Patents

Literature

154 results about "2-Ethylhexanoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

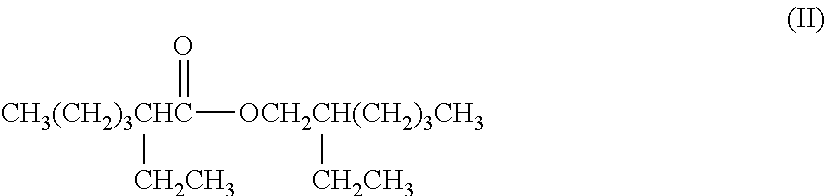

2-Ethylhexanoic acid is the organic compound with the formula CH₃(CH₂)₃CH(C₂H₅)CO₂H. It is a carboxylic acid that is widely used to prepare lipophilic metal derivatives that are soluble in nonpolar organic solvents. 2-Ethylhexanoic acid is a colorless viscous oil. It is supplied as a racemic mixture.

D1369 d radiation curable secondary coating for optical fiber

A new radiation curable Secondary Coating for optical fibers is described and claimed wherein said composition comprises a Secondary Coating Oligomer Blend, which is mixed with a first diluent monomer; a second diluent monomer; optionally, a third diluent monomer; an antioxidant; a first photoinitiator; a second photoinitiator; and optionally a slip additive or a blend of slip additives; wherein said Secondary Coating Oligomer Blend comprises:α) an Omega Oligomer; andβ) an Upsilon Oligomer;wherein said Omega Oligomer is synthesized by the reaction ofα1) a hydroxyl-containing (meth)acrylate;α2) an isocyanate;α3) a polyether polyol; andα4) tripropylene glycol; in the presence ofα5) a polymerization inhibitor; andα6) a catalyst;to yield the Omega Oligomer;wherein said catalyst is selected from the group consisting of dibutyl tin dilaurate; metal carboxylates, including, but not limited to: organobismuth catalysts such as bismuth neodecanoate; zinc neodecanoate; zirconium neodecanoate; zinc 2-ethylhexanoate; sulfonic acids, including but not limited to dodecylbenzene sulfonic acid, methane sulfonic acid; amino or organo-base catalysts, including, but not limited to: 1,2-dimethylimidazole and diazabicyclooctane; triphenyl phosphine; alkoxides of zirconium and titanium, including, but not limited to Zirconium butoxide and Titanium butoxide; and Ionic liquid phosphonium salts; and tetradecyl(trihexyl)phosphonium chloride; andwherein said Upsilon Oligomer is an epoxy diacrylate.

Owner:DSM IP ASSETS BV

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS7786336B2High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneAluminoxane

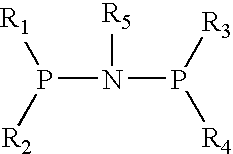

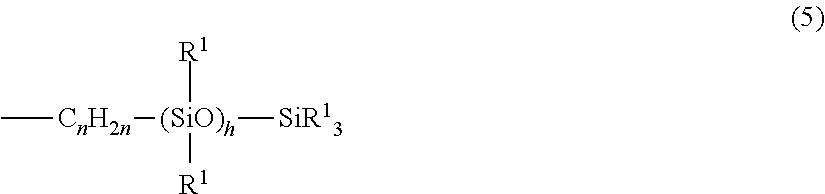

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as:in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; the accelerator is selected from the group consisting of 1,1,2,2,-tetrachloroethane, 1,1,2,2-tetrabromoethane, 1,1,2,2-tetrafluoroethane, and compounds having a formula of X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkylene or arylene group; the molar ratio of chromium compound, ligand containing P and N, activator and accelerator is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·ma−1 Cr·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

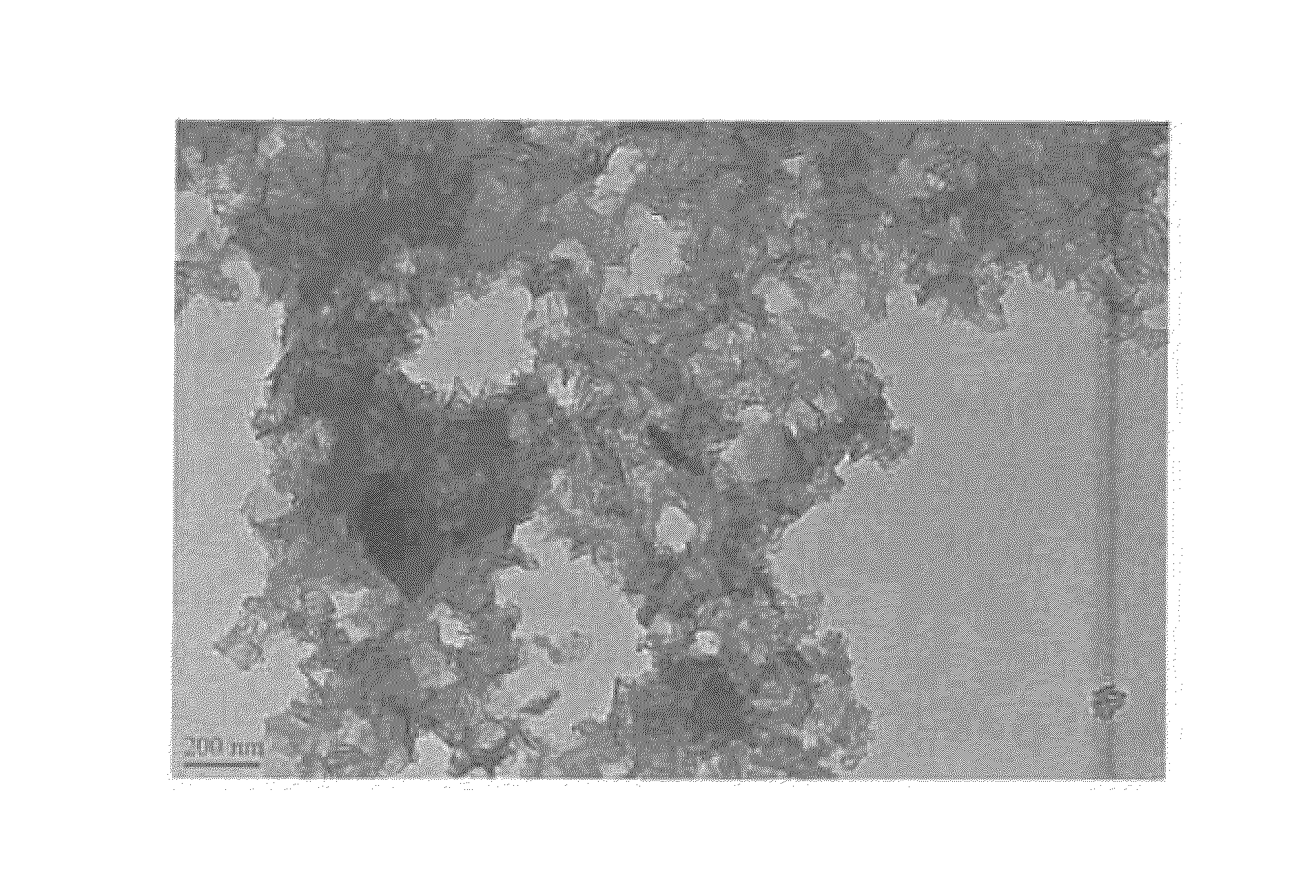

Metal delivery system for nanoparticle manufacture

ActiveUS20060229197A1Improve productivityWell mixedRare earth metal oxides/hydroxidesMolten spray coating2-Ethylhexanoic acidMetallacarboxylic acid

Described is a method for the production of pure or mixed metal oxides, wherein at least one metal precursor that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3, e.g. the 2-ethyl hexanoic acid salt, is formed into droplets and e.g. flame oxidized. The method is performed at viscosities prior to droplet formation of usually less than 40 mPa s, obtained by heating and / or addition of one or more low viscosity solvents with adequately high enthalpy.

Owner:ETH ZURICH THE SHORT NAME OF EID GENOSSISCHE TECHN HOCHSCHULE ZURICH

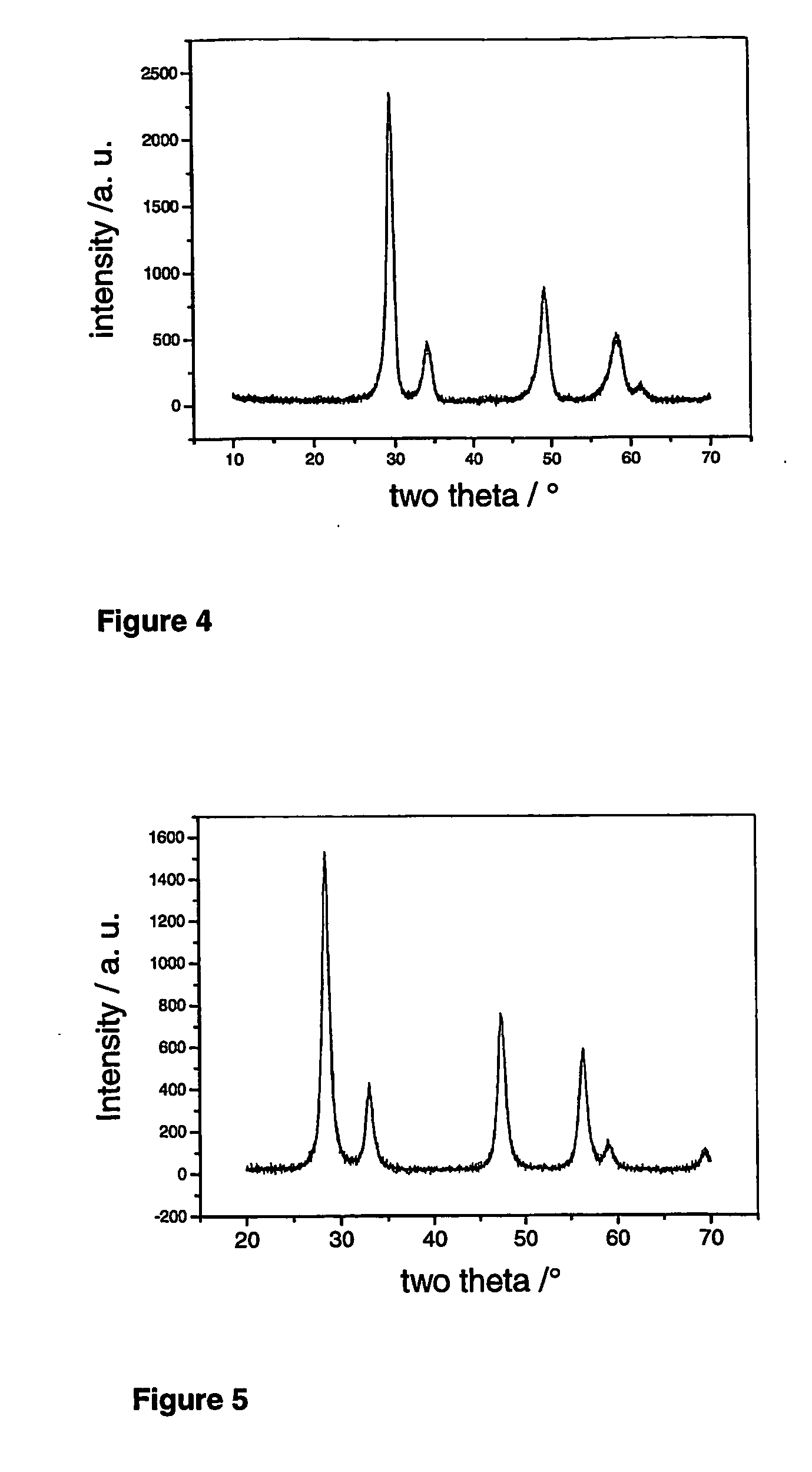

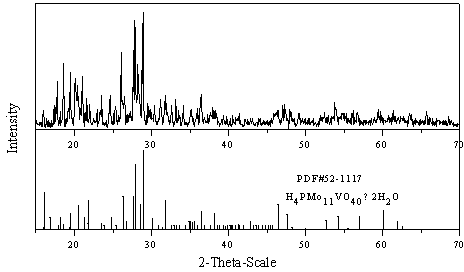

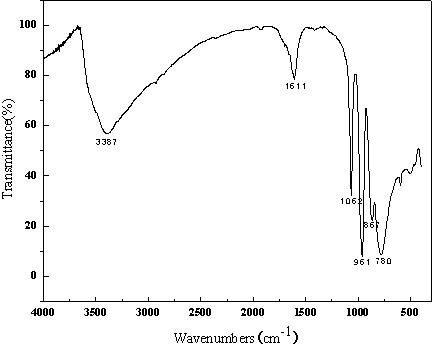

Method for preparing 2-ethyl hexanoic acid by catalytically oxidizing 2-ethylhexanal by molybdovanadophosphoric acid

InactiveCN102701944AStable chemical propertiesImprove thermal stabilityPhysical/chemical process catalystsOrganic compound preparation2-Ethylhexanoic acidReaction temperature

The invention discloses a method for preparing 2-ethyl hexanoic acid by catalytically oxidizing 2-ethylhexanal by molybdovanadophosphoric acid, and relates to a method for preparing a chemical preparation. The method comprises the following steps: weighing molybdovanadophosphoric acid and dissolving the molybdovanadophosphoric acid in distilled water at first and then in hydrochloric acid to prepare a catalyst solution; adding 2-ethylhexanal and the prepared catalyst in an ordinary-pressure reaction device, slowly heating and stirring the mixture, regulating oxygen flux, and starting to introduce oxygen when the temperature rises to the reaction temperature; after the reaction is ended, separating out the aqueous phase solution on the lower layer to obtain organic phase matter on the upper layer; and depressurizing and distilling the organic phase matter to obtain colorless transparent and pungent oily liquid, 2-ethyl hexanoic acid. By changing the ratio of molybdenum to vanadium of the catalyst and optimizing the reaction condition, the conversion rate of the 2-ethylhexanal reaches above 99%, and the selection and yield of the 2-ethyl hexanoic acid reach above 98% respectively.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Fast cure EVA solar cell adhesive film

InactiveCN101870854AIncrease productivityReduce consumptionMonocarboxylic acid ester polymer adhesivesFilm/foil adhesivesCross-linkAdhesive

The invention relates to a fast cure EVA solar cell adhesive film, and overcomes the technical defects of unreasonable compatibility, slow crosslinking speed and the like in the prior art. The EVA solar cell adhesive film comprises the following matters in parts by weight: 100 parts of ethylene-vinyl acetate, 0.5-3 parts of silane coupling agent, 1-3 parts of peroxide cross-linking agent, 0.1-0.5 part of anti-oxidant, 0.1-0.5 part of heat stabilizer and 0.05-0.2 part of hindered amine light stabilizer, wherein the peroxide cross-linking agent comprises peroxide-2-ethyl hexanoic acid tert-butyl crosslinker. Compared with the prior art, the fast cure EVA solar cell adhesive film has the advantages that the temperature for lamination is lower, the lamination time is shortened and the crosslinking degree is not lowered; and fast curing can be realized, the production efficiency is effectively improved and the production cost is reduced.

Owner:诸暨市枫华光伏材料有限公司

Antifreeze Concentrate and Coolant Compositions and Preparation Thereof

InactiveUS20090001313A1Improve thermal stabilityOther chemical processesHeat-exchange elementsBenzoic acidOctanoic Acids

A toxicological friendly antifreeze composition having improved thermal stability is provided. In one embodiment, the antifreeze composition comprises from 5 to 80 wt. % of an aqueous freezing point depressant selected from alkali metal salts of acetates, formates, proprionates, adipiates, and succinates, and mixtures thereof; 0.1 to 10 wt. % of at least one of a 2-ethylhexanoic acid, isononanoic acid and 3,5,5-trimethylhexanoic acid; and 0.1 to 10 wt. % of at least one of octanoic acid, nonanoic acid, decanoic acid, undecanoic acid, dodecanoic acid, neodecanoic acid, benzoic acid, 2-hydroxybenzoic acid, p-terbutylbenzoic acid, and mixtures thereof. In one embodiment, the composition is employed as a concentrate in admixture with 10 to 90 wt. % water.

