Patents

Literature

31results about How to "No thickening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

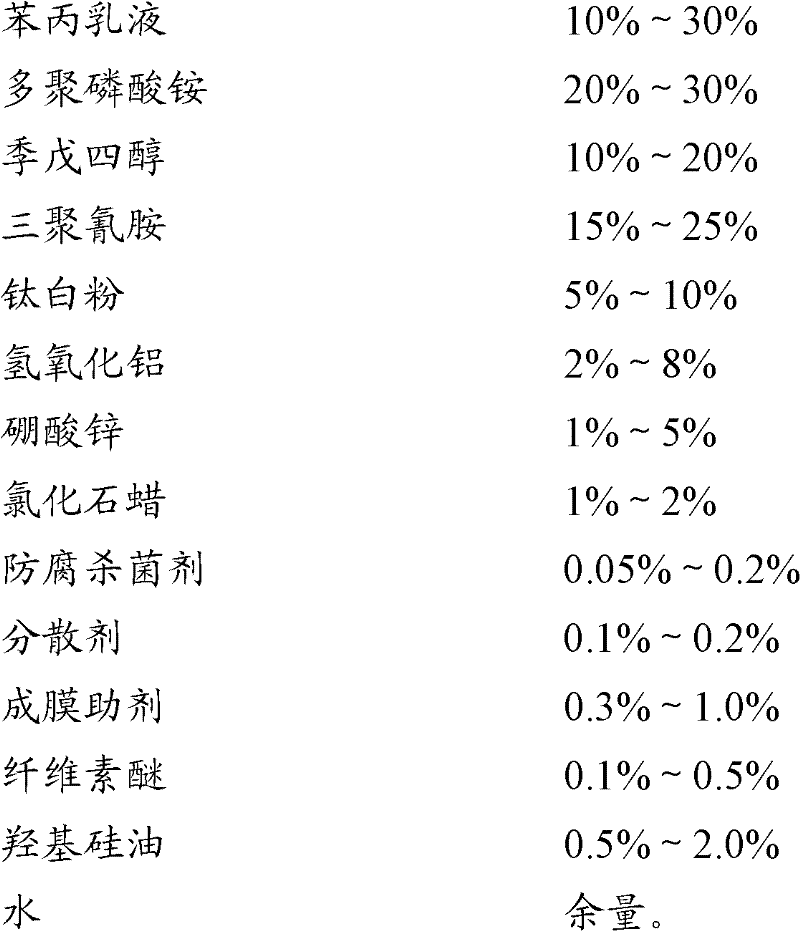

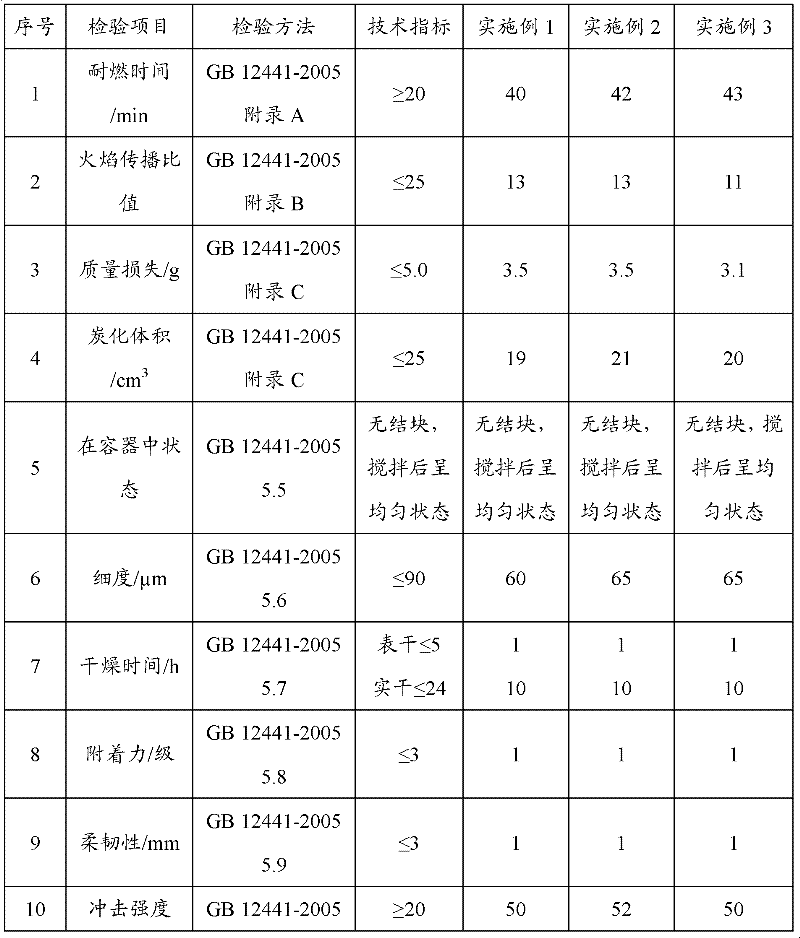

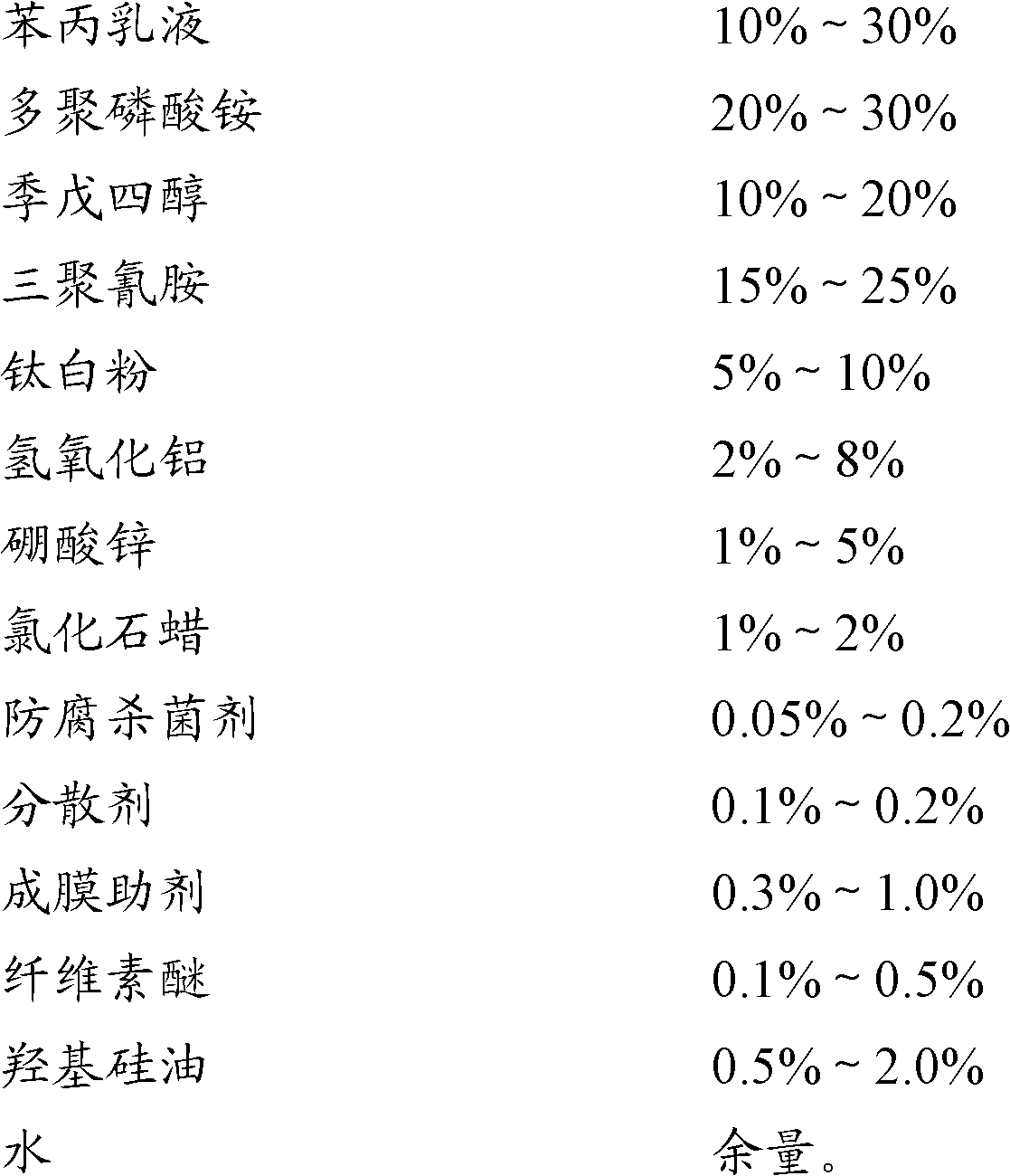

Expanded type aqueous facing fireproof coating and preparation method thereof

ActiveCN102675992AImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

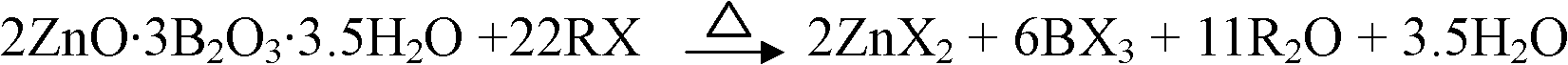

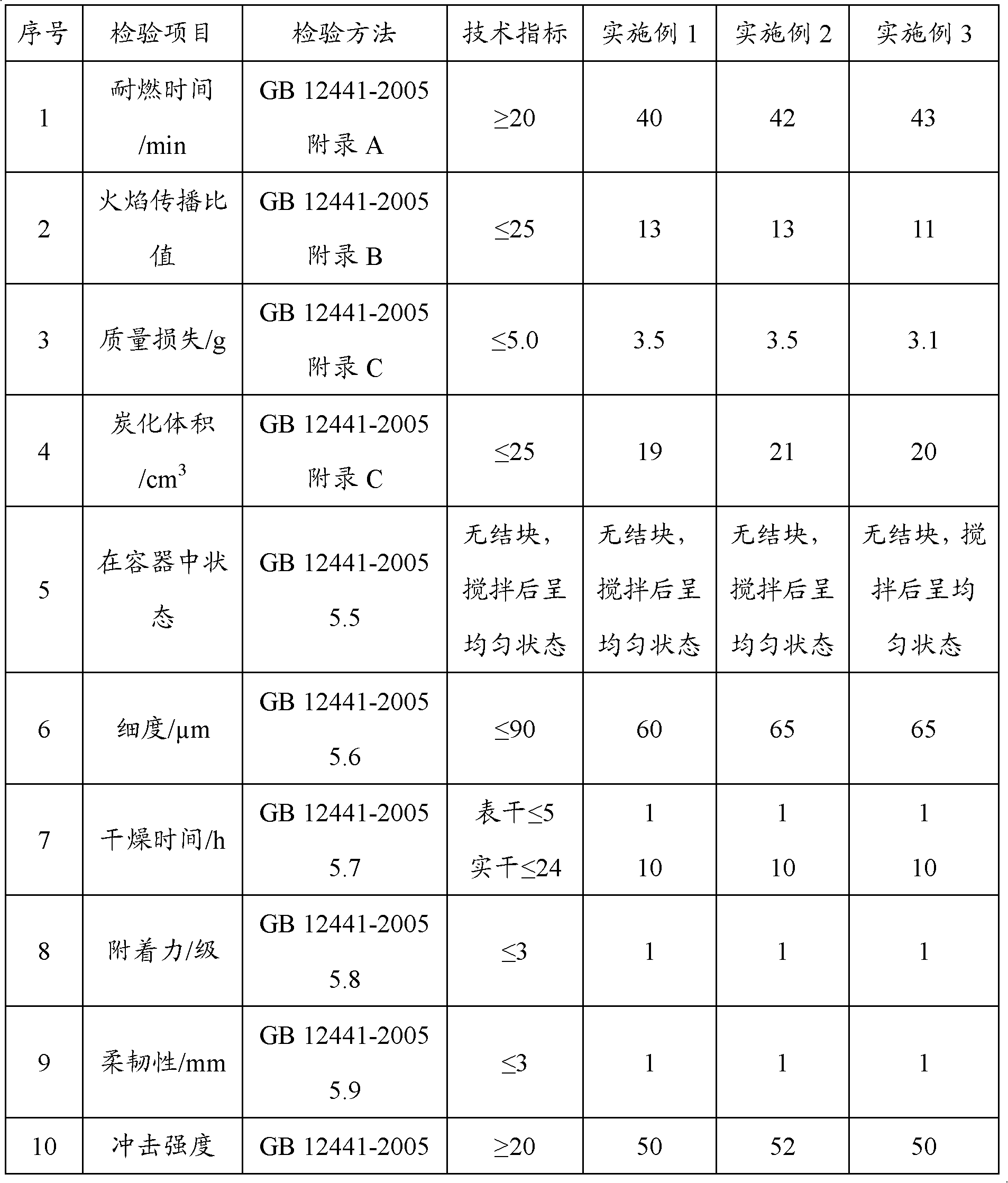

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

Silane modified polyurethane glass primer and preparation method thereof

ActiveCN102516921AFast film formationIncrease the density of crosslinksNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventChemistry

The invention discloses a silane modified polyurethane glass primer and a preparation method thereof. The glass primer is prepared from the following raw materials by weight: 20 to 60 parts of silane-terminated polyurethane perpolymer, 30 to 65 parts of a solvent, 1 to 3 parts of a water-removing additive, 2 to 10 parts of carbon black, 1 to 2 parts of an anti-settling agent, 2 to 5 parts of a cross-linking promoter and 0.05 to 0.2 part of a catalyst A, wherein, raw materials for the silane-terminated polyurethane perpolymer comprise, by weight, 15 to 25 parts of polyether polyol, 12 to 24 parts of diisocyanate, 0.01 to 0.05 part of dibutyltin dilaurate or stannous octoate, 30 to 60 parts of ethyl acetate and 12 to 22 parts of an end-capping reagent. According to the invention, disadvantages of the prior art are overcome; when the silane modified polyurethane glass primer is used at normal temperature for 40 min in the air, the phenomenon of obvious thickening does not appear, and a film is not formed on the surface of the glass primer; the glass primer facilitates construction and is simple to use, and when used, the glass primer is directly poured into a container and then is directly used for brush coating within 40 min.

Owner:SHANDONG NORTH MODERN CHEM IND

Expanded type aqueous facing fireproof coating and preparation method thereof

ActiveCN102675992BImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

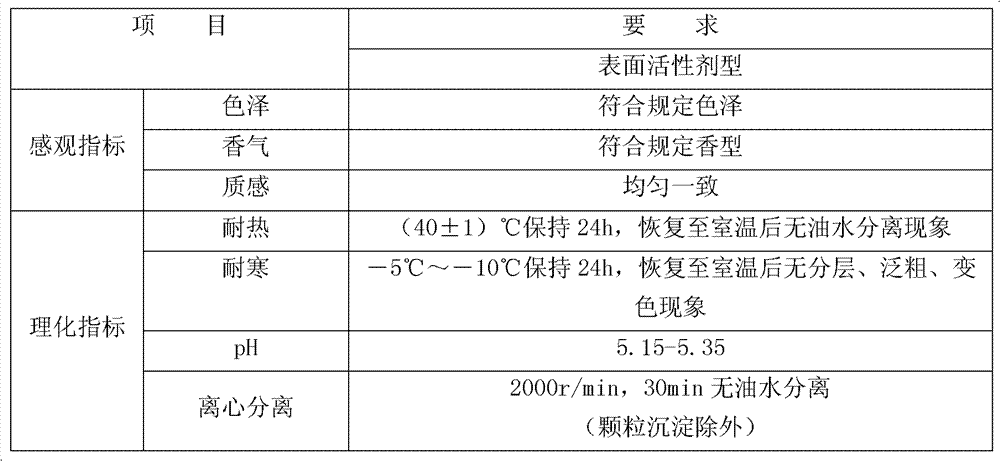

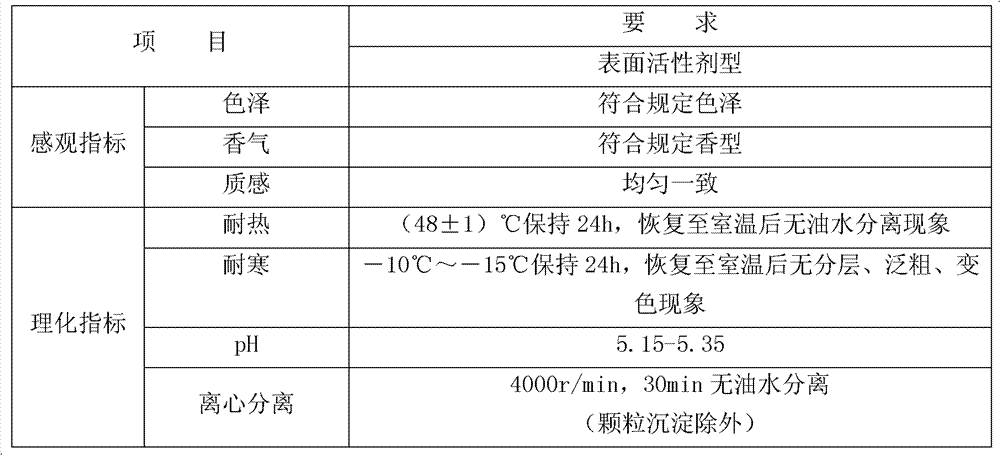

Amino acid cleansing cream and preparation method thereof

ActiveCN102327198AImprove stabilityNo phototoxicityCosmetic preparationsToilet preparationsBetaineCocoyl glutamate

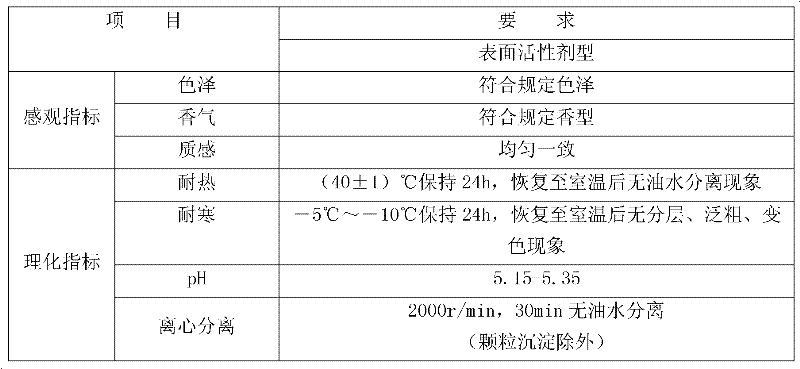

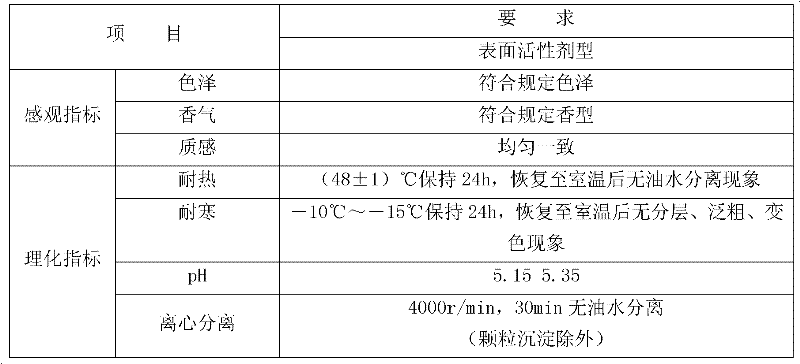

The invention discloses an amino acid cleansing cream and a preparation method thereof. The amino acid cleansing cream comprises the following components in percent by weight: 3-8 percent of glycerol, 0.05-0.2 percent of hydroxyethylcellulose, 5-13 percent of propylene glycol, 25-30 percent of sodium lauroyl glutamate, 5-8 percent of sodium cocoyl glutamate, 0.5-1.5 percent of ethal-octadeca-composite fatty alcohol, 0-2 percent of ethylene glycol distearate, 0.2-0.6 percent of cetearyl alcohol ether (20), 0.5-1.5 percent of cocoaminopropyl dimethyl betaine, 0.5-1.5 percent of cetearyl alcoholether-60 myristyl glycol, 1-3 percent of acrylate / polyoxyethylene-20 stearin alcohol ether methacrylate copolymer, 0.4-0.8 percent of citric acid, 0.1-0.2 percent of diazolidiny urea, 0.10-0.15 percent of methyl phydroxybenzoate and the balance of deionized water. the amino acid cleansing cream has better stability and solid content of sodium lauroyl glutamate of more than or equal to 25 percent,and can create a comfortable and clear microenvironment for healthy growth and metabolism for skin cells on the face.

