High-adhesion thermoset acrylic resin and preparation method thereof

An acrylic resin and high adhesion technology, which is applied in the field of resin for coatings, can solve the problems of poor coating film, difficult adhesion, and poor adhesion durability of the paint film, and achieve good adhesion effect, strong adhesion, and satisfactory The effect of market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

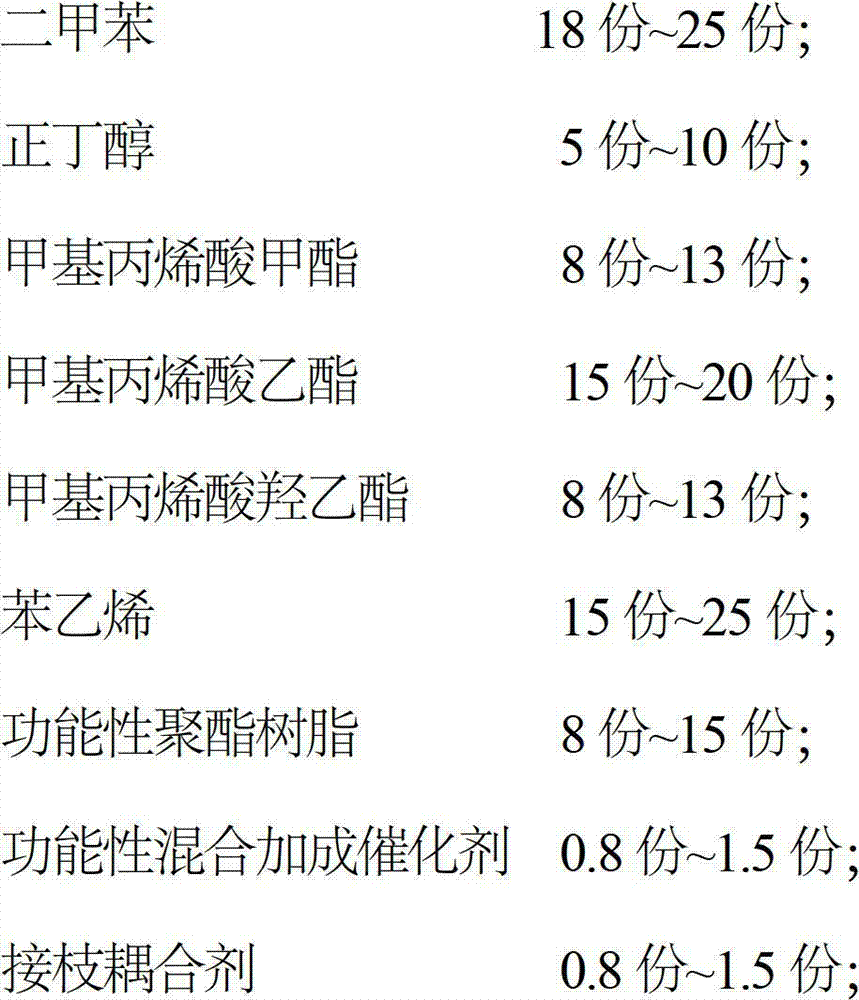

[0026] The high-adhesion thermosetting acrylic resin in this embodiment is made of the following components by weight:

[0027]

[0028] The high adhesion thermosetting acrylic resin of the present embodiment, its preparation method is as follows:

[0029] 1) Put material A into the reaction kettle and stir evenly;

[0030] 2) Add material B dropwise, the reaction temperature in the reactor is controlled at 120°C, and the time for adding material B dropwise is controlled at 3.5-4.5 hours;

[0031] 3) After the dropwise addition is completed, keep the temperature at 100° C. for 2 hours;

[0032] 4) add C material, and keep warm for 5 hours;

[0033] 5) Cool down to within 75°C, filter, and obtain;

[0034] in:

[0035] Material A is mixed by 20 parts by weight of xylene, 10 parts by weight of n-butanol, 10 parts by weight of functional polyester resin, 1 part by weight of graft coupling agent and 0.3 parts by weight of functional mixed addition catalyst ;

[0036] Mate...

