Patents

Literature

148results about "Cellulose derivative coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lacquers containing highly branched copolyester polyol

Owner:AXALTA COATING SYST IP CO LLC

Coatings containing functionalized graphene sheets and articles coated therewith

Coatings comprising functionalized graphene sheets and at least one binder. In one embodiment, the coatings are electrically conductive.

Owner:THE TRUSTEES FOR PRINCETON UNIV +1

High-temperature far infrared paint and preparing method thereof

ActiveCN1552779AImprove adhesion strengthImprove thermal shock resistanceCellulose derivative coatingsFire clayBrown iron oxide

A refractory far infrared paint is prepared from zirconium oxide, Cr2O3, refractory clay, bentonite, TiO2 powder, brown corundum, iron oxide, silicon carbide, adhesive PA80 or water glass and carboxymethyl cellulose through proportional mixing, and nano-class superfine processing. Its advantage is high emissivity (0.93) at high temp.

Owner:山东慧敏科技开发有限公司

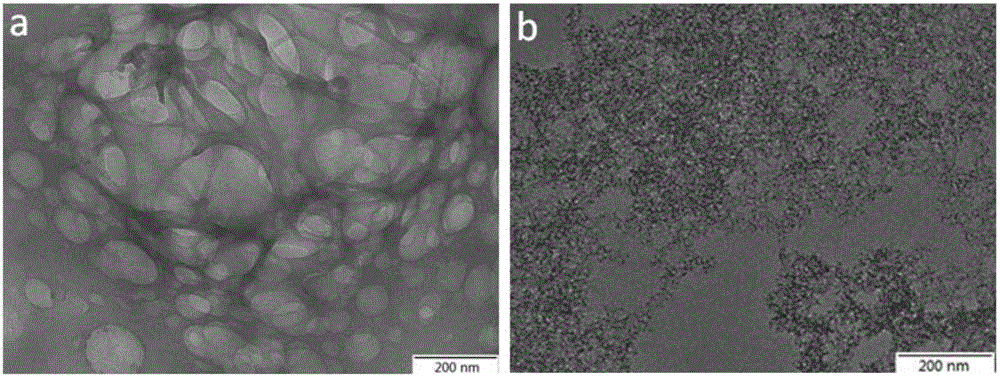

Biodegradable nano-composition for application of protective coatings onto natural materials

InactiveUS20100233468A1Improved waterproofingImproved grease-resistant propertyNon-fibrous pulp additionLiquid surface applicatorsNatural materialNanocellulose

The invention relates to a method for manufacturing a biodegradable composition containing nano-particles of cellulose for forming a protective coating on natural materials. It is an object of the invention to provide a composition for forming a protective coating layer on a biodegradable natural material that imparts to the material improved waterproofing and grease-resistant properties. It is another object to provide a composition for forming a protective coating on natural biodegradable materials that is based on the use of nano-cellulose particles and that protects these materials from swelling, warping, and mechanical damage during contact with water, other aqueous liquids, or grease.

Owner:LIFSCHITZ YAKOV MARK +1

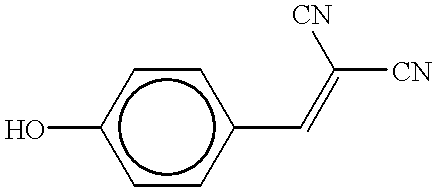

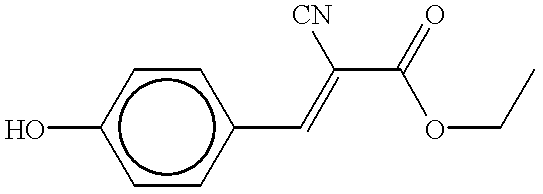

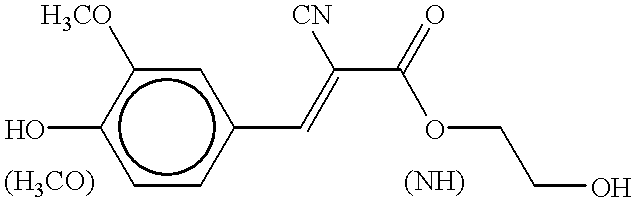

Fast-etching, thermosetting anti-reflective coatings derived from cellulosic binders

InactiveUS6316160B1Improve compatibilityGood stability at room temperatureSemiconductor/solid-state device manufacturingCellulose derivative coatingsCelluloseAnti-reflective coating

Owner:BREWER SCI

Fogdrop-proof coating combination and preparation method thereof

ActiveCN101037559AGood dispersionImprove placement stabilityAntifouling/underwater paintsPaints with biocidesAdhesiveSmall particle

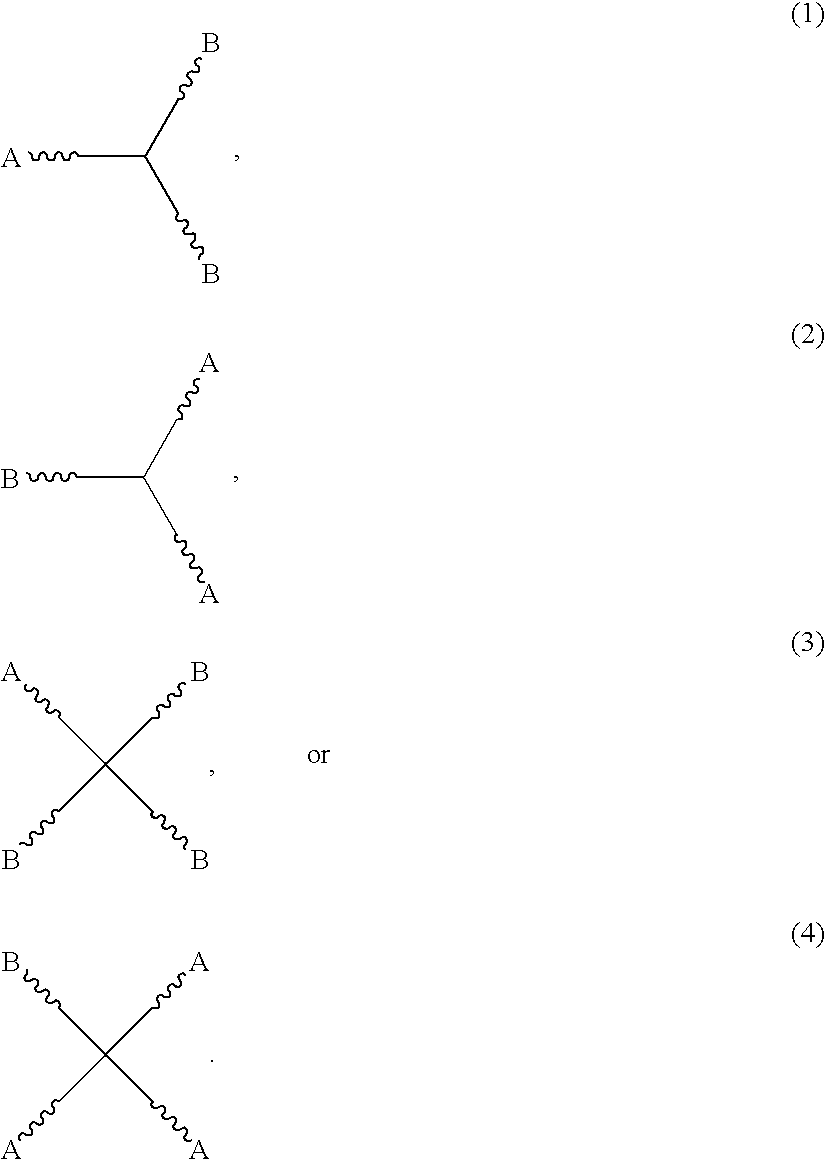

The invention relates to a anti-fogdrop painting composition, which includes four components of A, B, C and water, A is colloid aluminum oxide and content thereof is 0.9-3.6%, B is polyoxyethylene-containing non-ion surfactant and content thereof is 0.1-0.5%, C is water-soluble cellulose derivative adhesive and content thereof is 0.01-0.04%, and residual component is water. The composition possesses good dispersivity and placing stability, low viscosity, and small particle diameter; can reach to painting demand without grinding of colloid mill; and can endow thin film after coating to polyethylene thin film with good initial anti-fog property and long anti-drop validity period of at least three years. The invention also discloses preparation method for the anti-fogdrop painting composition, which is simple, low-cost and pollution-free to environment.