Owner:SHENZHEN GENE BIOLOGICAL TECH

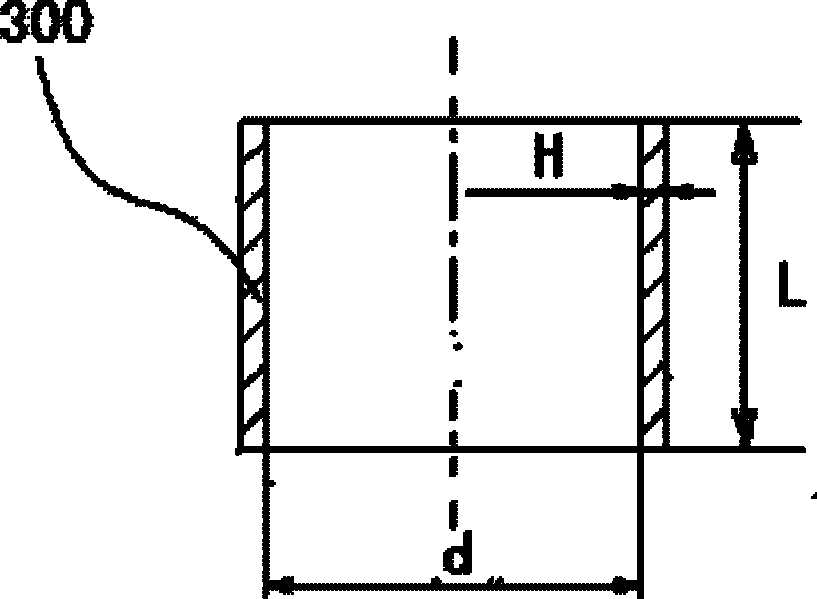

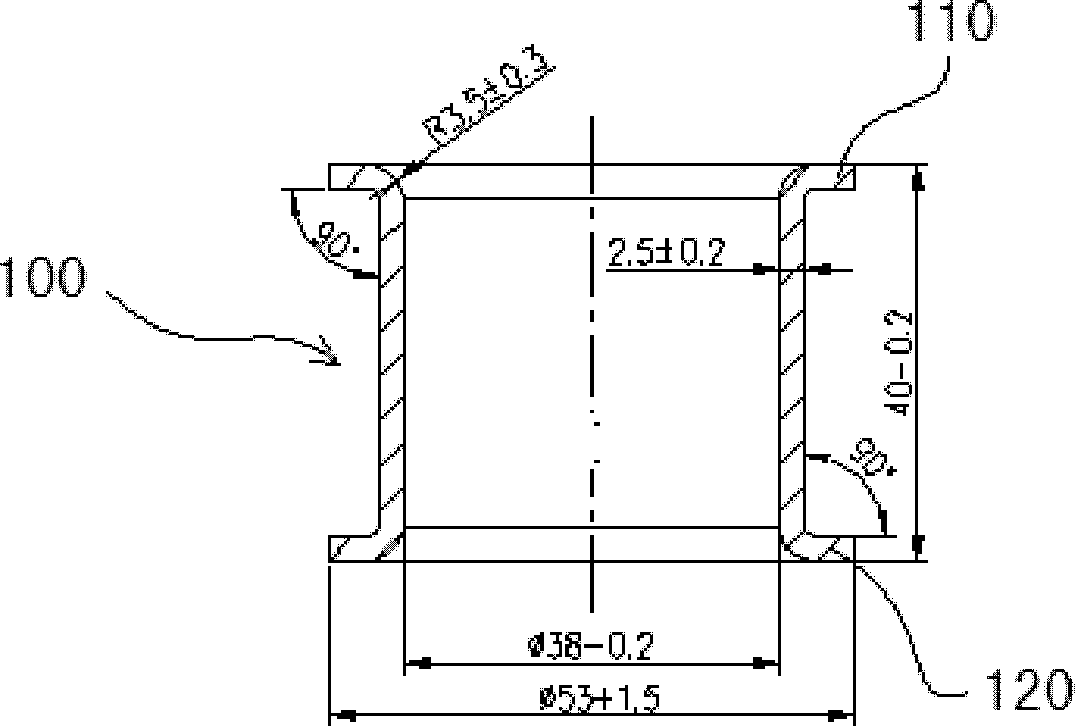

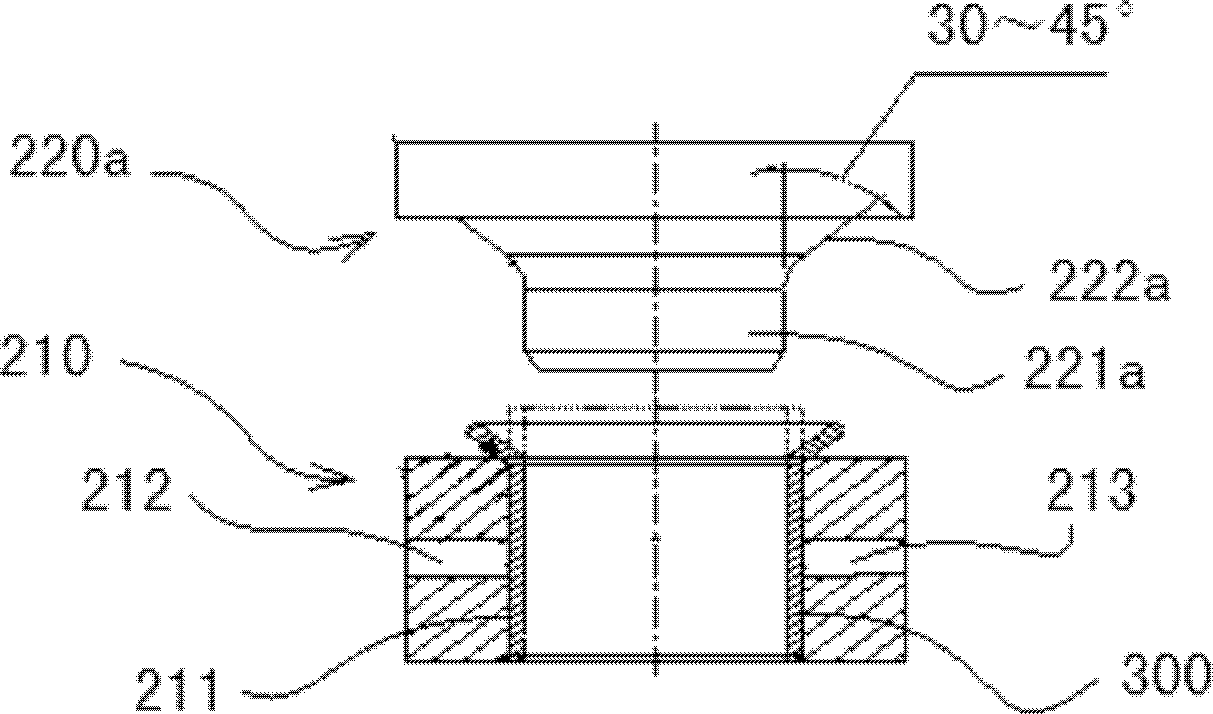

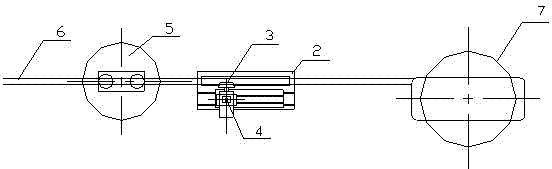

Processing method and die for shaft sleeve used for automobile steering transmission mechanism

The invention discloses a processing method for a shaft sleeve used for an automobile steering transmission mechanism. In the method, an E35+N seamless steel tube is used as a parent material, a flanging die composed of a male die and a female die is used, and the shaft sleeve is manufactured by flanging each end of the seamless steel tube for three times, wherein a first flanging angle is 30-45 degrees, a second flanging angle is 45-70 degrees and the third flanging angle is 70-93 degrees; while flanging the first end, a descending speed of the male die is controlled to be 50-100 mm / min; while flanging the second end, the descending speed of the male die is controlled to be 150-200 mm / min; in each flanging process, lubricating oil is injected between the parent material and the female die through a lubricating oil hole on the male die, and simultaneously, compressed air is injected between the parent material and the female die through a cooling air hole on the male die so as to cool the parent material; one end is flanged firstly, and the other end is flanged later. The method has the following technical benefits that: at a part with an inner angle of 90 degrees, the phenomenon of thickening cannot be caused; 2, at an excircle part of the flange, the phenomenon of thickness reduction cannot be caused, and hair cracks and wrinkle the material can be effectively avoided. The method further discloses a die using the method.

Owner:SHANGHAI ZUNMA AUTO PIPE CO LTD

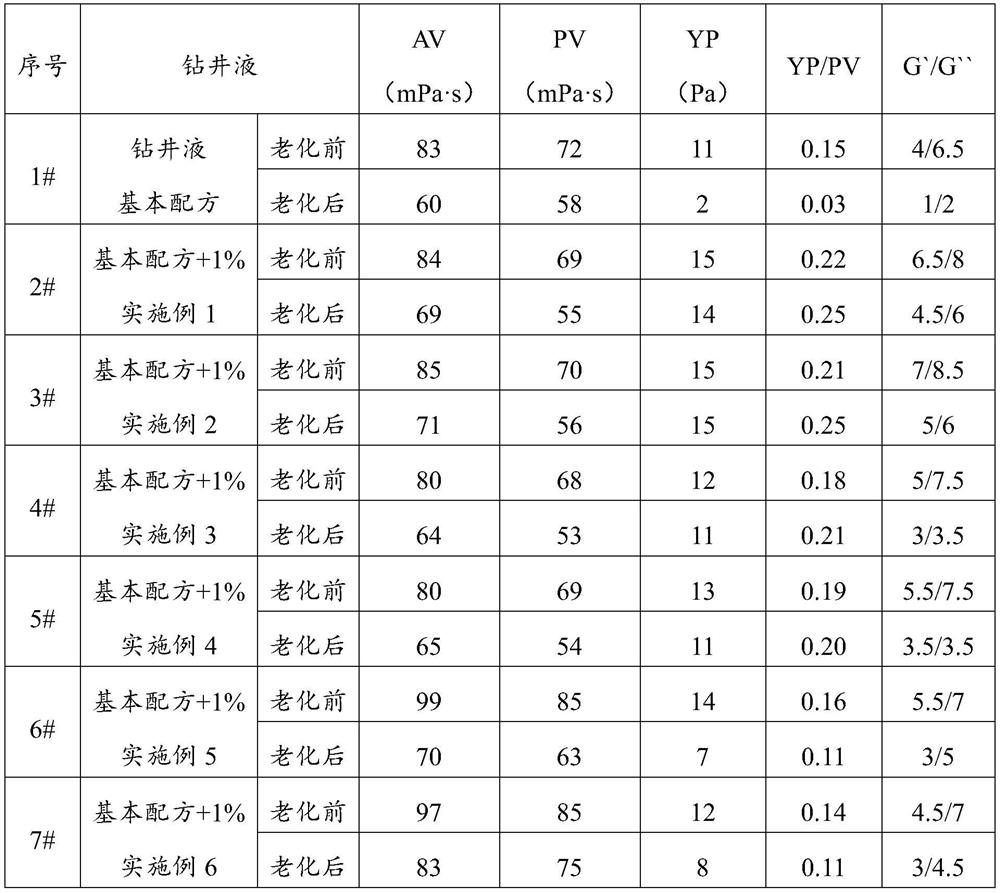

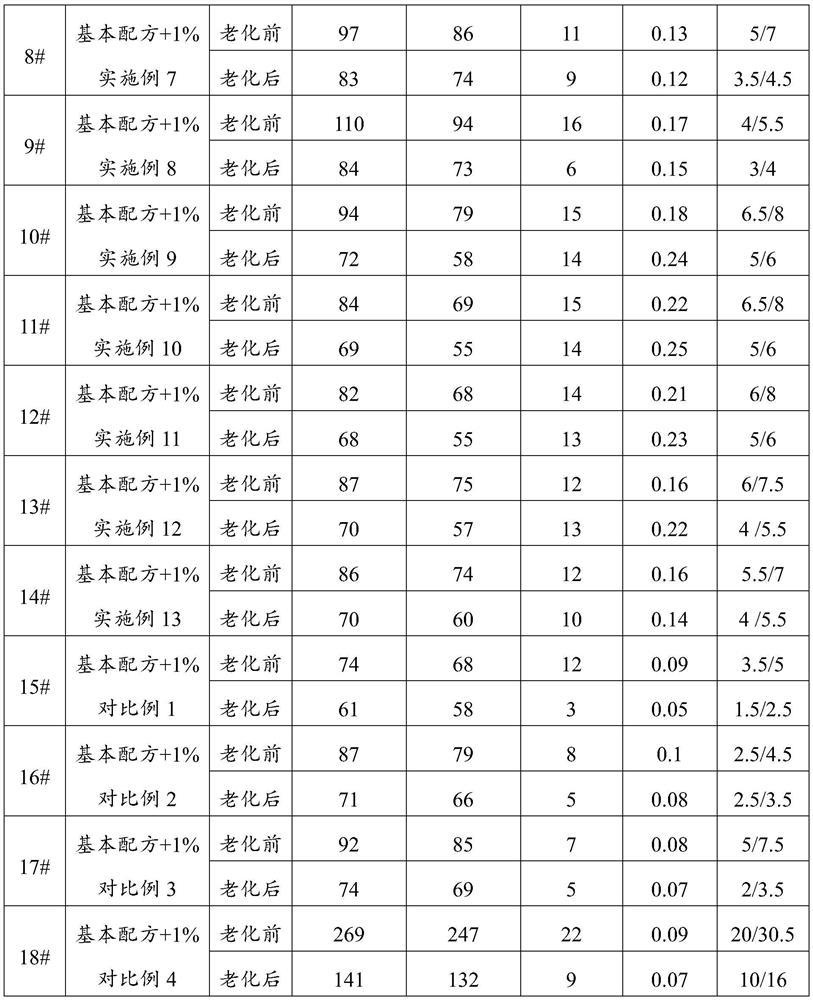

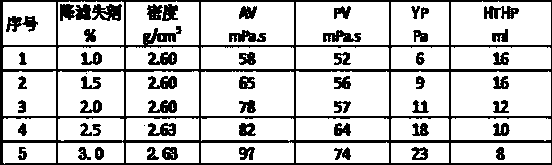

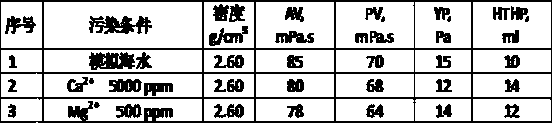

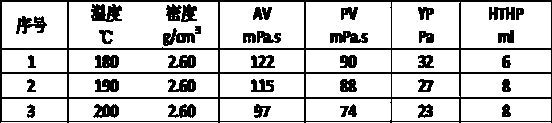

High-temperature-resistant drilling fluid as well as preparation method and application thereof

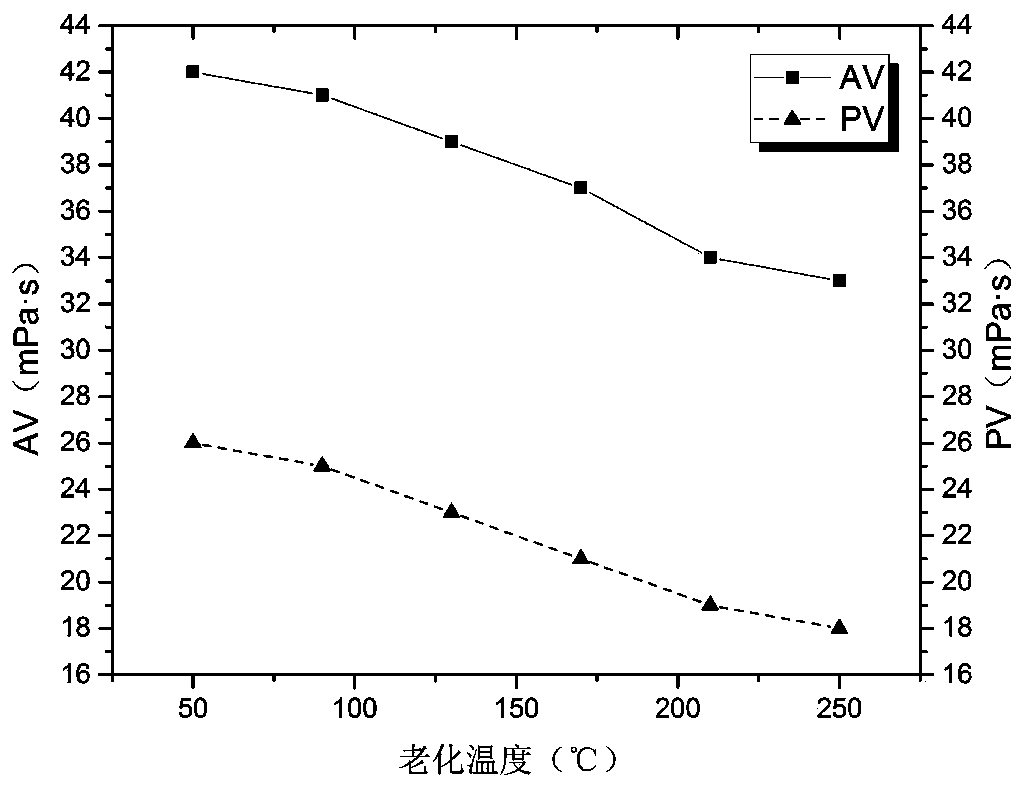

PendingCN111286310AAvoid percolationRheology can be easily adjusted at high temperatureFlushingDrilling compositionThermodynamicsTackifier

