Spring mounting tooling of semi-automatic spring mounting machine for shock absorber and spring mounting method of spring mounting tooling

A shock absorber, semi-automatic technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of limited spring loading compression stroke, low spring spring head position rate, low spring loading efficiency, etc. The area is increased, the assembly is guaranteed to be in place, and the paint is not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

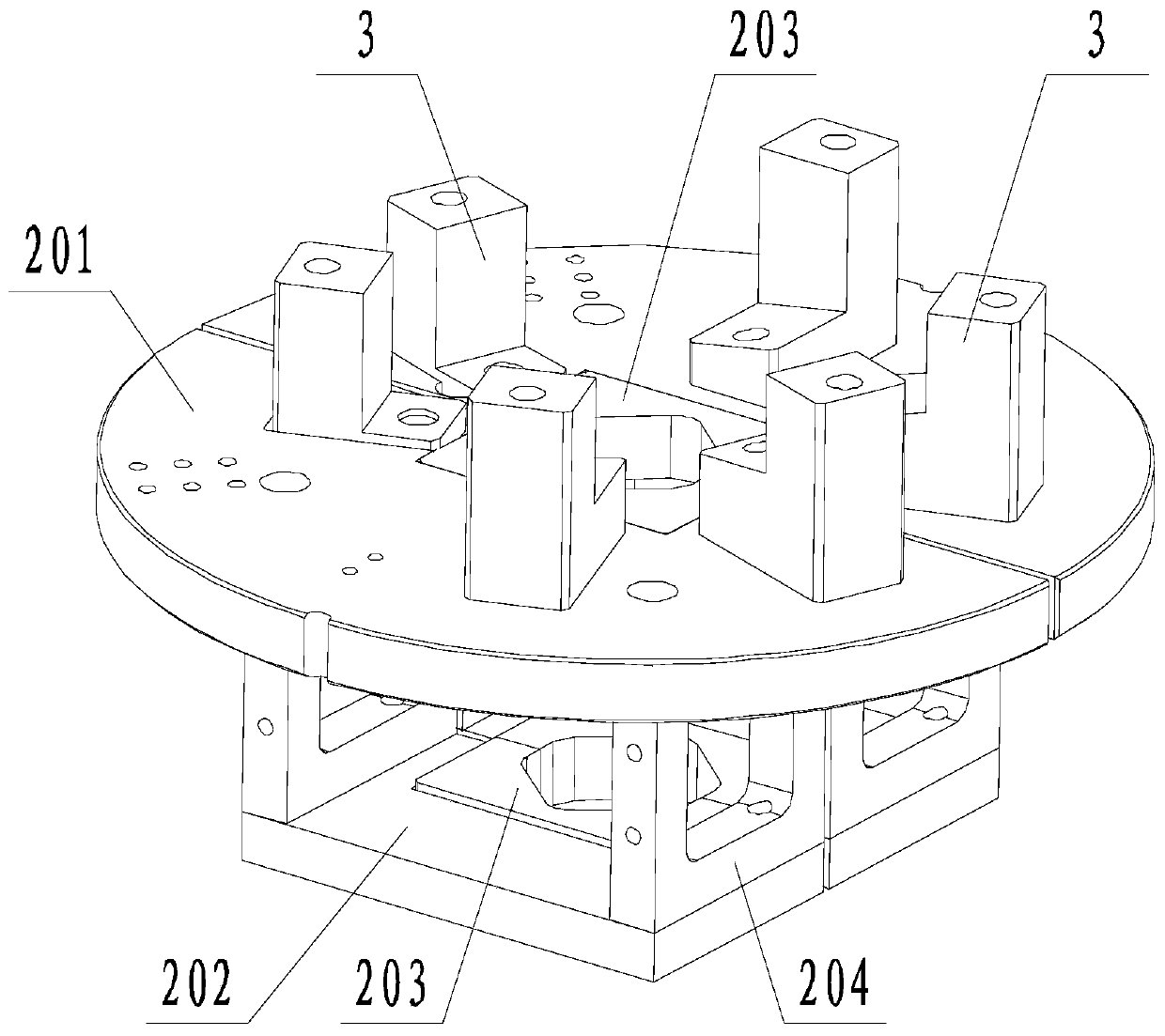

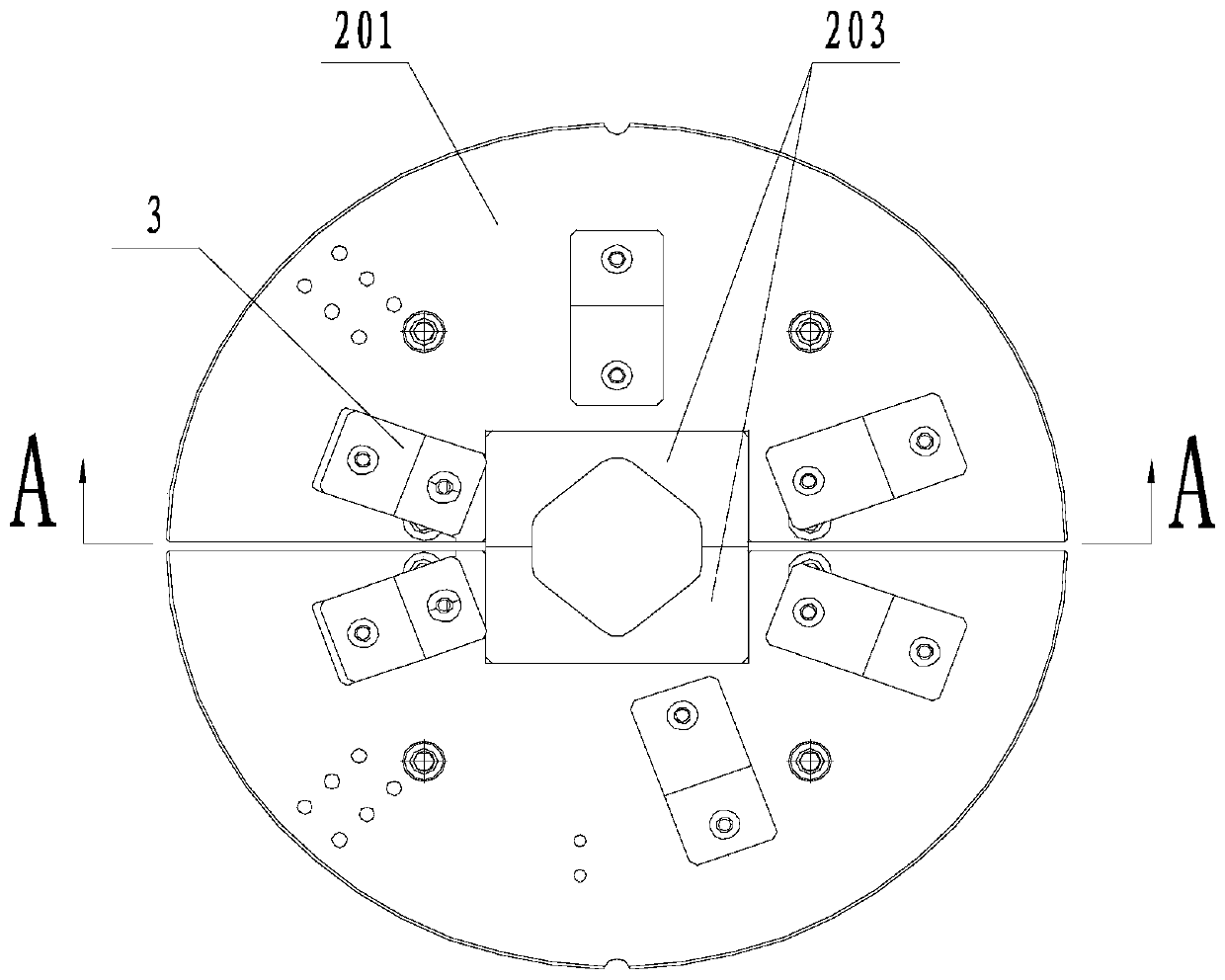

[0042] A semi-automatic spring loading tool for a shock absorber, including an upper compression spring tool, and a lower compression spring tool located below the upper compression spring tool, the lower compression spring tool is used to fix the shock absorber to be installed, And the lower compression spring frock is provided with a through hole for the shock absorber to be loaded to pass through; the upper surface of the lower compression spring frock is provided with a spring disk positioning frock, and the spring disk positioning frock is used for positioning the spring disk.