Owner:CHEVROU USA INC

Fluid Loss Control Composition and Method of Using the Same

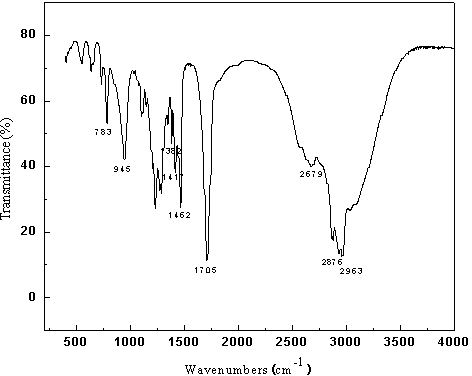

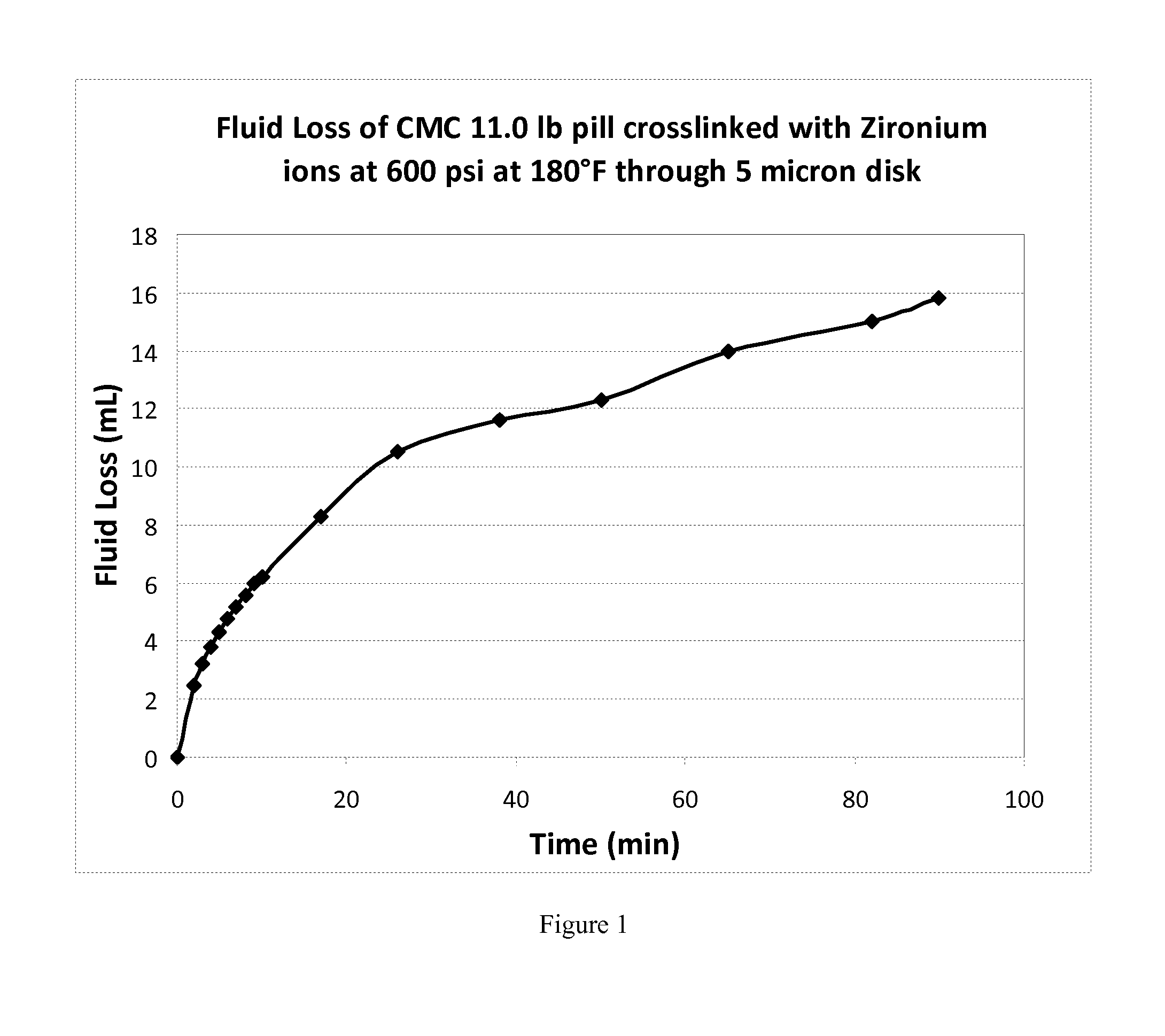

Fluid loss materials including carboxymethylcellulose and zirconium-based crosslinkers may be employed as fluid loss materials in methods of treating subterranean formations. One method includes providing a treatment fluid including carboxymethylcellulose (CMC) and a crosslinker including zirconium, wherein the carboxymethylcellulose has a degree of substitution in a range of from about 0.5 to about 2.5, wherein the crosslinker including zirconium includes one selected from the group consisting of ammonium zirconium fluoride, zirconium 2-ethylhexanoate, zirconium acetate, zirconium neodecanoate, zirconium acetylacetonate, tetrakis(triethanolamine) zirconate, zirconium carbonate, ammonium zirconium carbonate, zirconyl ammonium carbonate, zirconium complex of hydroxyethyl glycine, zirconium malonate, zirconium propionate, zirconium lactate, zirconium acetate lactate, and zirconium tartrate, and placing the treatment fluid in a subterranean formation, wherein the treatment fluid controls fluid loss in a permeable portion of the subterranean formation penetrated by a wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

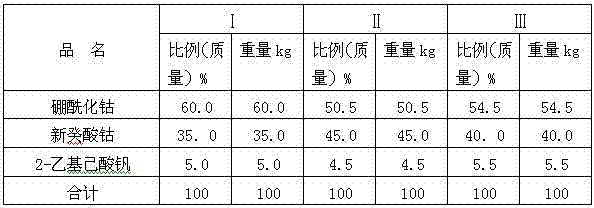

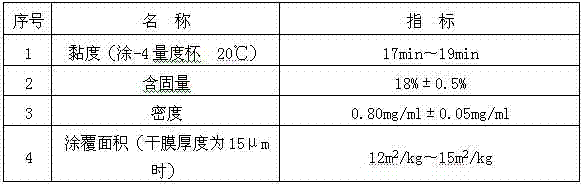

Cobalt salt adhesive for retreading radial wire cord tire and preparation method thereof

InactiveCN102504720AHigh catalytic activityEasy to useNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesive2-Ethylhexanoic acid

The invention discloses a cobalt salt adhesive for retreading a radial wire cord tire and a preparation method thereof. The adhesive comprises a composite adhesive, rubber and an addition agent, wherein the composite adhesive is mainly composed of a main adhesive and an auxiliary adhesive to form a component A; the main adhesive comprises cobalt boroacylate and cobalt neocaprate; the auxiliary adhesive is 2-vanadium ethylcaproate; the rubber comprises natural rubber and butadiene styrene rubber; the addition agent comprises an anti-ageing agent, a plasticizer, a reinforcing agent, an accelerant, an activating agent, a silane coupling agent and a vulcanizing agent. The cobalt salt adhesive for retreading the radial wire cord tire is prepared by the following steps of: dispersing the component A into a rubber carrier to be matched with the addition agent to form an adhesion master batch B; and dissolving the adhesion master batch B by a solvent gasoline to prepare adhesive slurry. The cobalt salt adhesive for retreading the radial wire cord tire provided by the invention has the advantages of good heat stability, good dynamic mechanic property, capability of being directly coated, low cost, and resource saving, and is applicable to the adhesion of new tread rubber and a previous belt compound in a retreading process of the radial wire cord tire, and the high-strength adhesion of the new tread rubber and polished belt steel wires.

Owner:镇江泛华新材料科技发展有限公司

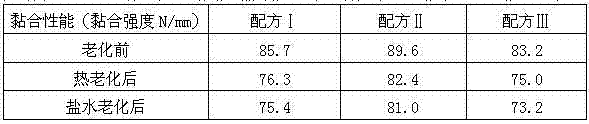

High-adhesion thermoset acrylic resin and preparation method thereof

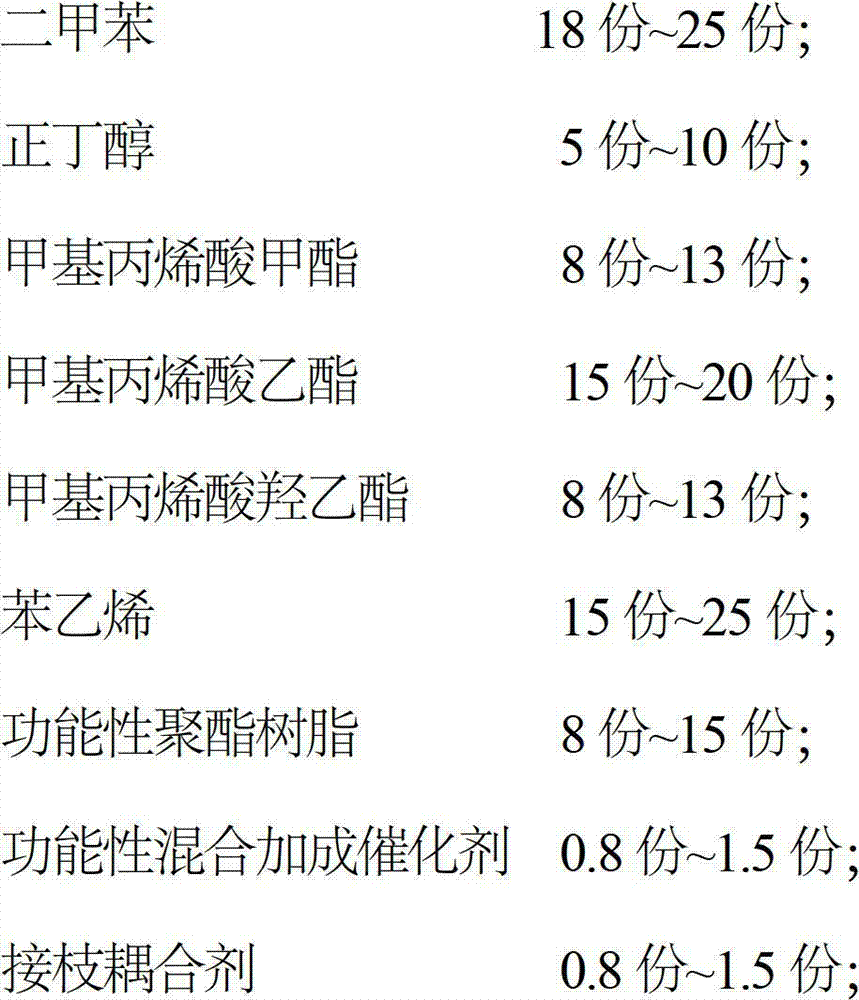

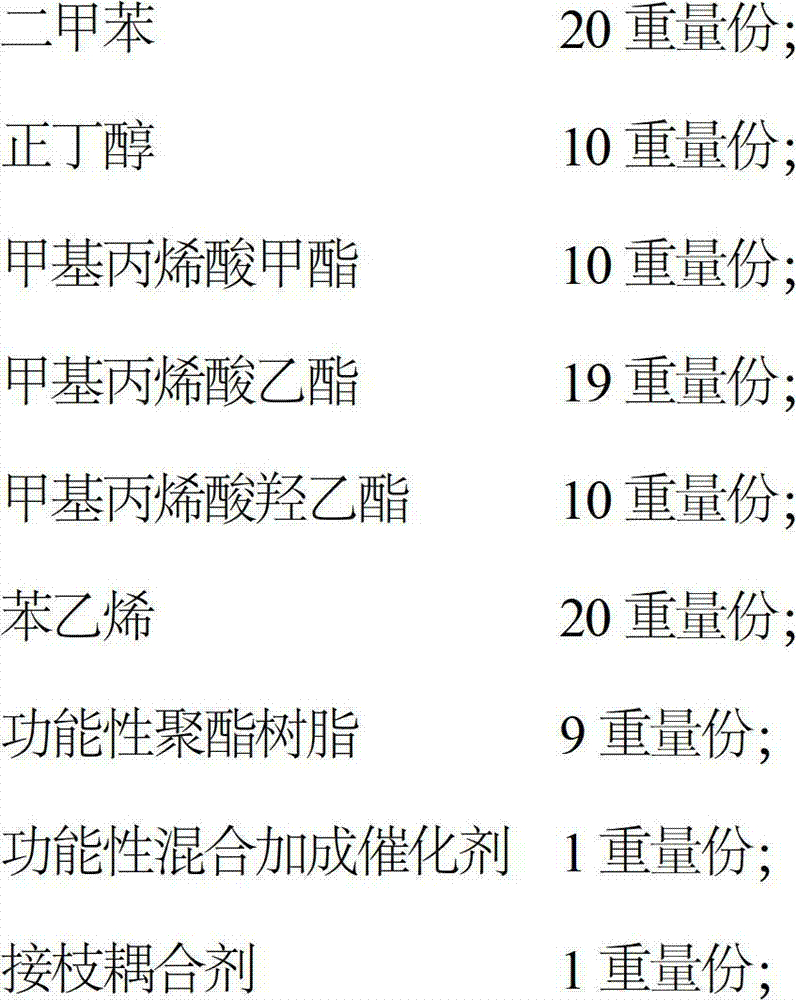

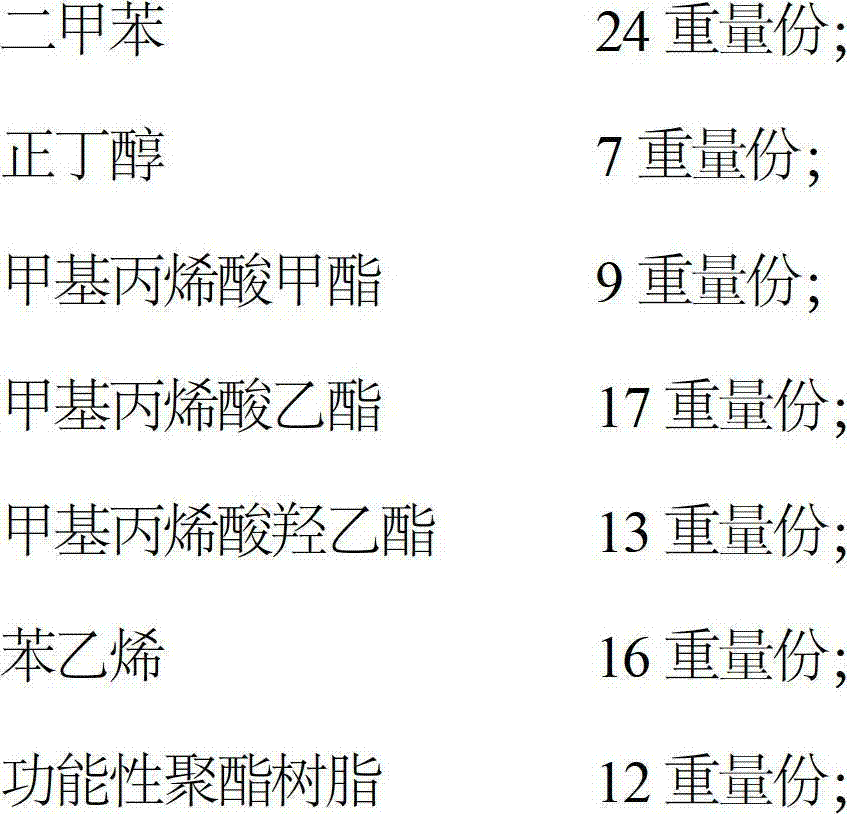

The invention discloses high-adhesion thermoset acrylic resin which comprises, by weight, 18-25 parts of dimethylbenzene, 5-10 parts of n-butyl alcohol, 8-13 parts of methyl methacrylate, 15-20 parts of ethyl methacrylate, 8-13 parts of methacrylic acid ethyl ester, 15-25 parts of styrene, 8-15 parts of functionality polyester resin, 0.8-1.5 parts of functionality mix addition catalyst and 0.8-1.5 parts of grafting couplant. The functionality polyester resin comprises, by weight, 28-33 parts of neopentyl glycol, 12-17 parts of trimethylolproprane, 5-10 parts of adipic acid and 40-50 parts of isophthalic acid and is obtained through esterification synthesis by using a high-temperature melting method. The functionality mix addition catalyst is mixture of 8-12 parts of peroxidation 2-ethylhexoic acid tert-butyl ester, 20-30 parts of azobisisobutyronitrile, 50-60 parts of peroxidation tertiary butyl and 10-15 parts of tert-butyl perbenzoa. Phenomena of layering, pig skin and livering can not occur during storage and construction of paint made from the high-adhesion thermoset acrylic resin, and good adhesion is achieved when the paint is directly coated on a base material hard to attach.