The invention relates to a high-temperature-resistant drilling fluid as well as a preparation method and application thereof, and belongs to the technical field of drilling fluids. The high-temperature-resistant drilling fluid is prepared from the following preparation raw materials in parts by mass: 100 parts of water, 2-4 parts of attapulgite, 3-6 parts of an inorganic tackifier, 0.05-0.15 partof an alkalinity regulator, 0.4-1.0 part of a high-temperature-resistant polymer filtrate reducer, 3-6 parts of a high-temperature-resistant sulfonated filtrate reducer, 2-5 parts of a high-temperature-resistant anti-collapse agent, 3-8 parts of a high-temperature stabilizer and 0.3-1.0 part of a deoxidant. The drilling fluid provided by the invention has good rheological property, and can maintain stable performance under a long-term high-temperature condition; besides, the drilling fluid has good wall-building property, inhibition property and anti-pollution capability under the conditions of high temperature and high pressure, is beneficial to well wall stability, can overcome the possible influence of abnormal temperature and pressure, complex stratums and the like in deep wells and construction on the performance of the drilling fluid, and can be suitable for various drilling engineering.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

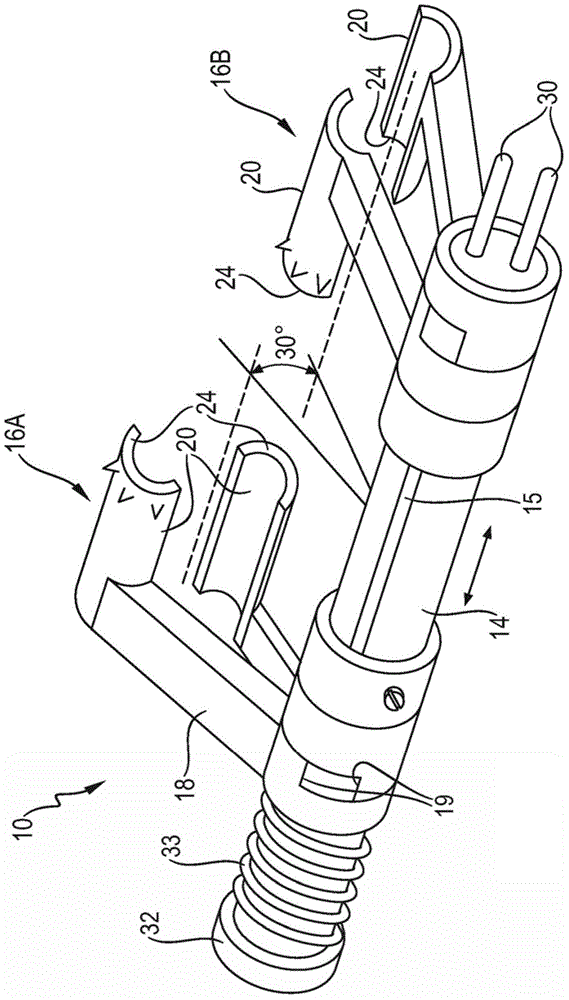

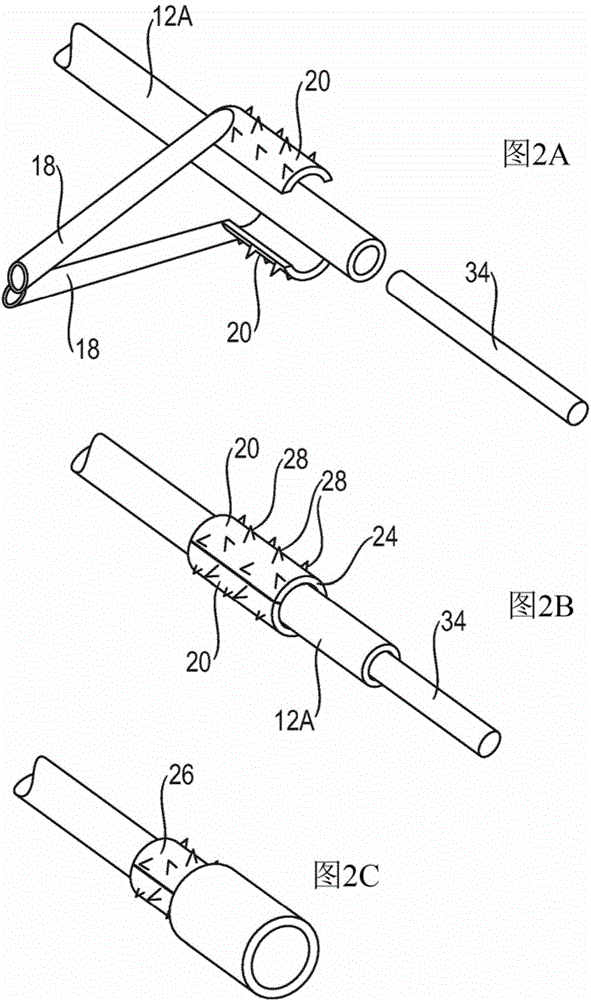

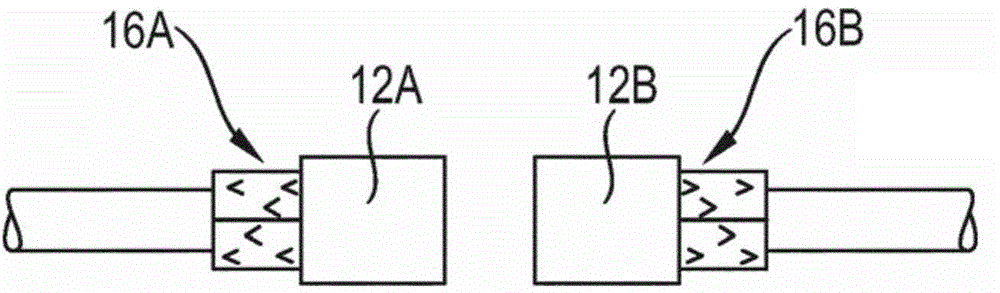

Electrosurgical instrument for producing an end-to-end anastomosis

ActiveCN104602620ANo thickeningWill not cause narrowingSurgical instruments for heatingSurgical forcepsSurgical instrumentationBiomedical engineering

The invention relates to an electrosurgical instrument (10) for producing an end-to-end anastomosis between two hollow organ sections (12), comprising two tools (16) that can be moved in relation to each other, each of the tools having a high-frequency electrode (24), by means of which the hollow organ sections (12) can be fused to each other. According to the invention, the two tools (16) are substantially sleeve-shaped or at least can be brought into a sleeve shape such that a first tool (16A) can surround a first hollow organ section (12A) and a second tool (16B) can surround a second hollow organ section (12B). The electrodes (24) are each formed on an end face (22) of the sleeve-shaped tools (16), around which end face the respective hollow organ section (12) can be everted, and the two tools (16) can be moved in relation to each other in such a way that the electrodes (24) can be aligned and can clamp the everted hollow organ sections (12A, 12B) between the electrodes.

Owner:AESCULAP AG

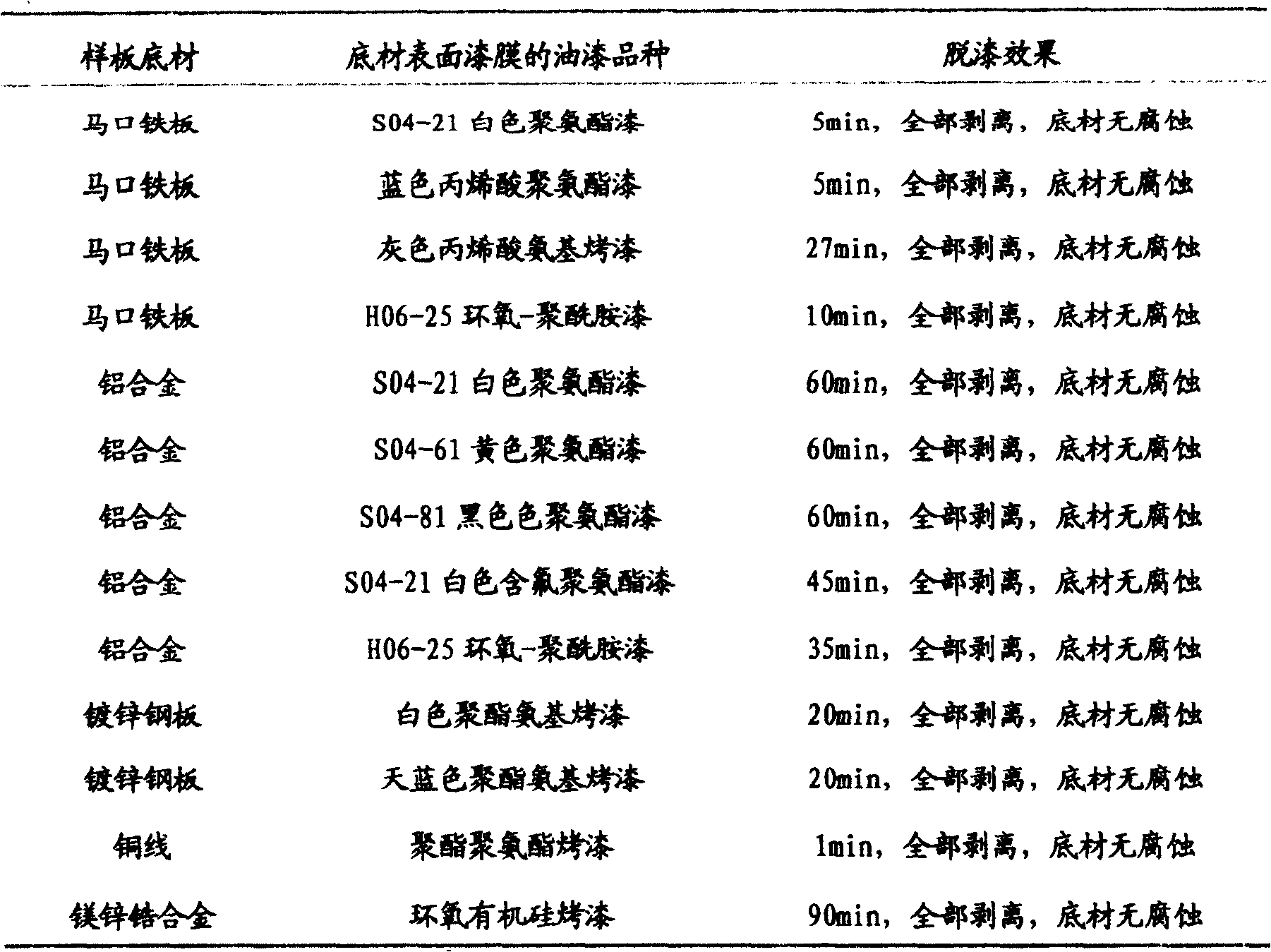

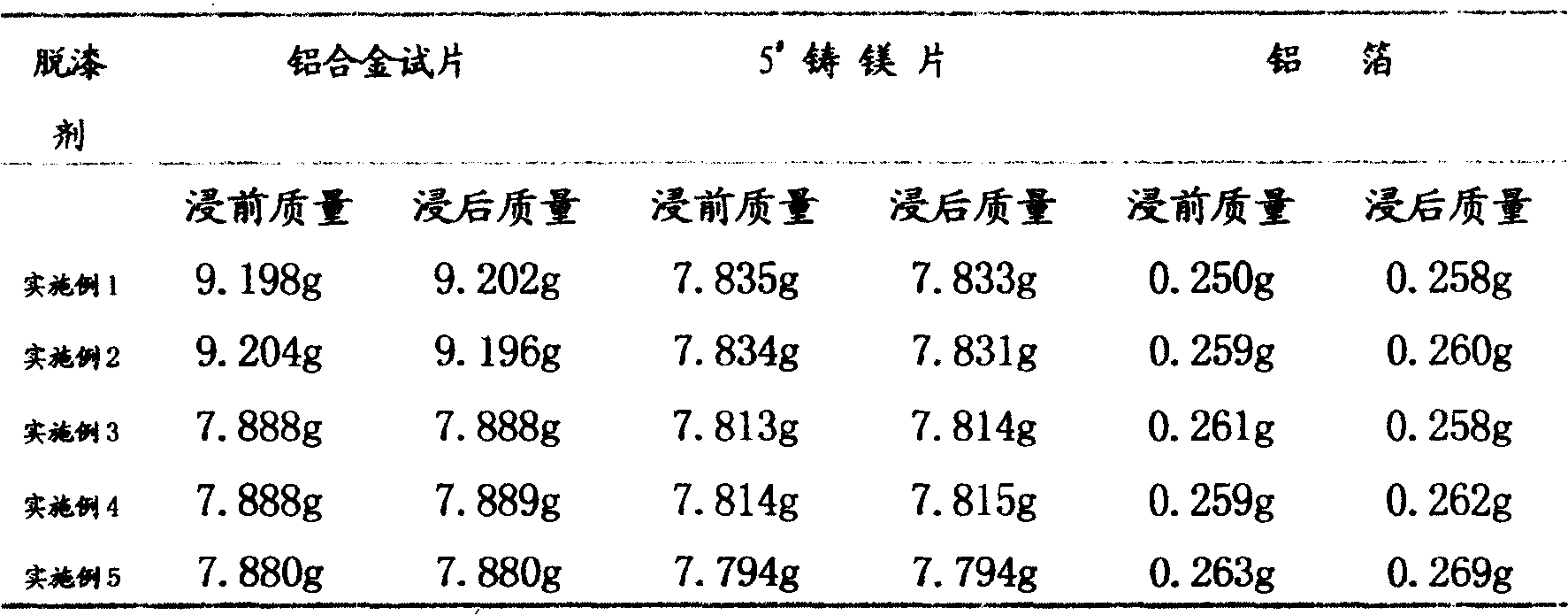

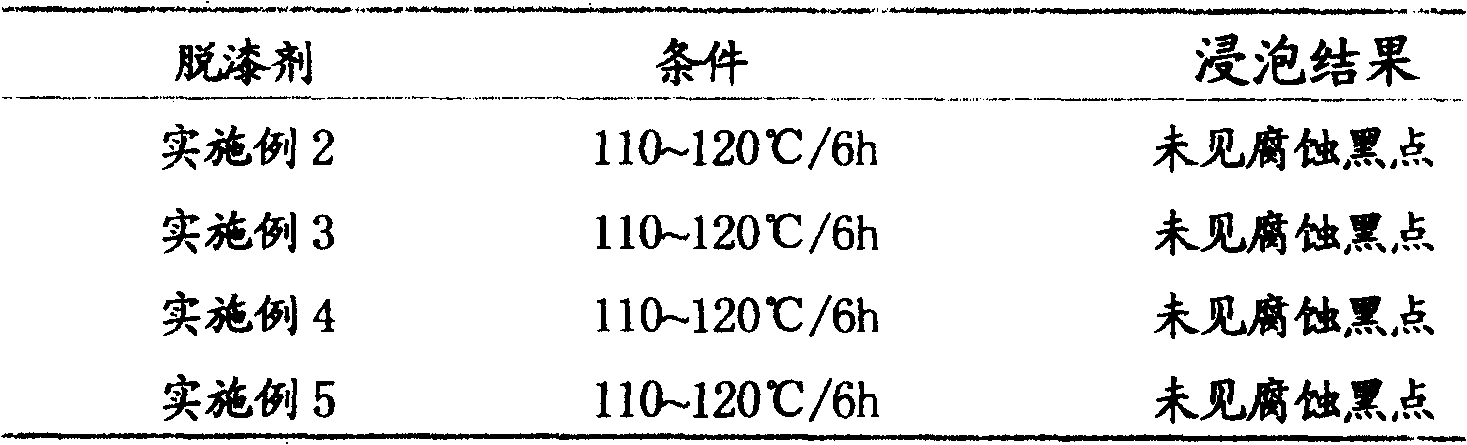

Novel paint remover and preparation method thereof

InactiveCN102372943ASmall molecular weightStrong permeabilityChemical paints/ink removersMineral oilOrganic base

The invention relates to a novel paint remover and a preparation method thereof. The novel paint remover is composed of organic base, an organic solvent, and a corrosion inhibitor. During storage and application periods, the novel paint remover is coated by an oil sealant coating. The organic base is hydramine. The boiling point of the organic solvent is at least 200 DEG C. The corrosion inhibitor is a saccharide. The oil sealant coating is vegetable oil or mineral oil with a density lower than the novel paint remover. The oil sealant coating is insoluble or slightly soluble in the novel paint remover. The paint remover is simple to prepare, easy to use, and satisfies the requirement of environment protection. With the novel paint remover provided by the invention, various paint films can be removed, the paint removing speed is high, and no corrosion is brought to various substrates. Therefore, the paint remover is suitable to be used in paint removing of large complicated work-pieces and sensitive substrates.

