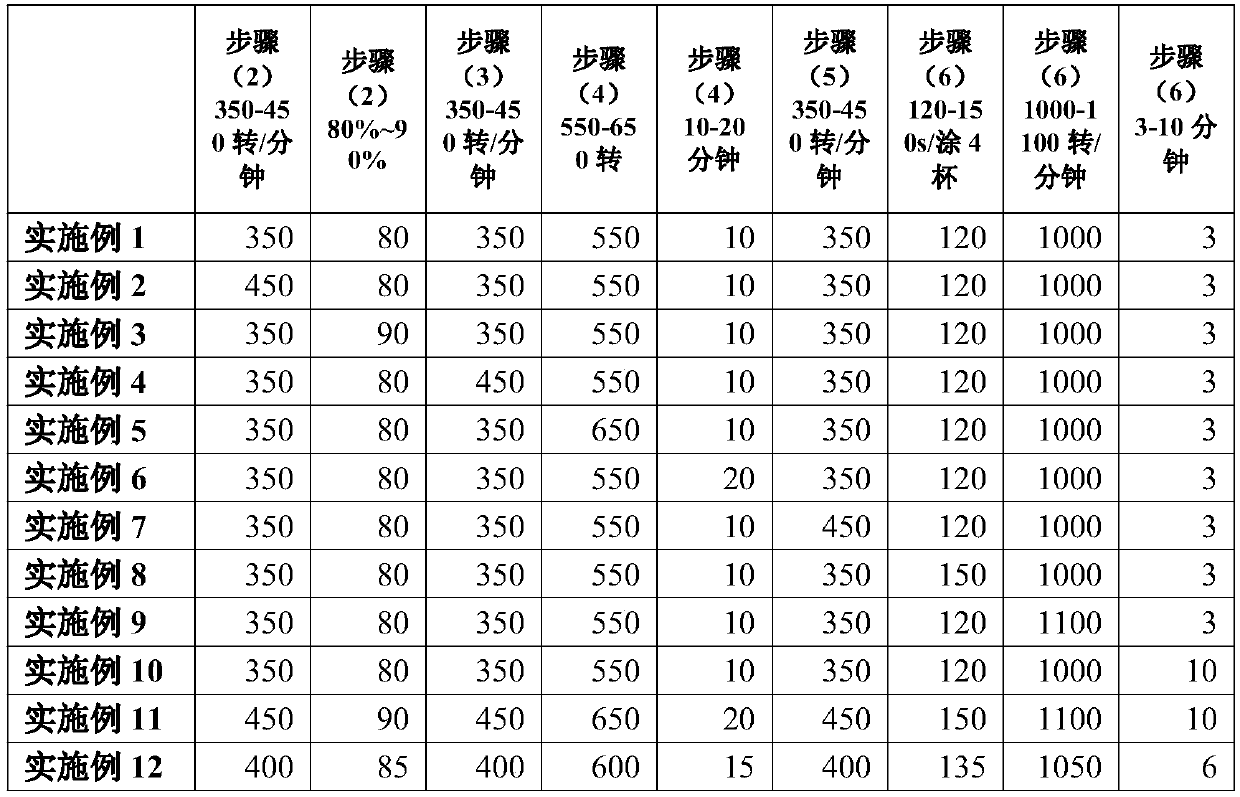

[0027] The preparation steps of the water-based simulated copper coating in Examples 1 to 12 are as follows:

[0028] Step (1): Add the aqueous electroplating silver dispersion and dimethylethanolamine into the mixing tank, stir at a low speed to neutralize;

[0029] Step (2): adding 80% to 90% of the total amount of coalescence aids under stirring conditions of 350-450 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com