Owner:广东迪爱生彤德树脂有限公司

Coating and conductive resin of film zinc coat

ActiveCN103265661AImprove bindingIncrease roughnessAnti-corrosive paints(Hydroxyethyl)methacrylateHydrazine compound

The invention discloses a coating and conductive resin of a film zinc coat, which is prepared by the following steps of: weighing an organic solvent, methyl methacrylate, hydroxybutyl acrylate, hydroxyethyl methylacrylate, hydroxyethyl methacrylate phosphate, tert-butyl peroxy-2-ethylhexanoate and graphene oxide; adding 3 / 4 of the organic solvent and the graphene oxide into a reaction kettle A and mixing uniformly; uniformly mixing the methyl methacrylate, hydroxybutyl acrylate, hydroxyethyl methylacrylate, hydroxyethyl methacrylate phosphate and 3 / 4 of the tert-butyl peroxy-2-ethylhexanoate, dropwise adding the mixture into a dropwise adding tank B, and then dropwise adding into the reaction kettle A; uniformly mixing the residual organic solvent and tert-butyl peroxy-2-ethylhexanoate, dropwise adding the mixture into the dropwise adding tank B, then dropwise adding into the reaction kettle A at 113-118 DEG C, preserving heat for 0.8-1.2 hours, cooling and filtering; and performing ultrasonic treatment, adding hydrazine hydrate for reaction, filtering, washing and drying. The prepared film zinc coat has better corrosion resistance.

Owner:HUNAN JINPAN NEW MATERIAL TECH CO LTD

Metal paste and film formation method using the same

InactiveUS20050127332A1Increasing the thicknessLower resistanceConductive materialNon-conductive material with dispersed conductive material2-Ethylhexanoic acidColloidal particle

Owner:TANAKA PRECIOUS METAL IND

External preparation for skin

InactiveUS20110250248A1Prolong lifeSuperior in useabilityBiocideCosmetic preparations2-Ethylhexanoic acidEthylene Homopolymers

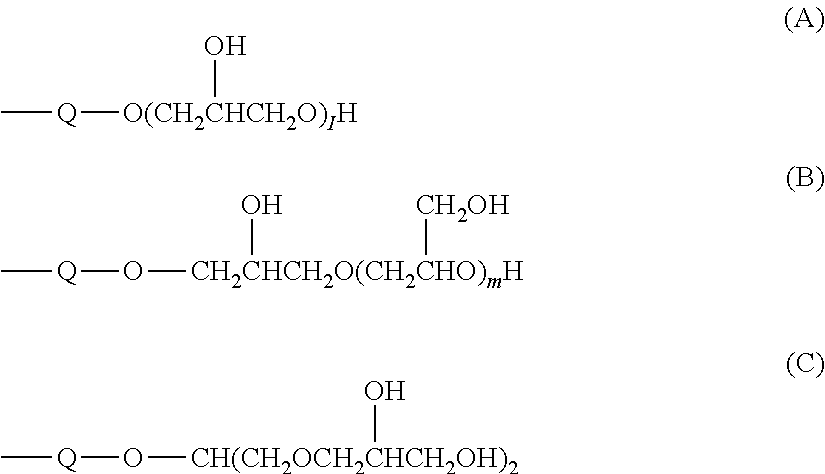

An external preparation for the skin containing isononyl 2-ethylhexanoate and / or 2-ethylhexyl 2-ethylhexanoate (i.e., component (a)); an oil-in-water emulsion type skin cosmetic composition containing the ingredient (a), (b) one or more ingredients selected from higher fatty acids and higher alcohols which are solid to semi-solid at an ordinary temperature (25° C.), (c) a homopolymer, copolymer, cross polymer, or mixture containing one or more ingredients selected from 2-acrylamide-2-methylpropane sulfonic acid and acrylic acid and its derivatives as constituent units and (d) one or more ingredients selected from nonionic surfactants having an HLB value of 9 or more; and an oil-in-water or a water-in-oil emulsion type sunscreen cosmetic composition containing (a) 2-ethylhexyl 2-ethylhexanoate and / or isononyl 2-ethylhexanoate, (b) an ultraviolet absorber, (c) an ultraviolet scatterer and (d) a silicone oil.

Owner:SHISEIDO CO LTD

PC anti-fog spectacle glasses and preparation method thereof

InactiveCN104151807AHigh light transmittanceHigh refractive indexOptical articlesOptical elementsPolymer sciencePhosphate

The invention discloses PC anti-fog spectacle glasses and a preparation method thereof. The method includes following steps: weighing PC, 2-ethyl-2-oxazoline, 2-ethylhexyldiphenyl phosphate, polypropylene glycol, polyglycerol fatty acid ester, diphenyl sulphone, an ultraviolet absorbent, 3,4-dimethylbenzalsorbitol, tert-butyl peroxy-2-ethylhexanoate, PA6, an anti-oxidant, PA66, cumyl peroxyneodecanoate, DOP and dicumyl peroxide as raw materials, mixing the raw materials uniformly, performing an extrusion granulating process, performing solidification and an edge-deburring process, performing a film coating process, a cleaning process, a drying process and performing a test and package process. The spectacle glasses are 95-98% in light transmittance which is increased by 5-15% and is 1-3% in haze. A cantilever beam impact strength is 900-1000 J / m and a -30 DEG C notch impact strength is 18-20 kJ / m<2>. The spectacle glasses are 1.8-2.0 in a refractive index which is increased by 0.2-0.5. A bending strength is 125-130 MPa.

Owner:东莞冠道体育用品有限公司

Metal delivery system for nanoparticle manufacture

InactiveUS8007758B2Add featureImprove homogeneityRare earth metal oxides/hydroxidesMolten spray coating2-Ethylhexanoic acidCarboxylic salt

Described is a method for the production of pure or mixed metal oxides, wherein at least one metal precursor that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3, e.g. the 2-ethyl hexanoic acid salt, is formed into droplets and e.g. flame oxidized. The method is performed at viscosities prior to droplet formation of usually less than 40 mPa s, obtained by heating and / or addition of one or more low viscosity solvents with adequately high enthalpy.

Owner:ETH ZURICH THE SHORT NAME OF EID GENOSSISCHE TECHN HOCHSCHULE ZURICH

Hydroxyl acrylic resin and preparation method thereof

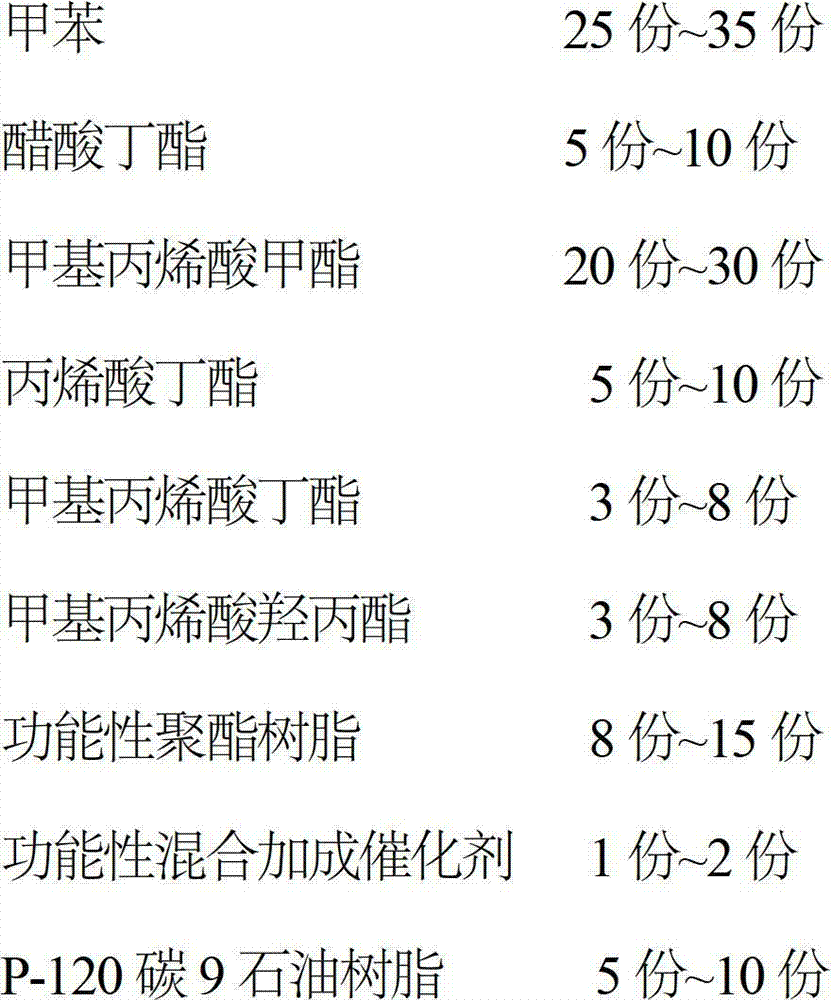

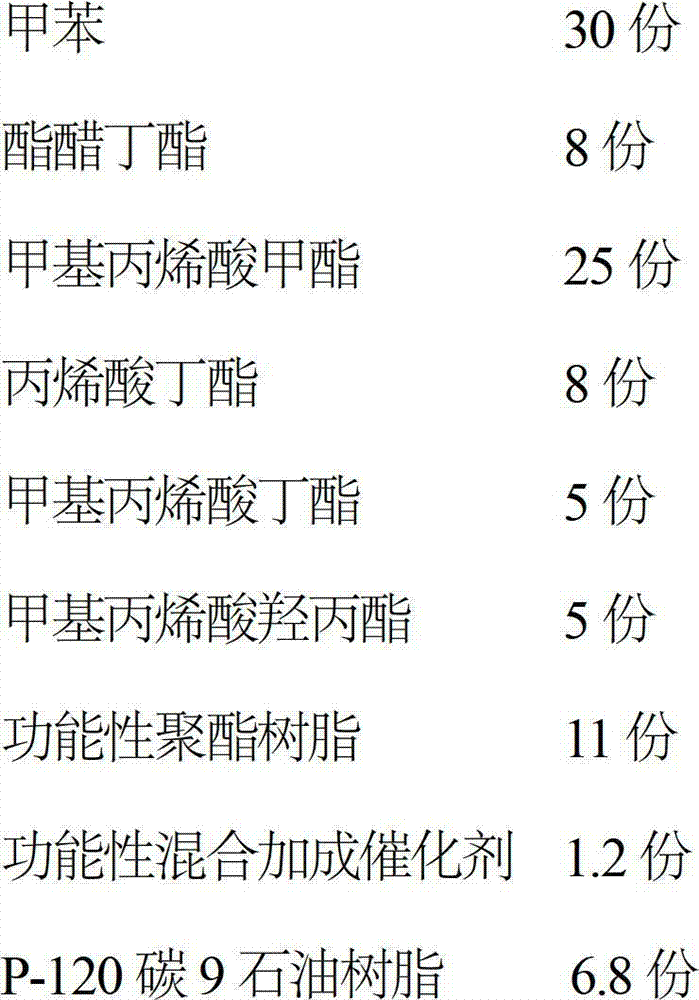

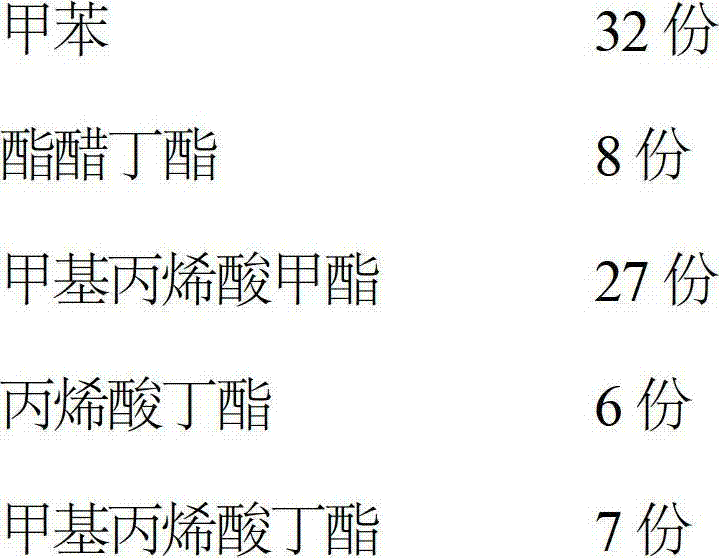

The invention discloses hydroxyl acrylic resin which comprises, by weight, 25-35 parts of toluene, 5-10 parts of butyl acetate, 20-30 parts of methyl methacrylate, 5-10 parts of butyl acrylate, 3-8 parts of butyl methacrylate, 3-8 parts of hydroxypropyl methacrylate, 8-15 parts of functionality polyester resin, 1-2 parts of functionality mixed addition catalyst and 5-10 parts of P-120 carbon 9 petroleum resin. The functionality polyester resin comprises, by weight, 5-10 parts of glycol, 30-40 parts of neopentyl glycol, 50-55 parts of adipic acid and 5-10 parts of fumaric acid and is obtained through esterification synthesis by using a high temperature melting method and diluted by using toluene. The functionality mixed addition catalyst is mixture of 8-12 parts of peroxide 2-ethylhexoic acid tert-butyl ester, 20-30 parts of azobisisobutyronitrile, 50-60 pats of peroxide teriary butyl and 10-15 parts of tert butyl perbenzoa. The hydroxyl acrylic resin has good adhesion when directly coated on nylon materials.

