A kind of drawing pencil without charcoal drawing core and preparation method thereof

A charcoal drawing core and charcoal technology, applied in non-moving pencils, printing, writing utensils, etc., can solve the problems of poor combination of UV paint and graphite core, complicated preparation process and process, and no good results are achieved, so as to save Wood, low cost, waste prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

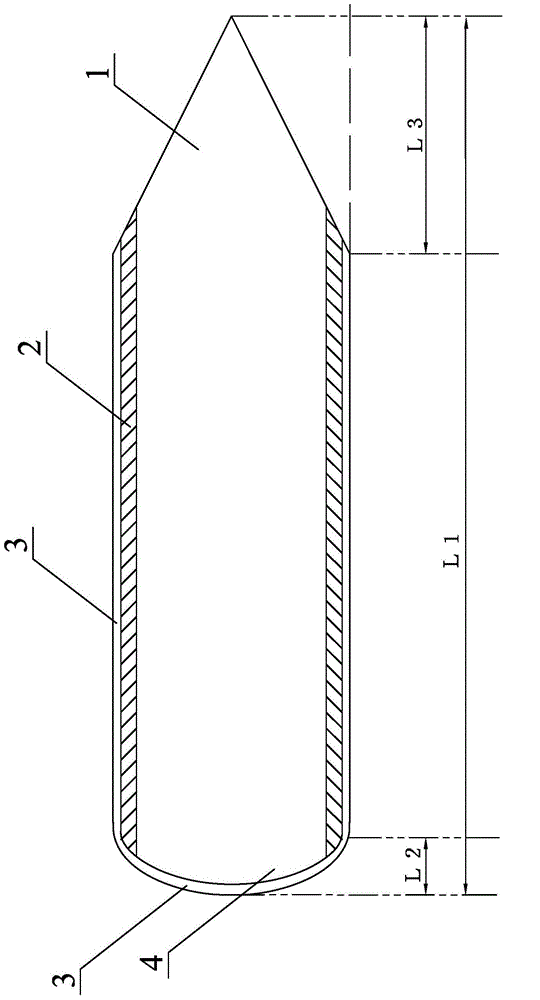

[0036] like figure 1 Shown, a kind of drawing pencil without charcoal drawing core, comprises charcoal drawing core 1, is coated with primer layer 2 on the side of described charcoal drawing core 1, is also coated with UV paint layer on described primer layer 2 3.

[0037] The above scheme has been able to achieve the advantages of making the drawing pencil without charcoal core draw with high gloss, beautiful appearance, good leveling, environmental protection, good surface corrosion resistance, not easy to drop paint, and scratch resistance. The following is given on the basis of this scheme. Preferred solution:

[0038] The charcoal painting core 1 is a cylinder with a length of 140-150 mm and a diameter of 7.40 mm. One end of the charcoal painting core 4 is a conical tip, and the surface of the arc-shaped top 4 is coated with UV paint. Layer 3, the primer layer 2 is nitro paint with a thickness of 0.08mm; the thickness of the UV paint layer 3 is 0.03mm.

Embodiment 2

[0040] A method for preparing a charcoal-free lead drawing pencil, comprising the steps of:

[0041] Step (A), preparing charcoal drawing core 1, specifically includes the following steps:

[0042] (a) Press the washed clay to a water content of 50%, then dry it and micronize it into a clay powder of more than 500 meshes, then press it with 600 mesh charcoal, 1600 mesh superfine talcum powder, and 800 mesh high-pigment carbon black. Add a mass ratio of 2:3:3:2 into a 1000L kneader for kneading, and knead for 8 hours to form a uniformly mixed dry powder;

[0043] (b) Put the uniformly mixed dry powder into a 1000L kneader, add water of the same quality as the uniformly mixed dry powder and knead for 24 hours, and when the core material with a water content of 30% is obtained, stop kneading and discharge the material for sealed storage Grind with a three-roller grinder after 24 hours, and grind continuously for 15 times to make the thickness of the core material reach 80 μm;

...

Embodiment 3

[0049] A method for preparing a charcoal-free lead drawing pencil, comprising the steps of:

[0050] Step (A), preparing charcoal drawing core 1, specifically includes the following steps:

[0051] (a) Press the washed clay to a water content of 55%, then dry it and micronize it into a clay powder of more than 500 meshes, then press it with 600 mesh charcoal, 1600 mesh superfine talcum powder, and 800 mesh high-pigment carbon black. The mass ratio is 2:3:3:2 and kneaded in a 1000L kneader, and kneaded for 8 hours to form a uniformly mixed dry powder;

[0052] (b) Put the uniformly mixed dry powder into a 1000L kneader, add water of the same quality as the uniformly mixed dry powder and knead for 24 hours, and when the core material with a water content of 35% is obtained, stop kneading and discharge the material for sealed storage Grind with a three-roller grinder after 24 hours, and grind 15 times continuously to make the thickness of the core material reach 100 μm;

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com