Waterborne amino stoving varnish for stainless steel vacuum cup and preparation method of waterborne amino stoving varnish

A technology of amino baking paint and thermos cup, applied in primers, coatings, epoxy resin coatings, etc., can solve the problems of paint surface wear, poor paint film adhesion, strong smell, etc., to achieve broad market prospects and improve adhesion , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

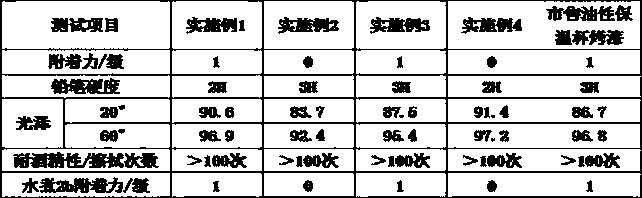

Examples

Embodiment 1

[0031] The water-based amino baking varnish of the stainless steel thermos cup in this embodiment includes a water-based amino baking varnish primer and a water-based amino baking varnish top coat.

[0032] The water-based amino baking varnish primer is composed of the following raw materials in parts by mass: 50 parts of epoxy hybrid acrylic resin dispersion; 0.3 parts of neutralizer; 3 parts of cosolvent; 5 parts of amino resin; 5 parts of blocked isocyanate; 35 parts of pigment concentrate; 2 parts of adhesion promoter; 0.1 part of wetting agent; 0.1 part of defoamer; 0.2 parts of blocked acid catalyst; 0.1 part of thickener. No water was added to the raw material of the primer in this embodiment.

[0033] Wherein, the water-based pigment concentrated slurry is water-based titanium white slurry. The water-based titanium dioxide slurry is composed of the following raw materials in parts by mass: 21 parts of water; 8 parts of dispersant; 1 part of fumed silica; 0.05 parts of...

Embodiment 2

[0045] The water-based amino baking varnish of the stainless steel thermos cup in this embodiment includes a water-based amino baking varnish primer and a water-based amino baking varnish top coat.

[0046] The water-based amino baking varnish primer is composed of the following raw materials in parts by mass: 65 parts of epoxy hybrid acrylic resin dispersion; 0.5 parts of neutralizer; 6 parts of water; 5 parts of cosolvent; 6.5 parts of amino resin; blocked isocyanate 2 parts; 10 parts of water-based pigment concentrate; 3 parts of adhesion promoter; 0.3 parts of wetting agent; 0.2 parts of defoamer; 0.4 parts of blocked acid catalyst; 1 part of thickener.

[0047] Wherein, the water-based pigment concentrated slurry is water-based scarlet slurry. The water-based scarlet pulp is composed of the following raw materials in parts by mass: 39.5 parts of water; 0.3 parts of a neutralizer; 15 parts of a dispersant; 0.5 parts of fumed silicon dioxide; 0.2 parts of a defoamer;

[00...

Embodiment 3

[0060] The water-based amino baking varnish of the stainless steel thermos cup in this embodiment includes a water-based amino baking varnish primer and a water-based amino baking varnish top coat.

[0061] The water-based amino baking varnish primer is composed of the following raw materials in parts by mass: 55 parts of epoxy hybrid acrylic resin dispersion; 0.4 parts of neutralizer; 10 parts of water; 5 parts of cosolvent; 8 parts of amino resin; blocked isocyanate 3 parts; 12 parts of water-based pigment concentrate; 5 parts of adhesion promoter; 0.5 parts of wetting agent; 0.3 parts of defoamer; 0.5 parts of blocked acid catalyst; 0.7 parts of thickener.

[0062] Wherein, the water-based pigment concentrated slurry is a water-based organic medium yellow slurry. The water-based organic medium yellow paste is composed of the following raw materials in parts by mass: 43.95 parts of water; 0.6 parts of neutralizer; 15 parts of dispersant; 0.3 parts of fumed silica; 0.15 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com