Owner:广东迪爱生彤德树脂有限公司

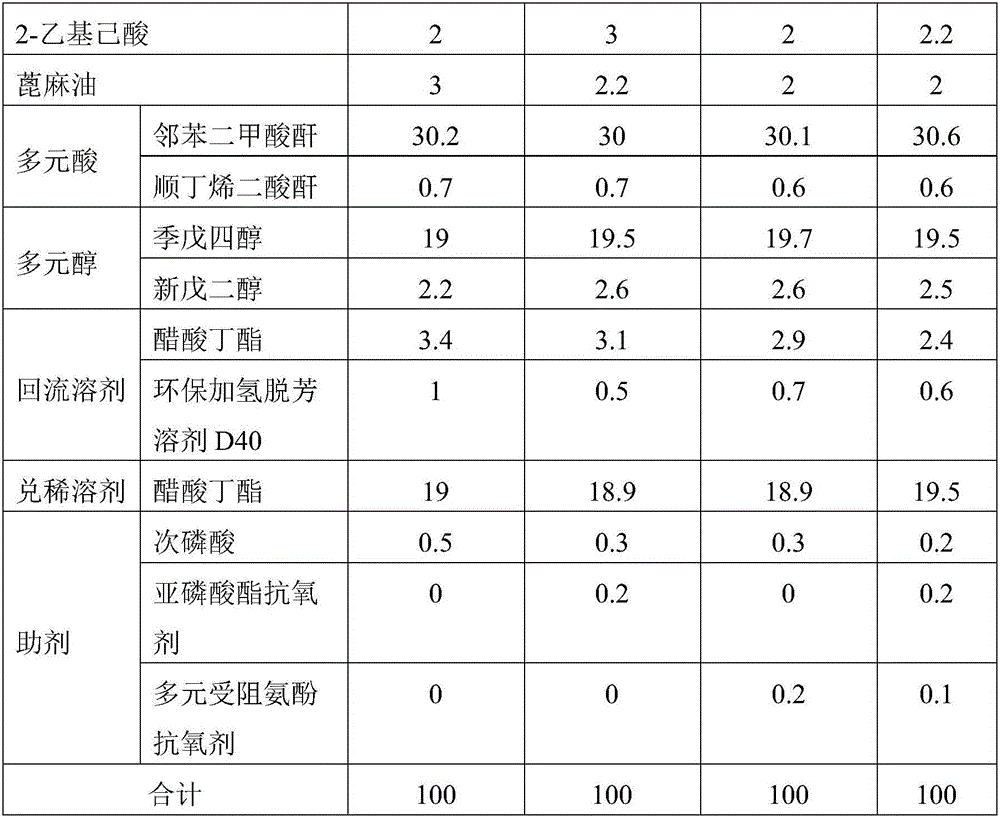

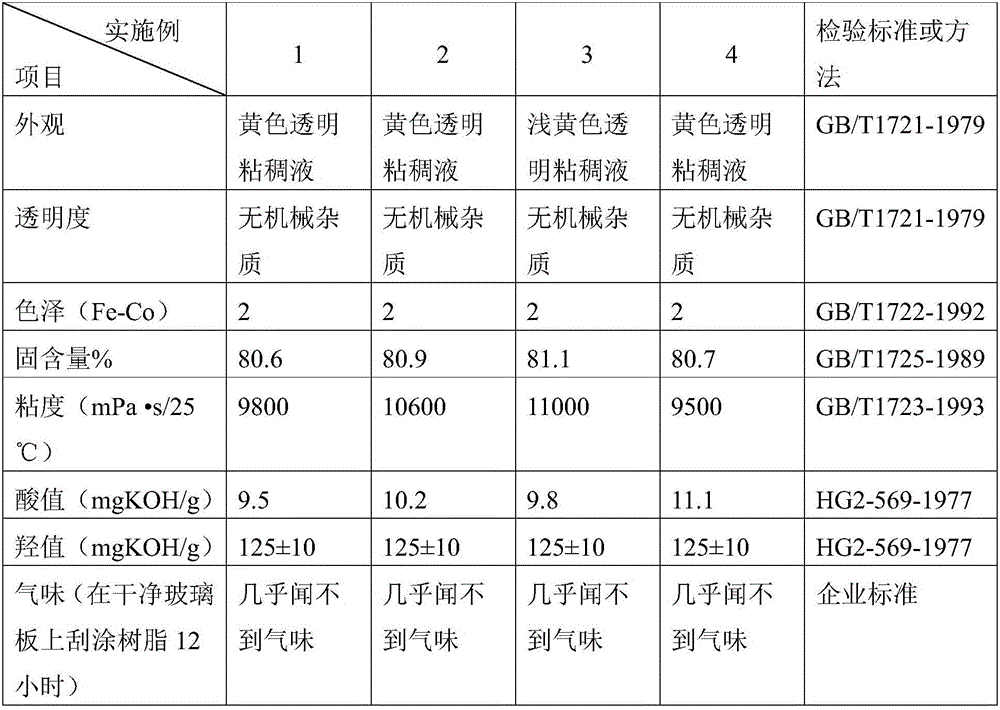

High-solid, low-viscosity and quick-drying odor removal alkyd resin, method for preparing same and application of high-solid, low-viscosity and quick-drying odor removal alkyd resin

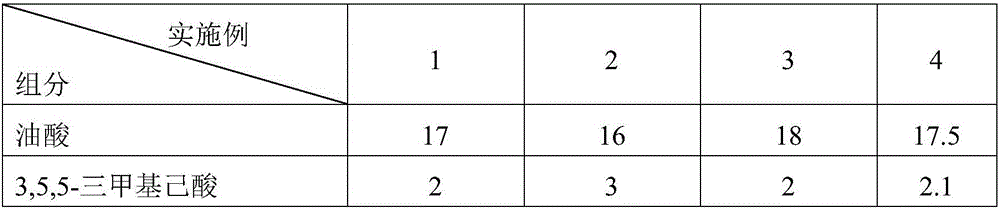

The invention discloses high-solid, low-viscosity and quick-drying odor removal alkyd resin, a method for preparing the same and application of the high-solid, low-viscosity and quick-drying odor removal alkyd resin. The high-solid, low-viscosity and quick-drying odor removal alkyd resin in a formula comprises, by weight, 15-20 parts of oleic acid, 2-4 parts of 3, 5, 5-trimethyl hexanoic acid, 2-4 parts of 2-ethylhexanoic acid, 2-4 parts of castor oil, 25-32 parts of polyacid, 18-26 parts of polyols, 3-5 parts of reflux solvents, 17-21 parts of diluting solvents and 0.5-2 parts of auxiliaries. The high-solid, low-viscosity and quick-drying odor removal alkyd resin, the method and the application have the advantages that the high-solid, low-viscosity and quick-drying odor removal alkyd resin has quick-drying and odor removal characteristics, the solvents can be quickly released when the high-solid, low-viscosity and quick-drying odor removal alkyd resin is coated, the high-solid, low-viscosity and quick-drying odor removal alkyd resin in construction sites rarely has odor and can be completely dried after being coated for 24 h, dried paint films hardly have odor, and people can hardly smell out smell and can have a sense of joy just like a sense of joy under the condition of water-based paint films; the solid content of the high-solid, low-viscosity and quick-drying odor removal alkyd resin prepared by the aid of the method is 80+ / -2%, the viscosity of the high-solid, low-viscosity and quick-drying odor removal alkyd resin is 10000+ / -2000 mpa.s / 25 DEG C, accordingly, the high-solid, low-viscosity and quick-drying odor removal alkyd resin has high-solid and low-viscosity characteristics, the usage of diluents can be reduced when paint is prepared, the VOC (volatile organic compounds) content can be reduced and is only 350 g / L after the paint is manufactured, and tax exemption requirement on construction VOC content lower than 420 g / L after the paint is manufactured can be sufficiently met.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

Neopentyl Glycol Diester

InactiveUS20130231498A1Good compatibilityOrganic compound preparationCarboxylic acid esters preparation2-Ethylhexanoic acidCarboxylic acid

A neopentyl glycol diester which is a mixed ester of neopentyl glycol and carboxylic acids is provided, wherein the carboxylic acids comprising isobutyric acid as well as 2-ethylhexanoic acid and / or 3,5,5-trimethylhexanoic acid. The neopentyl glycol diester may be used in a refrigerant oil or the like which exhibits excellent miscibility with a difluoromethane refrigerant among other properties.

Owner:KH NEOCHEM CO LTD

Titanium Dioxide Dispersion And Cosmetics Containing The Same

ActiveUS20110129509A1Good dispersionCosmetic preparationsPigmenting treatmentPolypropylene glycol2-Ethylhexanoic acid

The present invention provides a titanium dioxide dispersion having a good dispersibility and also provides a cosmetic containing the same. The titanium dioxide dispersion comprises (a) a hydrophobized, treated titanium dioxide powder; (b) one or more oils selected from isohexadecane, isododecane, 2-ethylhexyl 2-ethylhexanoate, isononyl isononate, 2-ethylhexyl isononanoate, isononyl 2-ethylhexanoate, and polypropylene glycol dipivalate; and (c) a siloxane compound represented by the following formula (1), preferably polyoxyalkylene / alkyl comodified organopolysiloxane.R1aR2bR3cSiO(4-a-b-c) / 2 (1)

