Method for manufacturing mobile phone middle frame and structure of mobile phone middle frame

A technology for a middle frame of a mobile phone and a manufacturing method, which is applied to the structure of the phone and other directions, can solve the problems of high cost and easy peeling of paint on the outer surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

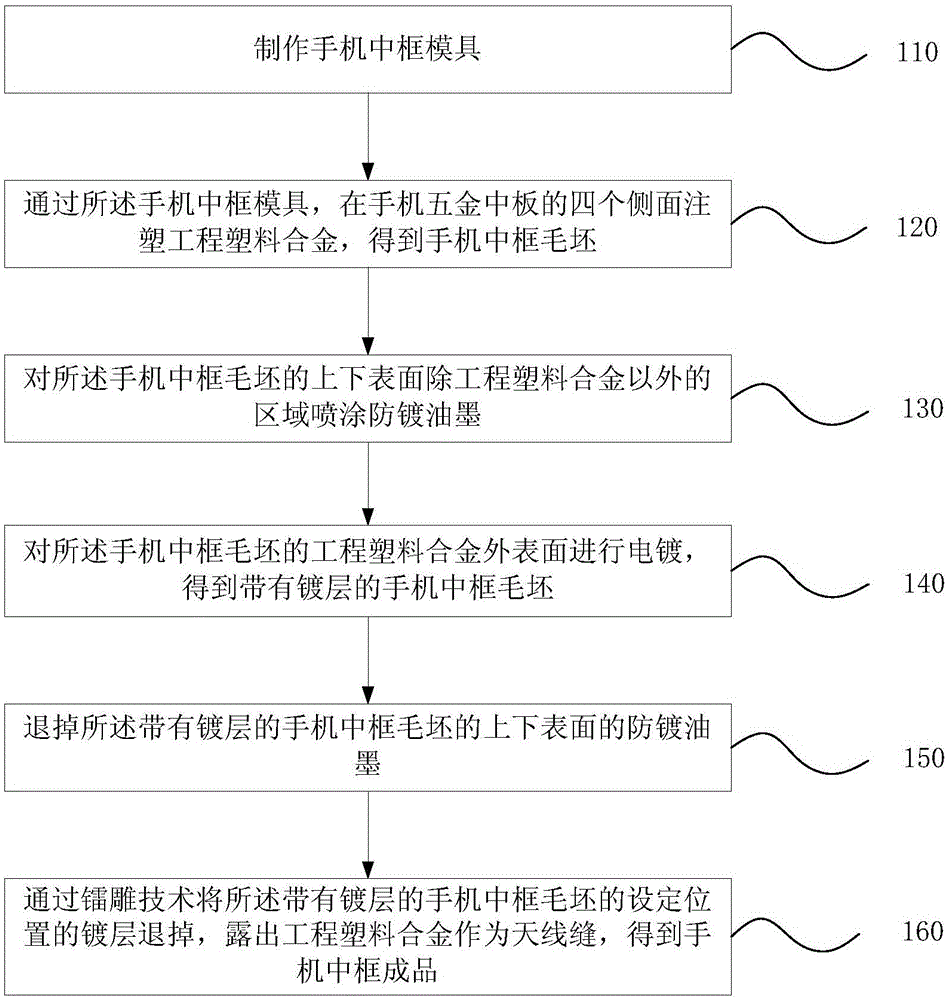

[0023] figure 1 It is a flowchart of a method for making a mobile phone middle frame provided by Embodiment 1 of the present invention. This embodiment is applicable to the case of making a mobile phone middle frame, and specifically includes the following steps:

[0024] Step 110, making a mobile phone middle frame mold;

[0025] The mobile phone middle frame includes the mobile phone hardware middle plate and the plastic outer frame around the mobile phone hardware middle plate. Before injection molding, the mobile phone middle frame mold is made into the shape of the mobile phone middle frame. The mobile phone middle frame mold is used to inject engineering plastic alloy on the four sides of the mobile phone hardware middle plate to form the plastic outer frame of the mobile phone middle frame. Specifically, during injection molding, put the prepared mobile phone middle frame mold into the injection molding machine, then put the mobile phone hardware middle plate into the ...

Embodiment 2

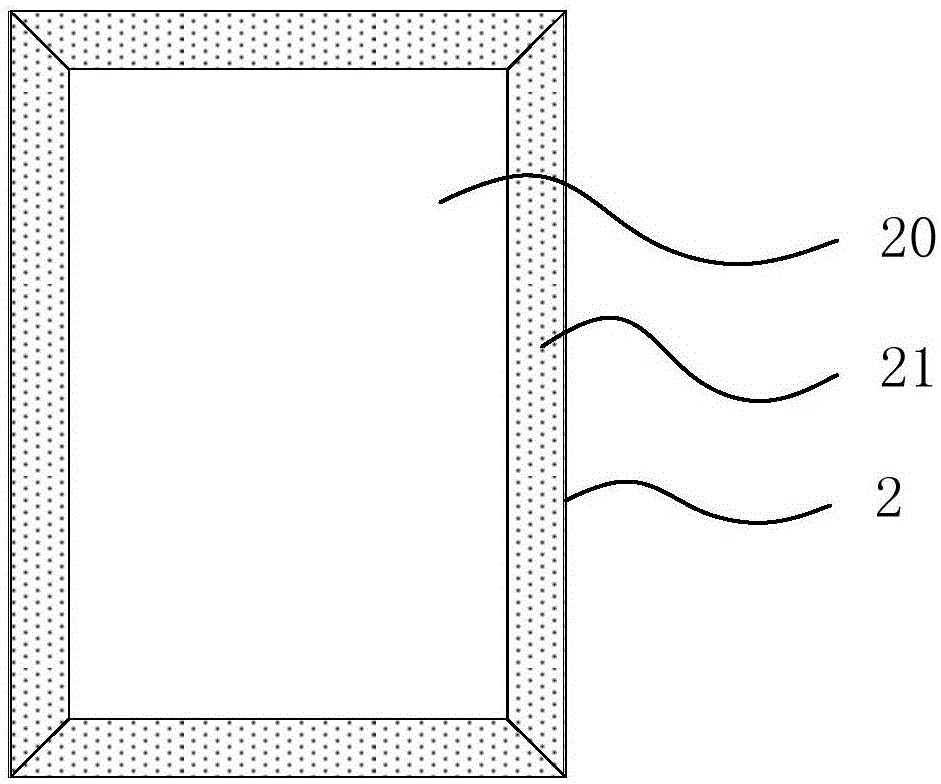

[0057] image 3 It is a cross-sectional schematic diagram of a mobile phone middle frame structure provided in Embodiment 2 of the present invention. This embodiment provides a mobile phone middle frame structure, and the mobile phone middle frame structure is made by using any one of the mobile phone middle frames provided in Embodiment 1. methods, including:

[0058] The mobile phone hardware middle plate 20, the engineering plastic alloy 21 injected on the four sides of the mobile phone hardware middle plate 20, the coating 23 formed by electroplating on the outer surface of the engineering plastic alloy, and the antenna slit 24 formed by radium carving the coating 23 at the set position. Specifically, the above components together constitute the finished product 6 of the middle frame of the mobile phone.

[0059] In the technical solution of this embodiment, the engineering plastic alloy is injected on the four sides of the mobile phone hardware middle plate, and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com