Owner:PETROCHINA CO LTD

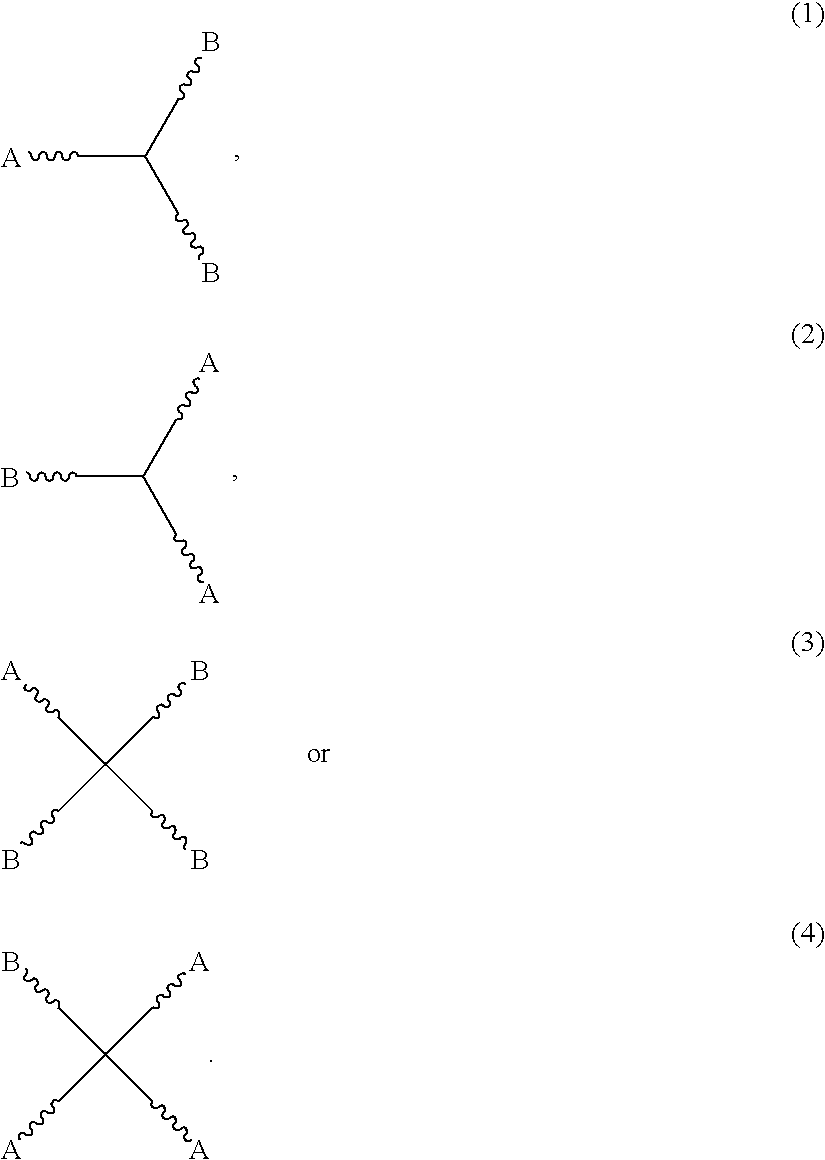

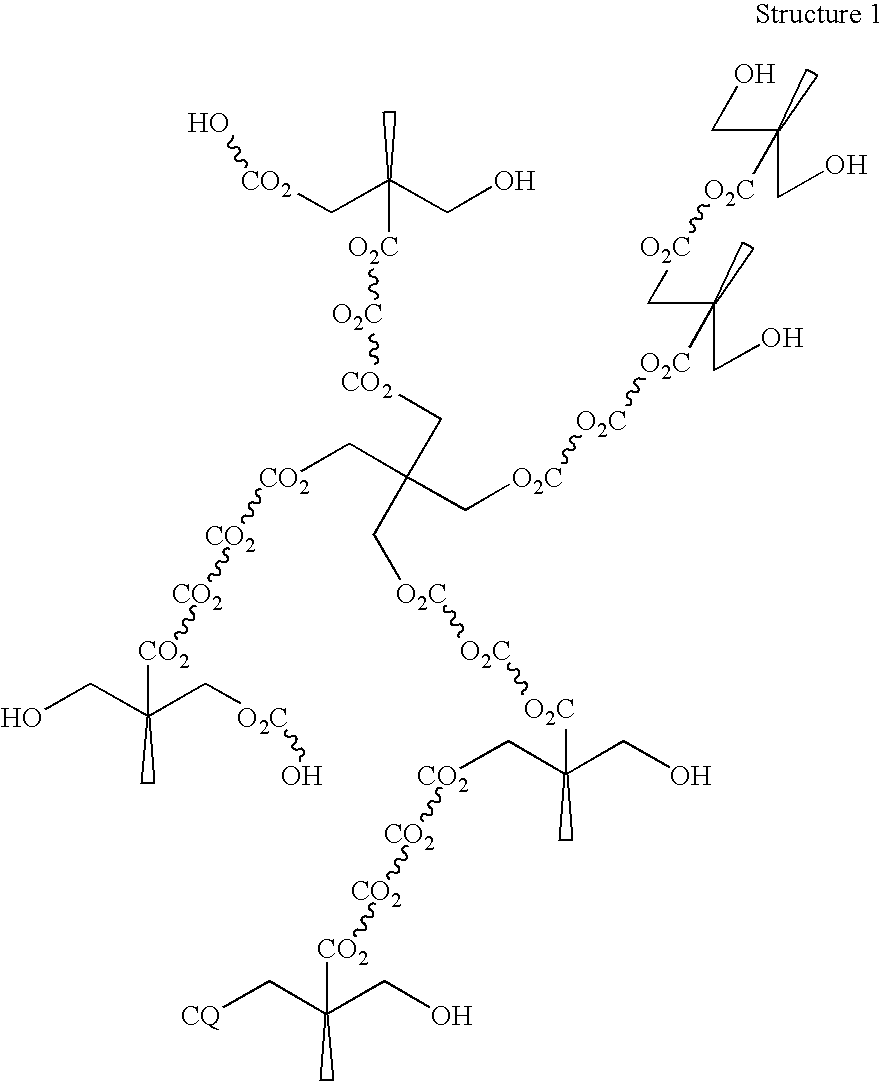

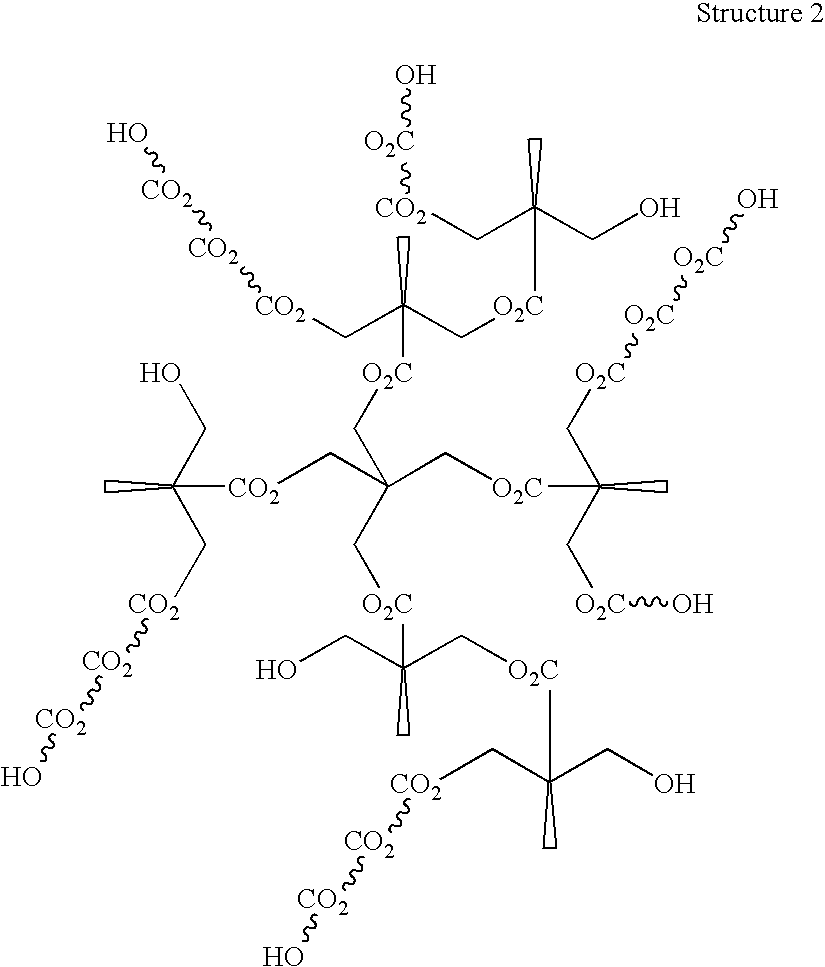

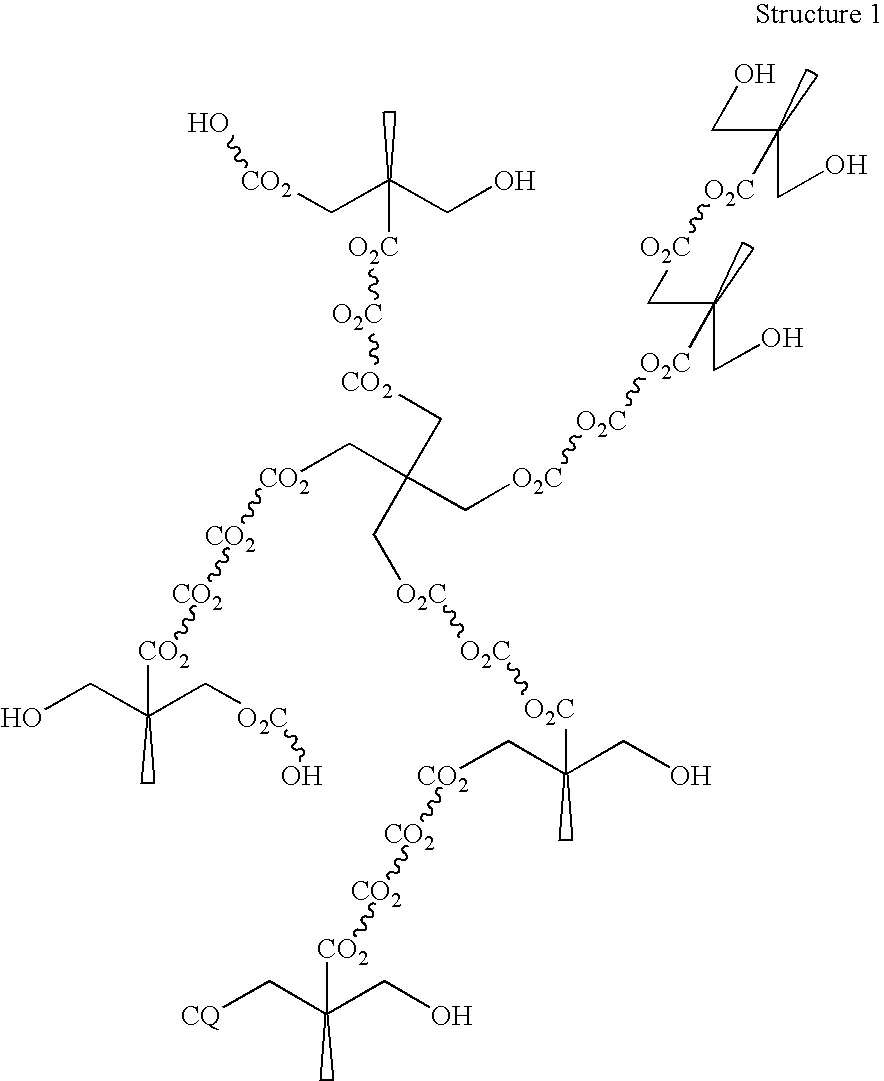

Lacquers containing highly branched copolyester polyol

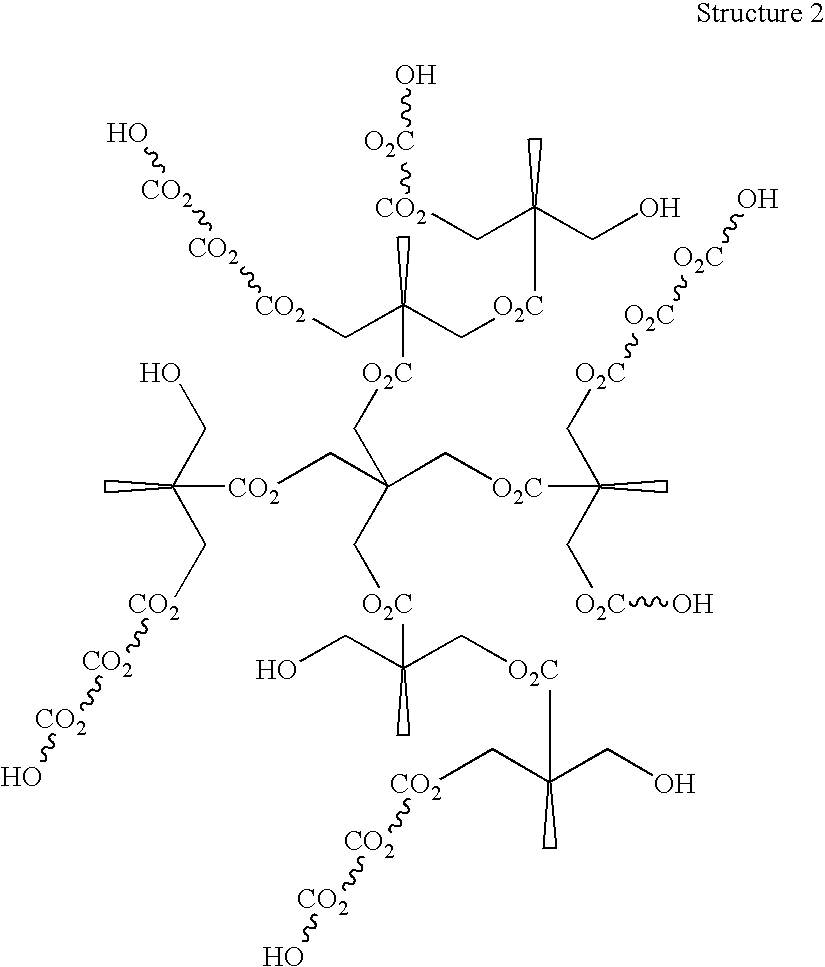

InactiveUS20030161961A1Improve chip resistanceExcellent humidity resistanceOther chemical processesPretreated surfacesPolyolAutomotive oem

This invention relates to rapid drying lacquers that are particularly useful for automotive OEM refinish applications. The lacquer includes a novel highly branched copolyester polyol. This invention is also directed to a process for producing coatings from the rapid drying lacquers. These lacquers are especially useful in providing for chip and humidity resistant coatings having improved adhesion.

Owner:AXALTA COATING SYST IP CO LLC

Biopolymer compositions and products thereof

This invention relates to biopolymer-based compositions and biopolymer-based formed bodies such as film, sheet, capsule, casing or coating-film or spray thereof. In another embodiment, the invention relates to a process for producing a biopolymer-based starting material and biopolymer-based formed bodies such as cited above, for the manufacture of pharmaceutical, veterinary, food for cosmetic products.