Owner:SHISEIDO CO LTD

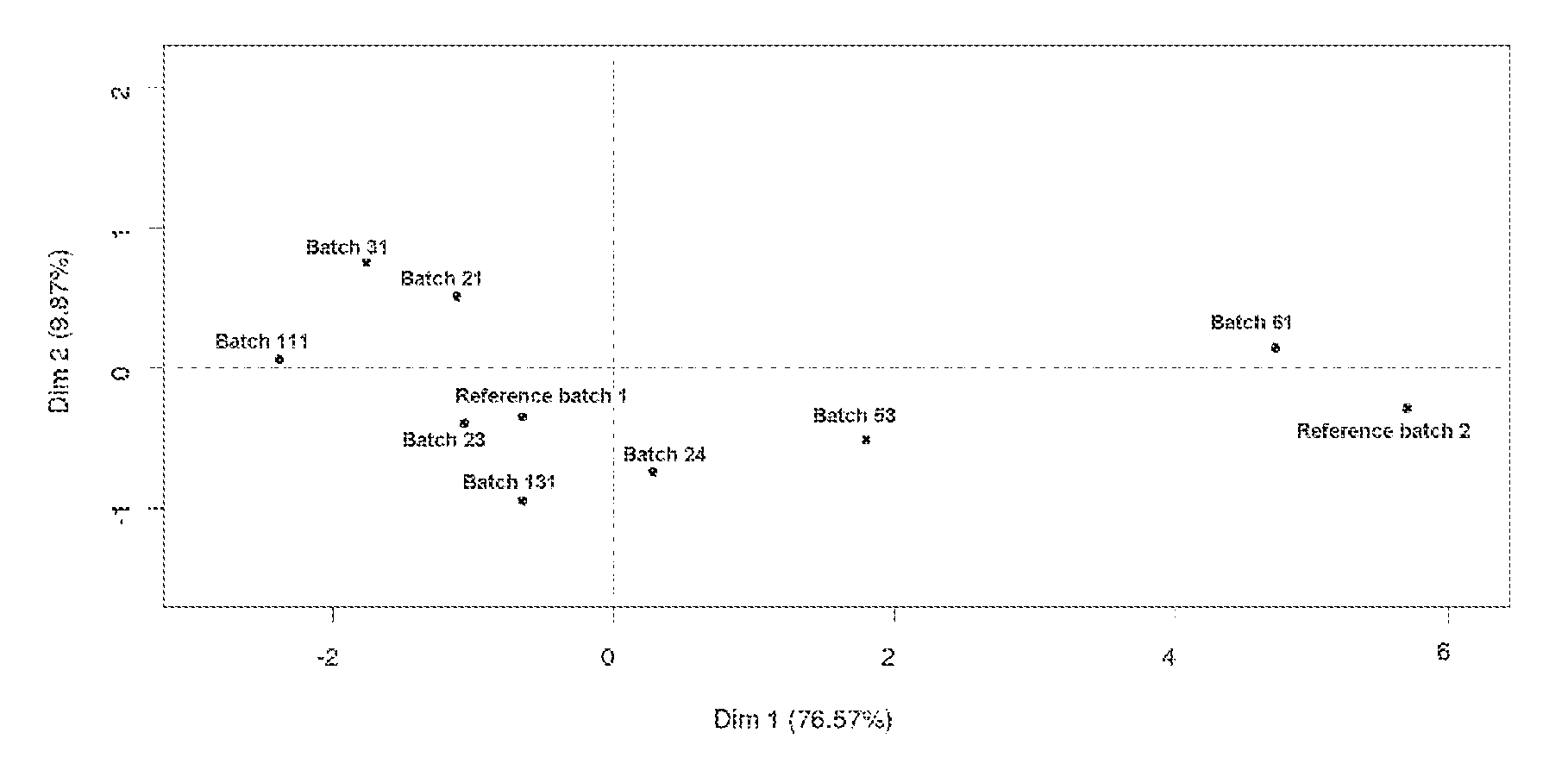

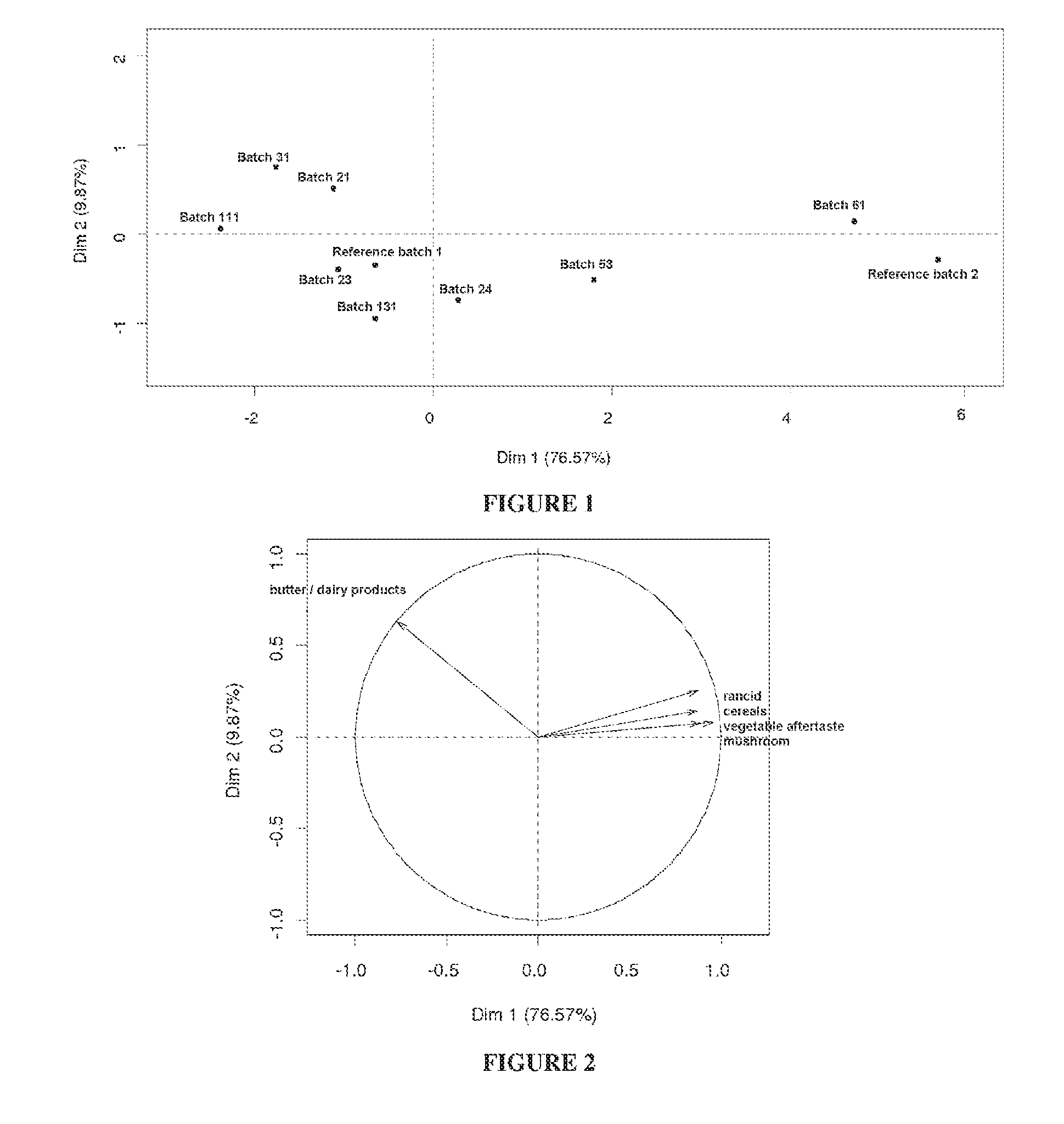

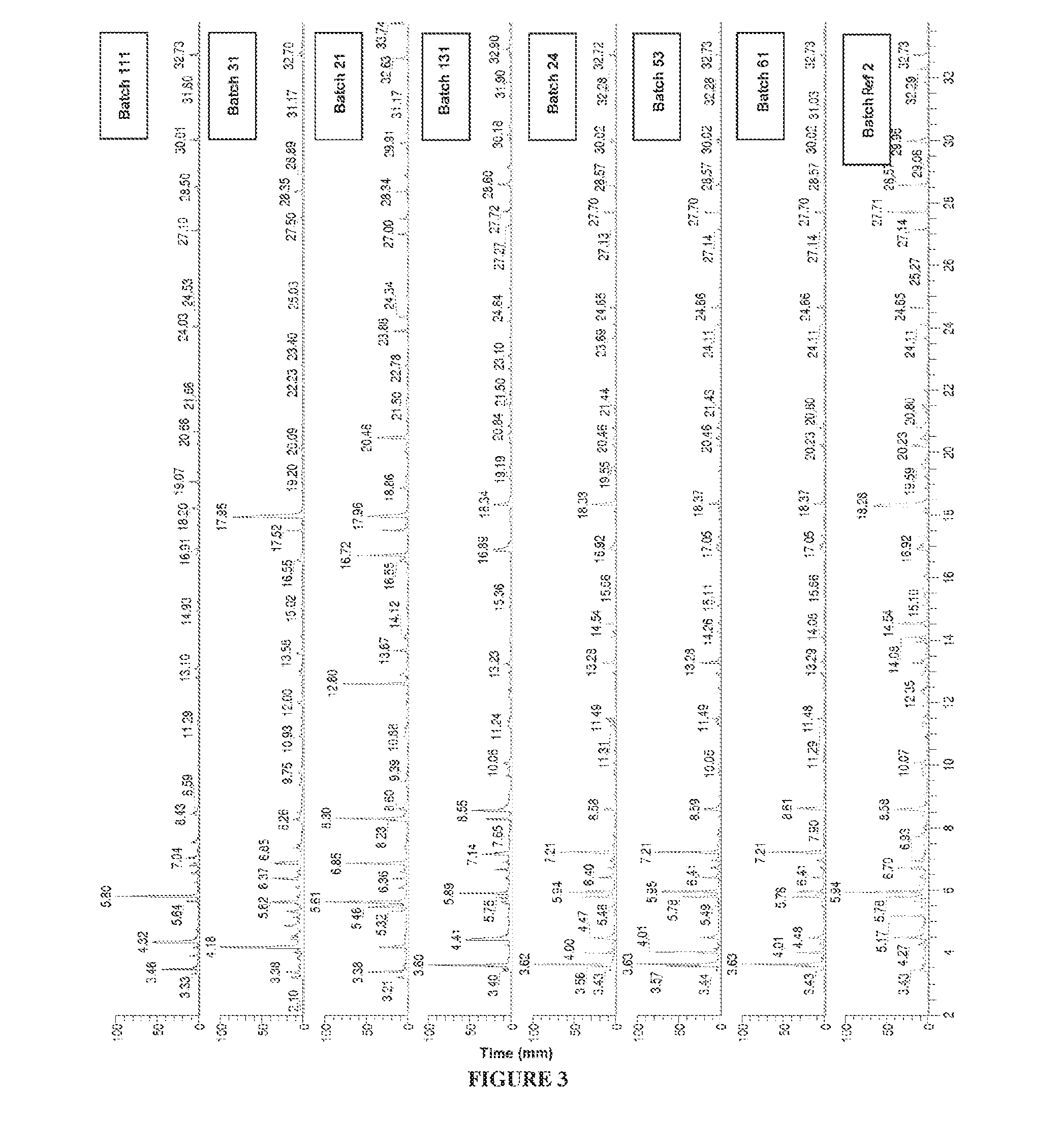

Microalgal flour compositions of optimised sensory quality

InactiveUS20160161460A1Improve sensory qualityReduce contentTesting starch susbtancesMilk preparation2-Ethylhexanoic acidKetone

Thus, the present invention relates to a method for determining the organoleptic quality of a microalgal flour composition, comprising determining the total content of 13 volatile organic compounds, the 13 volatile organic compounds being heptanal, 3-octen-2-one, 2,4-heptadienal, 3,5-octadien-2-one, 2,4-nonadienal, 2,4-decadienal, hexanoic acid, 2-ethylhexanoic acid, heptanoic acid, myristate-1, laurate-1, myristate-2 and geranyl acetone.