Owner:王雪

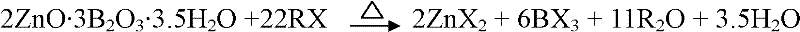

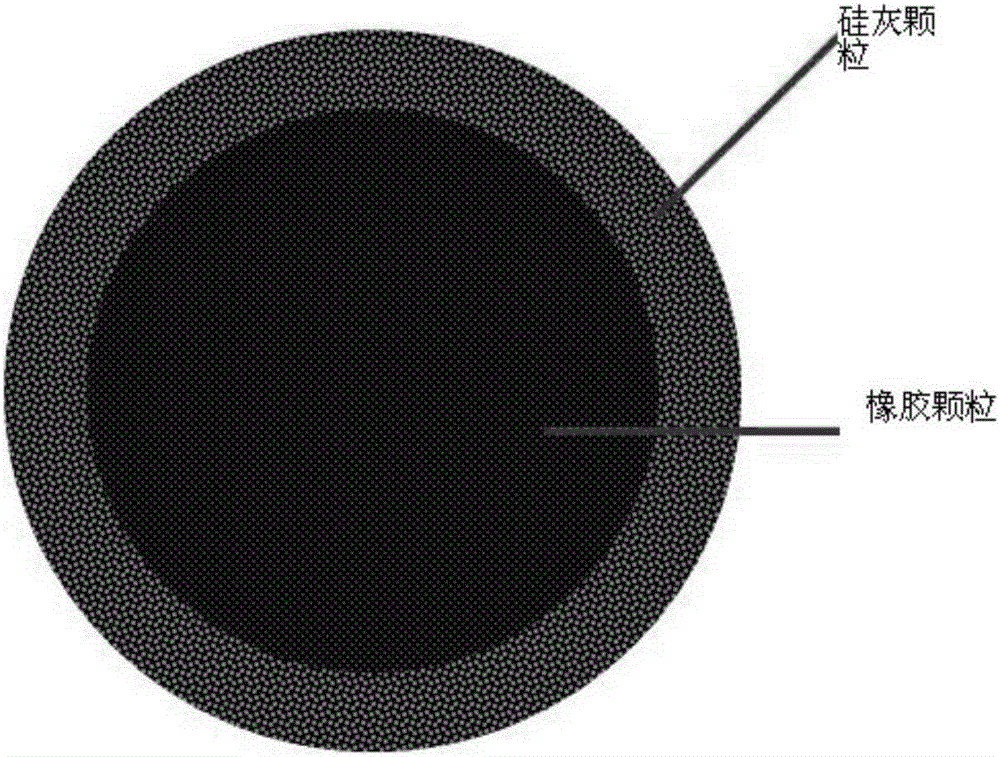

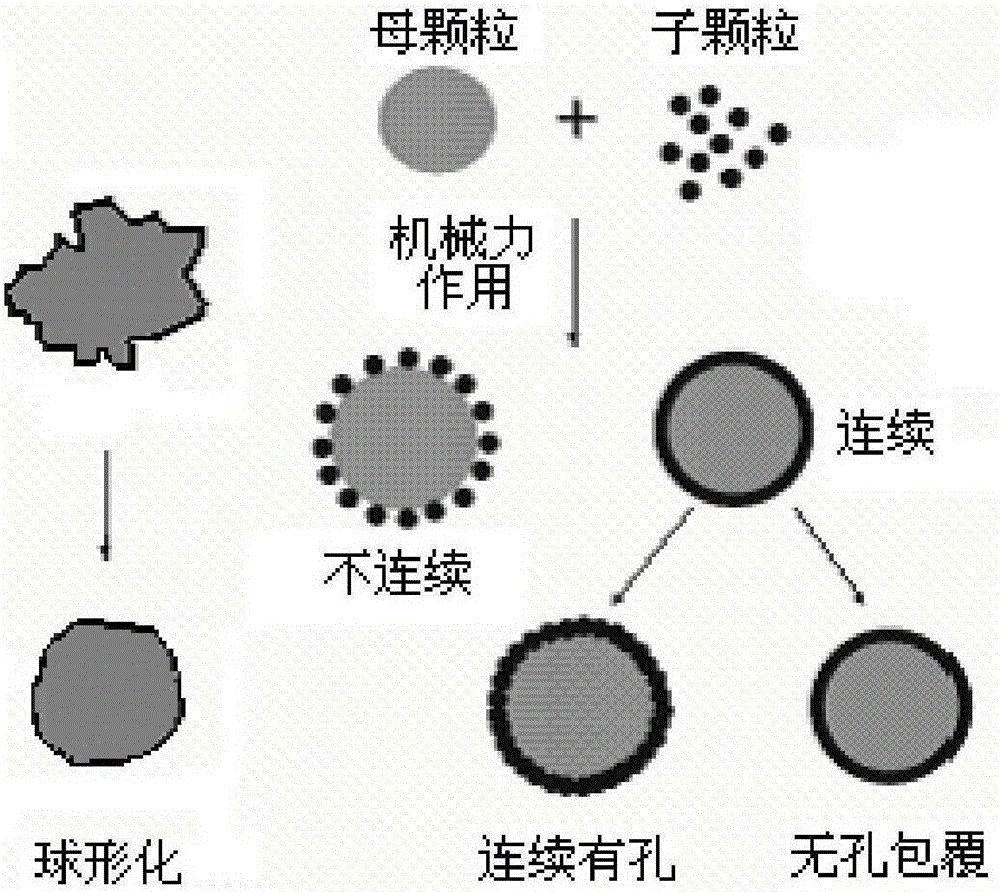

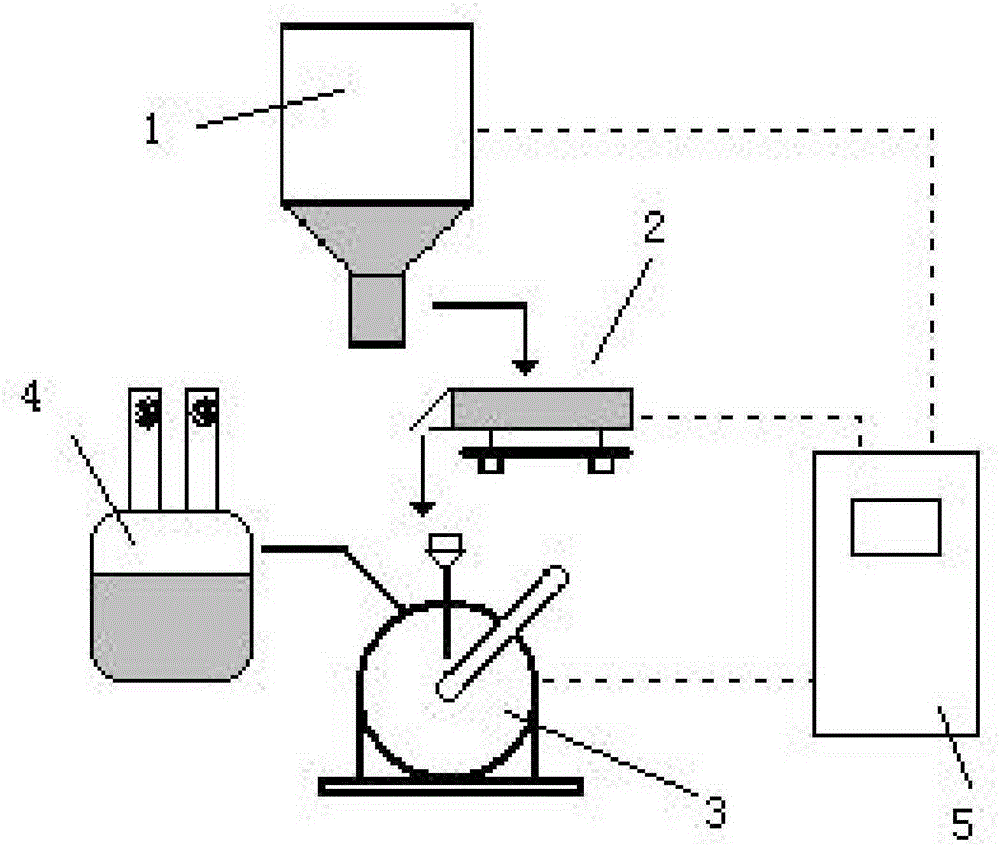

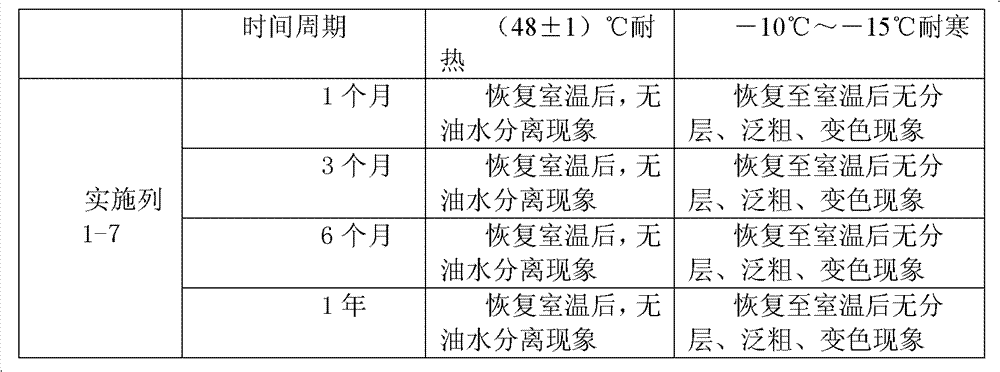

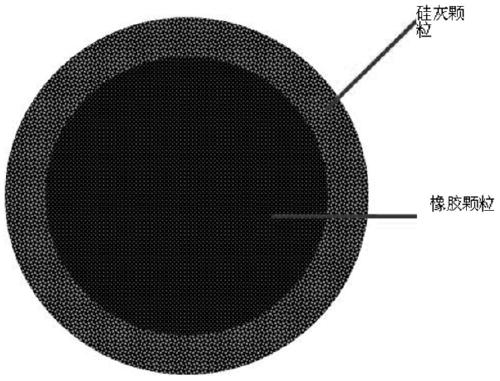

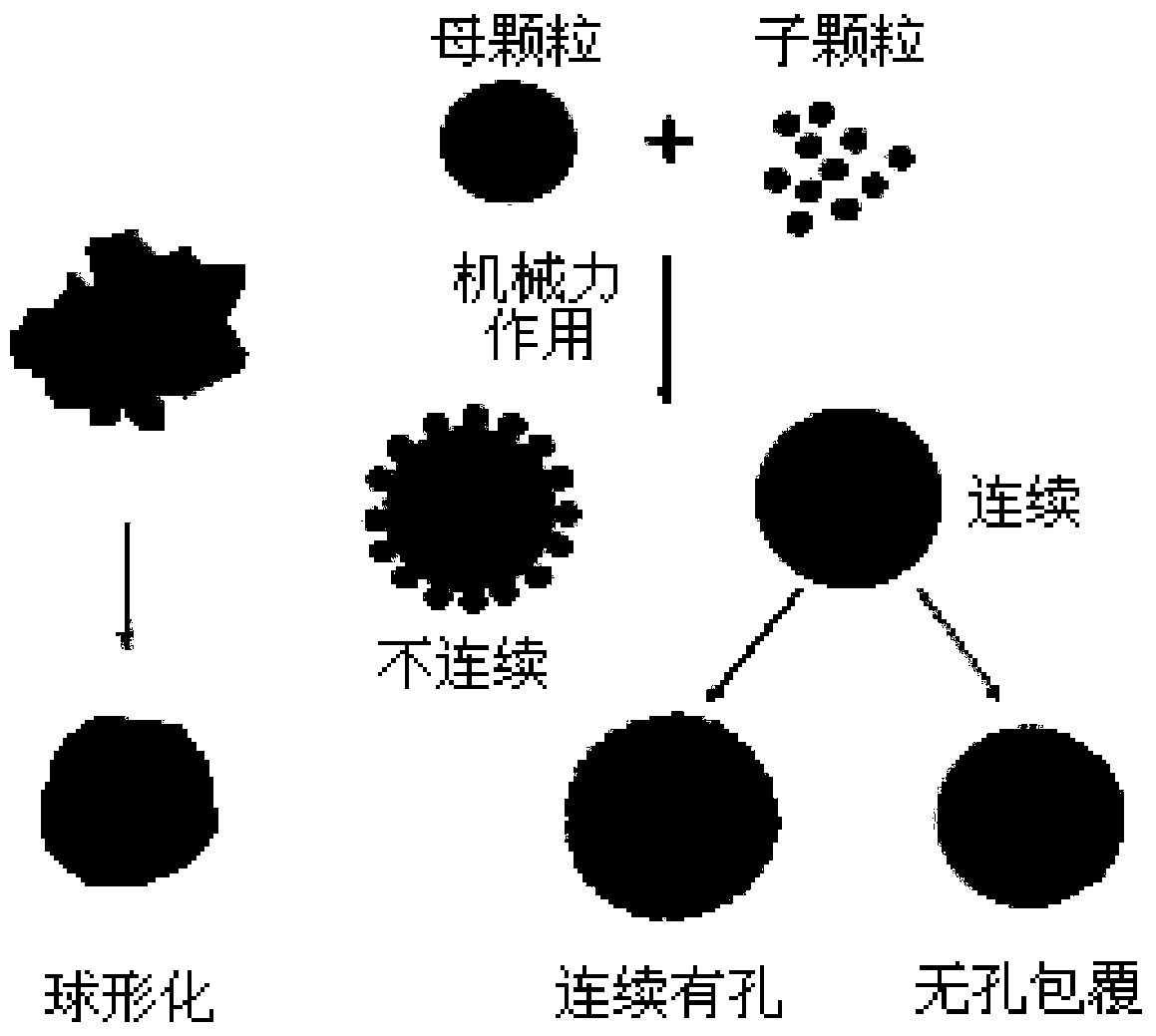

Composite particle, and preparation method and application thereof

ActiveCN106565383AImprove temperature resistanceGood acid and alkali resistanceFertiliser formsFertilizer mixturesWell cementingTemperature resistance

The invention relates to the technical field of oil gas well cementing, and especially relates to a composite particle, and a preparation method and an application thereof. The composite particle comprises a core which is an elastic particle and a shell layer which is a rigid particle and coats the external surface of the core. The preparation method of the composite particle is characterized in that airflow entrainment is used to drive the elastic particle and the rigid particle to move relative to each other in order to form the composite particle. The composite particle has high temperature resistance, improves the acid and alkali resistance of the elastic particle, has good stability, has good compatibility with cement mortar, has no floatation phenomenon, has no thickness increase phenomenon in the curing process, obviously reduces the elastic modulus of set cement, increases the deformation ability of the set cement, is spherical, and facilitates increase of the fluidity of the cement mortar.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gel synergizing type polymer lithium ion battery and preparation method thereof

ActiveCN1838470AImprove charge retentionImprove cycle performanceFinal product manufactureElectrolyte accumulators manufactureCyclic processDischarge rate

This invention discloses a gelatin synergy polymer lithium iron battery and its making method, which includes: cell core composed of positive plate and negative plate, polymer gelatin on the diaphragm surface of the battery core's anode and cathode, and the polymer gelatin is composed of polymethacrylates, polyacrylonitrile, or copolymer composed of polyvinylidene fluoride and hexafluoropropene, wherein hexafluoropropene molecular weight takes up 10-20% of the copolymer's. Making battery includes the following steps: covering the polymer driving solution on the two ends of the battery core, drying, then injecting electrolyte to make the polymer driving immerse into the electrolyte completely, electrochemically activing the core to form the gelatin, finally obtaining gelatin synergy polymer lithium iron battery. This invention discloses the problem that the discharging rate increases, the voltage lowers and the capacity declines from the battery core 's internal short-circuit.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

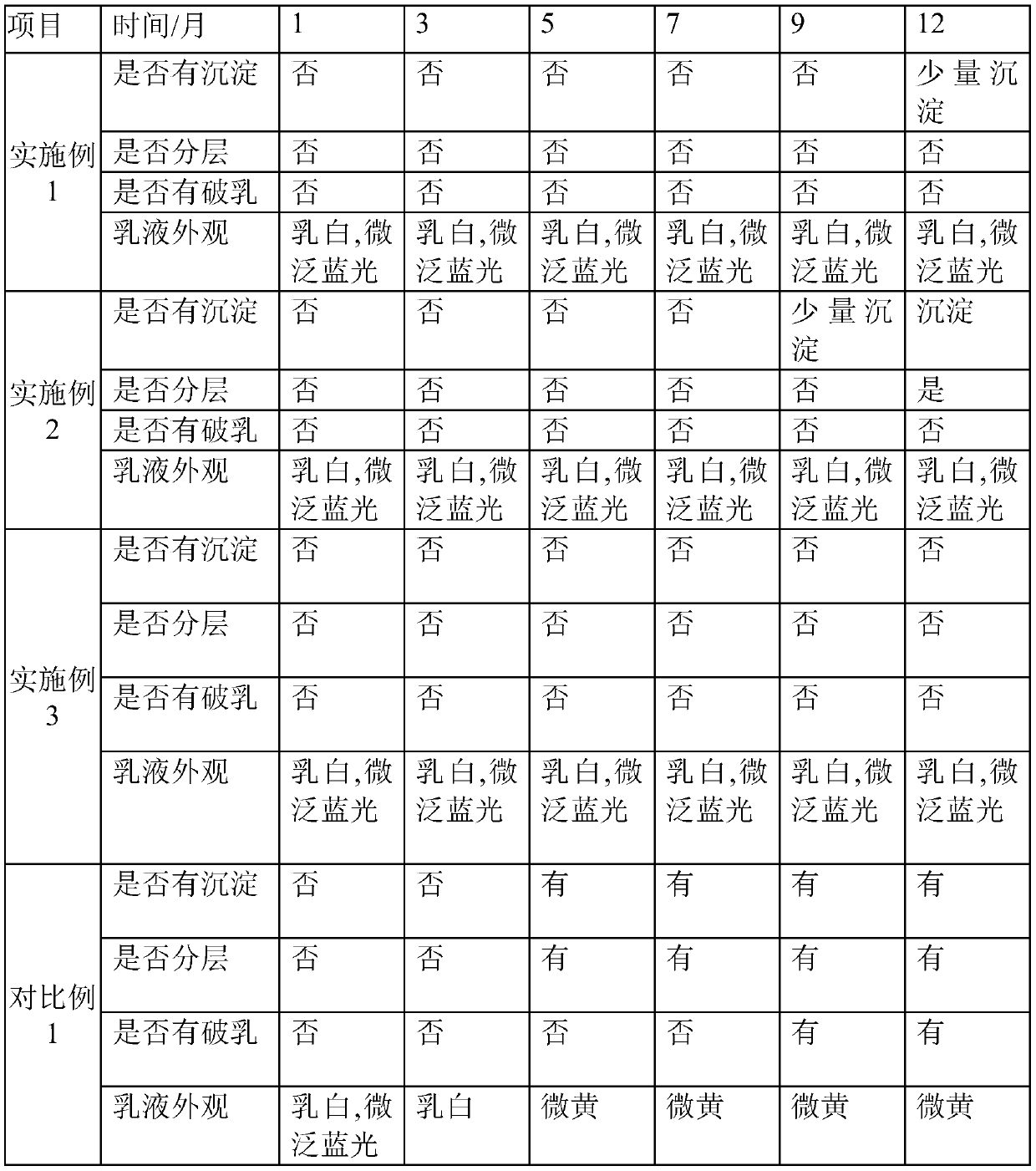

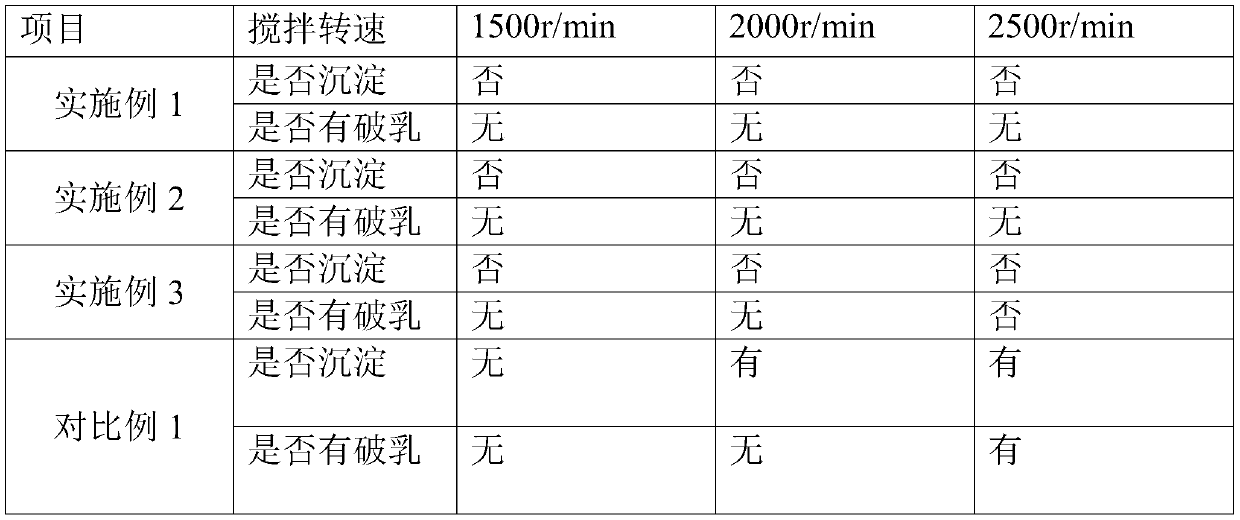

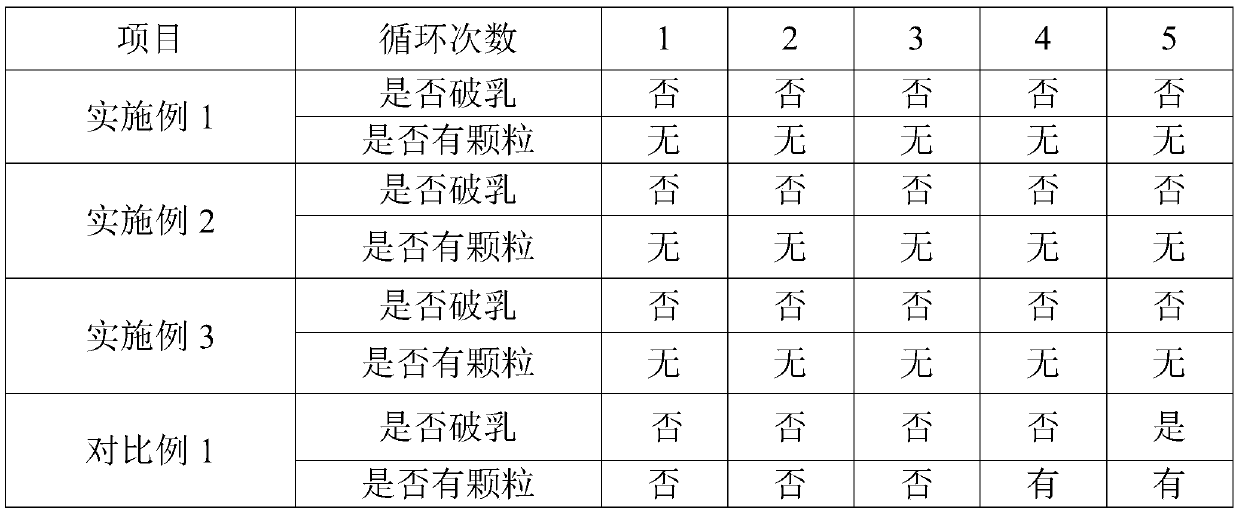

Anionic water-borne epoxy resin emulsion as well as preparation method and application thereof