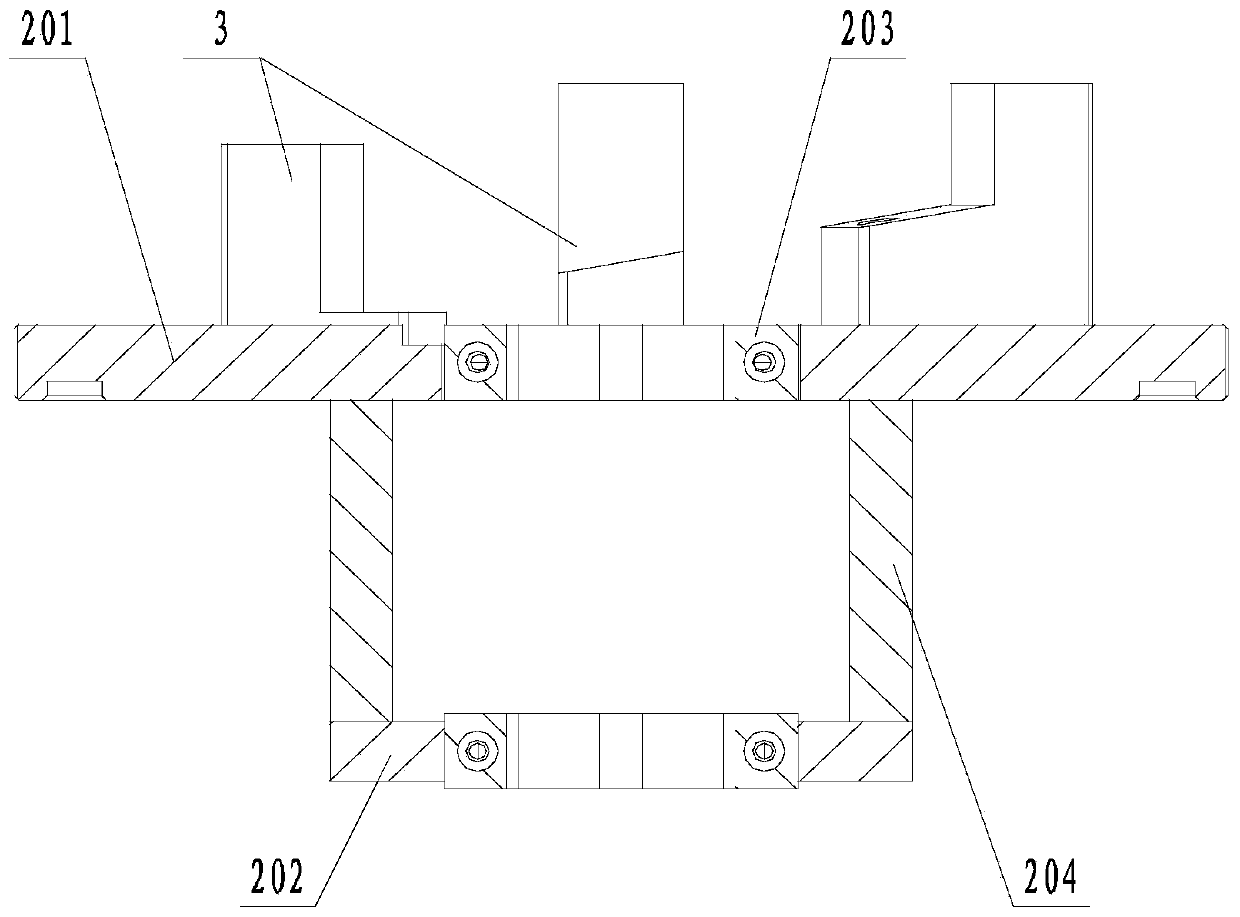

[0043] Preferably, the lower compression spring tooling includes upper and lower supporting blocks 201 and positioning plates 202, and the supporting blocks 201 and positioning plates 202 are two-petal structures. The upper compression spring tooling includes two arc-shaped plates 101 that can be spliced, and several limit blocks 102 are fixed at the bottom of the arc-shaped plates 101, and the lim...

Embodiment 2

[0046] Such as figure 1 In the semi-automatic spring loading tool for shock absorbers shown in 8, on the basis of Embodiment 1, one support block 201 faces the side of the other support block 201, and one positioning plate 202 faces the other positioning plate There are notches on one side of 202, and the opposite two notches are joined together to form a through hole; the opposite two-lobed tooling can be opened and closed freely by the servo drive, ensuring that the product can pass through freely when opened, and the shock absorber is fixed when closed. A spring clamp block 203 is arranged in the gap, and the spring clamp block 203 is V-shaped with the concave surface facing outward; the spring clamp block 203 is made of flexible material. The supporting block 201 is fixedly connected to the positioning plate 202 through several connecting blocks 204 . The spring disk positioning tool includes several ring-shaped spring pads 3, the positioning surface of each spring pad 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com