Owner:CORBION BIOTECH INC

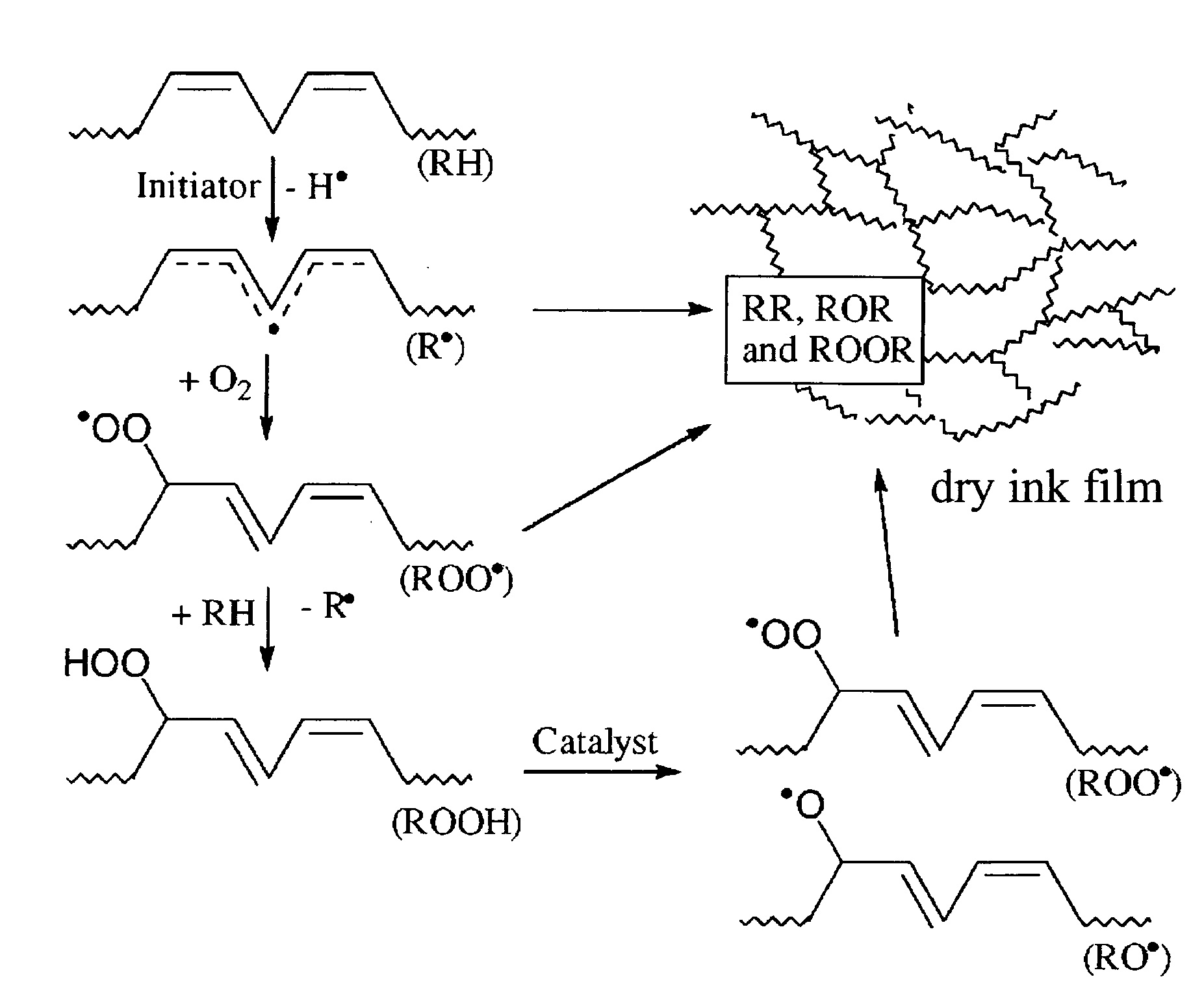

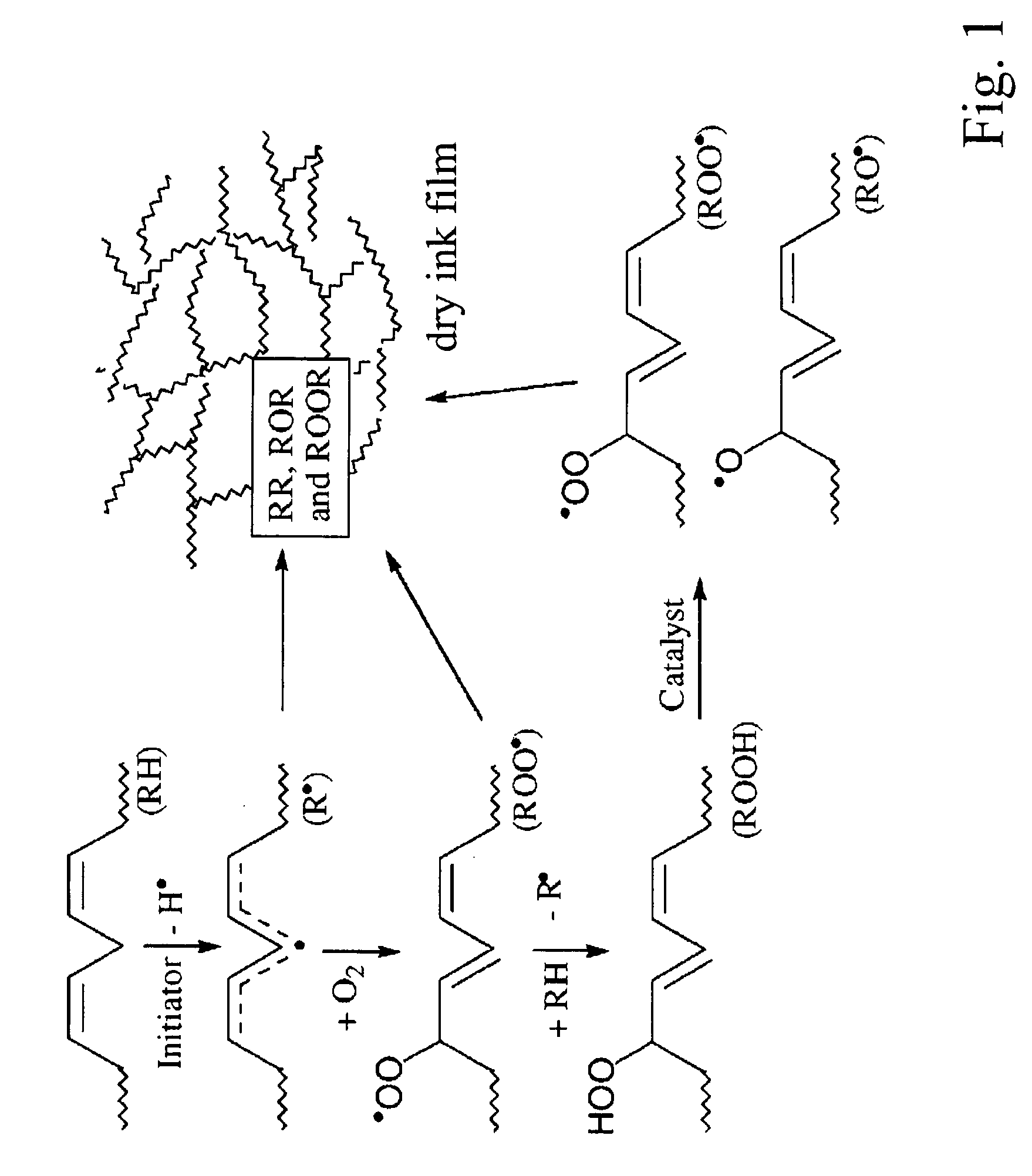

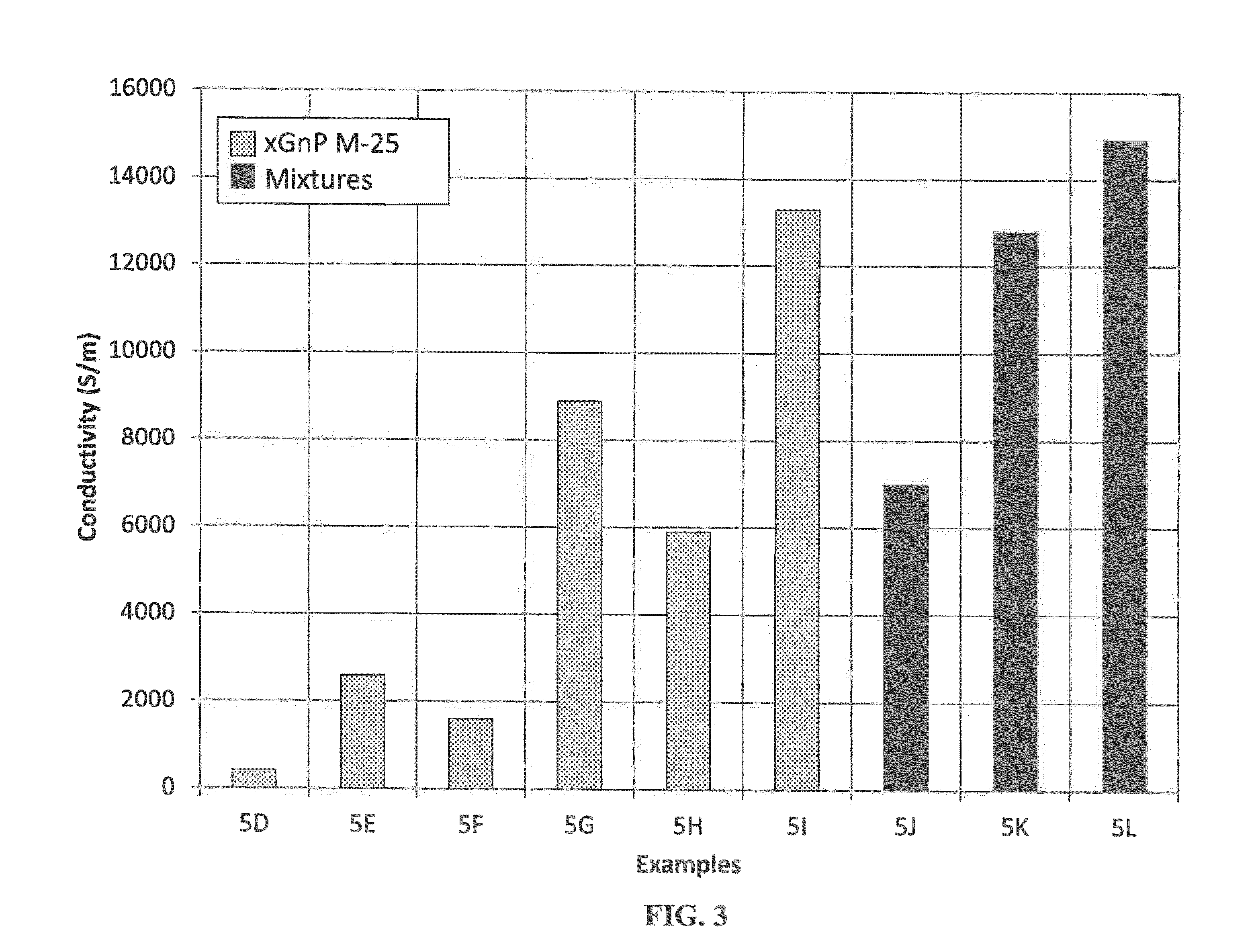

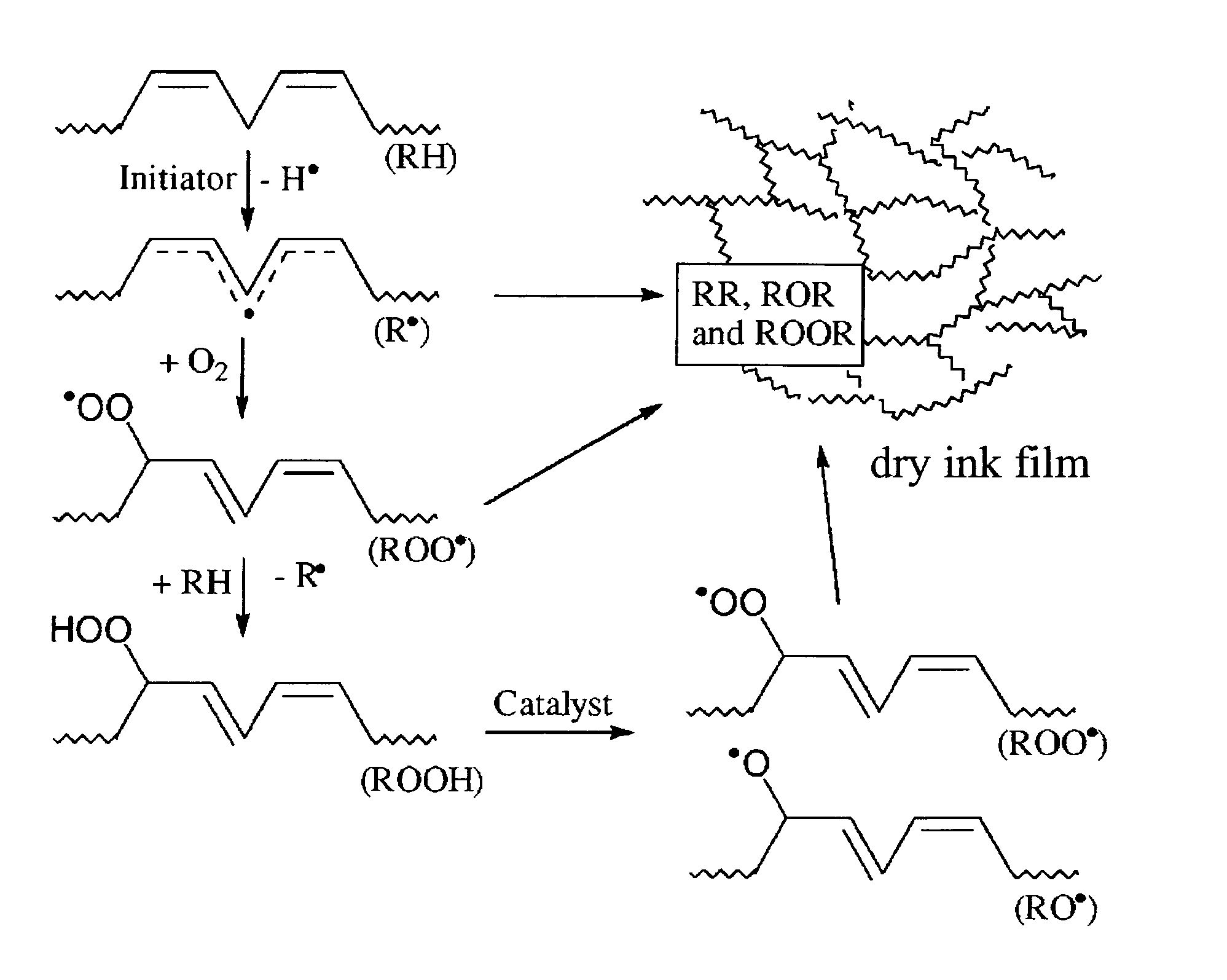

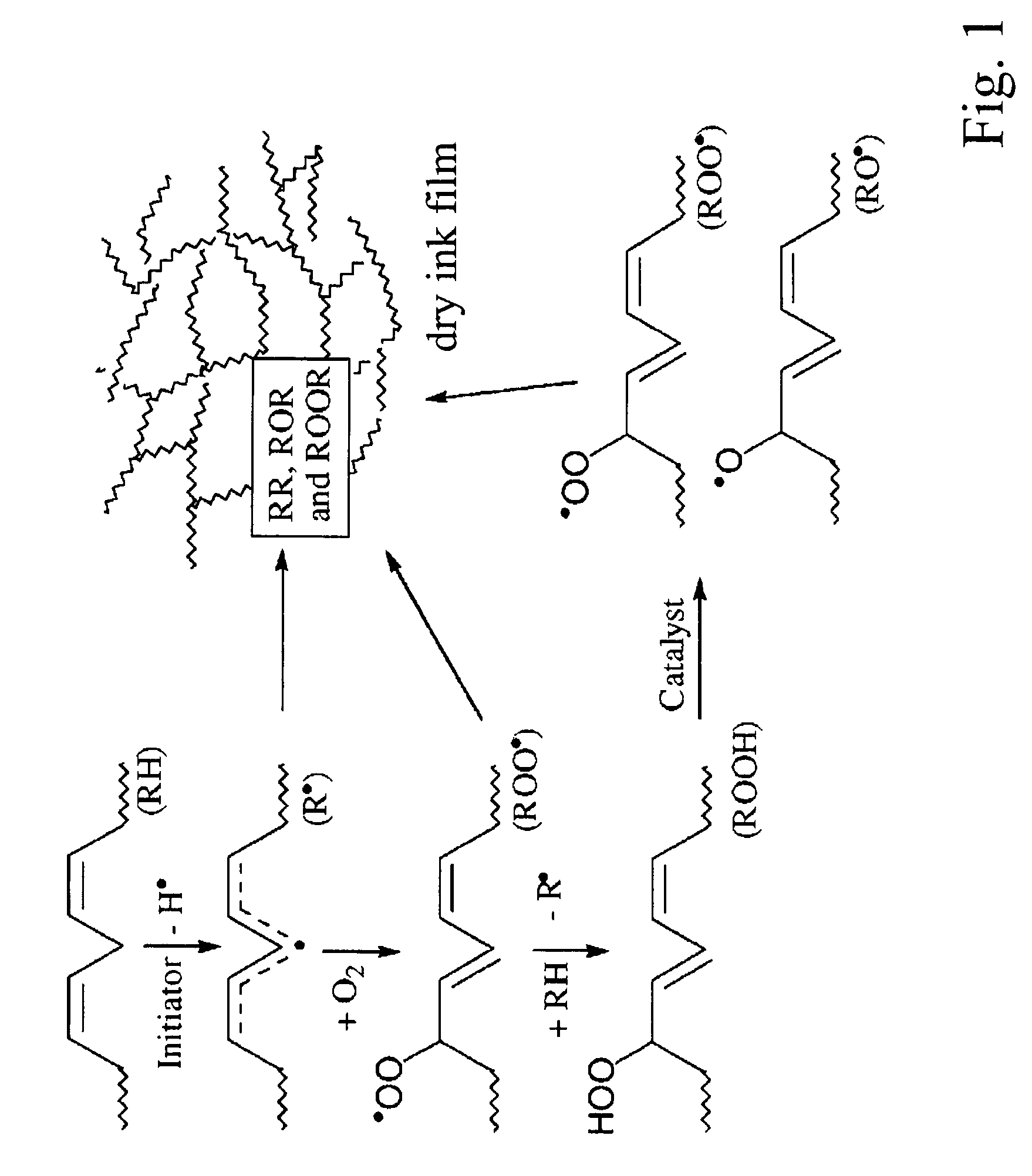

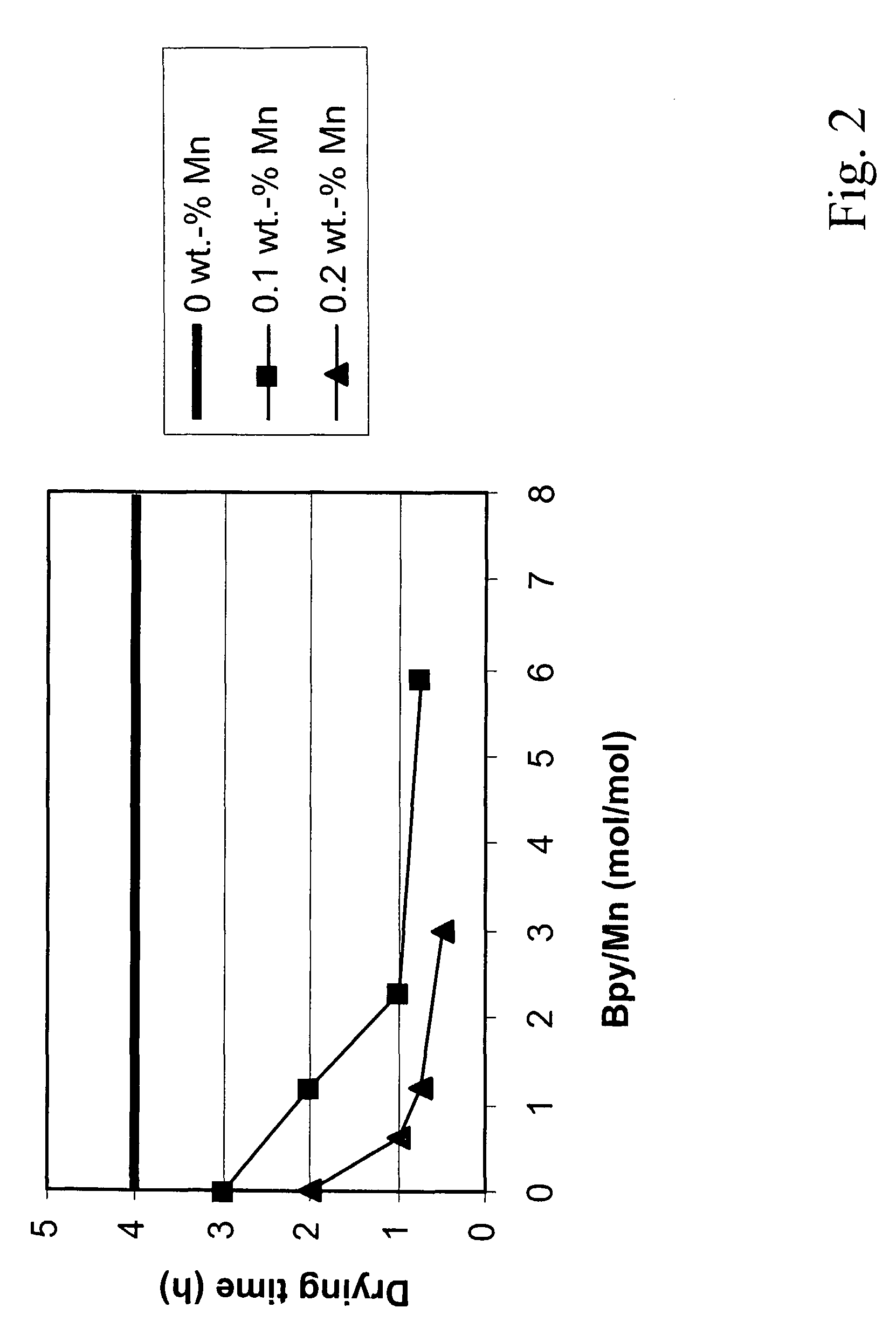

Coating Composition for Offset Paper

Coating for an offset paper comprising a catalyst for fixing polymerisable or crosslinkable constituents of the offset ink. The chemical drying time can be substantially reduced if such a catalyst system is added to the coating, wherein preferentially such a catalyst is a transition metal complex / salt, like Mn (2-ethylhexanoate, bpy).

Owner:SAPPI NETHERLANDS SERVICES

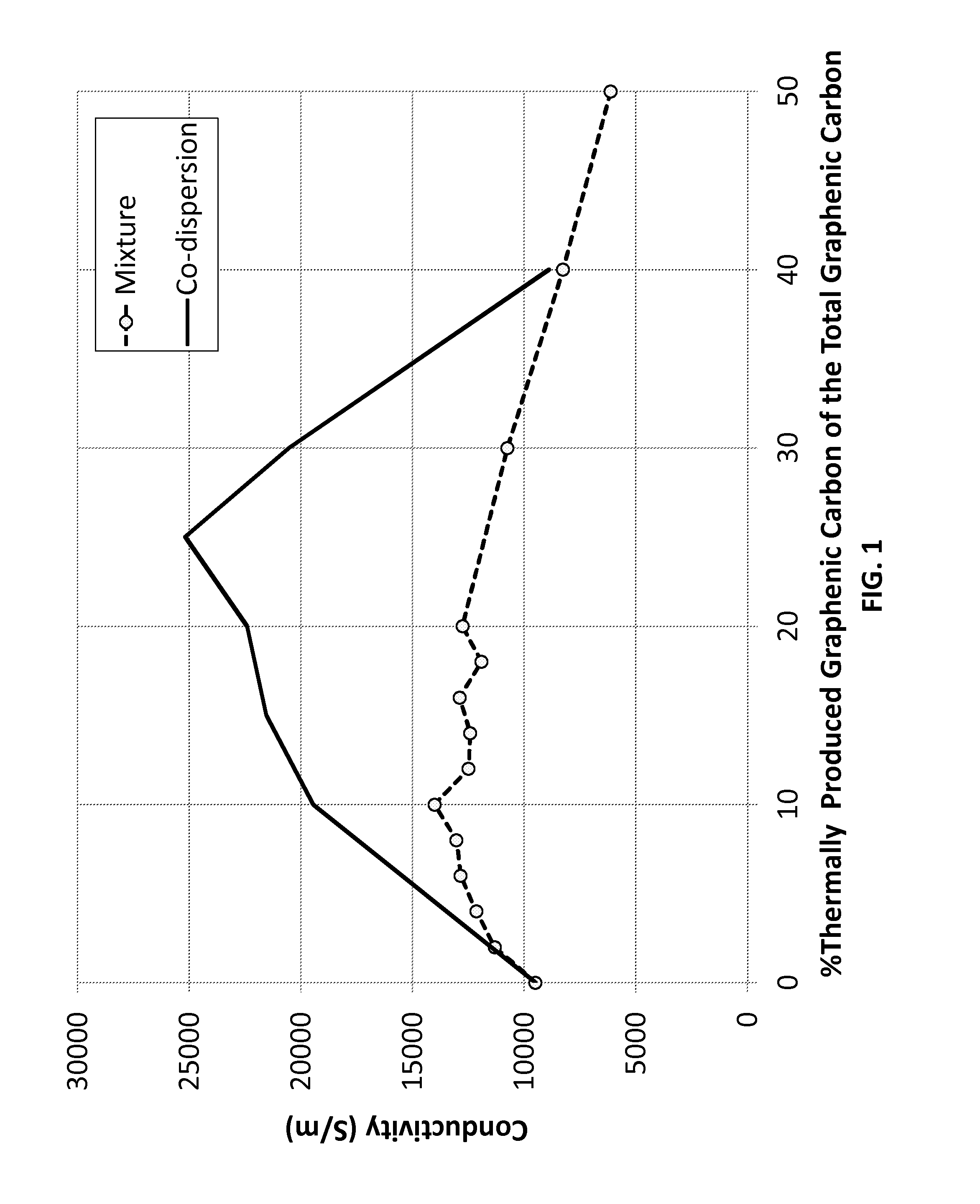

Graphenic carbon particle co-dispersions and methods of making same

Co-dispersions of different types of graphenic carbon particles are produced using a polymeric dispersant. A portion of the graphenic carbon particles may be thermally produced. The polymeric dispersant may include an anchor block comprising glycidyl (meth)acrylate, 3,4-epoxycyclohexylmethyl(meth)acrylate, 2-(3,4-epoxycyclohexyl)ethyl(meth)acrylate, allyl glycidyl ether and mixtures thereof, reacted with a carboxylic acid comprising 3-hydroxy-2-naphthoic acid, para-nitrobenzoic acid, hexanoic acid, 2-ethyl hexanoic acid, decanoic acid and / or undecanoic acid. The polymeric dispersant may also include at least one tail block comprising at least one (meth)acrylic acid alkyl ester.