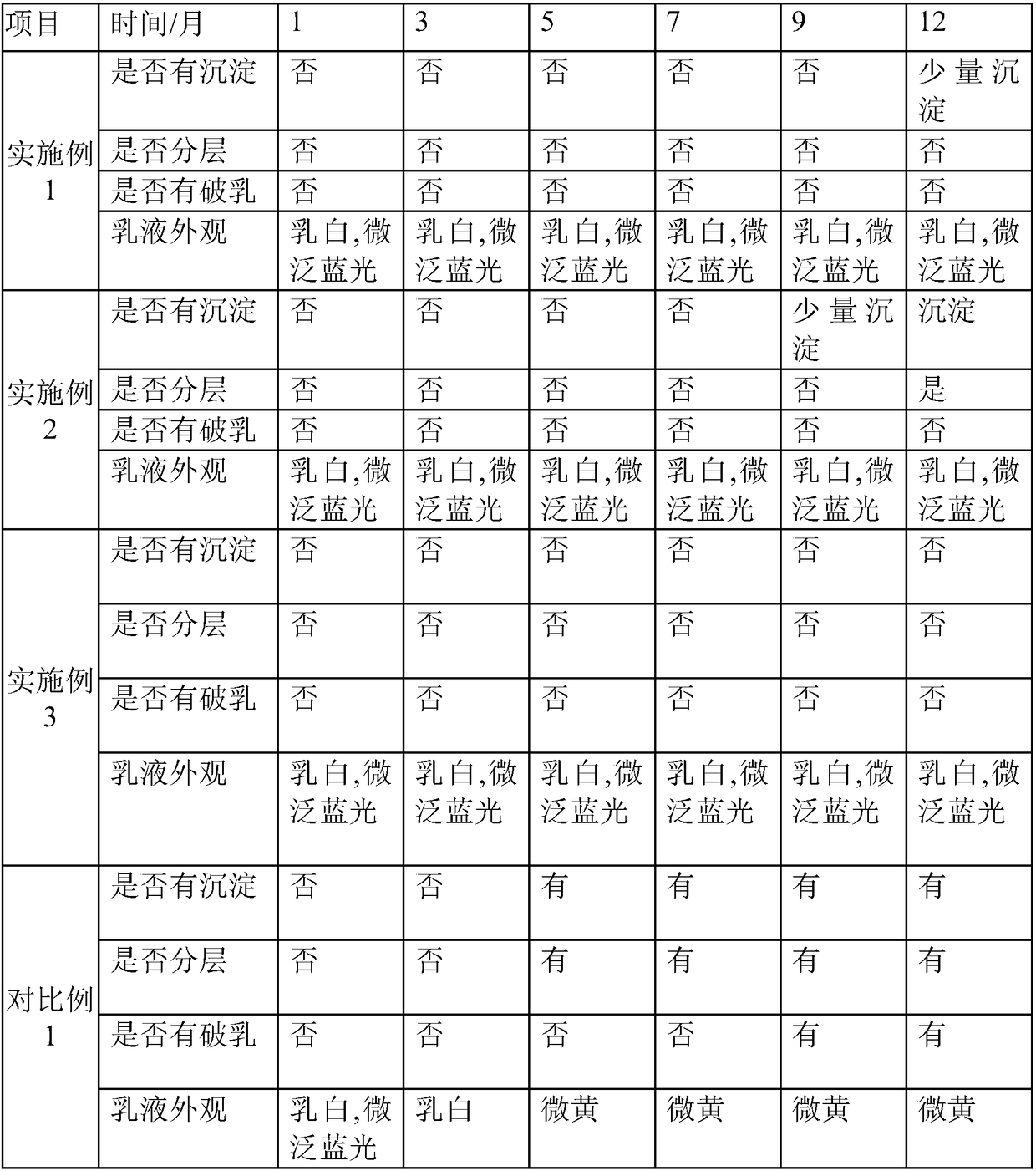

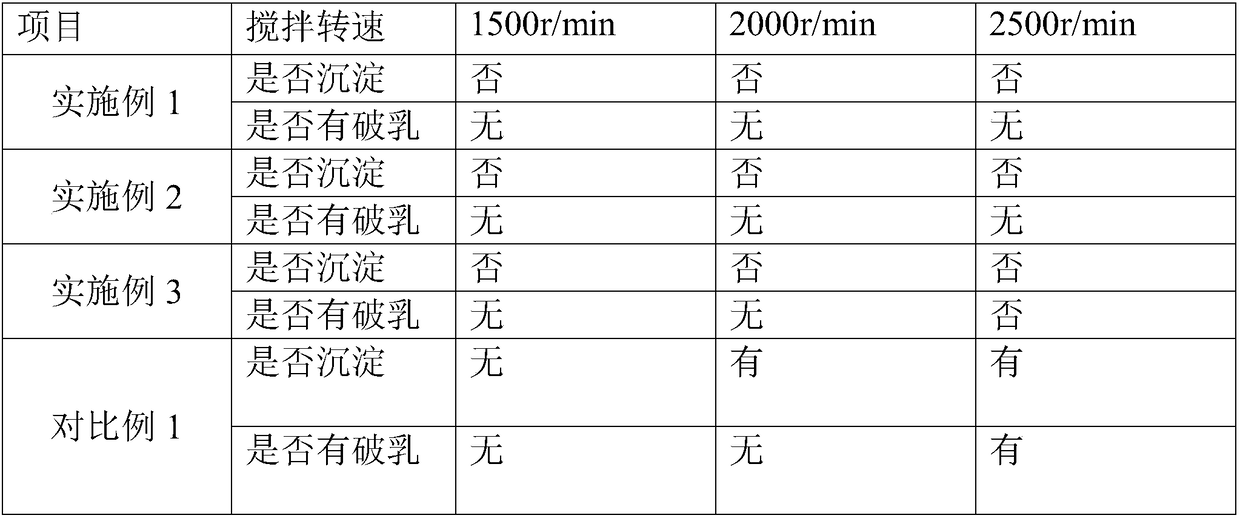

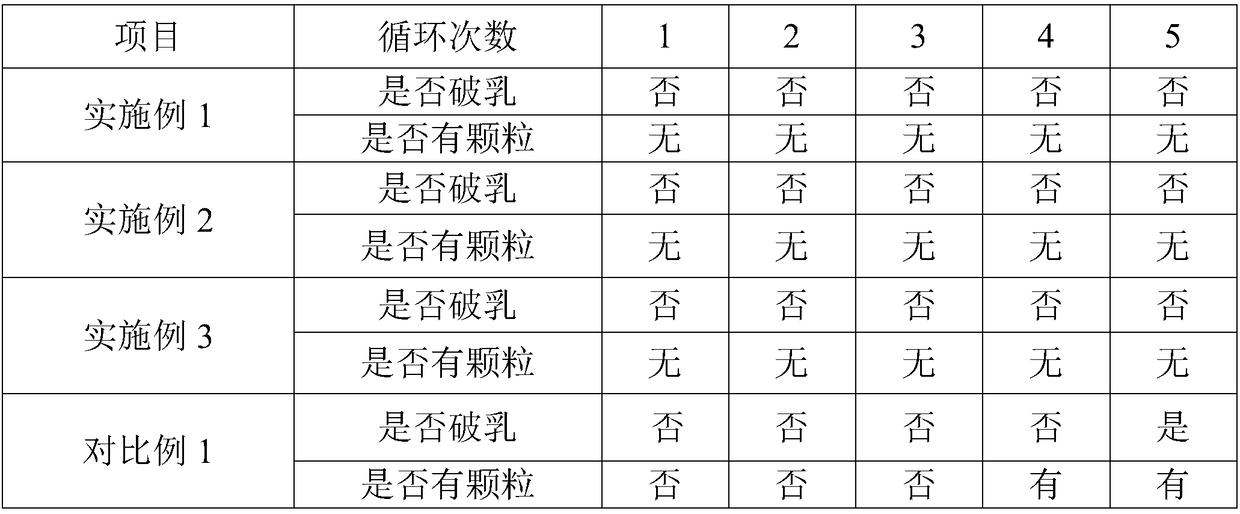

ActiveCN108178976ADetermine overall performanceImprove performanceAntifouling/underwater paintsPaints with biocidesFreeze thawingEpoxy

The invention discloses an anionic water-borne epoxy resin emulsion and a preparation method thereof. The preparation method comprises following steps: S1, 160-200 parts of epoxy resin E-44 is added to a reaction vessel, and after heating, 210-250 parts of diisocyanate is added for a reaction; S2, 40-50 parts of polycaprolactone and 30-50 parts of small-molecule diol are added, and a heat insulating reaction is performed for a period of time; S3, 30-40 parts of dimethylolbutyric acid is added, a catalyst is dropwise added, and the heat insulating reaction is performed for a period of time; S4,content of NCO in a system is detected, when content of NCO reaches 1.5%-4.0%, 50-80 parts of epoxy resin E-51 is added, then 10-20 parts of hydrogen peroxide is added, the heat insulating reaction is performed for a period of time, and 300-400 parts of acetone is added for reducing viscosity; S5, cooling is performed, caustic soda is added for neutralization, an emulsifier is added for emulsification, and acetone is removed from the system through vacuum pumping. The anionic water-borne epoxy resin emulsion prepared with the method is milky white and fine in appearance, excellent in storagestability, mechanical stability and freeze-thaw stability, good in water resistance, high in hardness and high in adhesive force.

Owner:GUANGZHOU LEOBO PAINT TECH

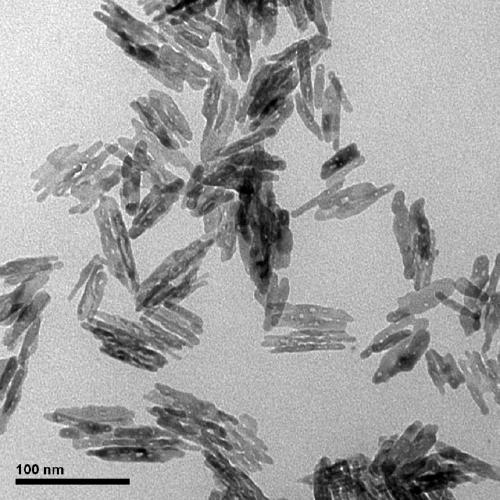

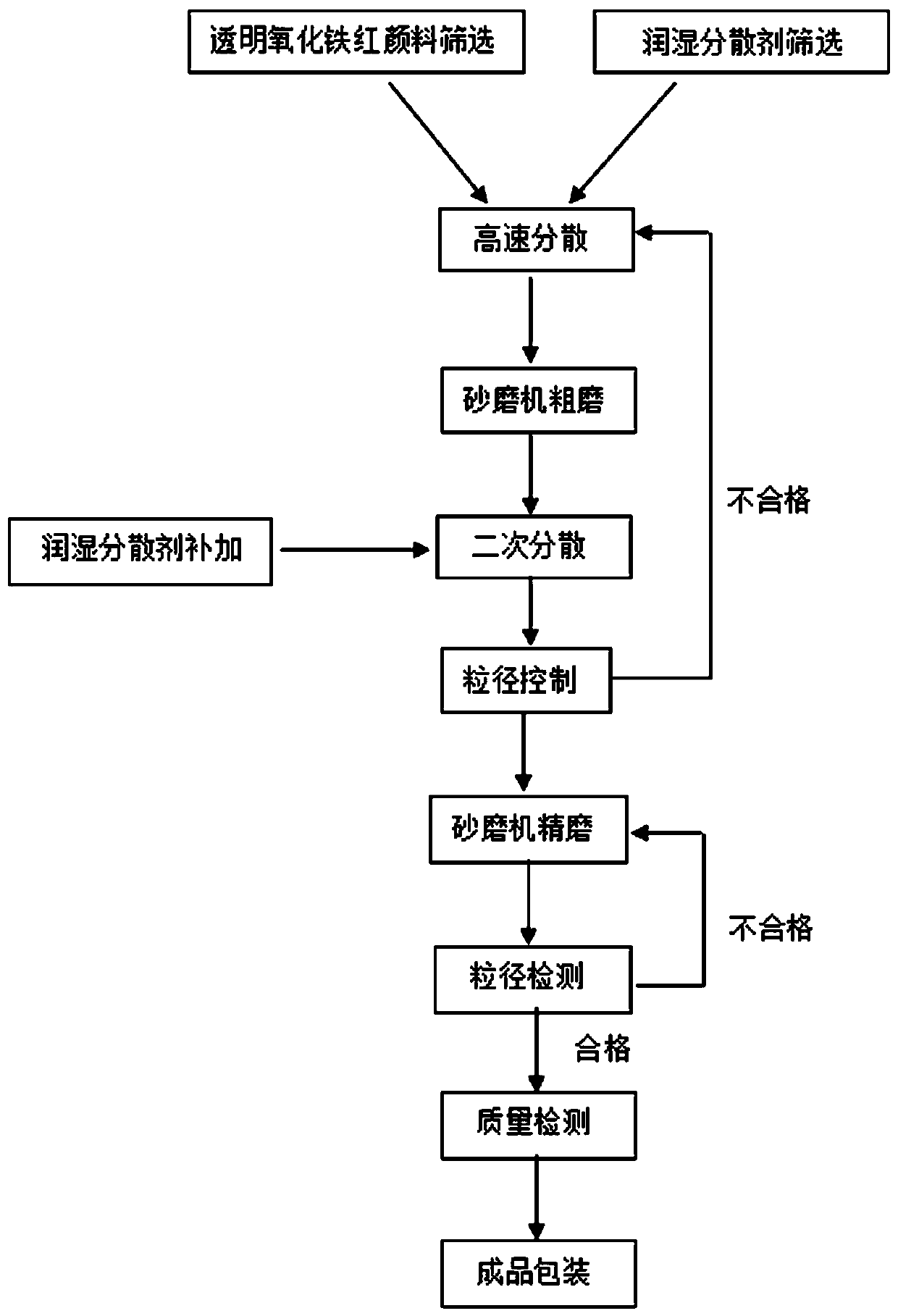

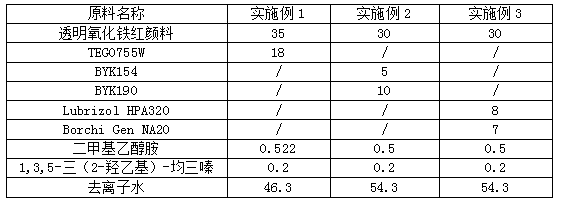

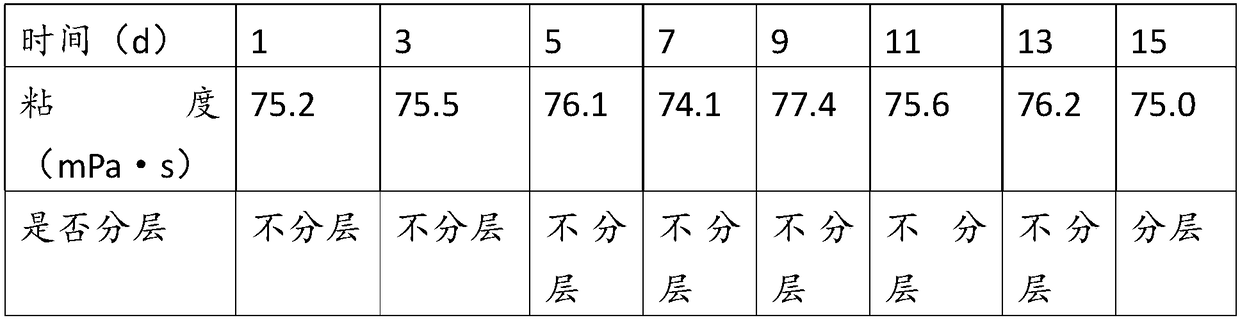

Transparent nano-ferric oxide ink-jet color paste and preparation method thereof

The invention relates to transparent nano-ferric oxide ink-jet color paste. The transparent nano-ferric oxide ink-jet color paste contains the following components in parts by weight: 30-35 parts of ferric oxide, 15-20 parts of a dispersing agent, 0.4-0.6 part of a pH adjuster, 0.2-0.4 part of a sterilizing agent and 45-55 parts of water. By utilizing a brand new processing process and equipment and a preferable color paste formula, the particle size of the color paste can reach the nanoscale, and the storage stability is good; and the color past is of a resin-free system, does not contain a solvent component, is environment-friendly and can be widely applied to various types of ink-jet coatings.

Owner:ZHEJIANG NAMEI MATERIAL TECH

Anti-radiation composite latex and preparation method and application thereof and anti-radiation gloves

The invention belongs to the technical field of latex products, and particularly relates to anti-radiation composite latex and a preparation method and application thereof and anti-radiation gloves. The preparation method of the anti-radiation composite latex comprises the following steps that 1, barium sulfate, a surface modifying agent, sodium dodecyl benzene sulfonate, sodium methylene dinaphthalene sulfonate and water are subjected to ball-milling treatment, and a barium sulfate sizing agent with the modified surface is obtained; step 2, the barium sulfate sizing agent with the modified surface, the latex and a sodium hydroxide solution are mixed to obtain the composite latex with the pH value being 10-13; and the preparation method of the latex comprises the step that rubber latex, sulphur, zinc oxide, a promoting agent and an anti-oxidation agent are mixed, and the anti-radiation composite latex is obtained. The anti-radiation composite latex can effectively solve the technical problem that the dispersing stability of current anti-radiation composite latex is still poor.