Owner:PFIZER INC

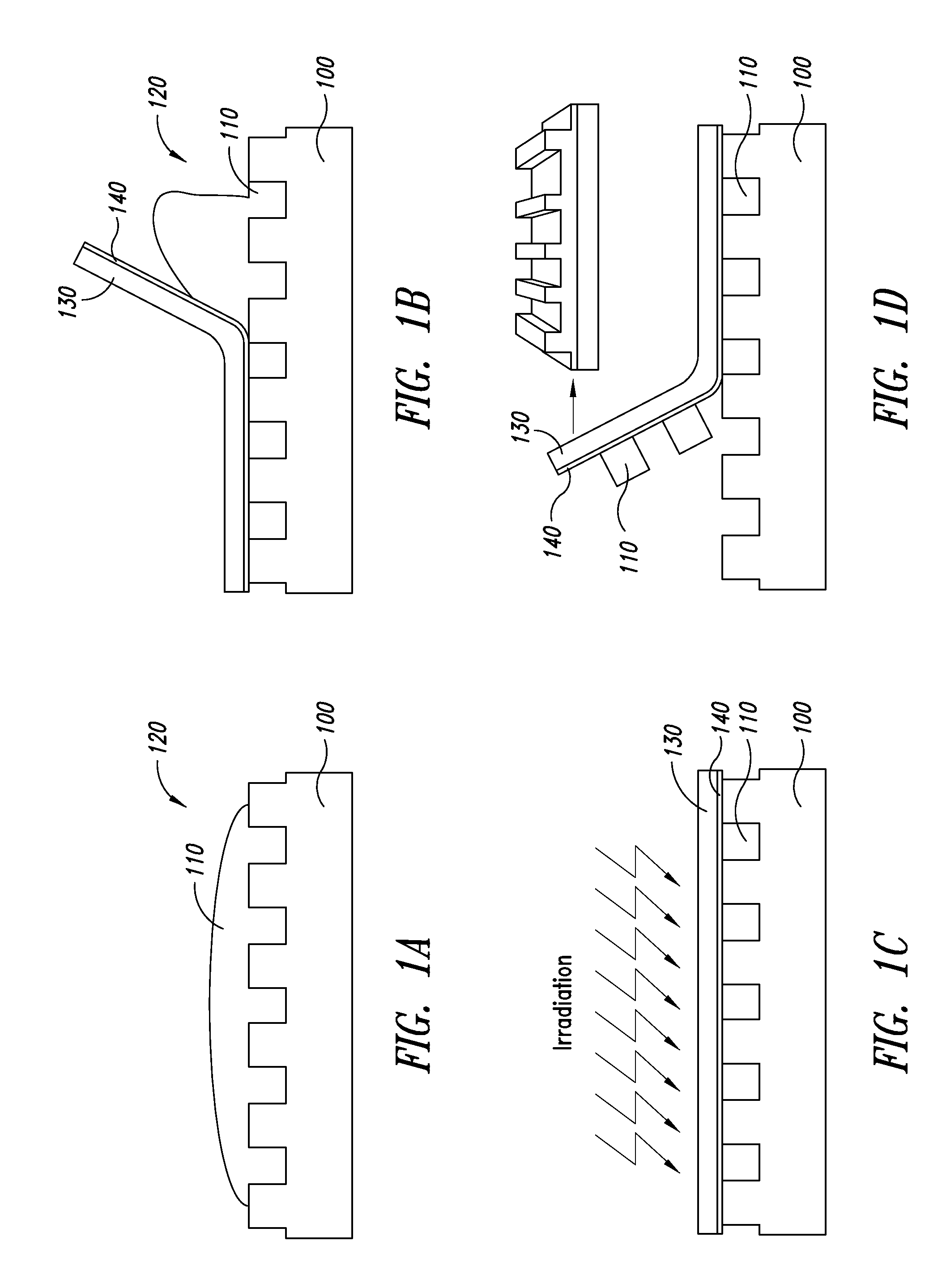

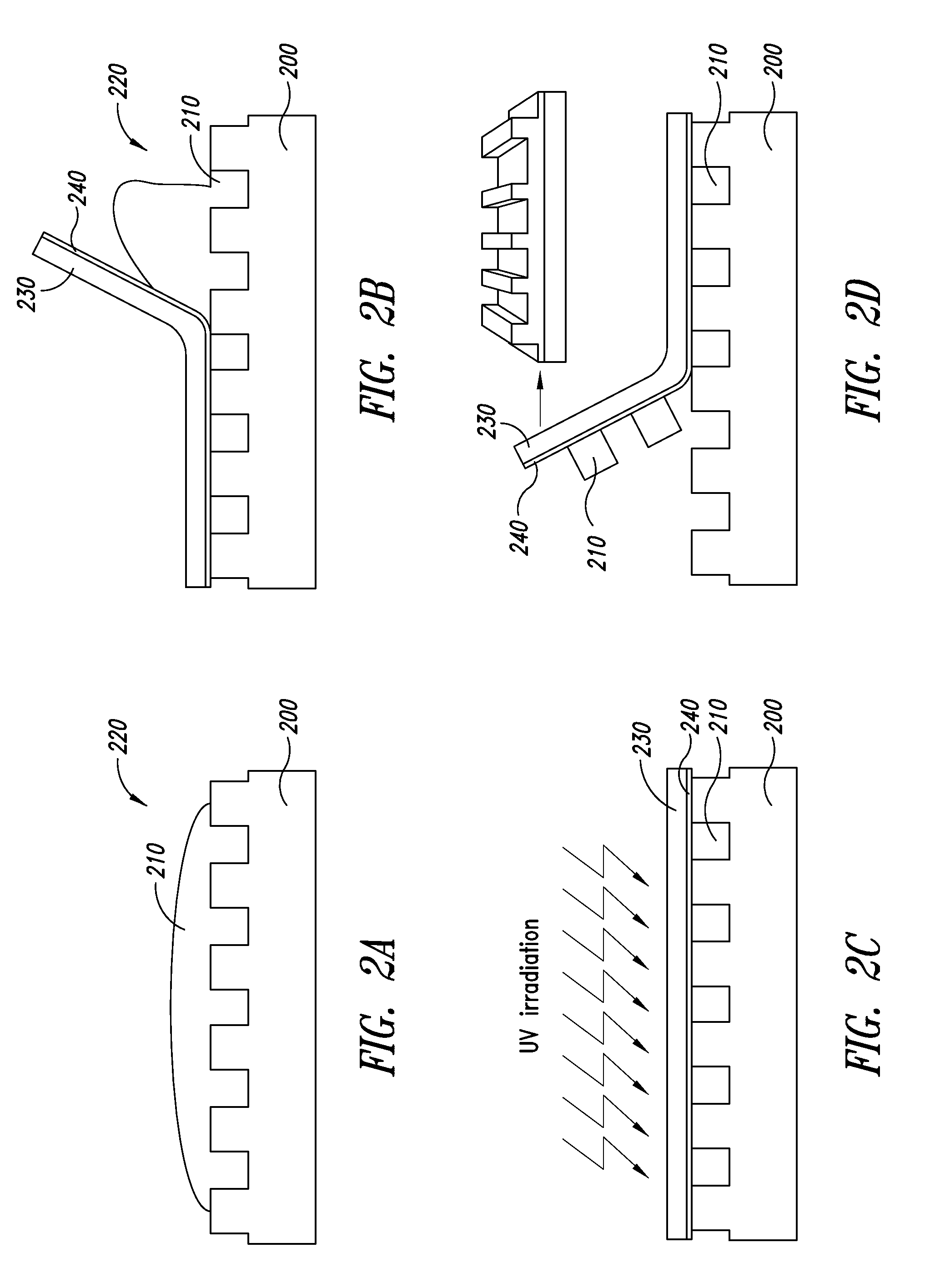

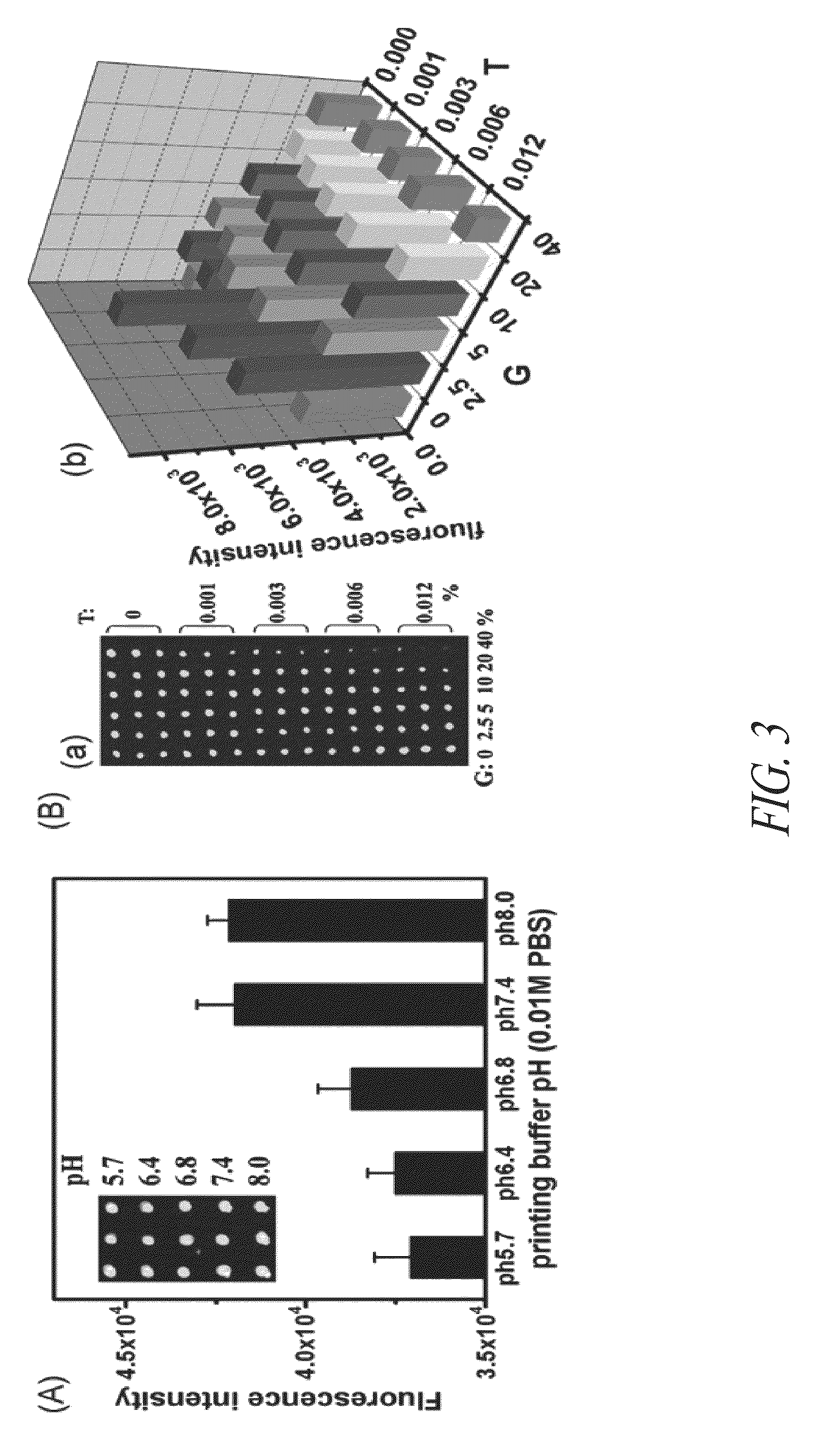

Method of manufacturing micro patterned device and device obtained by the method

The present invention refers to a method of manufacturing a micro patterned device. The method can comprise or consist of applying a light curable epoxy resin to a mold to obtain a curable resin filled mold. In a further step a polymeric film or an epoxy resin-coated glass is applied over the curable resin filled mold. Subsequently, the curable resin filled mold to which the polymeric film or the epoxy resin-coated glass is applied is irradiated to cure the resin. In another aspect the present invention refers to a micro patterned device obtained by a method described herein.

Owner:NANYANG TECH UNIV

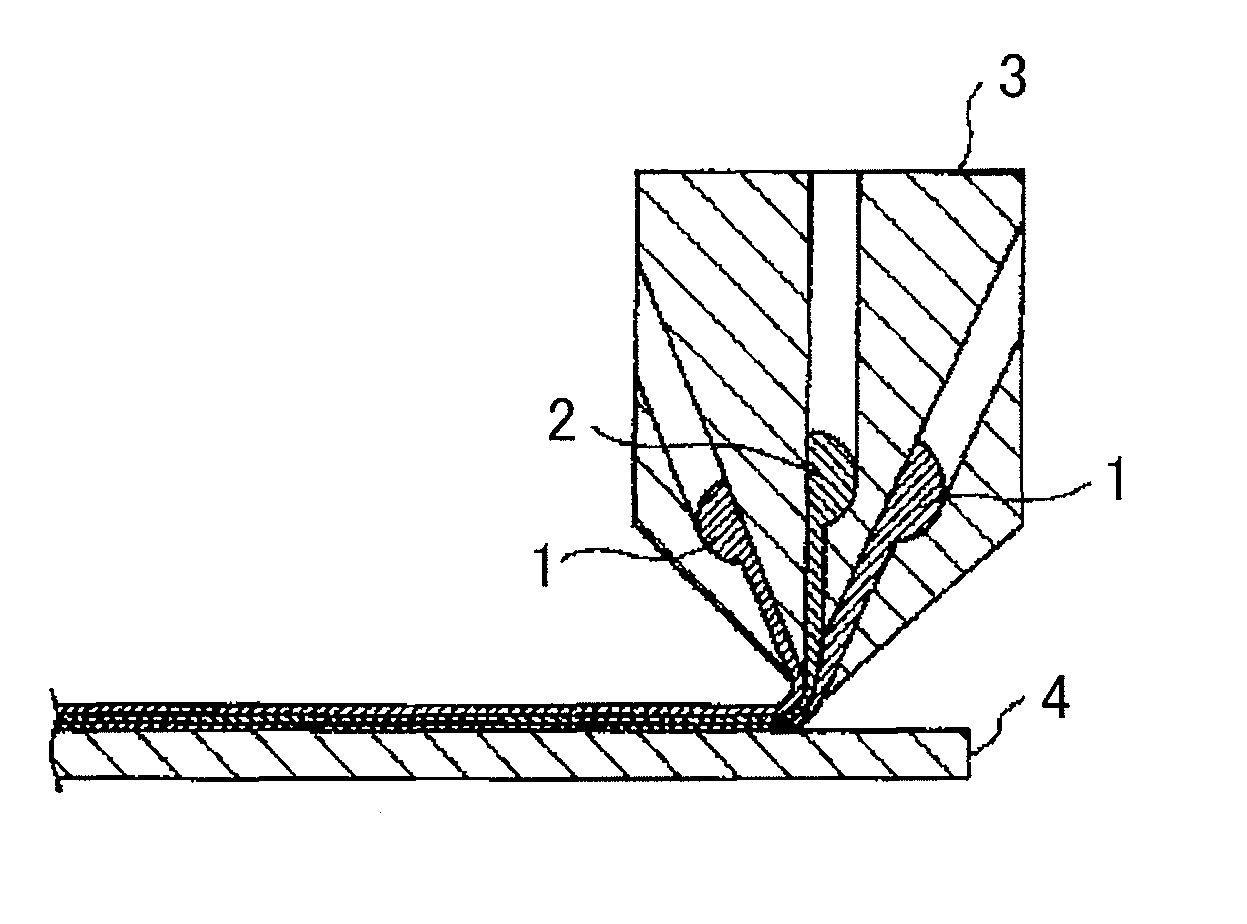

Resin film and method for producing it, polarizer and liquid crystal display device

ActiveUS20110223435A1Increased durabilityHigh product yieldLiquid crystal compositionsSynthetic resin layered productsOrganic acidPolymer science

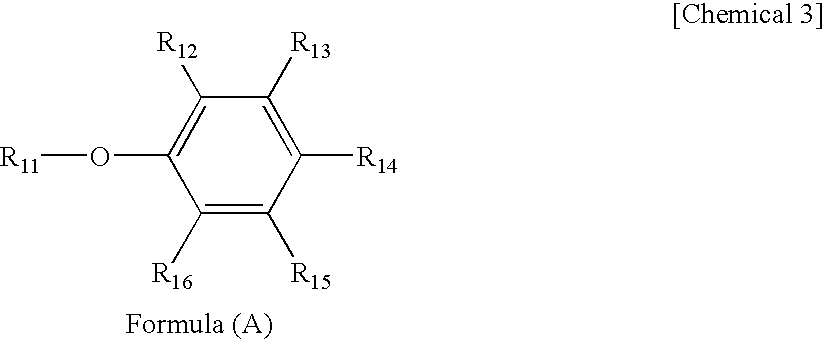

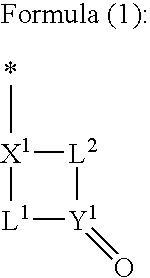

A resin film including a resin and an organic acid represented by the following formula (1), wherein the ratio of the organic acid to the resin is from 0.1 to 20% by mass:X-L-(R1)n Formula (1)

Owner:FUJIFILM CORP

Porous film and secondary battery electrode

ActiveUS20110091774A1Improve featuresImprove bindingElectrode manufacturing processesHybrid capacitor electrodesParticulatesWater insoluble

Provided is a porous film that can contribute to improving the cycle characteristics of an electric cell by improving binding characteristics, for a porous film provided on a surface of an electrode used in a secondary cell and the like. The porous film comprises a water-soluble polymer, an inorganic filler, and a water-insoluble particulate polymer including 0.5-40 mass % of a monomer unit having a hydrophilic group selected from the group consisting of carboxylic acid groups, hydroxyl groups, and sulfonate groups.