Owner:PPG IND OHIO INC

Composition and material for cleaning printing machines

InactiveUS7037882B2Maintain good propertiesNot adversely affect surfaceSurface-active detergent compositionsKitchenware cleaners2-Ethylhexanoic acidDibasic ester

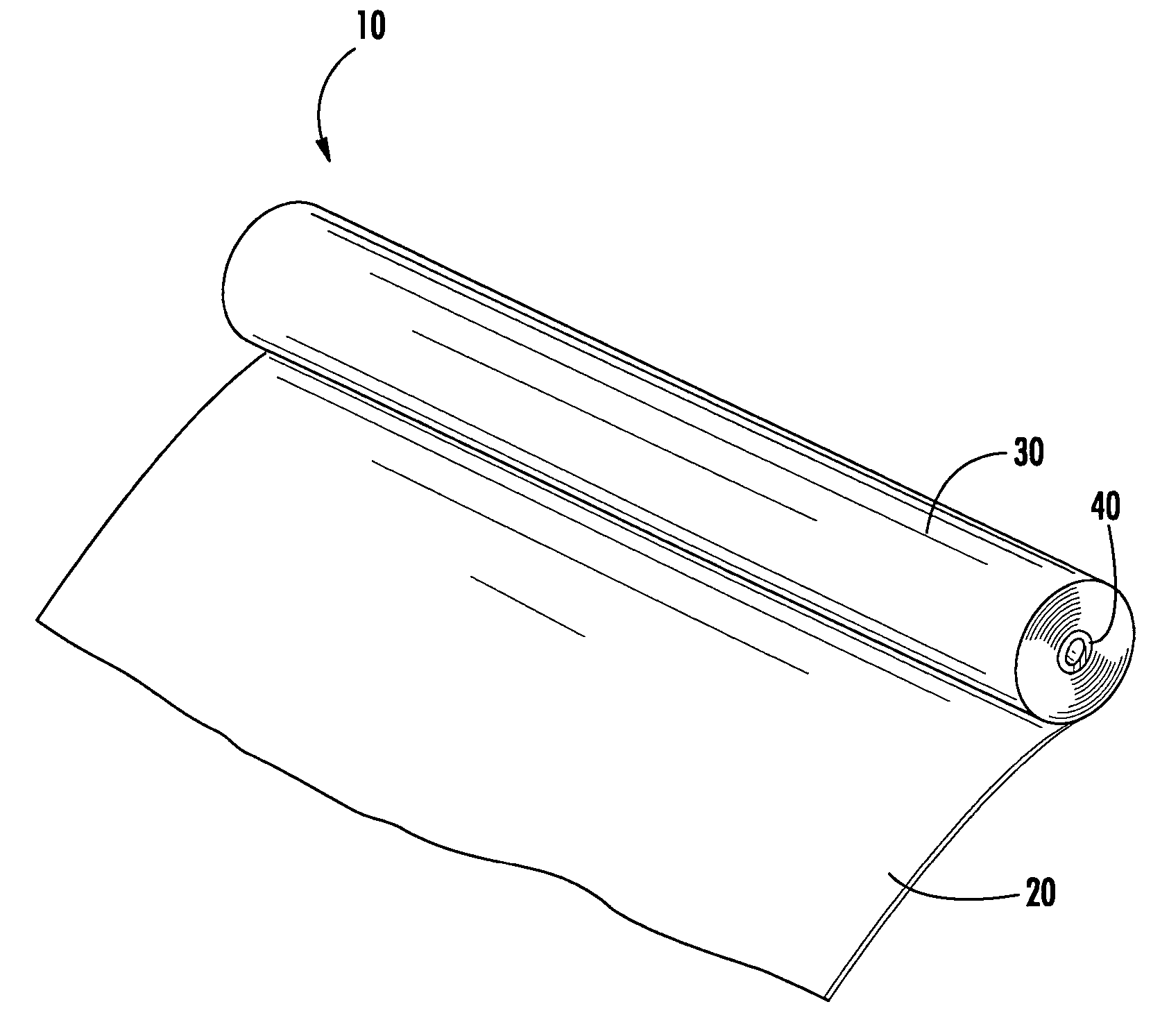

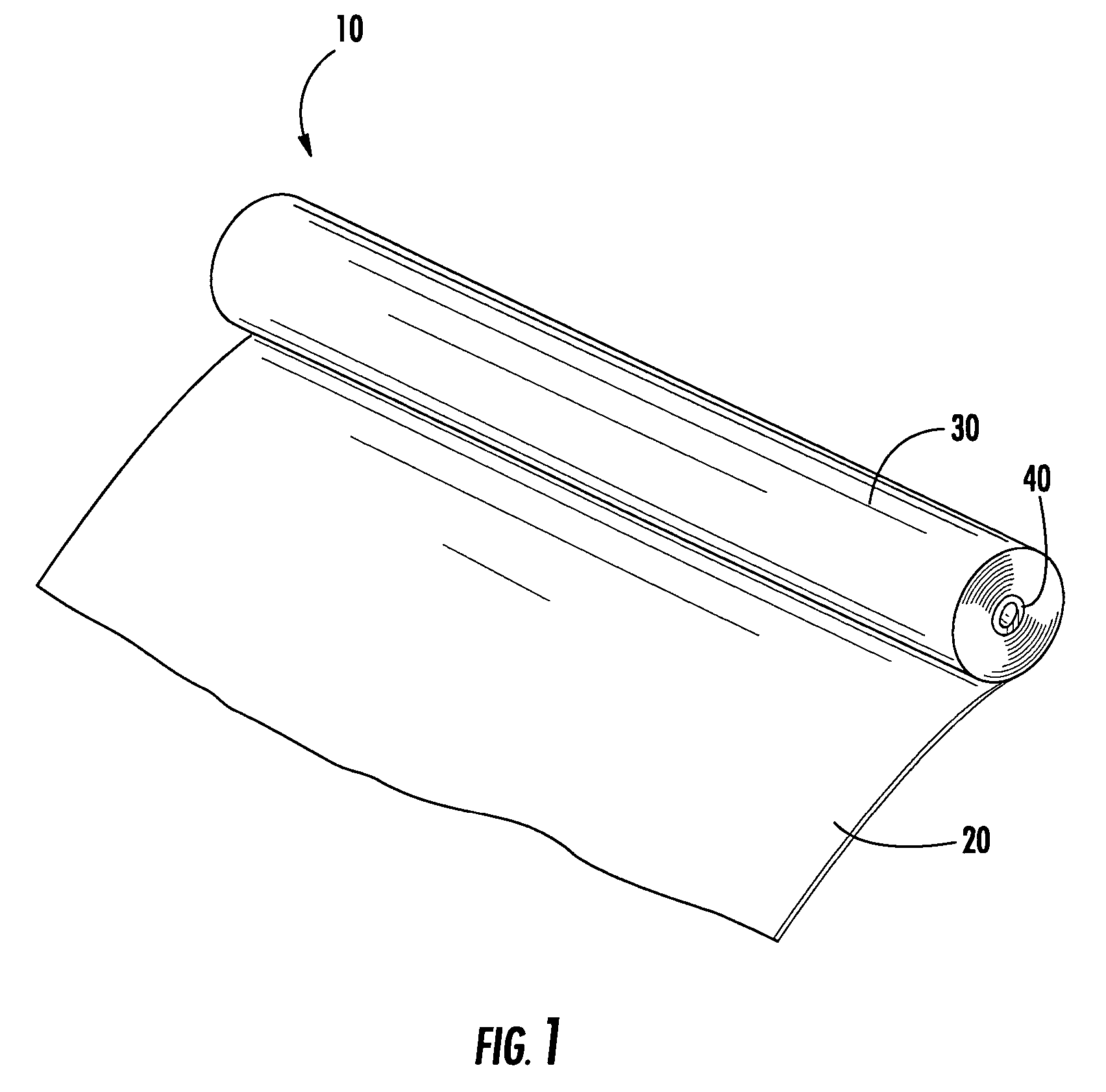

The invention is a cleaning material for cleaning printing machines. The cleaning material is comprised of a fabric that has been impregnated with a cleaning composition having branched chain monobasic and / or dibasic esters that contain 2-ethyl hexanoate. The cleaning composition can also include additional low volatility solvents and surfactants. A particularly useful cleaning composition is comprised of isobutyl stearate in combination with branched chain monobasic and / or dibasic esters that contain 2-ethyl hexanoate. The cleaning material can be wound onto a roll that can be adaptable to fit commercially available printing machine cleaning devices.

Owner:FIBERWEB SIMPSONVILLE

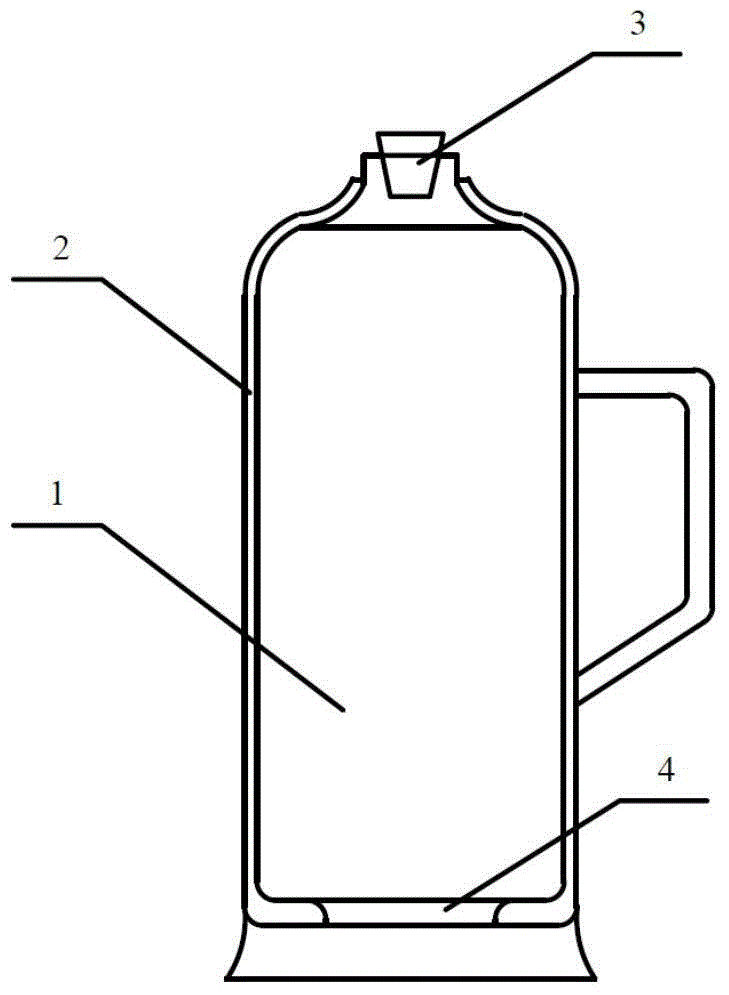

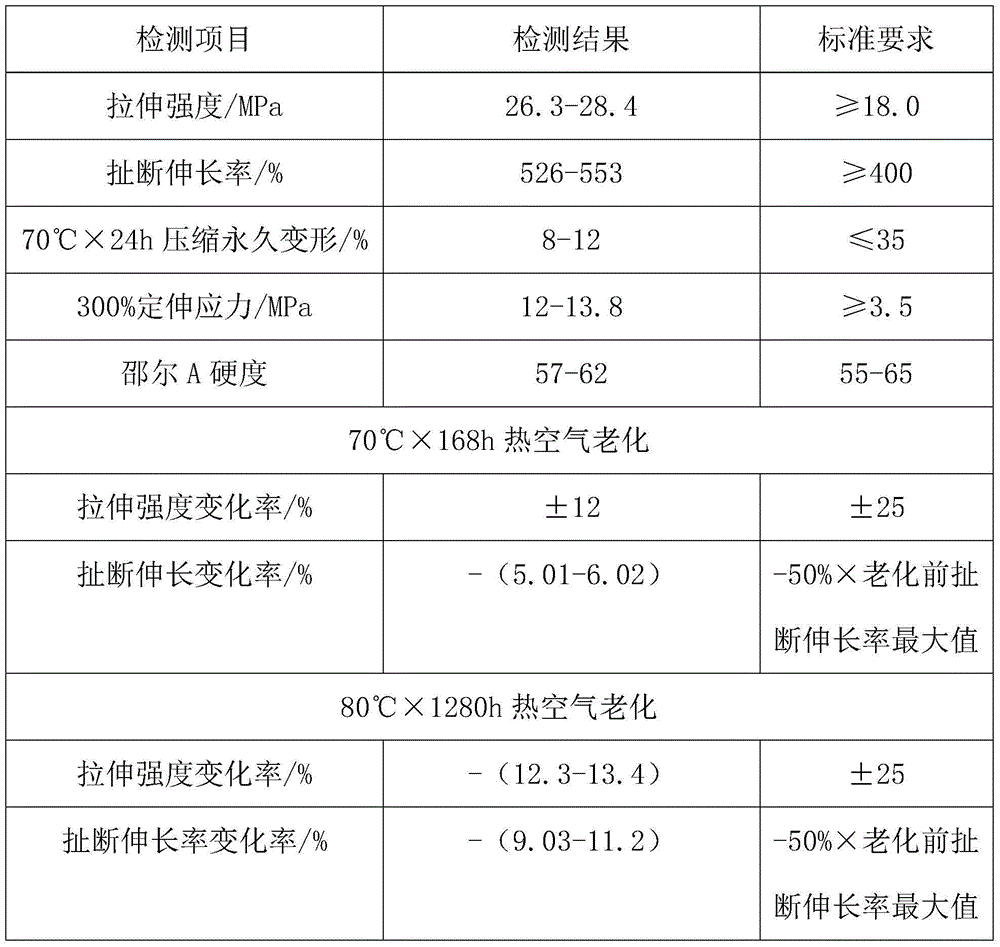

Aging-resistant thermos bottle

The invention discloses an aging-resistant thermos bottle comprising a liner, a housing, a bottle plug and a rubber pedestal. The liner is positioned in the housing. The rubber pedestal is used for fixing the liner. The rubber pedestal is manufactured with a modified natural rubber material. The raw materials for the modified natural rubber material comprise natural rubber, neoprene, nitrile rubber, epoxidized natural rubber, semi-reinforcing carbon black, high-abrasion furnace black, organic modified montmorillonite, zinc oxide, zinc 2-ethylhexanoate, sulfur, benzoyl peroxide, calcium stearate, an accelerator, an anti-aging agent D, an anti-aging agent RD, an anti-aging agent MB, coumarone, tricresyl phosphate, magnesium hydroxide, a silane coupling agent, cobalt boronacylate, monobutyl maleate dibutyltin, and dilauryl thiodipropionate. The aging-resistant thermos bottle provided by the invention has the advantages of excellent aging resistance, long service life, and low safety risk.

Owner:蚌埠市耀得保温容器有限公司

Graphenic carbon particle dispersions and methods of making same

Dispersions of graphenic carbon particles are produced using a polymeric dispersant. The polymeric dispersant includes an anchor block comprising glycidyl (meth)acrylate, 3,4-epoxycyclohexylmethyl(meth)acrylate, 2-(3,4-epoxycyclohexyl)ethyl(meth)acrylate, allyl glycidyl ether and mixtures thereof, reacted with a carboxylic acid comprising 3-hydroxy-2-naphthoic acid, para-nitrobenzoic acid, hexanoic acid, 2-ethyl hexanoic acid, decanoic acid and / or undecanoic acid. The polymeric dispersant also includes at least one tail block comprising at least one (meth)acrylic acid alkyl ester.

Owner:PPG IND OHIO INC

Coating composition for offset paper

InactiveUS7871681B2Shorten the timeSiccativesDrying-oil polymerisation2-Ethylhexanoic acidDrying time

Coating for an offset paper comprising a catalyst for fixing polymerisable or crosslinkable constituents of the offset ink. The chemical drying time can be substantially reduced if such a catalyst system is added to the coating, wherein preferentially such a catalyst is a transition metal complex / salt, like Mn (2-ethylhexanoate, bpy).

