Hydroxyl acrylic resin and preparation method thereof

A technology of hydroxyacrylic acid and resin, which is applied in the field of resin for coatings, can solve problems such as complicated process and time-consuming, achieve the effect of reducing processing cost, saving processing procedures, and meeting market use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

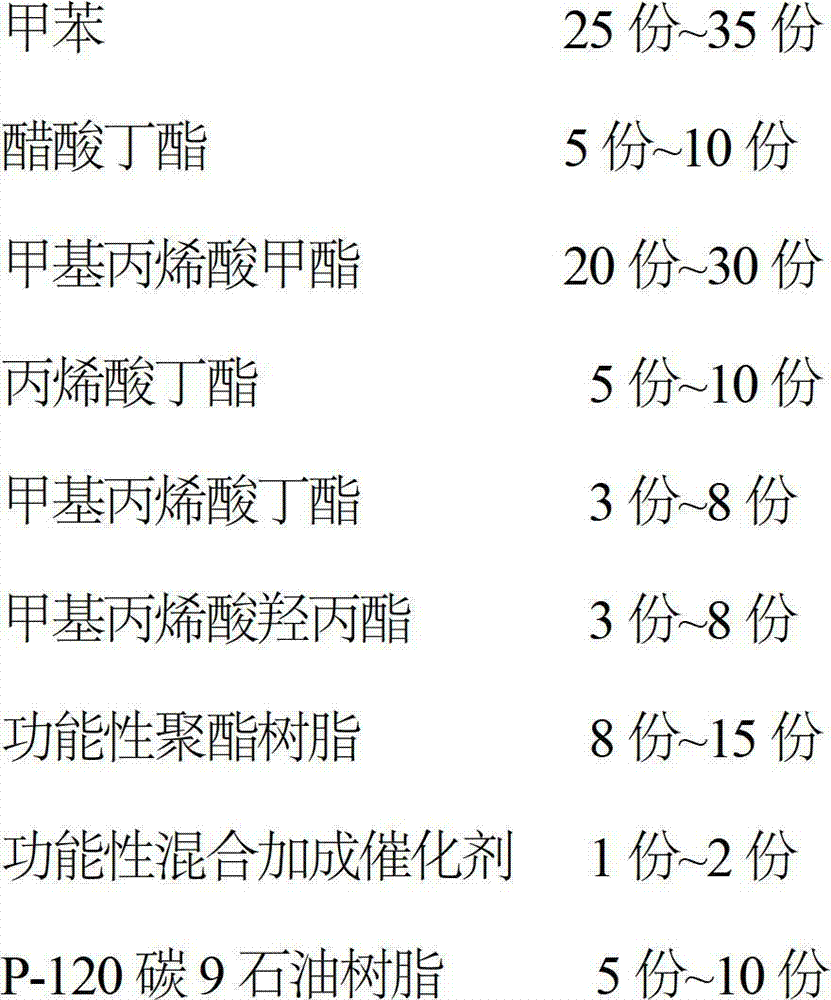

[0028] The hydroxyl acrylic resin in the present embodiment is made of the following components by weight:

[0029]

[0030] The hydroxyl acrylic resin of the present embodiment, its preparation method is as follows:

[0031] 1) Put material A into the reaction kettle and stir evenly;

[0032] 2) Add material B dropwise, the reaction temperature in the reactor is controlled at 108°C, and the time for adding material B dropwise is controlled at 3 hours;

[0033] 3) After the dropwise addition is completed, keep the temperature at 100° C. for 1 hour;

[0034] 4) Add material C, raise the temperature to 125°C and keep it warm for 5 hours;

[0035] 5) Add material D and maintain the reaction for 2 hours;

[0036] 6) Cool down to below 75°C, filter, and obtain;

[0037] Material A is mixed by 25 parts by weight of toluene, 8 parts by weight of butyl acetate, 11 parts by weight of functional polyester resin, and 0.2 parts by weight of a functional mixed addition catalyst; mat...