Owner:ZEON CORP

Environment-friendly heat-resistant waterborne polyurethane coating

InactiveCN104293159AImprove heat resistanceStrong water resistanceCellulose derivative coatingsPolyurea/polyurethane coatingsVegetable oilGlycerol

The invention discloses an environment-friendly heat-resistant waterborne polyurethane coating. The raw materials of the waterborne polyurethane coating comprise the following components in parts by weight: 50-80 parts of modified waterborne polyurethane, 10-30 parts of waterborne acrylic resin, 10-20 parts of epoxy resin, 5-8 parts of aliphatic polyisocyanate, 15-30 parts of organically modified clay, 8-20 parts of modified nano-cellulose, 5-20 parts of silk fibroin, 3-8 parts of nanometer titanium dioxide, 10-18 parts of nanometer montmorillonite, 5-8 parts of vegetable oil, 1-1.8 parts of glycerol, 0.5-1.8 parts of ethylene glycol propyl ether, 0.8-1.9 parts of propylene glycol monomethyl ether, 0-1.5 parts of pentaerythritol, 1-3 parts of organosilicone microspheres and 3-6 parts of modified carbon nanotubes. The environment-friendly heat-resistant waterborne polyurethane coating disclosed by the invention has the advantages of good heat resistance, strong water resistance, high hardness and long service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Nano-cellulose liquid crystal membrane and application thereof

InactiveCN102703092APrevent attempts at forgeryHigh strengthLiquid crystal compositionsStampsCrystallographyCredit card

The invention discloses a nano-cellulose liquid crystal membrane. The liquid crystal membrane is provided with rainbow stripes, and is prepared by the following steps of: adding water into cellulose nano-crystal powder to obtain cellulose nano-crystal suspension at the mass concentration of 0.1 to 10 percent; and putting the suspension into a culture vessel or spraying the suspension onto the surface of a medium, and heating and evaporating at the temperature of 20 to 80 DEG C for 1 to 12 hours to obtain the nano-cellulose liquid crystal membrane. The liquid crystal membrane can be used for decoration, anti-fake labels, color coatings and temperature sensors or optical verification equipment. For example, the membrane is sprayed on a substrate carrying data such as an identity card or a credit card so as to stop the attempt of faking by using a color copying machine.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Coatings containing functionalized graphene sheets and articles coated therewith

Coatings comprising functionalized graphene sheets and at least one binder. In one embodiment, the coatings are electrically conductive.

Owner:THE TRUSTEES OF PRINCETON UNIV +1

Coatings containing functionalized graphene sheets and articles coated therewith

Owner:THE TRUSTEES FOR PRINCETON UNIV +1

Construction exterior wall paint with superior heat preserving performance

InactiveCN101434772AImprove waterproof and thermal insulation performanceImprove adhesionCellulose derivative coatingsFiberChemical Linkage

A building exterior wall coating with good thermal insulation property is characterized by the compositions of polyvinyl alcohol, expanded perlite, aluminium silicate powder, oyster shell whiting, methylcellulose, glass microballoon, fiber glass, nanometer silicon dioxide, acryloid cement, elm bast fiber, an antifoaming agent and calcium carbonate. By virtue of methyl silica high polymer formed after the reaction among heated silicate, nanometer silica powder and organosilicone, the coating can form the binding of chemical bonds when being coated on the rigid surface of a concrete wall, with the fastness being far superior to that of the physical covering of a conventional coating; in the coating, the expanded perlite is further adopted as heat insulation base material and therefore, the coating is characterized by good waterproof and thermal insulation property, no bubbling and cracking and good adhesive force.

Owner:于士井

High-resistance polymer coating fluid

InactiveCN102382525AExcellent oxygen barrier propertiesEasy to prepareStarch dervative coatingsCellulose coatingsHigh resistancePolymer science

The invention discloses a high-resistance polymer coating fluid which is prepared from the following components of: 6-18 percent by weight of water-soluble high polymer with high hydroxyl density, 0.45-1.2 percent by weight of cross-linking agent, 0-7 percent by weight of nano size metal oxide, 0.01-2.5 percent by weight of viscosity modifier, 0.1-6 percent by weight of polymer dispersant, 0-1.3 percent by weight of coupling agent, 1-28 percent by weight of drying regulator and 40-92.44 percent by weight of water. The multi-component environment-friendly coating fluid prepared in the invention has excellent oxygen resistant performance under the condition that a thinner coating is formed and simultaneously has the advantages of simple preparation process and stable performance.

Owner:GREATVIEW BEIJING TRADING CO LTD

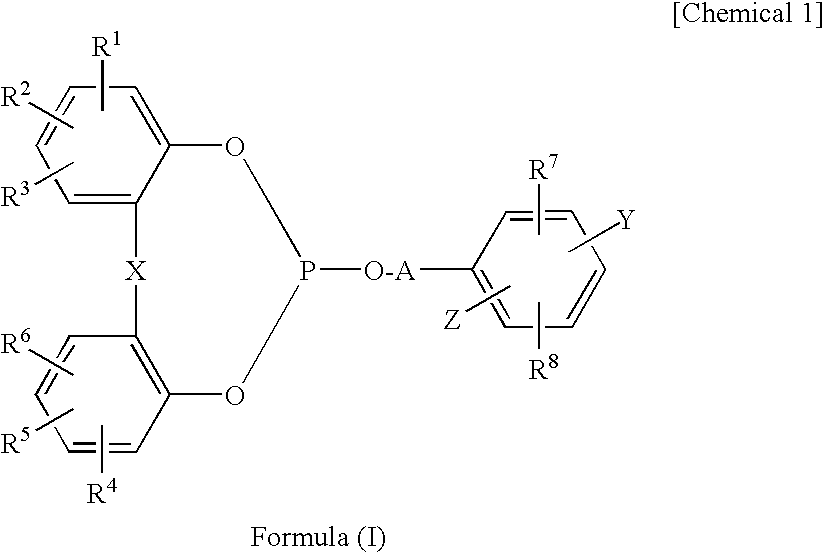

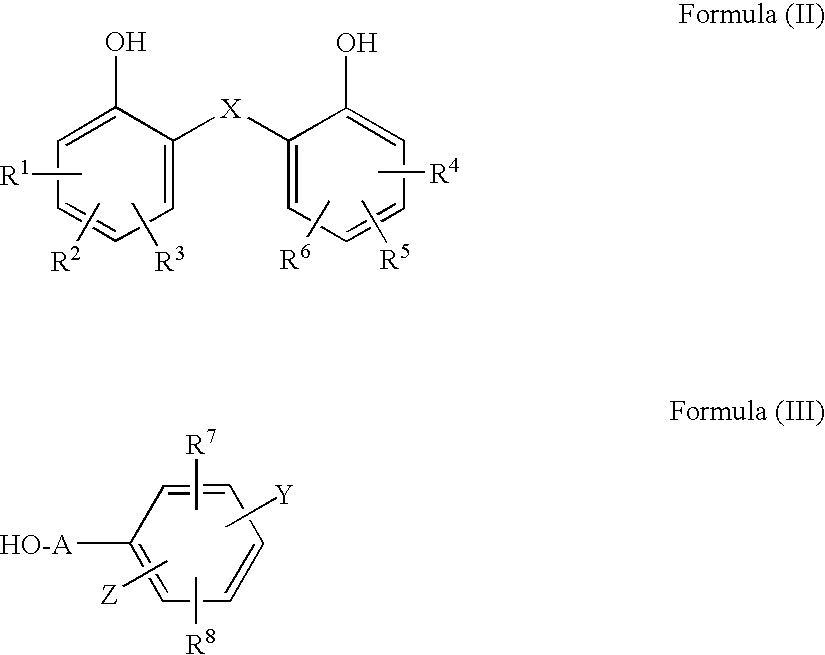

Cellulose Ester Film, Manufacturing Method Thereof, Optical Film, Polarizing Plate and Liquid Crystal Display

InactiveUS20090074989A1Reduce manufacturing burdenReduce burden facility burdenLiquid crystal compositionsSynthetic resin layered productsCellulose ester membraneLiquid-crystal display

An objective is to provide a cellulose ester film which can reduce a manufacturing burden and a facility burden caused by drying and recovering of a solvent used in the production process, a manufacturing method of the cellulose ester film and an optical film, and to specifically provide a polarizing plate employing the optical film as an excellent polarizing plate protective film exhibiting reduced fluctuation of retardation property in the width direction and a liquid crystal display employing the polarizing plate. Also disclosed is a cellulose ester film containing at least one compound having a phenol structure and a phosphite ester structure in a molecule.

Owner:KONICA MINOLTA OPTO

Cellulose acylate film and polarizer

InactiveUS20100040854A1Lower wet heat durabilityReduce heatSynthetic resin layered productsCellulosic plastic layered productsCellulosePolymer science

A cellulose acylate film comprising at least one compound having a negative birefringence and satisfying 30 nm<Re<100 nm and 80 nm<Rth<300 nm is excellent in the wet heat durability of Re and Rth.