Embodiment 2

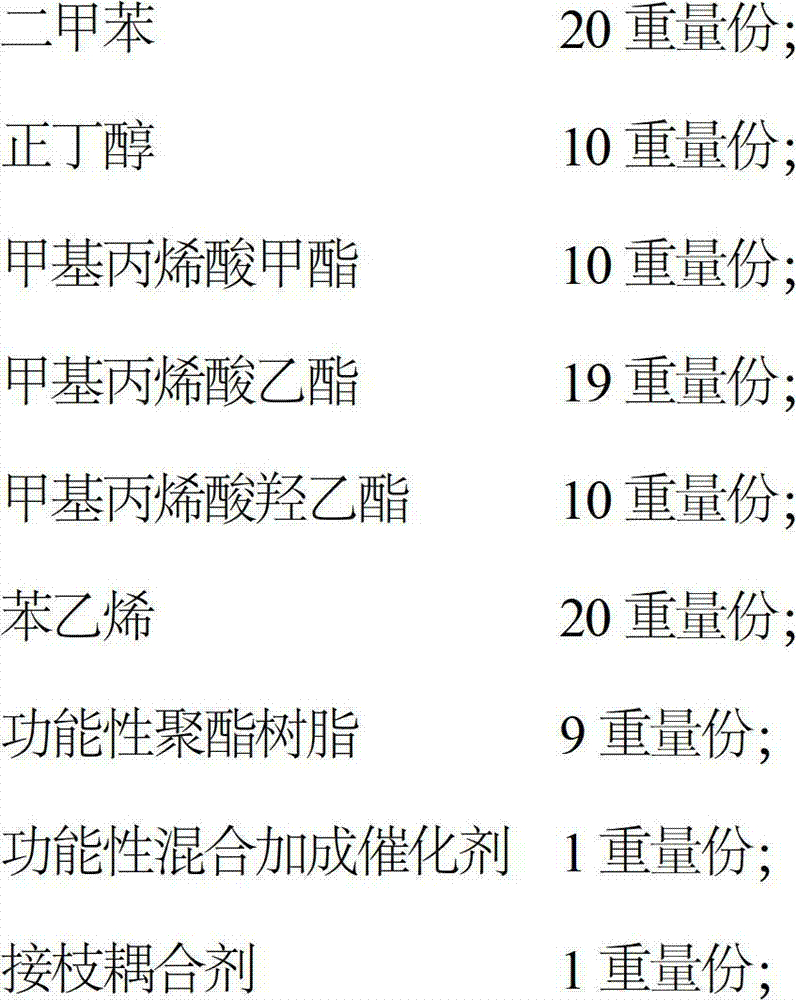

[0042] The high-adhesion thermosetting acrylic resin in this embodiment is made of the following components by weight:

[0043]

[0044]

[0045] The high adhesion thermosetting acrylic resin of the present embodiment, its preparation method is as follows:

[0046] 1) Put material A into the reaction kettle and stir evenly;

[0047] 2) Add material B dropwise, the reaction temperature in the reactor is controlled at 110°C, and the time for adding material B dropwise is controlled at 4 hours;

[0048] 3) After the dropwise addition is completed, keep the temperature at 110° C. for 2 hours;

[0049] 4) Add C material, and keep warm for another 6 hours;

[0050] 5) Cool down to within 75°C, filter, and obtain;

[0051] in:

[0052] Material A is mixed by 24 parts by weight of xylene, 7 parts by weight of n-butanol, 12 parts by weight of functional polyester resin, 1 part by weight of graft coupling agent and 0.3 parts by weight of functional mixing addition catalyst ; ...

Embodiment 3

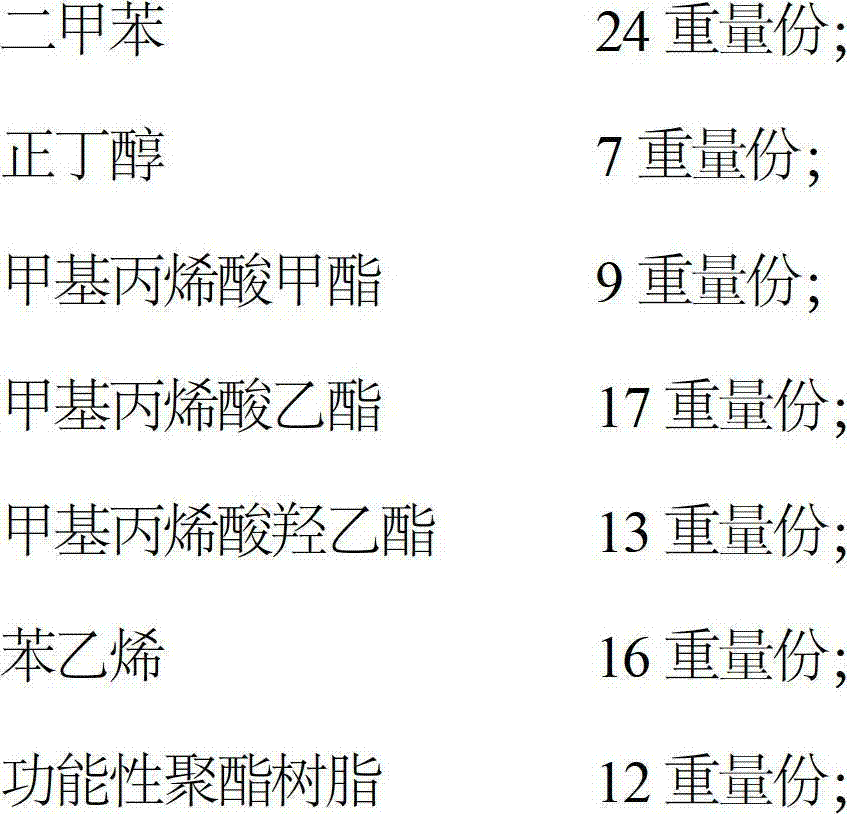

[0059] The high-adhesion thermosetting acrylic resin in this embodiment is made of the following components by weight:

[0060]

[0061] The high adhesion thermosetting acrylic resin of the present embodiment, its preparation method is as follows:

[0062] 1) Put material A into the reaction kettle and stir evenly;

[0063] 2) Add material B dropwise, the reaction temperature in the reactor is controlled at 110±10°C, and the time for adding material B dropwise is controlled at 3.5-4.5 hours;

[0064] 3) After the dropwise addition is completed, keep the temperature at 120° C. for 2 hours;

[0065] 4) Add C material, and keep warm for 7 hours;

[0066] 5) Cool down to within 75°C, filter, and obtain;

[0067] in:

[0068] Material A is mixed by 18 parts by weight of xylene, 8 parts by weight of n-butanol, 12 parts by weight of functional polyester resin, 1.5 parts by weight of graft coupling agent and 0.5 parts by weight of functional mixing addition catalyst ;

[0069...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com