Owner:GUANGZHOU FENGLI RUBBER TIRE +1

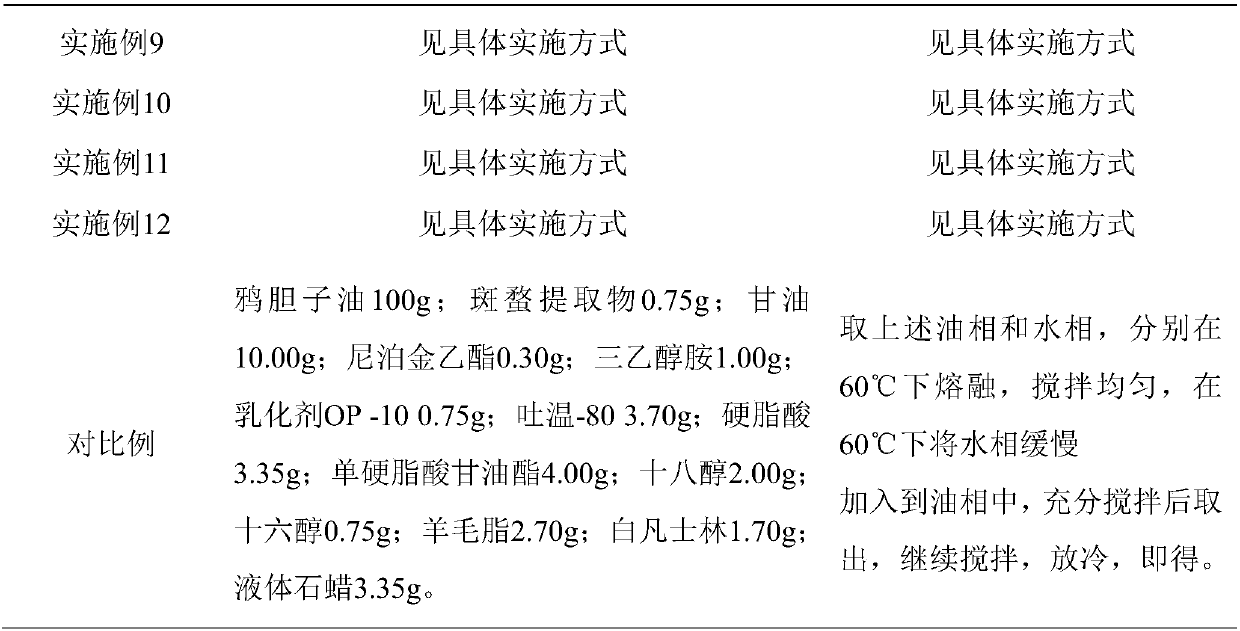

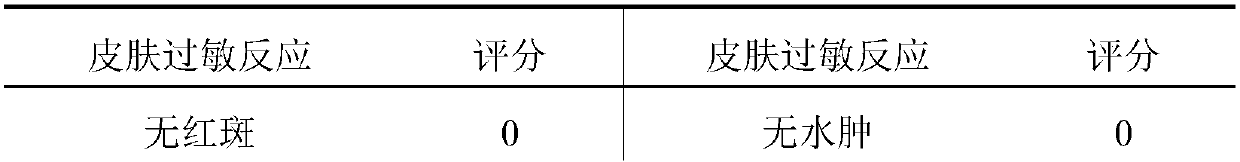

Traditional Chinese medicine composition for treating functional uterine bleeding and preparation of traditional Chinese medicine composition

InactiveCN109512848AImprove stabilityUniform appearance and colorAnthropod material medical ingredientsSexual disorderEthyl hydroxybenzoateParaffin wax

The invention discloses a traditional Chinese medicine composition for treating functional uterine bleeding and a preparation of the traditional Chinese medicine composition. The traditional Chinese medicine composition is prepared from the following bulk drugs in parts by weight: 500-800 parts of yadanziyou oleum bruceae and 5-60 parts of large blister beetle; and 15-30 parts of stearic acid, 20-40 parts of glycerin monostearate, 10-30 parts of octadecanol, 2-15 parts of cetanol, 10-30 parts of lanolin, 5-20 parts of albolene, 10-30 parts of liquid paraffin, 40-80 parts of glycerinum, 0.5-2.0parts of ethyl p-hydroxybenzoate, 5-20 parts of triethanolamine, 2-12 parts of an OP emulgator and 15-30 parts of tween-80 are added for preparing a cream, and purified water is added to prepare into1000 parts. The traditional Chinese medicine preparation for treating functional uterine bleeding has significant advantages in stability, safety and effectiveness, and the cream preparation processcan achieve production stability, is safe and effective, and is suitable for industrial production.

Owner:SHAANXI UNIV OF CHINESE MEDICINE

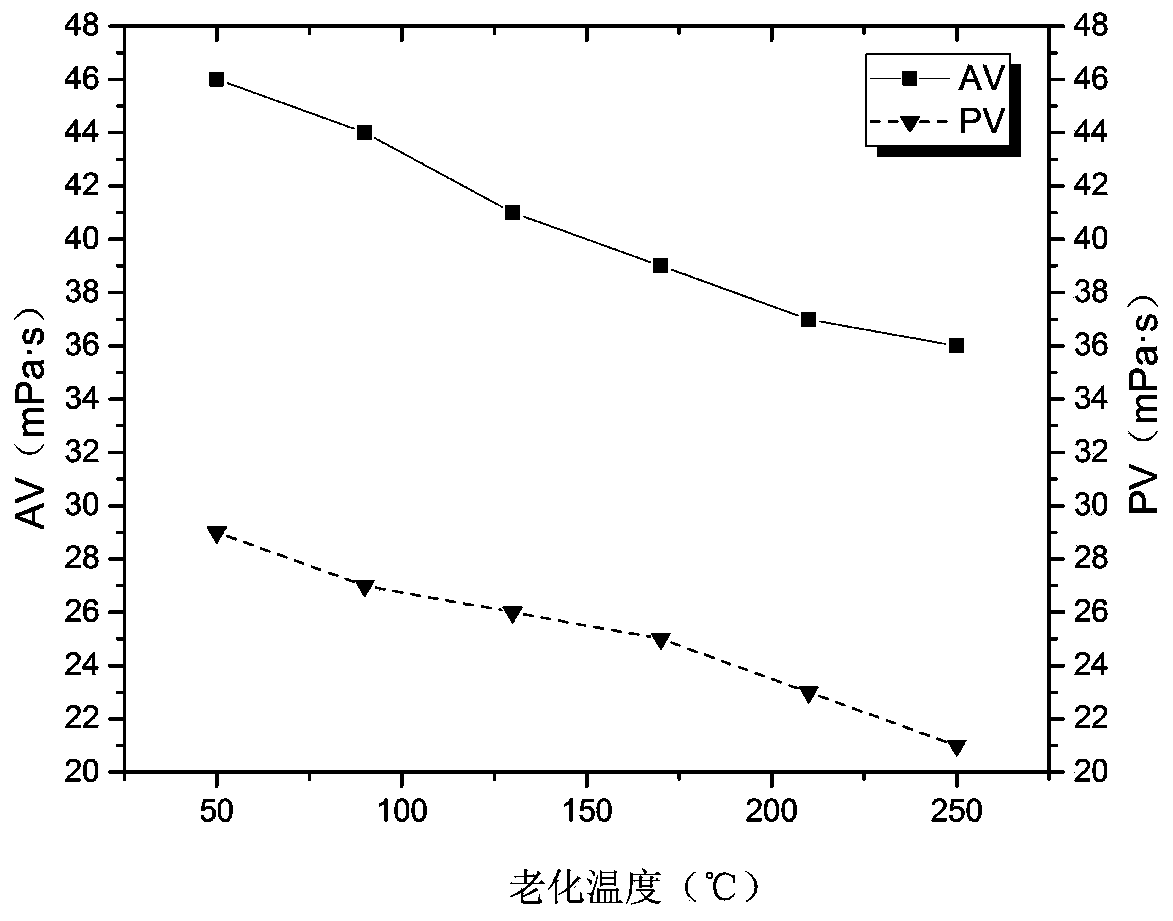

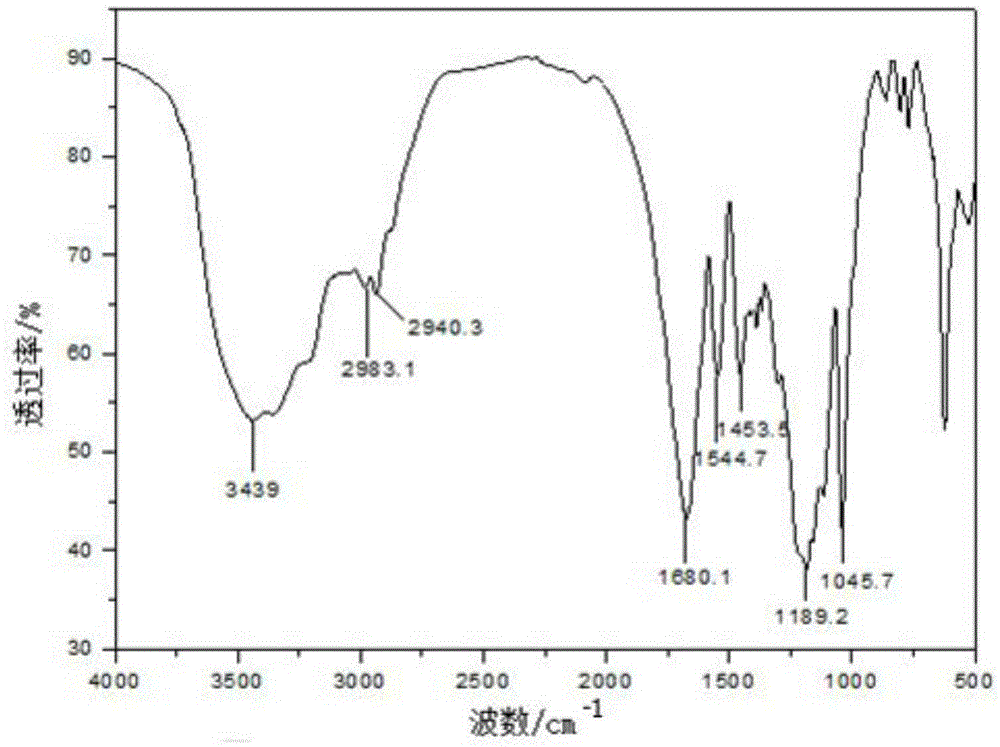

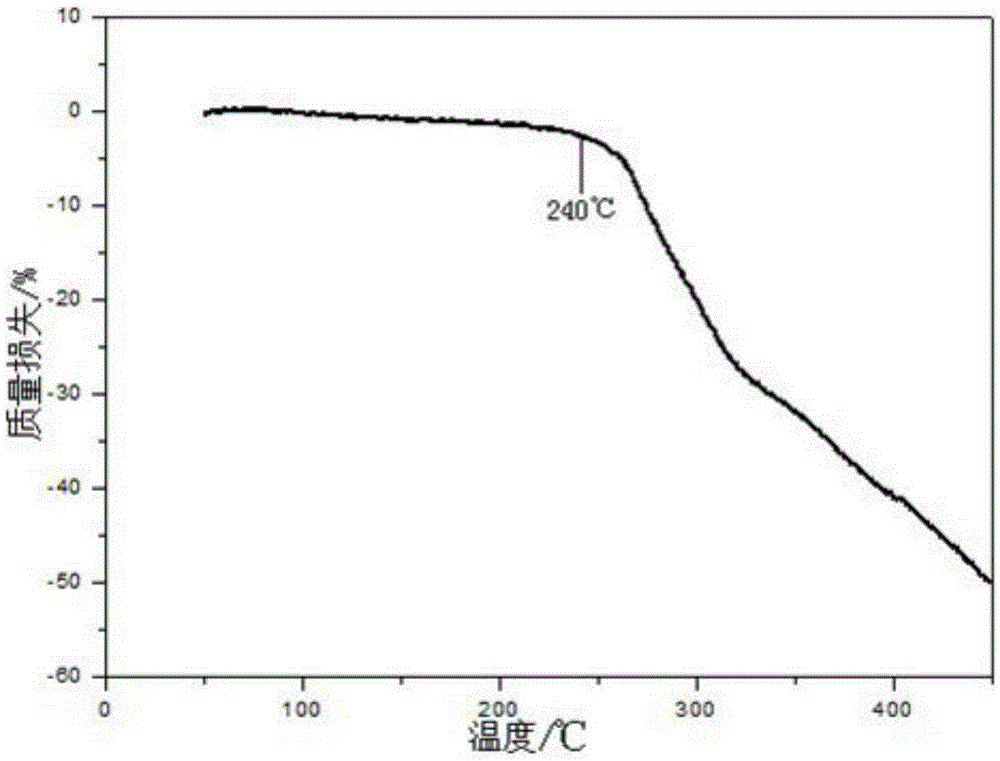

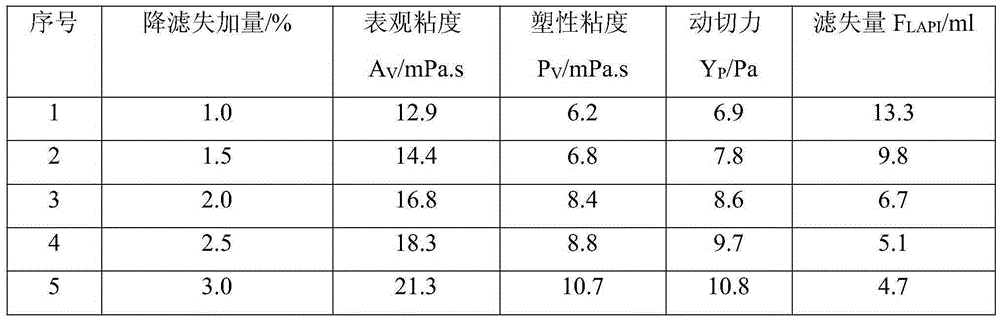

High-temperature-resistant oil-based drilling fluid shear strength improving agent as well as preparation method and application thereof

PendingCN113429525AExcellent cutting effectAdd lessFlushingDrilling compositionFunctional monomerAqueous solution

The invention provides a preparation method of a high-temperature-resistant oil-based drilling fluid shear strength improving agent, which comprises the following steps: 1) emulsifying an emulsifier aqueous solution, adding a high-temperature-resistant monomer and a diene monomer, uniformly mixing, and transferring into a high-temperature and high-pressure reaction kettle; (2) dropwise adding an initiator into the high-temperature and high-pressure reaction kettle under the pressure of 4.5 MPa, stirring and reacting the mixture at a low speed under the condition of 80-110 DEG C, and then adding a reaction terminator to obtain a first product; 3) keeping the pressure unchanged, reducing the temperature of the first product to 60-80 DEG C, introducing inert gas for 20 minutes to discharge redundant gaseous diene monomers, adding carboxylic acid monomers, dropwise adding an initiator, and stirring the mixture at a low speed to react for 2-3 hours; and 4) adding a nitrogen-containing functional monomer, and carrying out low-speed stirring reaction at the temperature of 60-80 DEG C, thereby obtaining the product. The invention also provides the oil-based drilling fluid shear strength improving agent and application thereof. The oil-based drilling fluid shear strength improving agent can resist the high temperature of 240 DEG C; besides, even in a high-temperature environment, the cutting-improving effect is still achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