Embodiment 2

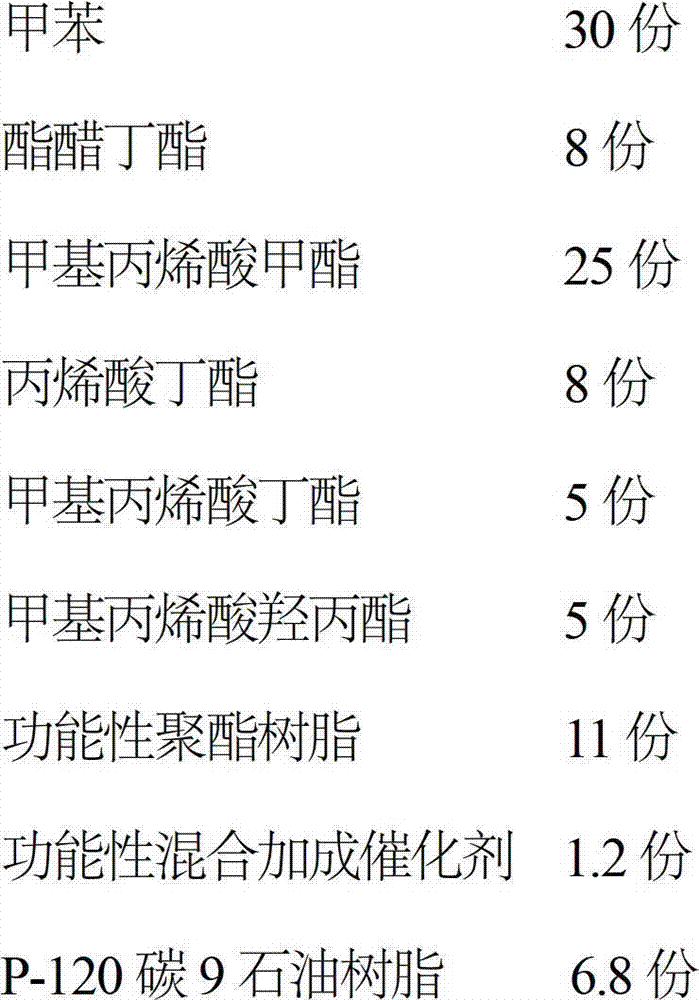

[0041] The hydroxyl acrylic resin in the present embodiment is made of the following components by weight:

[0042]

[0043]

[0044] The hydroxyl acrylic resin of the present embodiment, its preparation method is as follows:

[0045] 1) Put material A into the reaction kettle and stir evenly;

[0046] 2) Add material B dropwise, the reaction temperature in the reactor is controlled at 112°C, and the time for adding material B dropwise is controlled at 4.0 hours;

[0047] 3) After the dropwise addition is completed, keep the temperature at 120° C. for 1 hour;

[0048] 4) Add material C, raise the temperature to 125°C and keep it warm for 4.5 hours;

[0049] 5) Add material D and maintain the reaction for 2.5 hours;

[0050] 6) Cool down to below 75°C, filter, and obtain;

[0051] Material A is mixed by 28 parts by weight of toluene, 8 parts by weight of butyl acetate, 9 parts by weight of functional polyester resin, and 0.5 parts by weight of a functional mixed addit...

Embodiment 3

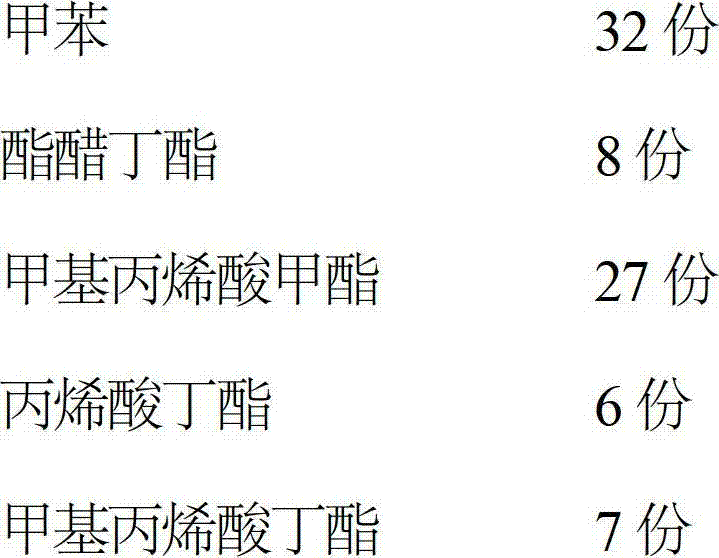

[0055] The hydroxyl acrylic resin in the present embodiment is made of the following components by weight:

[0056]

[0057] The hydroxyl acrylic resin of the present embodiment, its preparation method is as follows:

[0058] 1) Put material A into the reaction kettle and stir evenly;

[0059] 2) Add material B dropwise, the reaction temperature in the reactor is controlled at 115°C, and the time for adding material B dropwise is controlled at 3.5 hours;

[0060] 3) After the dropwise addition is completed, insulate at 115° C. for 1.5 hours;

[0061] 4) Add material C, raise the temperature to 115°C and keep it warm for 5 hours;

[0062] 5) Add material D and maintain the reaction for 2 hours;

[0063] 6) Cool down to below 75°C, filter, and obtain;

[0064] Material A is mixed by 22 parts by weight of toluene, 6 parts by weight of butyl acetate, 10 parts by weight of functional polyester resin, and 0.6 parts by weight of a functional mixed addition catalyst; material B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com