Owner:FUJIFILM CORP

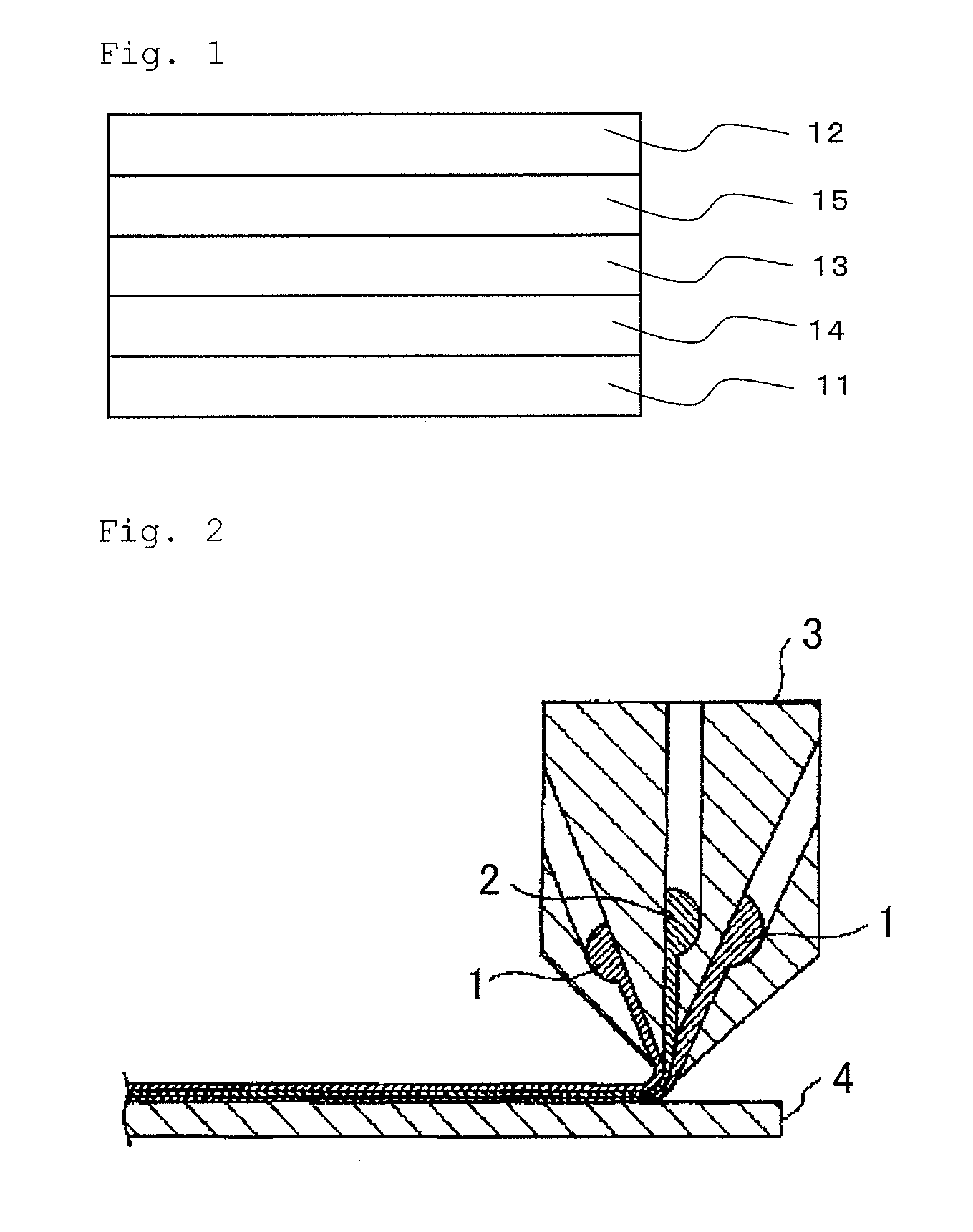

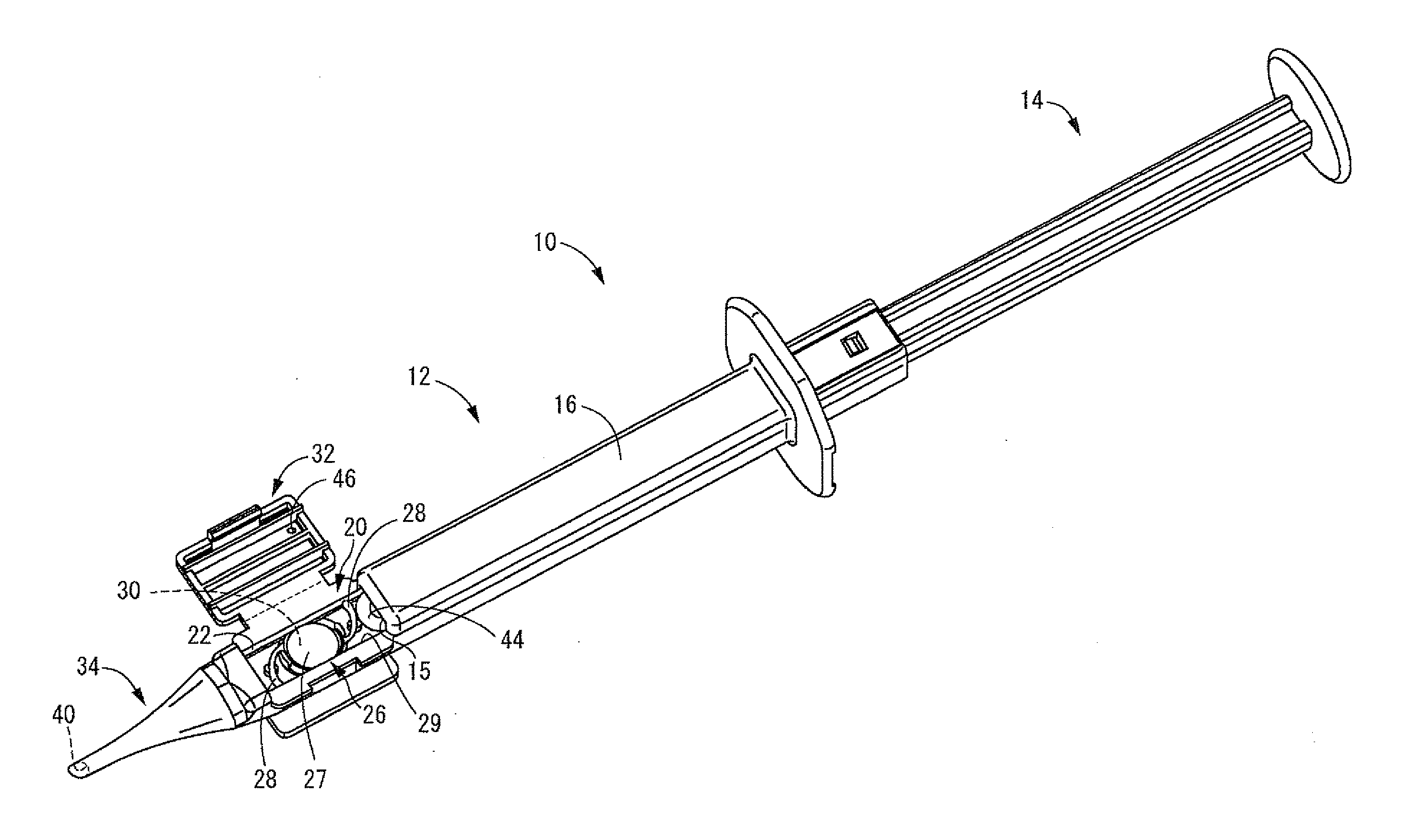

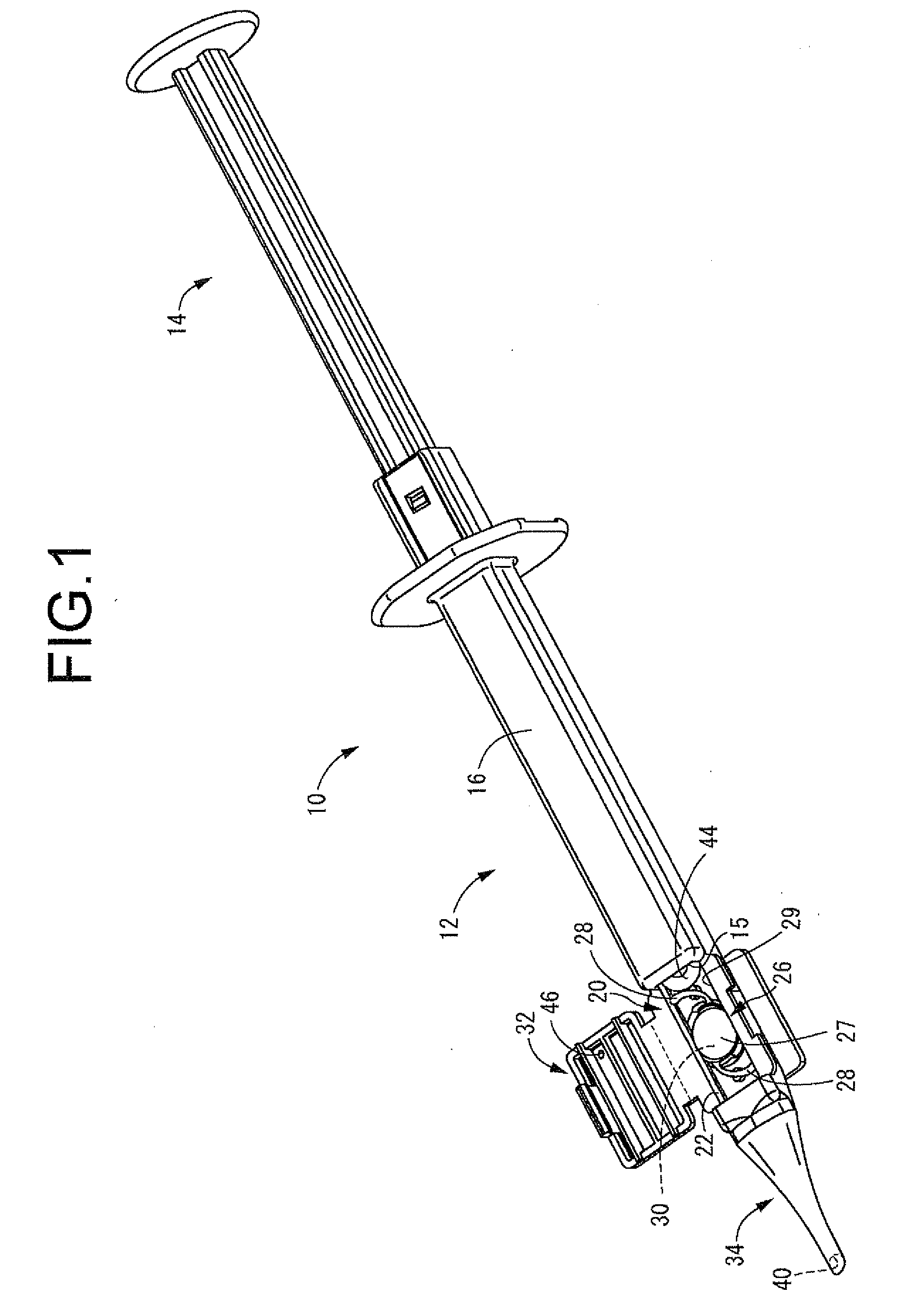

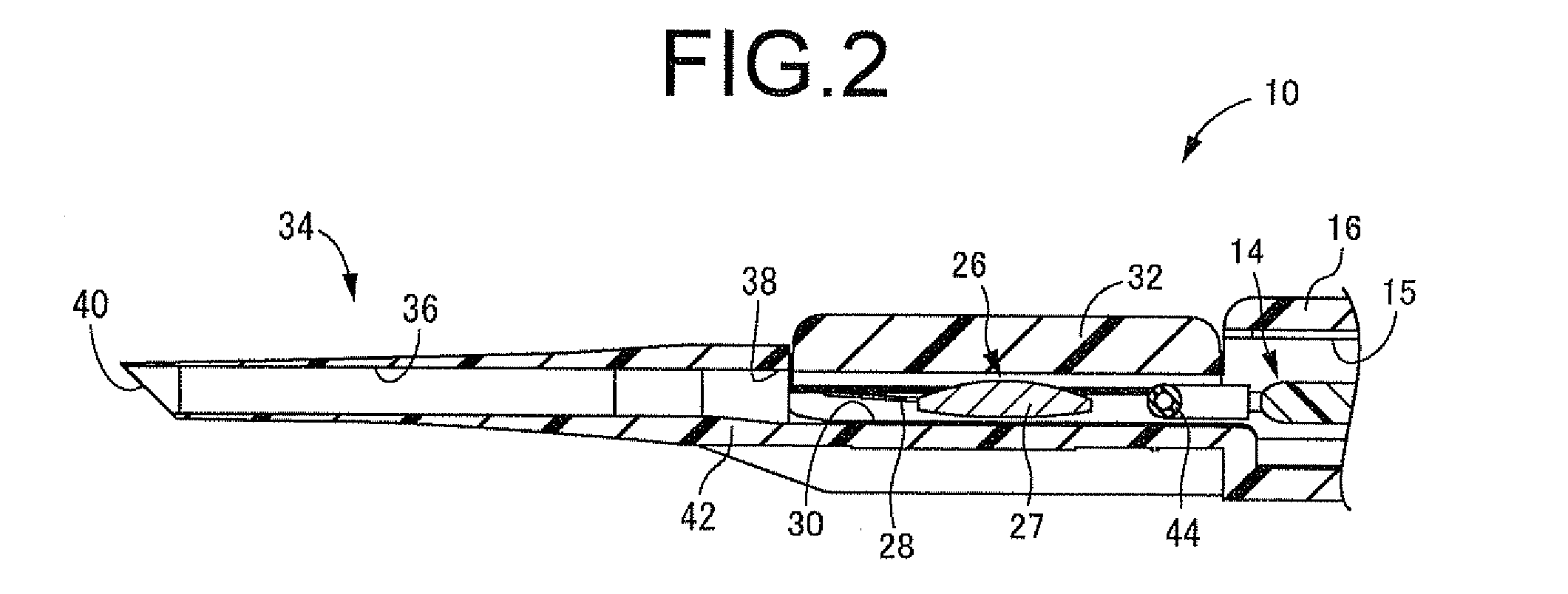

Method of producing medical instrument

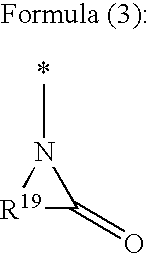

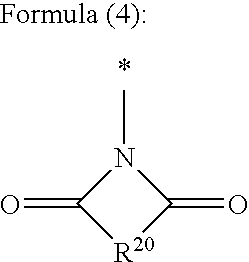

ActiveUS20100312255A1Exceptional hydrophilicityExceptional lubricityEye surgeryPharmaceutical containersChemical reactionWater insoluble

A method of producing a medical instrument whereby a highly hydrophilic and lubricant coating layer having a high durability can be formed by a simple technique and thus highly hydrophilic and lubricant properties can be imparted to a surface of a medical instrument. An intraocular lens insertion instrument having been subjected to a surface treatment as described above is also provided. The method comprises the steps of: preparing a coating solution by mixing at least a water-insoluble polymer having carboxyl group and a polyfunctional reactive compound with an organic solvent; applying this solution on the surface of the medical instrument; conducting crosslinking; and performing a chemical reaction process whereby the coating layer is made hydrophilic. The intraocular lens insertion instrument is made hydrophilic by forming the coating layer as described above on an inner surface of an insertion tube portion, crosslinking and then performing the chemical reaction process.

Owner:KOWA CO LTD

Biopolymer compositions and products thereof

InactiveCN1934181AShort manufacturing timeAmylose/amylopectin coatingsStarch dervative coatingsBiopolymerBio based

This invention relates to biopolymer-based compositions and biopolymer-based formed bodies such as film, sheet, capsule, casing or coating-film or spray thereof. In another embodiment, the invention relates to a process for producing a biopolymer-based starting material and biopolymer-based formed bodies such as cited above, for the manufacture of pharmaceutical, veterinary, food for cosmetic products.

Owner:WARNER LAMBERT CO LLC

Collagen-polysaccharide materials mimicking blood vessels, tissues and bones for medical, pharmaceutical and orthopedic applications, and processes for producing the same

Provided is a collagen-cellulose material containing, based on a total weight of the collagen-cellulose material: 1.0-9.0 wt. % of a collagen; 0.2-3.0 wt. % of cellulose or a derivative thereof; 0.5-6.5 wt. % of at least one acid selected from an inorganic acid, an organic acid, and mixtures thereof; and water. Also provided is a process for producing the collagen-cellulose material. Also provided is an artificial blood vessel containing the collagen-cellulose material which is in the form of a hollow tube, an artificial tissue containing the collagen-cellulose material which is in the form of a sheet, and an artificial bone containing the collagen-cellulose material which is in the form of a solid. Also provided is a medical device containing the collagen-cellulose material, as well as a process for testing phlebotomical, surgical or orthopedic instrumentation or practicing phlebotomical, surgical or orthopedic procedures using the medical device containing the collagen-cellulose material.