Owner:SAPPI NETHERLANDS SERVICES

Low-volatility plasticizer blends

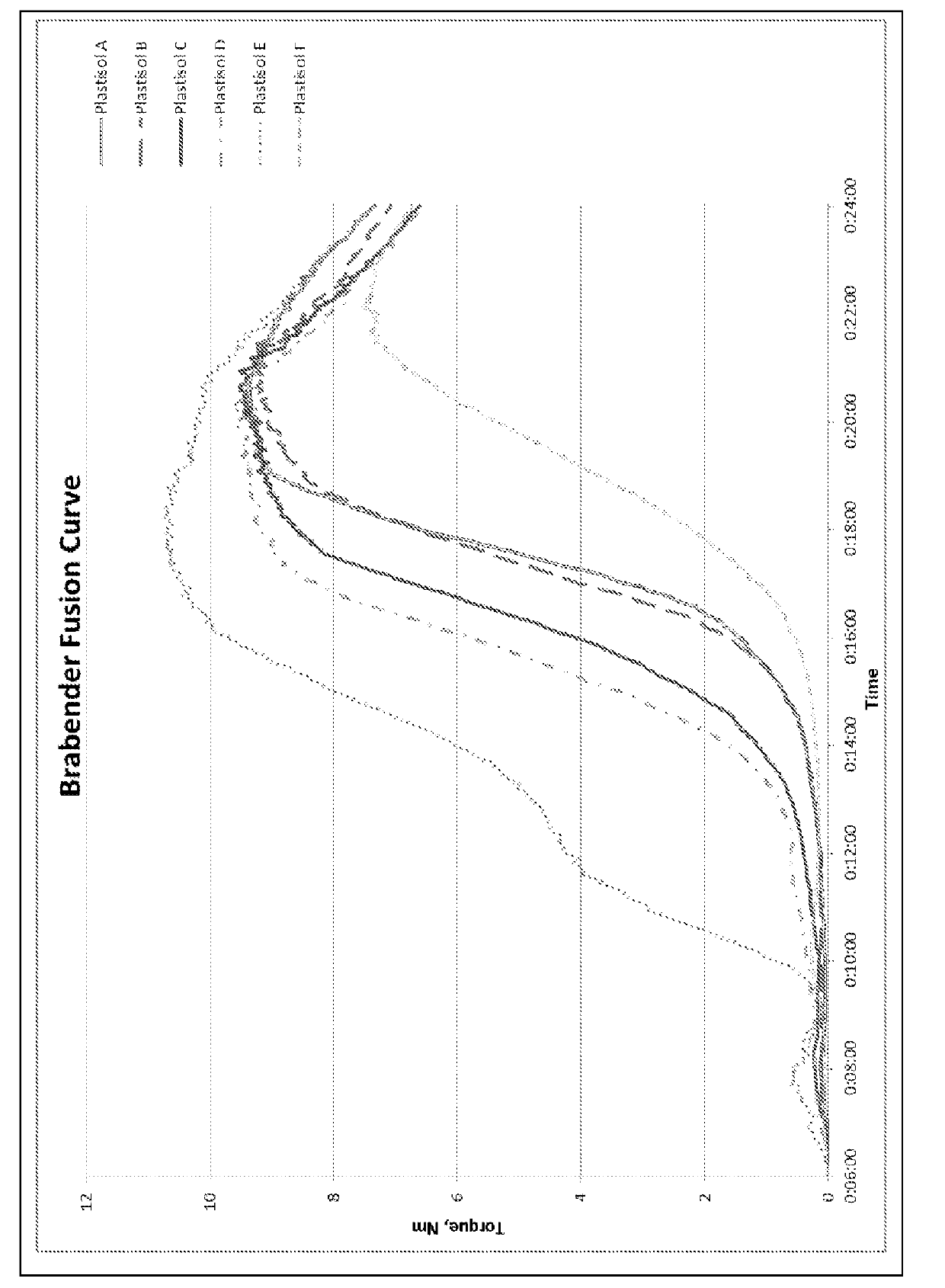

Disclosed is a plasticizer comprising xylylene glycol di-2-ethylhexanoate. The plasticizer can comprise xylylene glycol di-2ethylhexanoate and a second plasticizer. Also disclosed is a plastisol comprising a PVC resin dispersed in the liquid phase and a plasticizer comprising xylylene glycol di-2-ethylhexanoate and a second plasticizer. Additionally disclosed, an article can comprise the fused plastisol.

Owner:EASTMAN CHEM CO

Method of reducing wear of metal surfaces and maintaining a hydrolytically stable environment in refrigeration equipment during the operation of such equipment

InactiveUS20020055442A1Improve wear resistanceThe environment remains stableHeat-exchange elementsBase-materialsWorking fluid2-Ethylhexanoic acid

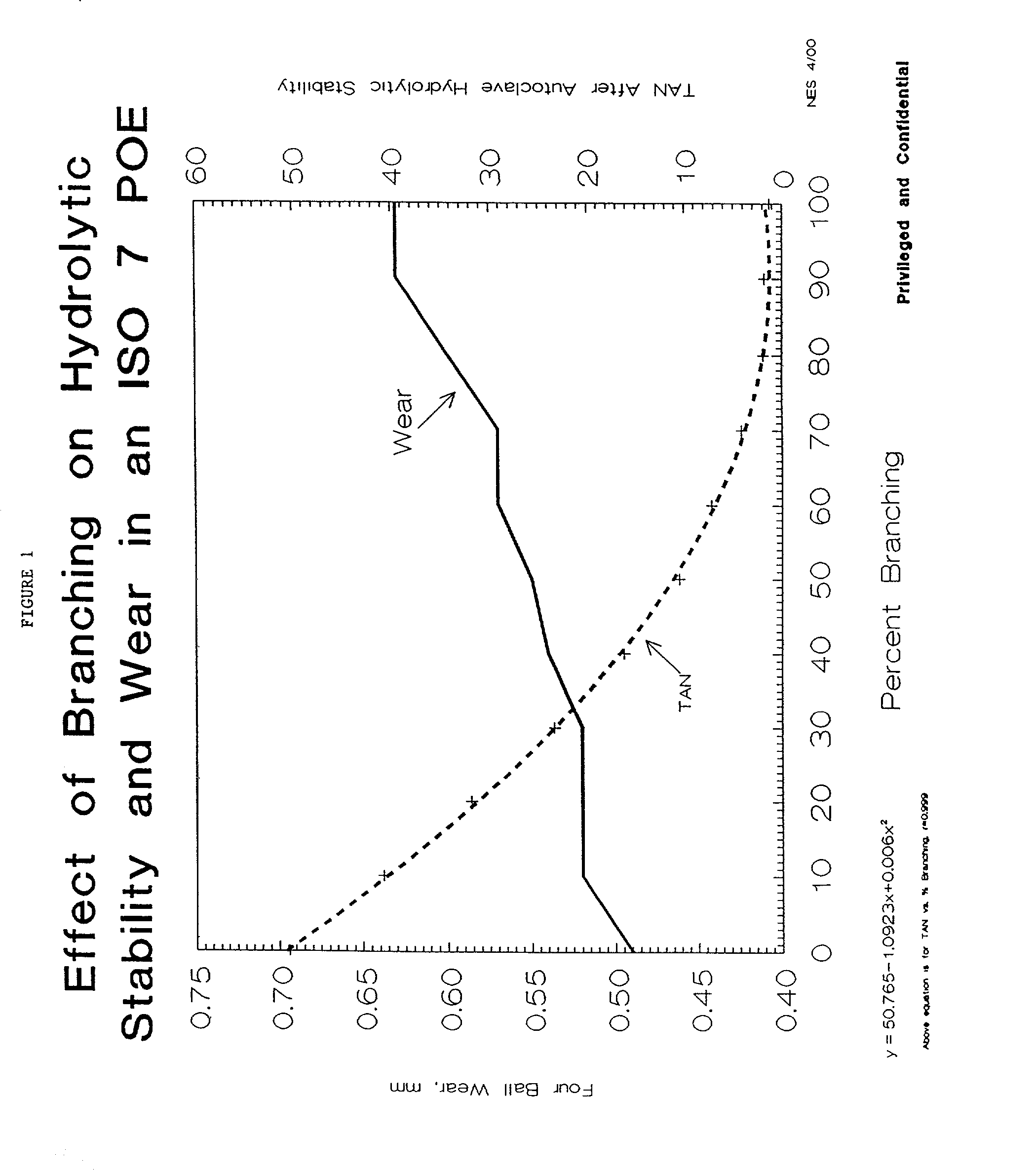

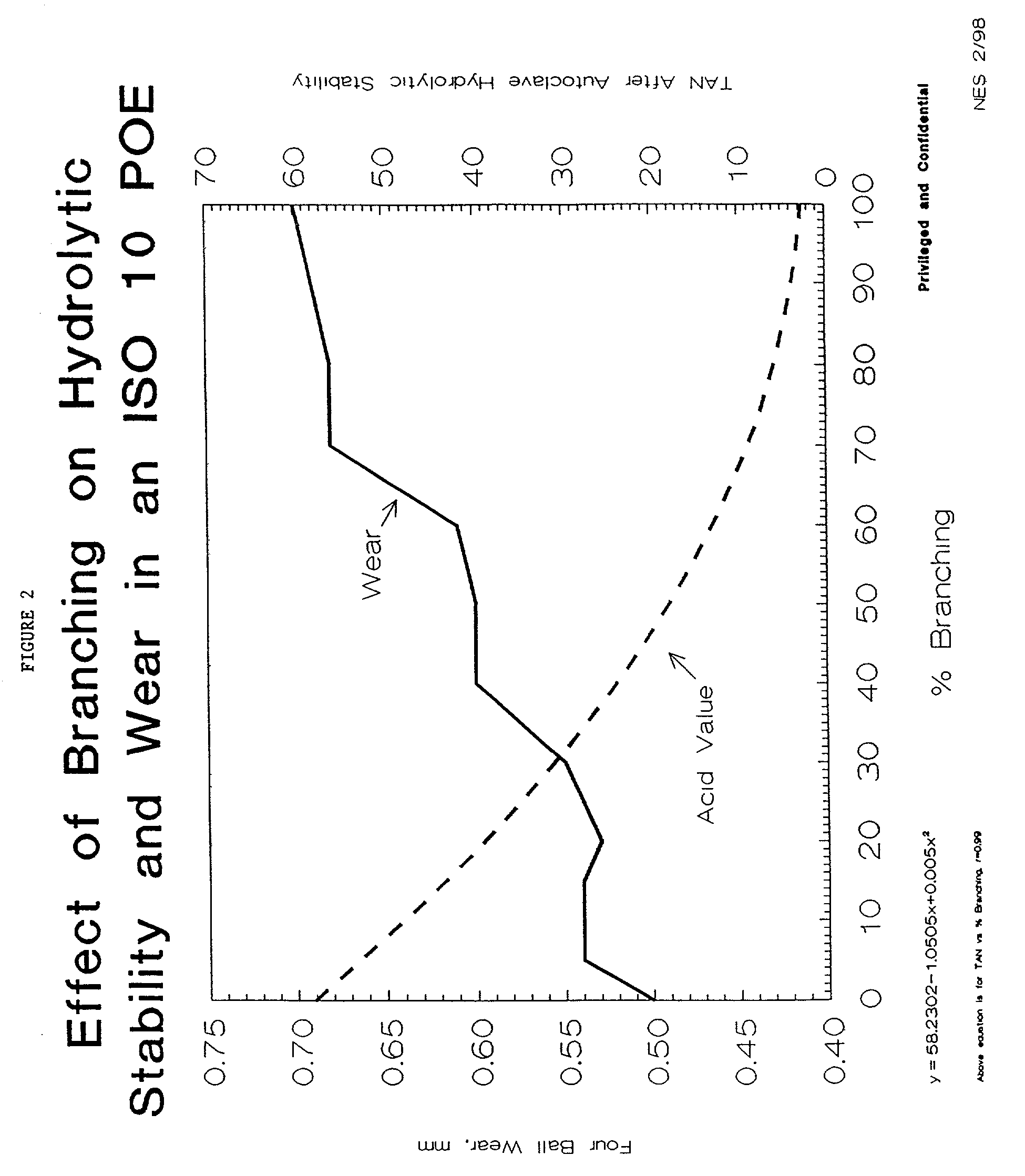

A method of improving wear of metal surfaces and maintaining a hydrolytically stable environment in refrigeration equipment during the operation of the equipment. The method involves contacting the metal surfaces with an ester lubricant base stock comprising blends of esters of neopentyl glycol and 2-ethylhexanoic acid and neopentyl glycol and at least one straight chain acid of four to ten carbon atoms and having a viscosity of about ISO 7-10. The lubricant can also be used in a working fluid with a chlorine-free fluoro-group heat transfer fluid such as 1,1,1,2-tetrafluoroethane.

Owner:COGNIS CORP

Process for treating and recycling industrial wastewater of peroxide-2-ethylhexoic acid tertiary butyl ester

InactiveCN102092905ARequirements to meet emission limit valuesHigh purityMultistage water/sewage treatmentSulfur-trioxide/sulfuric-acidChemical synthesisWater discharge

The invention discloses a process for treating and recycling industrial wastewater of peroxide-2-ethylhexoic acid tertiary butyl ester (an initiator OT), belonging to the technical field of industrial wastewater treatment. In the process, the industrial wastewater of peroxide-2-ethylhexoic acid tertiary butyl ester is directly collected from a sewage draining port of a production device and is subjected to stabilization treatment so as to basically eliminate the risk that organic peroxides in the wastewater are heated and severely decomposed, and tertiary butanol-tertiary butyl peroxide mixtures, concentrated sulfuric acid, sodium hydroxide and sodium chloride, which are recyclable, are separated and recycled from the wastewater. The wastewater subjected to removal of most organic matters and recycling of sulfuric phosphate, caustic soda and sodium chloride is subjected to hydrolysis-contact oxidation treatment, and C-Fe is subjected to micro-electrolysis decoloration, so that main water discharge indexes meet the requirements in Discharge Standards of Water Pollutants for Pharmaceutical Industry of Chemical Synthesis Products Category (GB21904-2008) for discharge limits of water pollutants for new enterprises. Therefore, the treatment of the peroxide-2-ethylhexoic acid tertiary butyl ester and the recovering and recycling of pollutants in the wastewater are realized.

Owner:NORTHWEST NORMAL UNIVERSITY

Oily cosmetic and cosmetic product

InactiveCN101909593ALiquidEvenly dispersedCosmetic preparationsMake-upSilicic acid2-Ethylhexanoic acid

Disclosed is an oily cosmetic which comprises: (a) 50 to 99 mass% of an oily phase which has a liquid form at 25 DEG C; (b) 1 to 7 mass% of dextrin (palmitate / 2-ethylhexanoate); and (c) 0.001 to 10 mass% of a coloring material and / or a pearlescent agent other than a laminated film powder, and which has a viscosity of 3000 to 20000 mPa s as measured on a BL viscometer at 30 DEG C. The oily cosmetic may further comprise (d) silicic acid anhydride and / or hydrophobized silicic acid anhydride.

Owner:SHISEIDO CO LTD

Ageing-resistant power cable

InactiveCN105206319AImprove thermal stabilityImprove aging resistancePlastic/resin/waxes insulatorsPower cablesInsulation layerElectrical conductor

The invention discloses a power cable, and particularly relates to an aging-resistant power cable. The aging-resistant power cable comprises a conductor, the conductor is coated with an insulation layer, the insulation layer is coated with an inner sheath layer, the inner sheath layer is coated with an armor layer, and a protection layer is arranged on the outermost layer. The insulation layer is made of metallocene polyethylene plastic, and the metallocene polyethylene plastic is prepared from metallocene polyethylene, methyl vinyl silicone rubber, 1,1,3,3-tetramethyl peroxy-2-ethylhexoic acid butyl ester, potassium dichromate ammonium, modified silkworm pupa protein fibers, nanosilicon dioxide, glass beads, kieselguhr, calcium carbonate, Ca-Zn composite stabilizer, isopropyl-3(positive ethylamino-ethylamino) titanate, cycloparaffin oil, chlorcosane, zinc stearate, 3(1-hexadecanol) ester, tri-caprate and acetylacetone titanium. The aging-resistant power cable is resistant to ageing and extremely good in heat stability.

Owner:ANHUI LAND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com