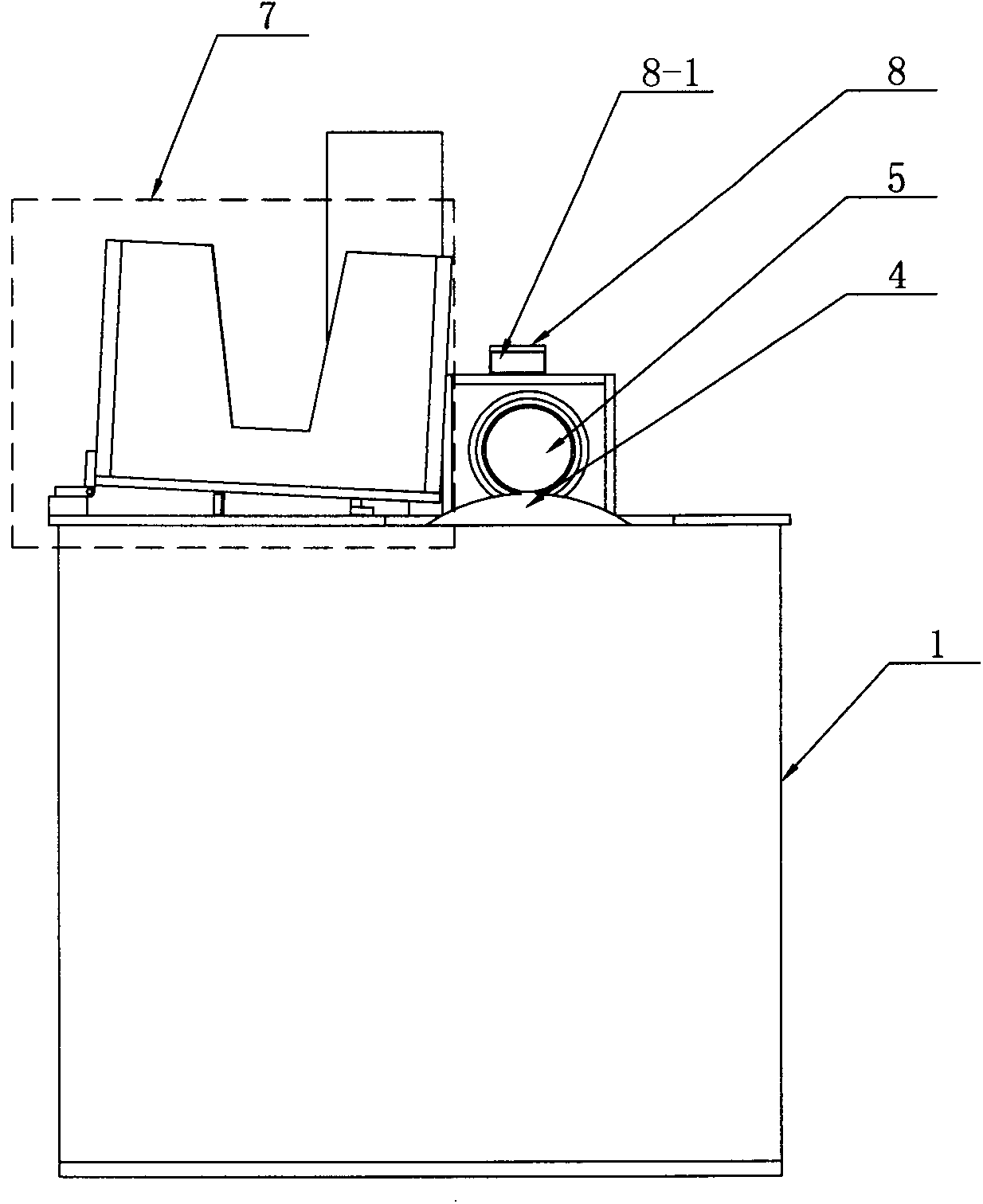

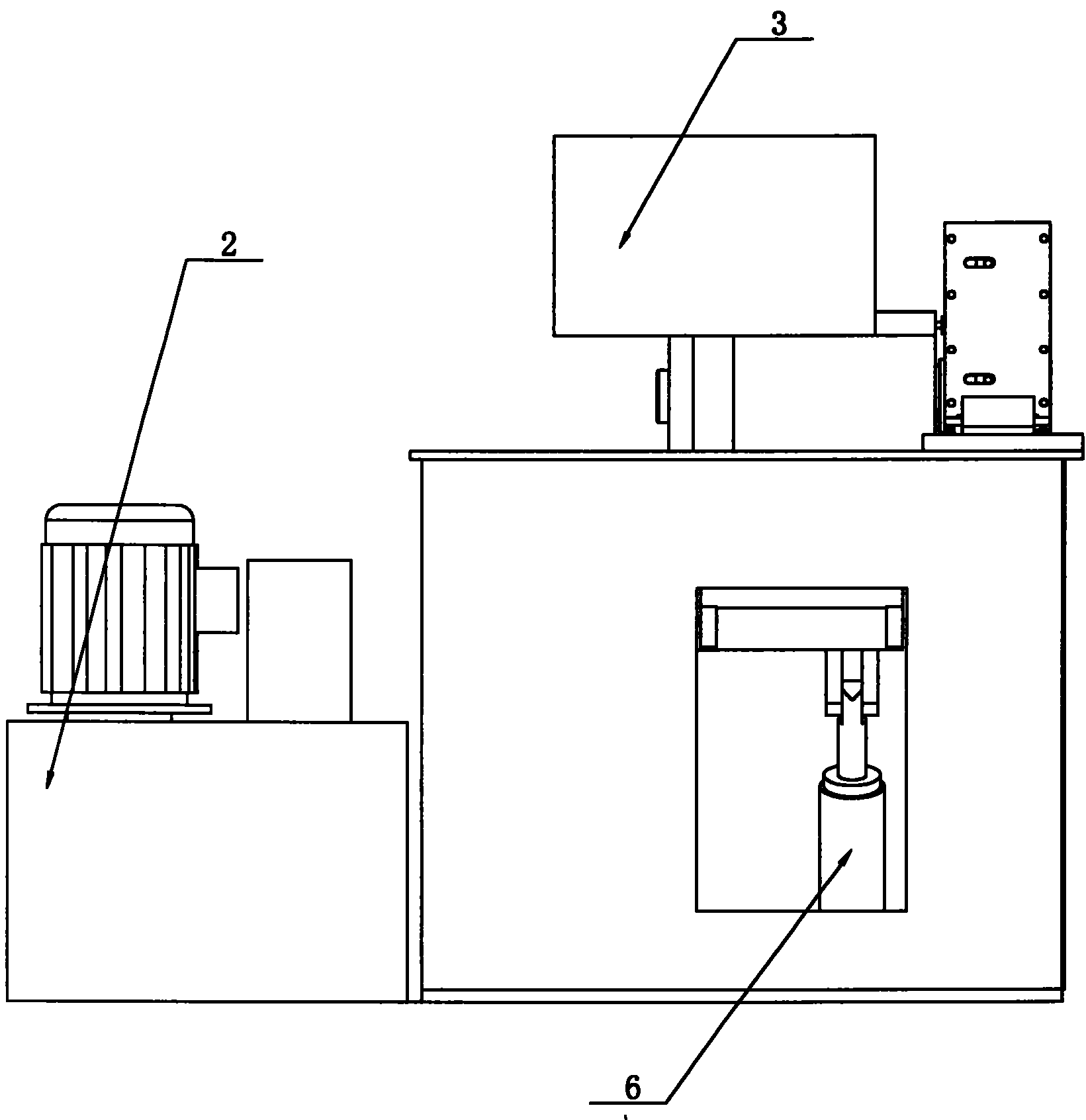

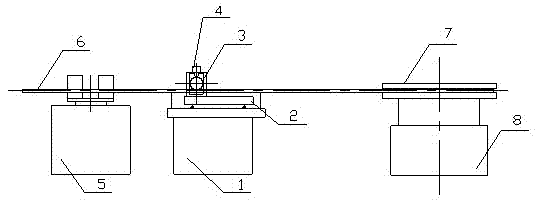

Numerical control flexible roll bending fully-automatic plate bending machine special for miniature motor enclosure

The invention discloses a numerical control flexible roll bending fully-automatic plate bending machine special for a miniature motor enclosure, and relates to the technical field of plate bending machines. A lower rubber-covered roller (4) is arranged on a rack (1), wherein an upper steel roller (5) is arranged on the upper side of the lower rubber-covered roller (4); a discharge mechanism (8) is arranged on the upper side of the upper steel roller (5); a piston rod of an oil cylinder (6) is connected with a rotating shaft of the lower rubber-covered roller (4); a hydraulic station (2) is arranged on one side of the rack (1); a touch operation desk (3) is arranged on one side of the discharge mechanism (8); a feeding mechanism (7) is arranged on one side of the lower rubber-covered roller (4) and the upper steel roller (5). According to the plate bending machine, the quality of a product can be improved, the production efficiency is improved, human resources are saved, the safety is improved, potential accidents are avoided, a process is simplified, equipment investment and mold cost are greatly reduced, and the production cost is lowered.

Owner:NANTONG CHAOLI ROLLING MACHINE PRODUCING +1

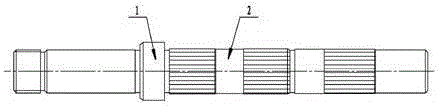

Rotating shaft of automobile generator

Owner:CHANGZHOU BEIANTE POWER MACHINERY

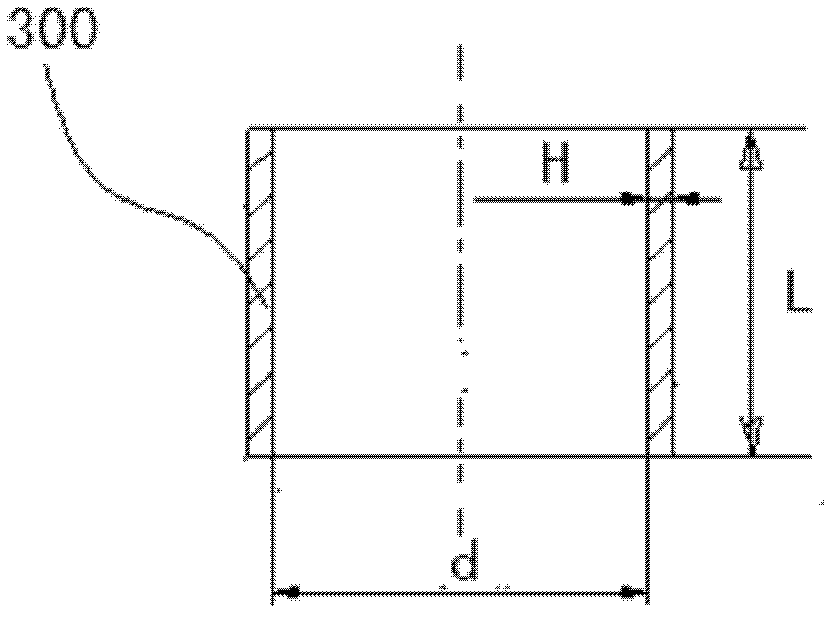

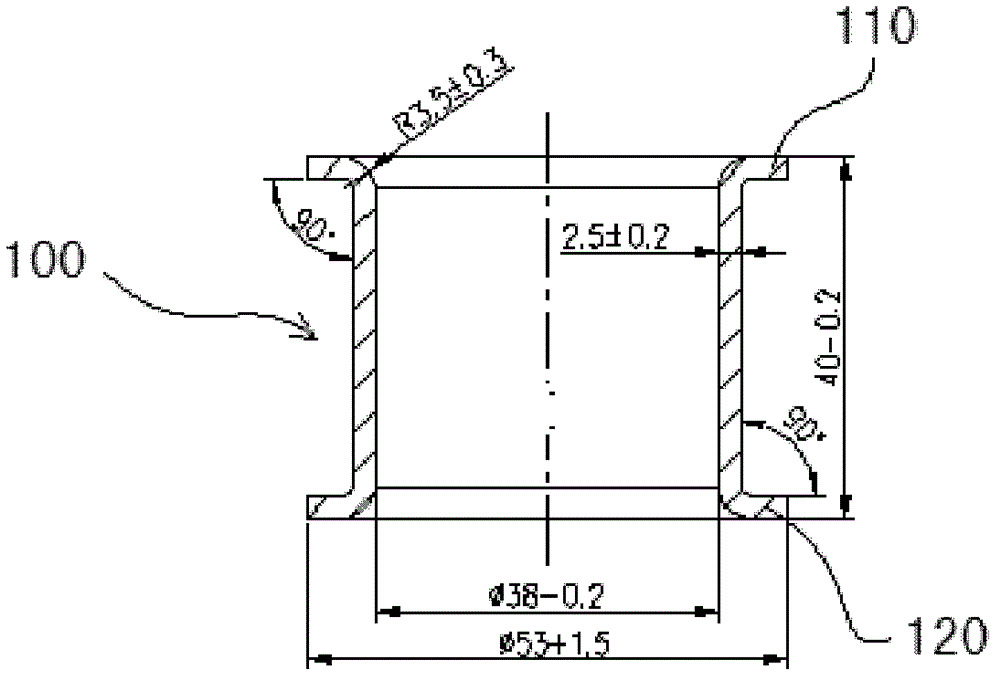

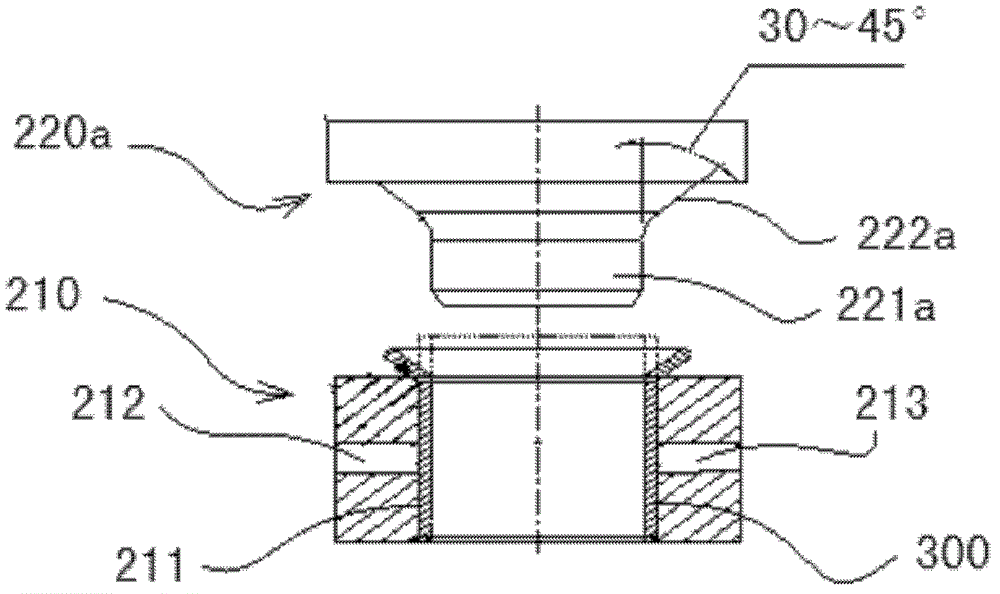

A processing method and mold for a shaft sleeve used in an automobile steering transmission mechanism

The invention discloses a processing method for a shaft sleeve used for an automobile steering transmission mechanism. In the method, an E35+N seamless steel tube is used as a parent material, a flanging die composed of a male die and a female die is used, and the shaft sleeve is manufactured by flanging each end of the seamless steel tube for three times, wherein a first flanging angle is 30-45 degrees, a second flanging angle is 45-70 degrees and the third flanging angle is 70-93 degrees; while flanging the first end, a descending speed of the male die is controlled to be 50-100 mm / min; while flanging the second end, the descending speed of the male die is controlled to be 150-200 mm / min; in each flanging process, lubricating oil is injected between the parent material and the female die through a lubricating oil hole on the male die, and simultaneously, compressed air is injected between the parent material and the female die through a cooling air hole on the male die so as to cool the parent material; one end is flanged firstly, and the other end is flanged later. The method has the following technical benefits that: at a part with an inner angle of 90 degrees, the phenomenon of thickening cannot be caused; 2, at an excircle part of the flange, the phenomenon of thickness reduction cannot be caused, and hair cracks and wrinkle the material can be effectively avoided. The method further discloses a die using the method.

Owner:SHANGHAI ZUNMA AUTO PIPE CO LTD

Silane modified polyurethane glass primer and preparation method thereof

ActiveCN102516921BEasy to dryHigh film strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilanesEthyl acetate

The invention discloses a silane modified polyurethane glass primer and a preparation method thereof. The glass primer is prepared from the following raw materials by weight: 20 to 60 parts of silane-terminated polyurethane perpolymer, 30 to 65 parts of a solvent, 1 to 3 parts of a water-removing additive, 2 to 10 parts of carbon black, 1 to 2 parts of an anti-settling agent, 2 to 5 parts of a cross-linking promoter and 0.05 to 0.2 part of a catalyst A, wherein, raw materials for the silane-terminated polyurethane perpolymer comprise, by weight, 15 to 25 parts of polyether polyol, 12 to 24 parts of diisocyanate, 0.01 to 0.05 part of dibutyltin dilaurate or stannous octoate, 30 to 60 parts of ethyl acetate and 12 to 22 parts of an end-capping reagent. According to the invention, disadvantages of the prior art are overcome; when the silane modified polyurethane glass primer is used at normal temperature for 40 min in the air, the phenomenon of obvious thickening does not appear, and a film is not formed on the surface of the glass primer; the glass primer facilitates construction and is simple to use, and when used, the glass primer is directly poured into a container and then is directly used for brush coating within 40 min.

Owner:SHANDONG NORTH MODERN CHEM IND

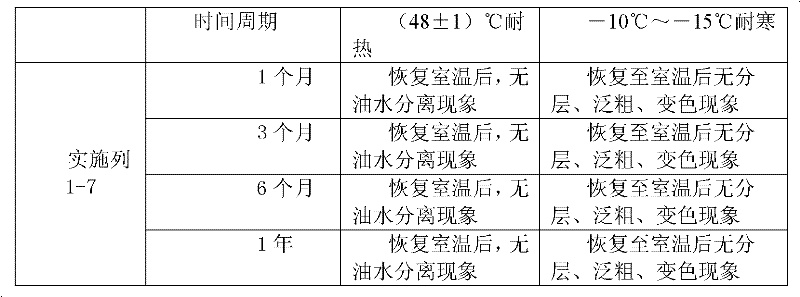

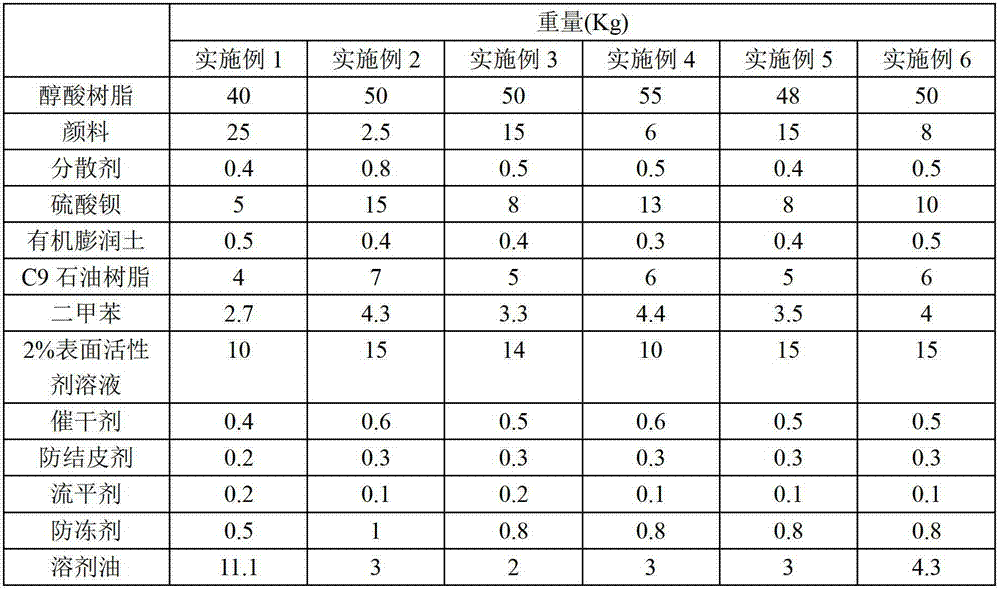

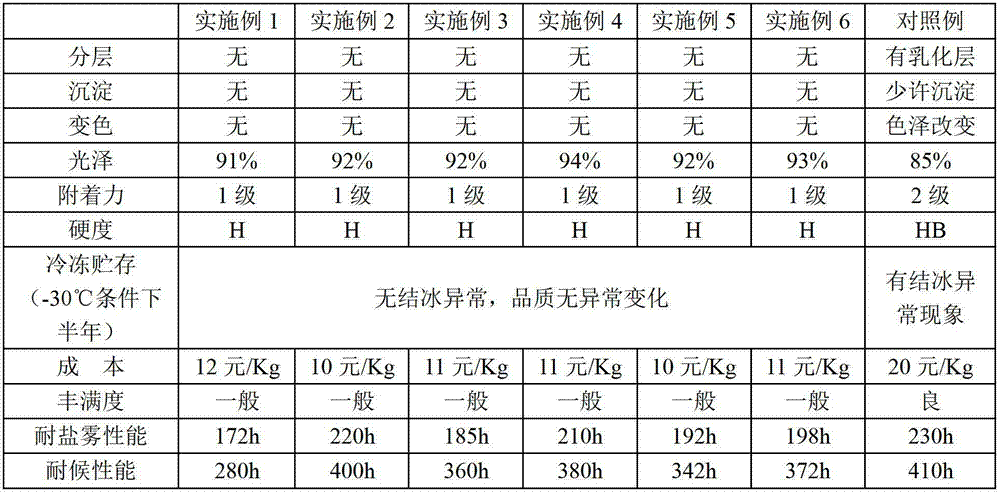

Coating with long-term stability

The invention provides a coating with a long-term stability, belong to the field of coating technology. The coating comprises the following components in percentage by weight: 40-55% of alkyd resin, 4-7% of petroleum resin, 3-25% of pigment, 5-15% of filler, 2-6% of auxiliary agent, 5-15% of organic solvent and 10-15% of surfactant solution with a mass concentration of 2%. The auxiliary agent is a mixture of a dispersing agent, an organobentonite, a catalyst, an anti-skinning agent, a leveling agent and an antifreezing agent at any proportion. The surfactant solution with a mass concentration of 2% is obtained through dissolving the surfactant into water. The product is low in cost, which cannot influence the gloss, adhesion and hardness of the coating. More particularly, the product has a good storing effect, does not have the phenomena such as precipitation, loss of gloss, oil-water separation, pig skin and discoloration after being used for 2 years, and is completely environment-friendly.