Owner:NITTA CASINGS

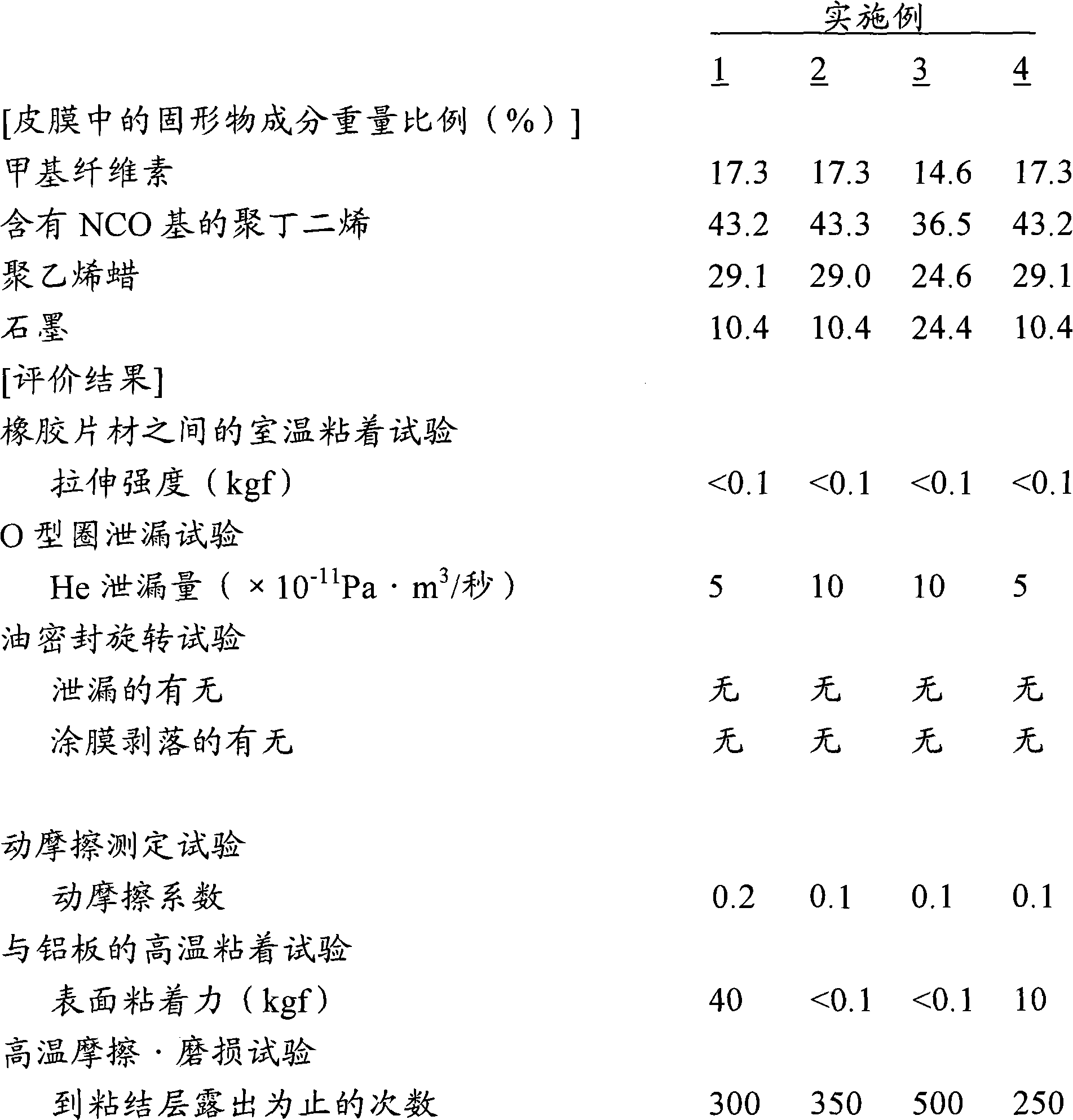

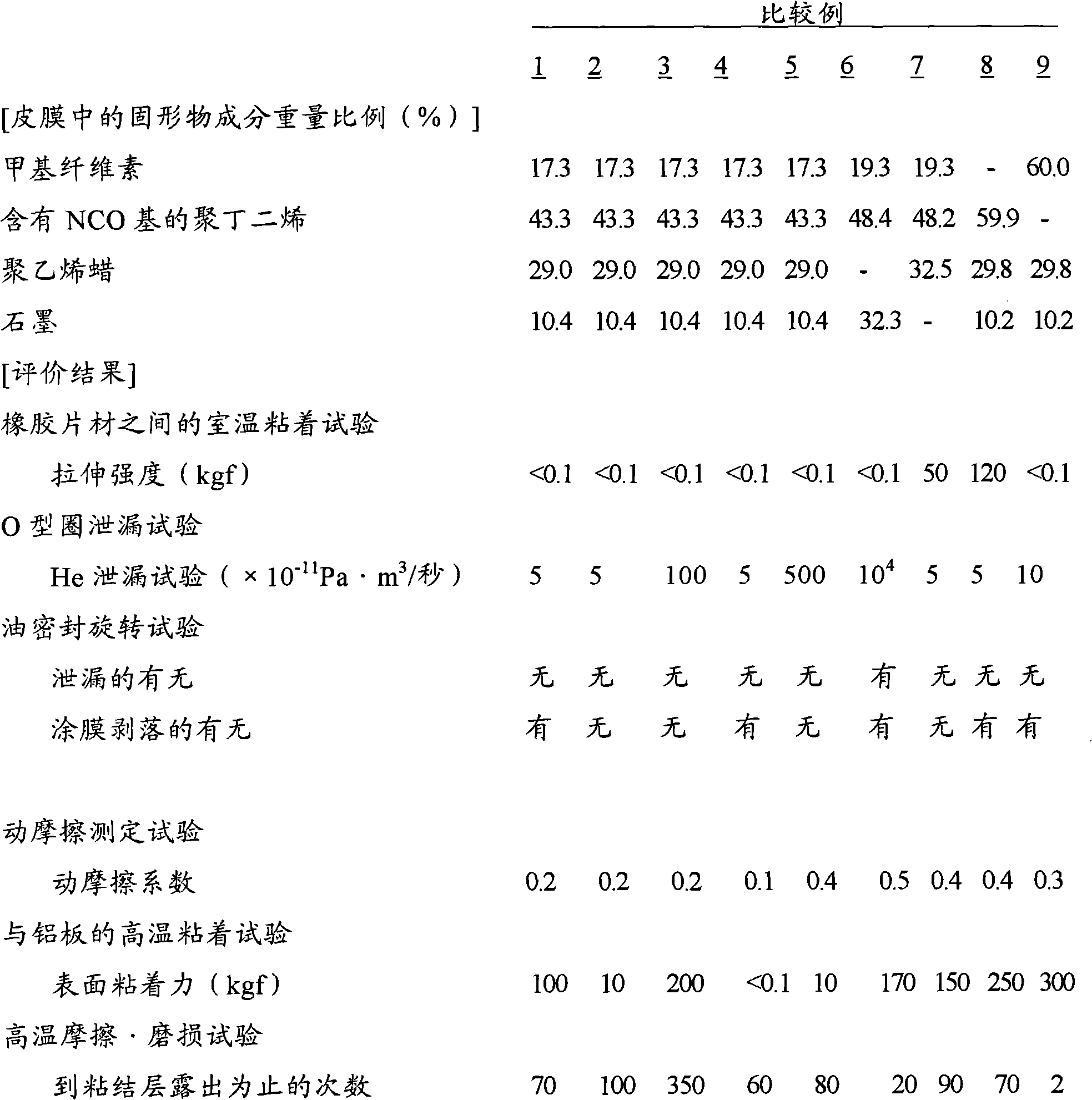

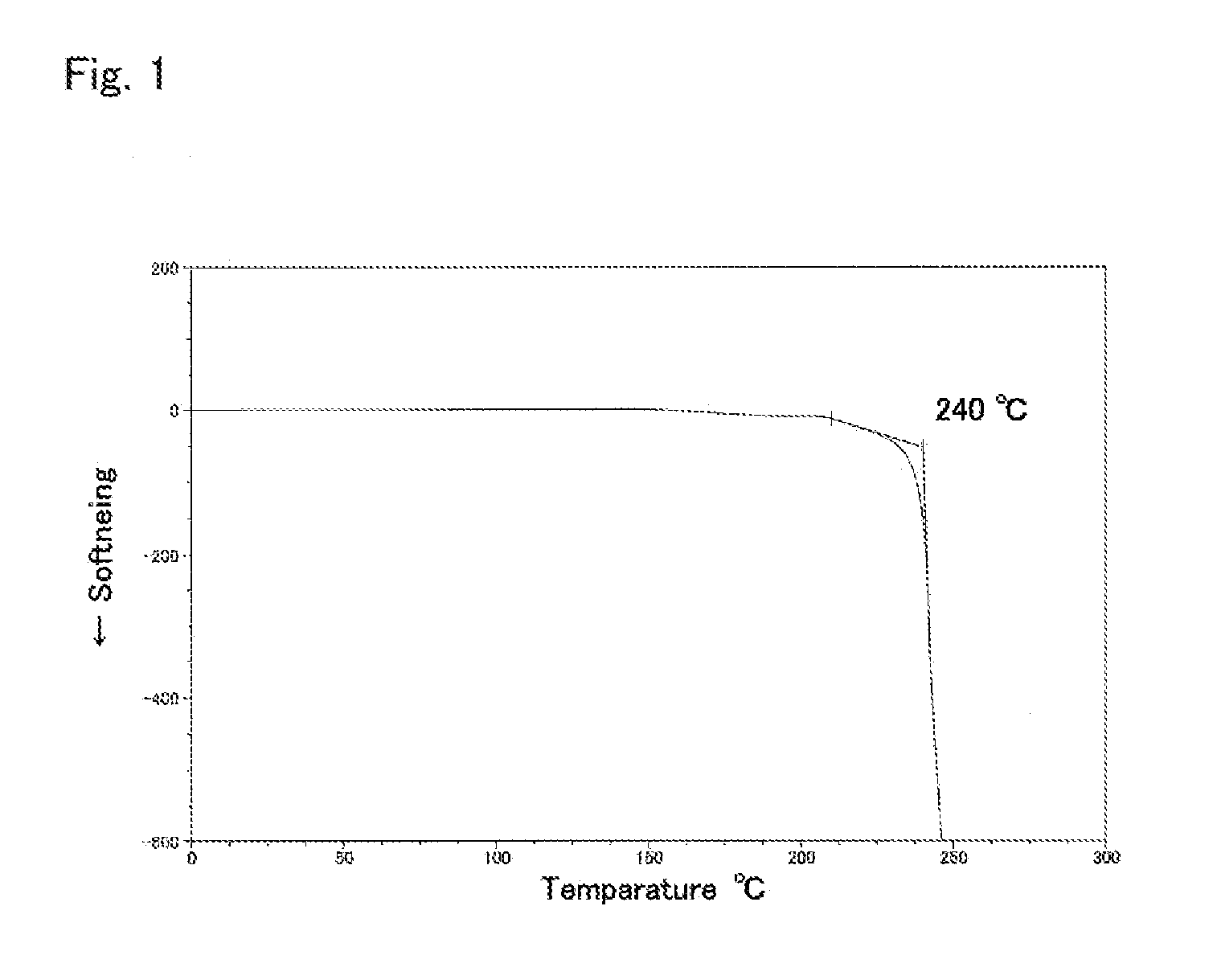

Coating agent

Disclosed is a coating agent comprising a cellulose derivative, a 1,2-polybutadiene having an isocyanate group, a synthetic wax having a softening point of 100 to 150 DEG C, an aliphatic amide having a softening point of 60 to 170 DEG C and graphite. The coating agent has satisfactory levels of properties required for a coating agent for a rubbery elastic material, such as a sticking-preventing property, an adhesion-preventing property, a blocking-preventing property, and improved abrasion resistance. The coating agent can be used as a surface treatment agent for a vulcanized rubber, which does not cause adhesion upon compression at a high temperature or detachment of a coating film by friction / abrasion under a high surface pressure.

Owner:NOK CORP

Coating liquid, coating film, and composite material

ActiveUS20170226365A1Improve adhesionModerate viscosityStarch dervative coatingsElectrode manufacturing processesN dimethylformamide2-Pyrrolidone

There is provided a coating liquid capable of forming a coating film that is excellent in adhesiveness to the surface of a base material such as a metal, glass, or a resin even though the coating film contains PVDF which exhibits a remarkable non-tackiness and that can exhibit various desired functionalities such as non-tackiness, an antifouling property, chemical resistance, a sliding property, water repellency, electrical conductivity, an antifungal / antimicrobial property, and a deodorizing property. The coating liquid contains a polar solvent such as N,N-dimethylformamide or N-methyl-2-pyrrolidone, a hydrophilic polymer such as a chitosan derivative or a cellulose derivative, and polyvinylidene fluoride.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Biodegradable composition, processed biodegradable article such as food container, and method of producing the same

InactiveUS20100236972A1Satisfactory strengthSatisfactory water resistanceTable equipmentsCellulose derivative coatingsFoam food containerPolyol

The present invention provides a processed biodegradable article having excellent water resistance and rigidity, which can be used as a food container, and a biodegradable composition required to produce the processed biodegradable article.The respective components are mixed such that the content of starch is 15% by mass or more and 75% by mass or less, the content of protein is 5% by mass or more and 50% by mass or less, the content of cellulose fiber is 3% by mass or more and 50% by mass or less, the content of polyphenols is 0.5% by mass or more and 20% by mass or less, and the content of sodium chloride is 0% by mass or more and 5% by mass or less, and then water is added in the amount of 10 parts by mass or more and 100 parts by mass or less based on 100 parts by mass of the mixture, followed by kneading the mixture using a mixer. Then, the kneaded mixture is press-molded into a predetermined shape such as a cup or a dish, and heat-treated at 120° C. or higher and 180° C. or lower to obtain a processed article having excellent biodegradability.

