Super-oleophilicity hydrophobic material and preparation method and application thereof

A hydrophobic material and hydrophobic technology, applied in the field of materials, can solve the problems of large raw material pollution, secondary pollution, and metal content, and achieve the effects of simple preparation process, good tolerance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

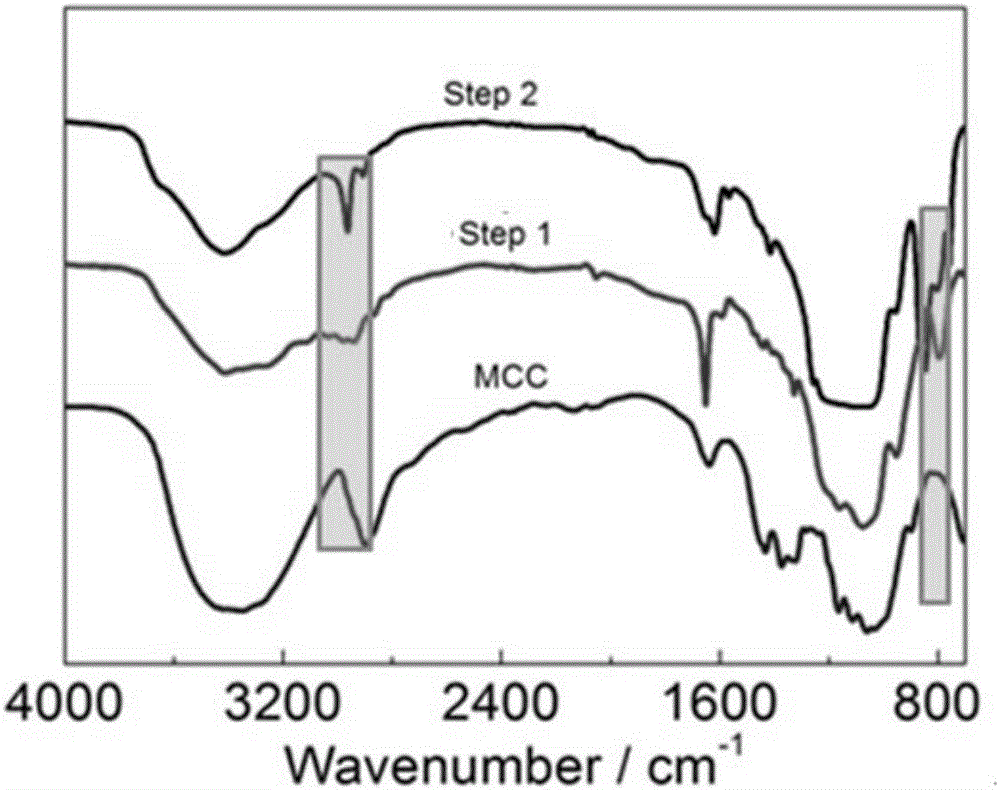

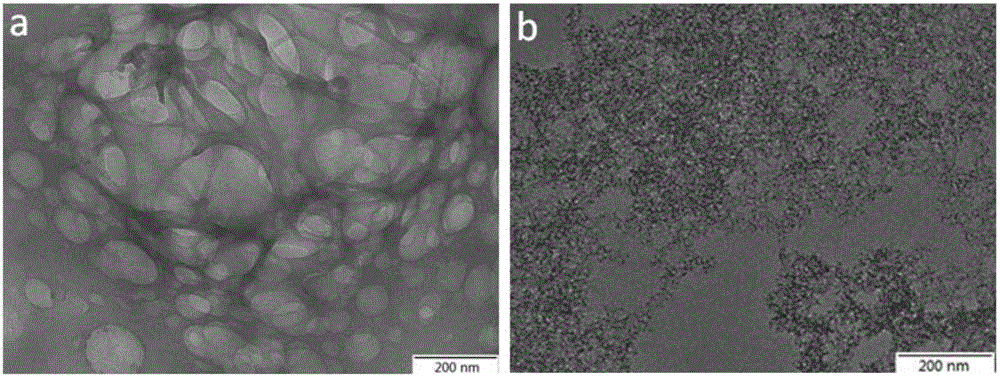

[0073] 1. Dissolving and activating microcrystalline cellulose (MCC) with carbon dioxide-based reversible ionic liquid: First, add 0.08g of MCC powder to 1mL containing 1,8-diazabicycloundec-7-ene (DBU) and Dimethyl sulfoxide (DMSO) mixed solution (the mass ratio of the mixed solution is 10:90), and then the solution was transferred to a reaction kettle, and the reaction kettle was placed in a constant temperature water bath at 40°C. After that, introduce 0.2MPa CO 2 The gas is sealed, and the activation reaction is carried out by stirring for 1 hour to obtain a light yellow transparent solution, that is, a cellulose solution.

[0074] 2. Preparation of silane hydrolyzate: prepare 30ml of tetraethoxysilane (TEOS) ethanol solution (2:3 by volume), 30ml of ammonia water and ethanol solution (1:1 by volume), and mix them in a certain proportion to make TEOS at room temperature After the polycondensation reaction occurred for 10 minutes, 5 ml of hydrochloric acid solution (concen...

Embodiment 2

[0080] The difference between this example and Example 1 is that the reversible ionic liquid DBU described in step 1 can be replaced by tetramethylguanidine (TMG). Others are the same as in Embodiment 1.

[0081] The structural formula of tetramethylguanidine (TMG) is as follows:

[0082]

Embodiment 3

[0084] This embodiment is different from embodiment 1 in that: the washing solvent described in step 4 is replaced by methanol or ethanol. Others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com