Owner:JIANGSU HUAXIA PAINT MAKING

Thickened non-phosphate acidic detergent

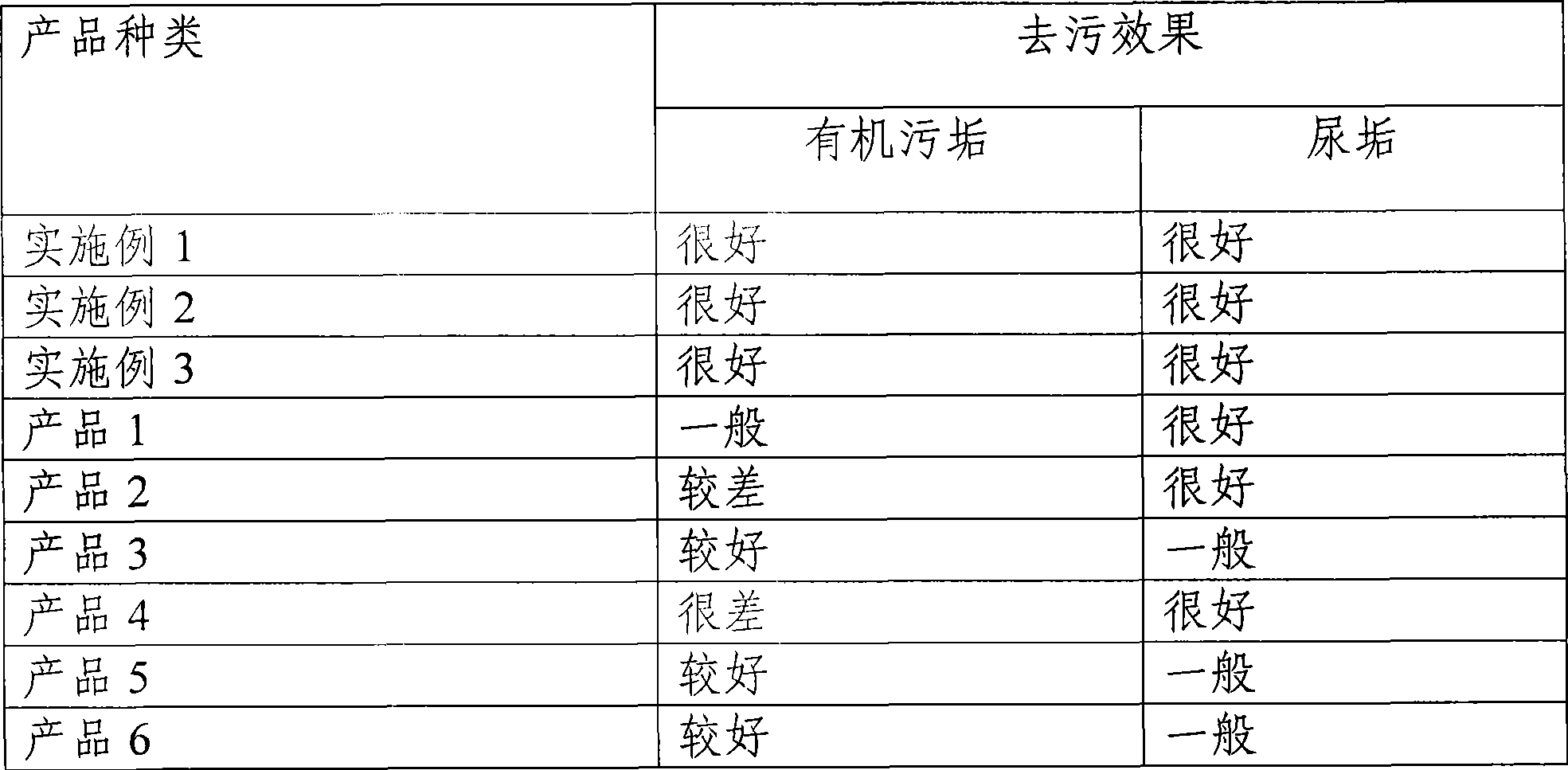

ActiveCN101372647BRaw materials are easy to getSimple and fast operationSurface-active detergent compositionsPhosphatePhosphoric acid

The invention relates to cleaning and washing products for sanitary facilities and discloses a thickened phosphoric acid-free detergent; the main active ingredients and the parts by weight thereof are as follows: 1-3 part(s) of straight chain dodecyl benzene sulfonic acid, 8-15 parts of non-ionic surface active agent, 0.2-1 part of corrosion inhibitor and 3-10 parts of hydrochloric acid, the non-ionic surface active agent is selected from or is the combination of any agents from nonyl phenol polyoxyethylene (4) ether, nonyl phenol polyoxyethylene (10) ether, fatty alcohol polyoxyethylene (3) ether and fatty alcohol polyoxyethylene (7) ether. The detergent disclosed by the invention has excellent wall cling property, can effectively remove human excrement, urine alkali and urine scale on the surfaces of enamel lavatory facilities as well as the rust and scale, and the like, in tap water and has the functions of stain removal, cleaning, sterilization and odor removal.

Owner:BEIJING REWARD HOME CARE CHEM

Anionic water-based epoxy resin emulsion and its preparation method and application

ActiveCN108178976BDetermine overall performanceImprove performanceAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention discloses an anionic water-borne epoxy resin emulsion and a preparation method thereof. The preparation method comprises following steps: S1, 160-200 parts of epoxy resin E-44 is added to a reaction vessel, and after heating, 210-250 parts of diisocyanate is added for a reaction; S2, 40-50 parts of polycaprolactone and 30-50 parts of small-molecule diol are added, and a heat insulating reaction is performed for a period of time; S3, 30-40 parts of dimethylolbutyric acid is added, a catalyst is dropwise added, and the heat insulating reaction is performed for a period of time; S4,content of NCO in a system is detected, when content of NCO reaches 1.5%-4.0%, 50-80 parts of epoxy resin E-51 is added, then 10-20 parts of hydrogen peroxide is added, the heat insulating reaction is performed for a period of time, and 300-400 parts of acetone is added for reducing viscosity; S5, cooling is performed, caustic soda is added for neutralization, an emulsifier is added for emulsification, and acetone is removed from the system through vacuum pumping. The anionic water-borne epoxy resin emulsion prepared with the method is milky white and fine in appearance, excellent in storagestability, mechanical stability and freeze-thaw stability, good in water resistance, high in hardness and high in adhesive force.

Owner:GUANGZHOU LEOBO PAINT TECH

Method and device for removing thickness of edge-wound coil in hydro generator or in motor rotor

InactiveCN103683736AImprove the safety of useNo thickeningManufacturing dynamo-electric machinesElectric machineEngineering

The invention discloses a method and a device for removing thicknesses of edge-wound coils in hydro generators or in motor rotors. The device comprises a bracket mounted on the bottom of the device and a sharpener fixed above the bracket. The sharpener is connected with a controller and a start button is arranged on the top of the sharpener. The device is positioned between a coil-press device and a forming die for edge-wound coils. A motor is connected with the bottom of the forming die for edge-wound coils. Two grinding heads are arranged inside the sharpener. According to this arrangement, the sections of the edge-wound coils to be thickened are processed by the device to thin out in advance, so that the thicknesses in the dead corners of the inner circles formed in winding the edge-wound coils are cancelled out by the sections thinned out by the device in advance, and therefore, the obvious thicknesses can be avoided. Accordingly, manpower and time can be saved, operation can be simplified and the safety in using edge-wound coils can be improved significantly.

Owner:CHONGQING WATER TURBINE WORKS

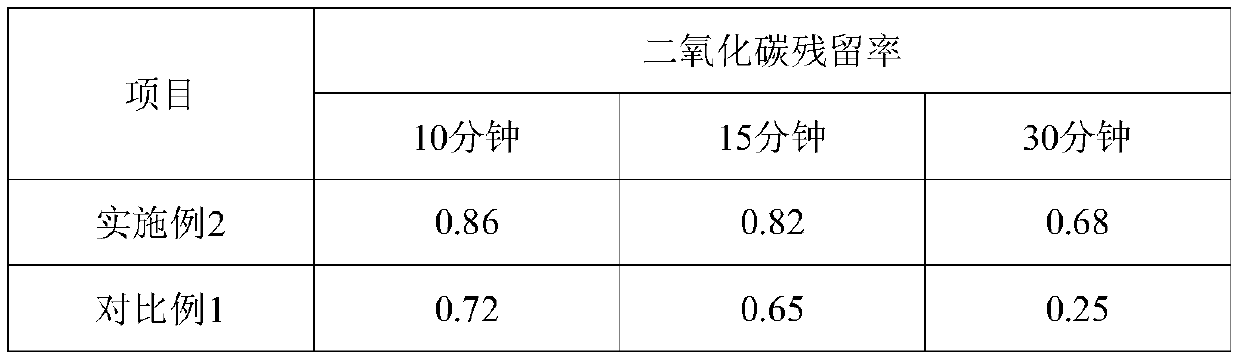

Preparation method of lime and carrot protein beverage

The invention provides a preparation method of a lime and carrot protein beverage, and belongs to the field of processing of functional food. The preparation method comprises the following steps: mixing a protein concentrate, lime juice, carrot juice, a foam control agent and a certain amount of pH regulator capable of providing pH of 2-5.6 in water to obtain a mixture; heating the mixture to 140-188 degrees Fahrenheit for 10-60 seconds; cooling the mixture to 40 degrees Fahrenheit in 5-10 minutes; adding carbon dioxide to the mixture to obtain a protein beverage containing carbonic acid gas;and cavitating the liquid containing the carbonic acid gas under pressure. The protein purity of soy protein in the lime and carrot protein beverage provided by the invention is as high as 95-99%; based on the carbonic acid gas contained, the lime and carrot protein beverage has the properties of fine bubbles and soft taste; and based on the foam control agent, the carbonated beverage has a bettermouthfeel and a good preservation effect.

Owner:浦江县泰如食品科技有限公司

Amino acid cleansing cream and preparation method thereof

ActiveCN102327198BImprove stabilityNo phototoxicityCosmetic preparationsToilet preparationsBetaineCocoyl glutamate

The invention discloses an amino acid cleansing cream and a preparation method thereof. The amino acid cleansing cream comprises the following components in percent by weight: 3-8 percent of glycerol, 0.05-0.2 percent of hydroxyethylcellulose, 5-13 percent of propylene glycol, 25-30 percent of sodium lauroyl glutamate, 5-8 percent of sodium cocoyl glutamate, 0.5-1.5 percent of ethal-octadeca-composite fatty alcohol, 0-2 percent of ethylene glycol distearate, 0.2-0.6 percent of cetearyl alcohol ether (20), 0.5-1.5 percent of cocoaminopropyl dimethyl betaine, 0.5-1.5 percent of cetearyl alcoholether-60 myristyl glycol, 1-3 percent of acrylate / polyoxyethylene-20 stearin alcohol ether methacrylate copolymer, 0.4-0.8 percent of citric acid, 0.1-0.2 percent of diazolidiny urea, 0.10-0.15 percent of methyl phydroxybenzoate and the balance of deionized water. the amino acid cleansing cream has better stability and solid content of sodium lauroyl glutamate of more than or equal to 25 percent,and can create a comfortable and clear microenvironment for healthy growth and metabolism for skin cells on the face.

Owner:SHENZHEN GENE BIOLOGICAL TECH

A kind of composite particle, its preparation method and application

ActiveCN106565383BImprove temperature resistanceGood acid and alkali resistanceDrilling compositionWell cementingCement mortar

The invention relates to the technical field of oil gas well cementing, and especially relates to a composite particle, and a preparation method and an application thereof. The composite particle comprises a core which is an elastic particle and a shell layer which is a rigid particle and coats the external surface of the core. The preparation method of the composite particle is characterized in that airflow entrainment is used to drive the elastic particle and the rigid particle to move relative to each other in order to form the composite particle. The composite particle has high temperature resistance, improves the acid and alkali resistance of the elastic particle, has good stability, has good compatibility with cement mortar, has no floatation phenomenon, has no thickness increase phenomenon in the curing process, obviously reduces the elastic modulus of set cement, increases the deformation ability of the set cement, is spherical, and facilitates increase of the fluidity of the cement mortar.

Owner:CHINA PETROLEUM & CHEM CORP +1

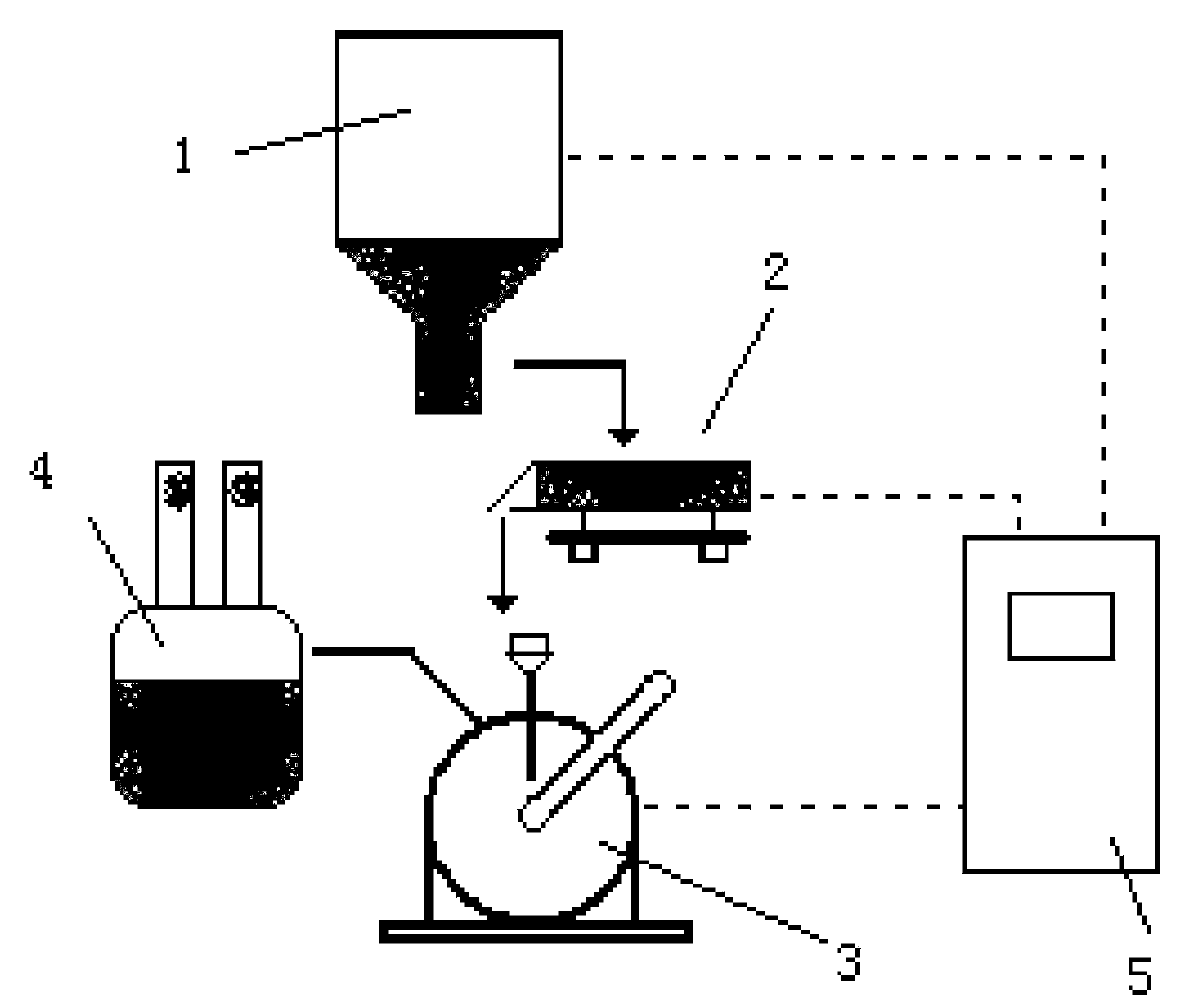

Paint remover and its preparing method and using method

InactiveCN100453606CGood paint removal effectEasy to prepareChemical paints/ink removersVegetable oilOrganic solvent

The present invention relates to one kind of paint remover and its preparation process and usage. The paint remover consists of organic base 30-55 wt %, organic solvent 40-65wt %, and corrosion inhibitor 0.5-7wt %, and during storage and use, its surface is covered with oil sealer. The organic base is alcohol amine with boiling point not lower than 160deg.c and molecular weight smaller than 200; the organic solvent has point not lower than 200deg.c; the corrosion inhibitor is saccharide; and the oil sealer is vegetable oil or mineral oil with density lower than the paint remover and insoluble in the paint remover. The paint remover has simple preparation process, convenient use and environment friendship, and may be used to remove several kinds of paint film in high speed and no corrosion to most of the substrate.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Gel synergizing type polymer lithium ion battery and preparation method thereof

ActiveCN100401574CIncreasing the thicknessNo micro short circuitFinal product manufactureElectrolyte accumulators manufactureCyclic processDischarge rate

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Filtrate reducer for water-based drilling fluid and preparation method of filtrate reducer

ActiveCN102585784BLow biological toxicityGood filter loss reduction effectDrilling compositionSulfonateMeth-

The invention discloses a filtrate reducer for a water-based drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer for the water-based drilling fluid comprises the following components in percentage by mass: 30-40 percent of acrylamide, 10-20 percent of 2-acryloylmino-2-methylpropyl sulfonate, 20-30 percent of maleic anhydride, 20-40 percent of sodium allylsulfonate, 0.1-0.2 percent of initiator and the balance of water. The filtrate reducer disclosed by the invention has the advantages of low biotoxicity, strong resistance to pollution of calcium ions and magnesium ions and good temperature resistance; and the requirements of the drilling of a gypsum-salt layer on a drilling fluid treating agent can be satisfied, and meanwhile, the filtrate reduction effect is still good in the high-density condition.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

A kind of humic acid grafted fluid loss reducer for high temperature drilling fluid and preparation method thereof

ActiveCN103725269BImprove thermal stabilityGood filter loss reduction effectDrilling compositionGraft TypePetroleum

The invention discloses a high temperature resistant humic acid grafting filtrate reducer for a drilling fluid and a preparation method thereof. The filtrate reducer is used for petroleum drilling. The invention aims at solving the problems that the filtrate reducer has poor salt and calcium resistance when being decomposed at high temperature of 200 DEG C and the filtrate reducer with good properties is expensive. The high temperature resistant humic acid grafting filtrate reducer is prepared from acrylamide, 2-acrylamide-2-methyl propanesulfonic acid, acrylic acid, sodium humate, water and initiator through copolymerization. The preparation method comprises steps of sequentially adding acrylamide, 2-acrylamide-2-methyl propanesulfonic acid, acrylic acid and sodium humate into water, stirring to dissolve, then regulating pH value to be 7-11, heating up to 50 DEG C-70 DEG C, aerating nitrogen for 25-35 minutes, then adding initiator in nitrogen condition, stirring for reacting for 2-4 hours, cooling down to room temperature, then shearing to pelletize, stoving, smashing so as to obtain the filtrate reducer.

Owner:大庆精诚化工有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com