Owner:NUCLEAR ENG

Shrink wrap label coating to facilitate recycling

ActiveUS20160200942A1Improve sealingEfficient de-seaming and removalDecorative surface effectsDuplicating/marking methodsEngineeringShrink wrap

The present invention discloses a method of enabling the easy separation of labels, including wrap around labels and sleeve labels, particularly shrink sleeve labels, from containers during recycling through the use of a specially formulated coating to be applied in the seam area. The coatings ensure proper bonding, and shrink properties, of the labels, and have been designed to help de-bonding of the seam in a hot caustic wash step, or a solvent wash step. The method does not rely on floatation separation and therefore may be applied to any container / label material combination regardless of their specific gravity differences.

Owner:SUN CHEM CORP

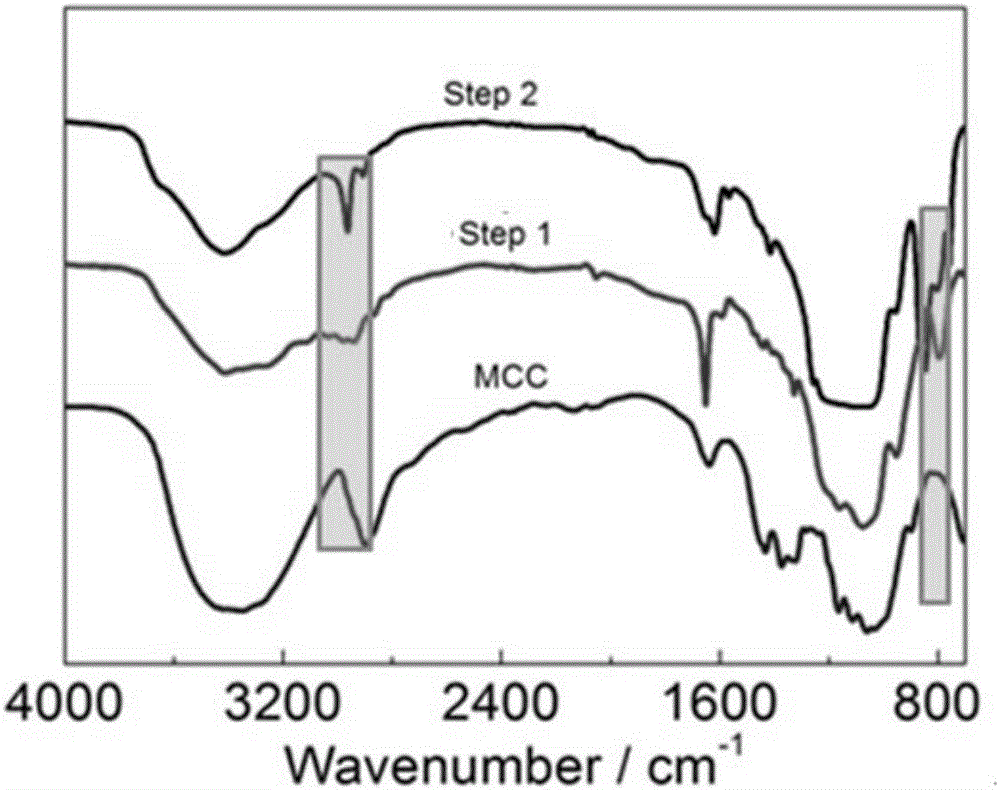

Super-oleophilicity hydrophobic material and preparation method and application thereof

ActiveCN106633112ASolve pollutionReduce usageOther chemical processesWater contaminantsHydrolysateSolvent

The invention discloses a super-oleophilicity hydrophobic material and a preparation method and application thereof. The preparation method for the hydrophobic material comprises the following steps: I, dissolving and activating microcrystalline cellulose by carbon-dioxide-based reversible ion liquid; II, preparing silane hydrolysate; III, adding cellulose solution to the hydrolysate, modifying the cellulose under the catalysis of ion liquid; IV, filtering, washing and drying the product, repeatedly using the solvent; and V, grinding solid and dispersing in ethanol solution. The dispersion liquid is sprayed to filter paper for oil-water filtering separation, the separation efficiency is more than 95%, and the organic pollutant in the water can be adsorbed. The normal sponge is soaked in the dispersion liquid for adsorbing the oil in the water. The surface contact angel of the filter paper prepared by the method is 165 degrees, and the rolling angle is smaller than 3 degrees. The whole raw material is green and environmental, and the preparation process is simple and efficient.

Owner:RENMIN UNIVERSITY OF CHINA

Transparent Substrate

InactiveUS20130184380A1Low coefficient of linear expansionHigh light transmittanceCosmetic preparationsImpression capsMoisture permeabilityOptical transmittance

The present invention provides a formed article, or more specifically a transparent substrate, which effectively utilizes a natural stuff and which has a low linear expansion coefficient, a high light transmittance and an appropriate level of moisture permeability. The transparent substrate includes at least an oxidized polysaccharide and has a linear expansion coefficient of 50 ppm / ° C. or less at 30-150° C. and a light transmittance of 70% or more at 660 nm. Its manufacturing method includes an oxidation process in which cellulose reacts with TEMPO or its derivatives as a catalyst to be oxidized in water under the presence of a co-oxidant, along with a fiberizing process in which the oxidized cellulose is fiberized in water to form a cellulose fiber, and a substrate-forming process in which a transparent substrate is formed from a cellulose dispersion liquid containing the cellulose fiber.

Owner:TOPPAN PRINTING CO LTD

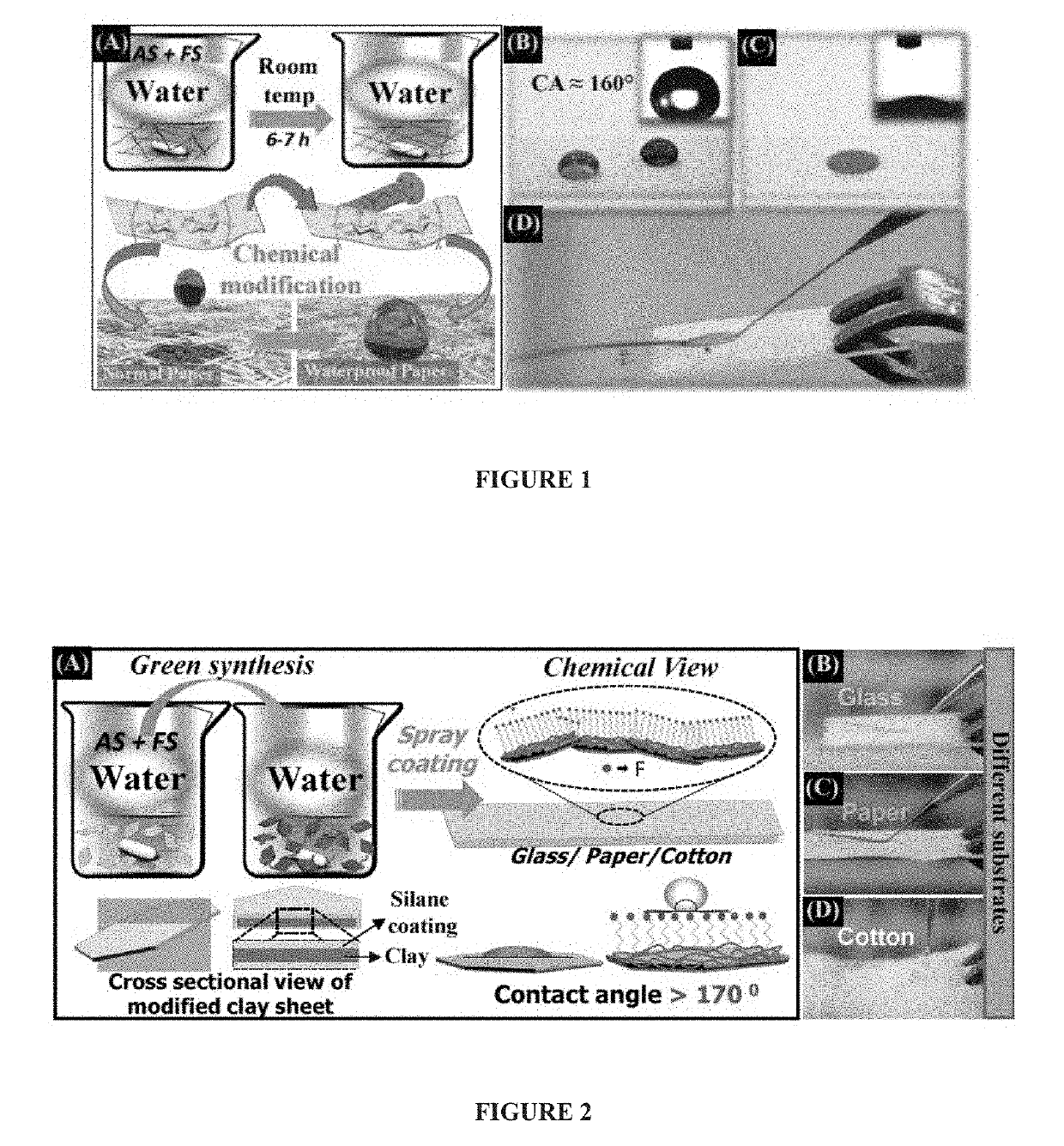

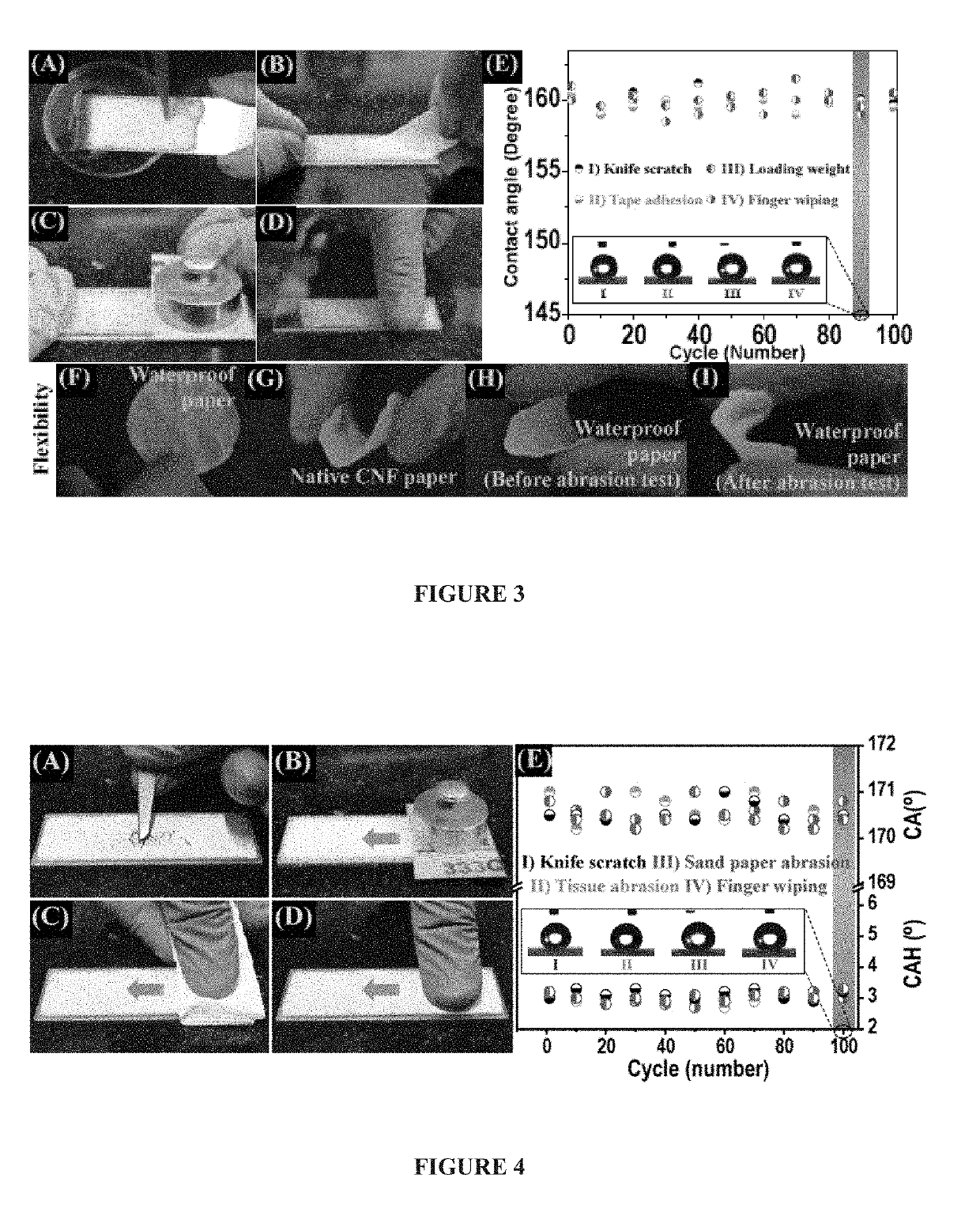

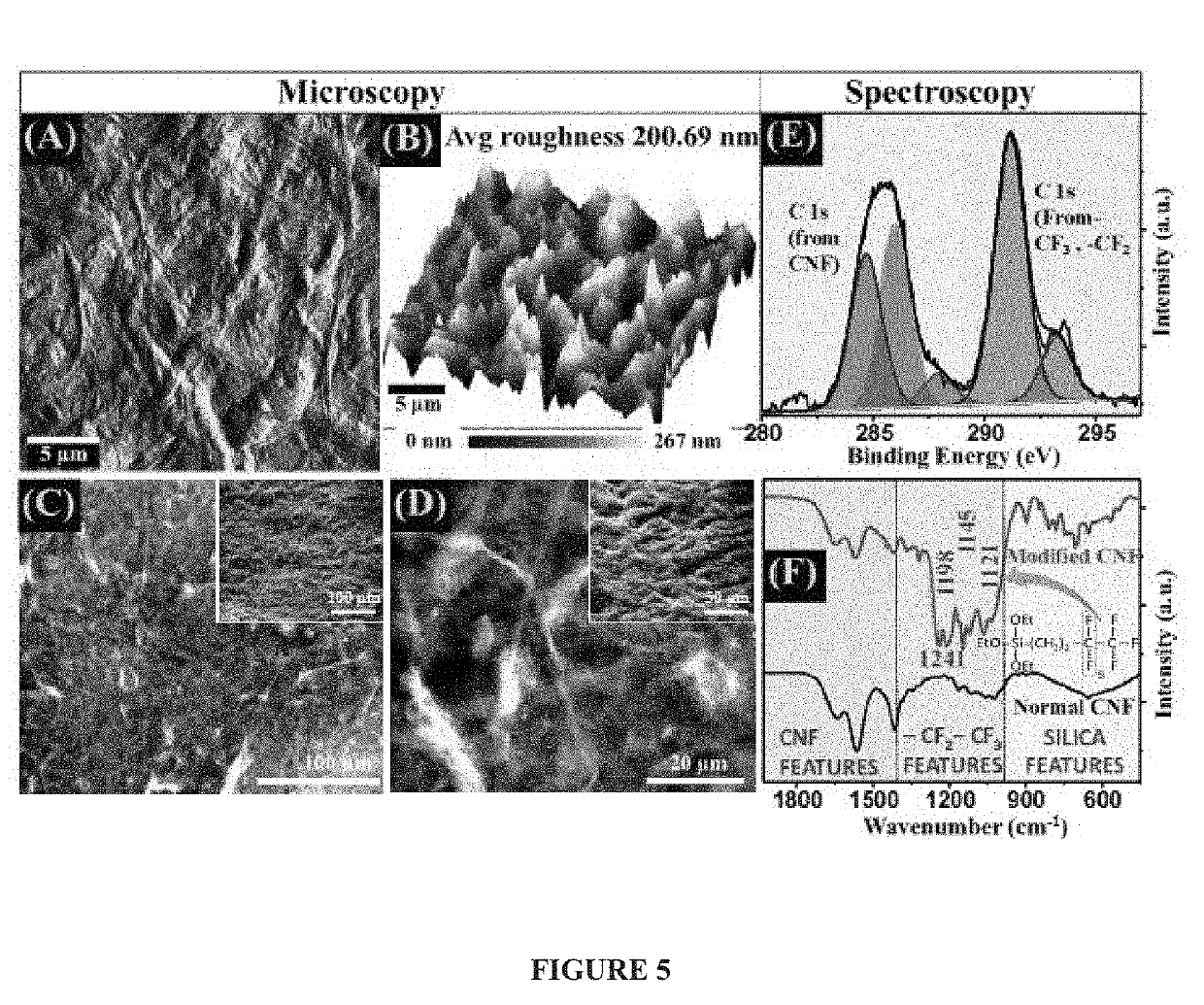

Aqueous composition and a method of producing durable and extremely efficient water repelling superhydrophobic materials at ambient condition thereof

ActiveUS20190112494A1Robust natureThermal stabilityCellulose coatingsCellulose derivative coatingsWater basedFiber

The present invention relates to adurable and multifunctional superhydrophobic coating composition and water based fabrication method of producing the durable and multifunctional superhydrophobic coating composition via chemical modification and functionalization of hydrophilic material by silanes under room temperature without any organic solvents. Synthesis of chemically modified cellulose nanofibers or clay in water forms excellent water repelling thin films upon coating over various substrates. The super hydrophobic materials are used as additive for paints, pigments, paper, varnish and, textile and used for various industrial applications such as construction of buildings and other super structures.

Owner:INDIAN INST OF TECH MADRAS

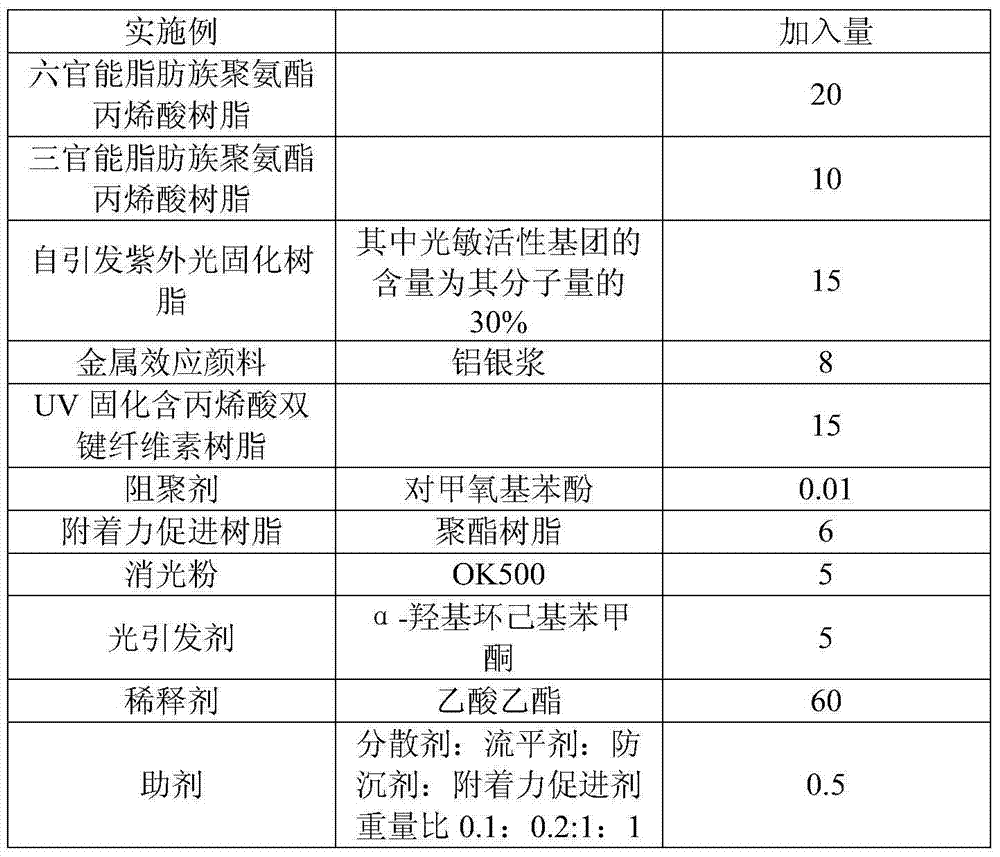

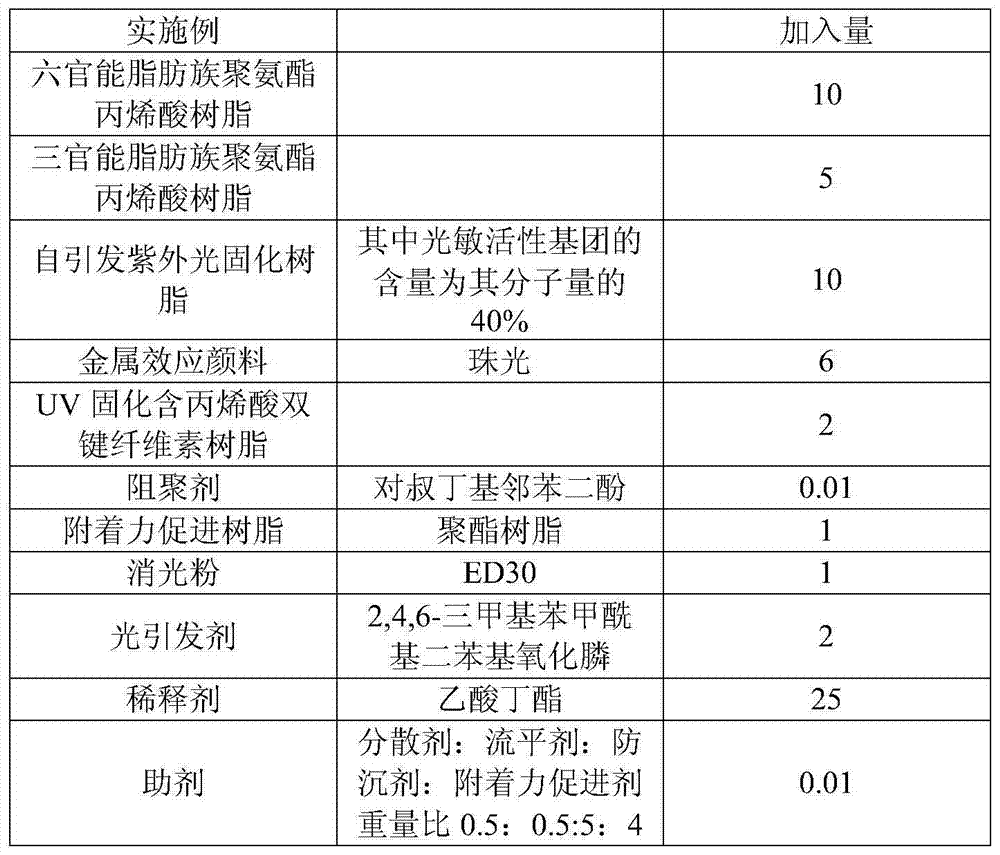

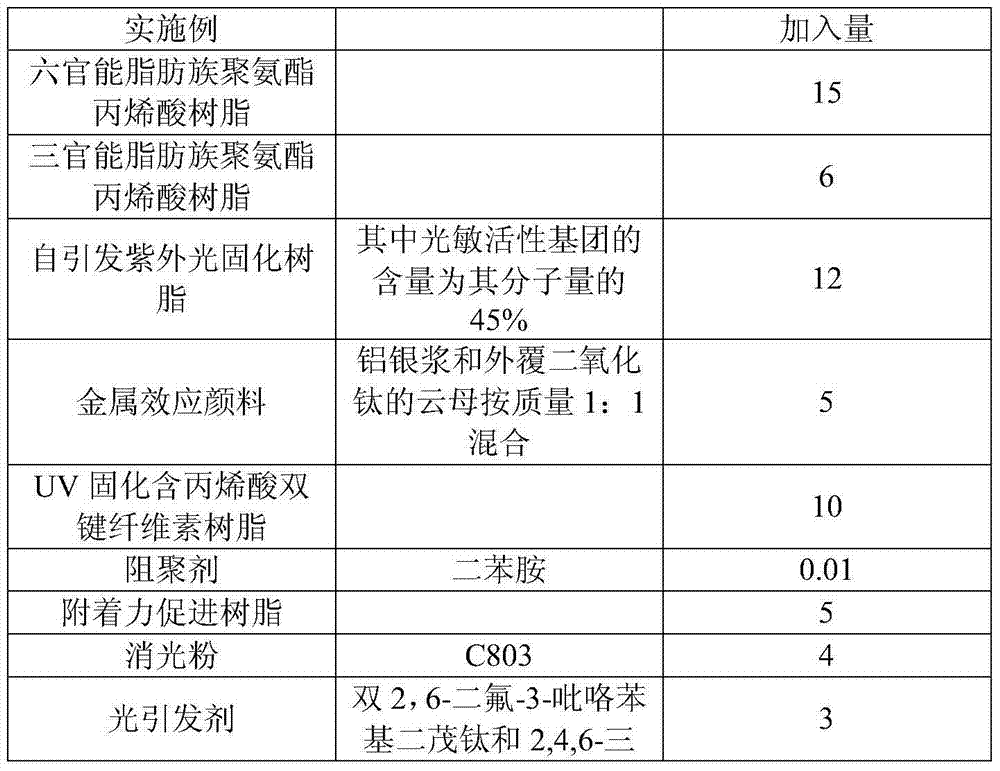

Ultraviolet curing coating raw material and coating prepared from same

ActiveCN104726014AIncrease crosslink densityPrevent flocculationCellulose derivative coatingsPolyurea/polyurethane coatingsCross-linkAcrylic resin

The invention provides an ultraviolet curing coating raw material and a coating prepared from same. The ultraviolet curing coating raw material comprises the following components in parts by weight: 10-20 parts of six-functional aliphatic polyurethane acrylic resin, 5-10 parts of three-functional aliphatic polyurethane acrylic resin, 10-15 parts of self-initialized ultraviolet curing resin, 2-8 parts of metal effect pigment, 2-15 parts of UV cured crylic acid double-bond celluosic resin, 0.01 part of a polymerization inhibitor, 1-6 parts of adhesion property prompting resin, 5 parts of extinction powder, 2-5 parts of a photoinitiator, 25-60 parts of a diluent and 0.01-0.5 part of an additive, wherein the self-initialized ultraviolet curing resin is DRE-527 purchased in Changxin in Taiwan. Due to addition of acrylic monomers, the reaction speed of the pigment with metallic effects and the acrylic monomers can be increased due to the groups in the acrylic monomers, and due to cross-linking reaction of the UV cured crylic acid double-bond celluosic resin with a double-bond orientation function and the UV resin with double bonds, the cross-linking density of the coating can be improved; due to addition of the polymerization inhibitor, problems such as flocculation and retrogradation can be solved when the coating is stored.

Owner:HUNAN SOKAN NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com