A kind of humic acid grafted fluid loss reducer for high temperature drilling fluid and preparation method thereof

A fluid loss control agent and drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high price of fluid loss control agent, poor salt and calcium resistance, etc., and achieve good economic benefits and Social benefits, good filtration loss reduction, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

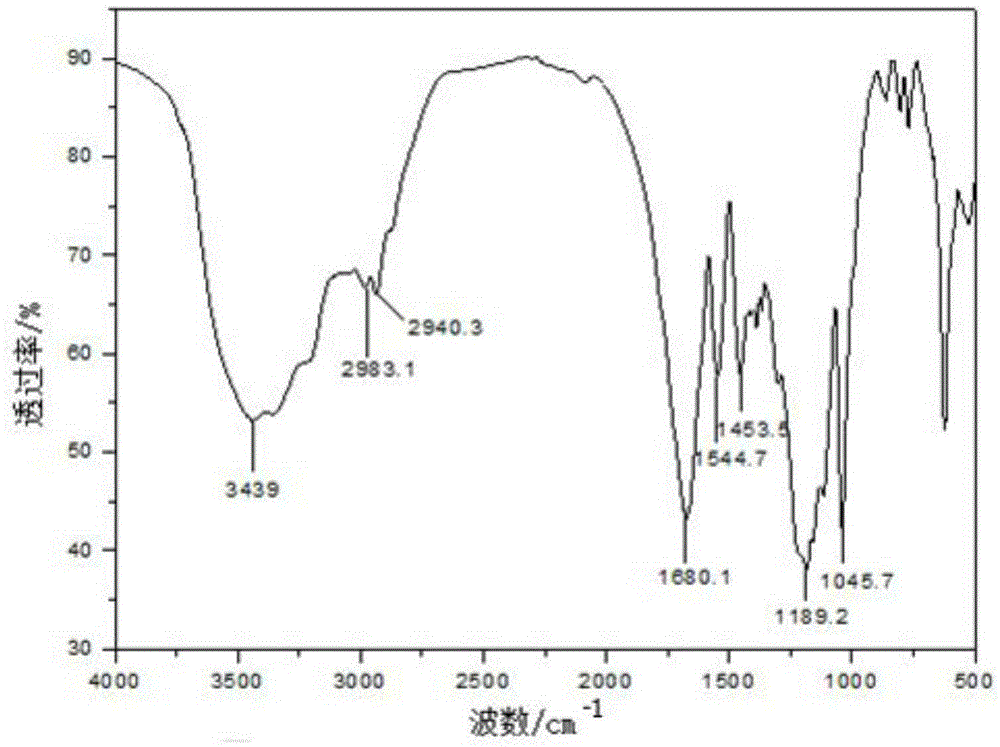

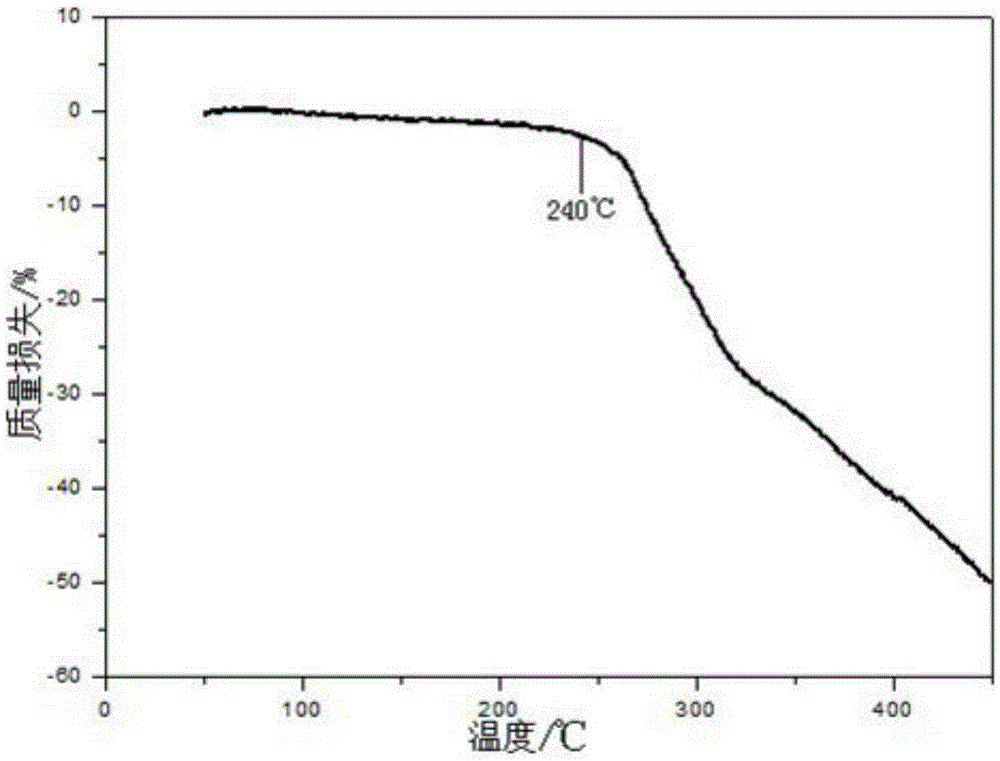

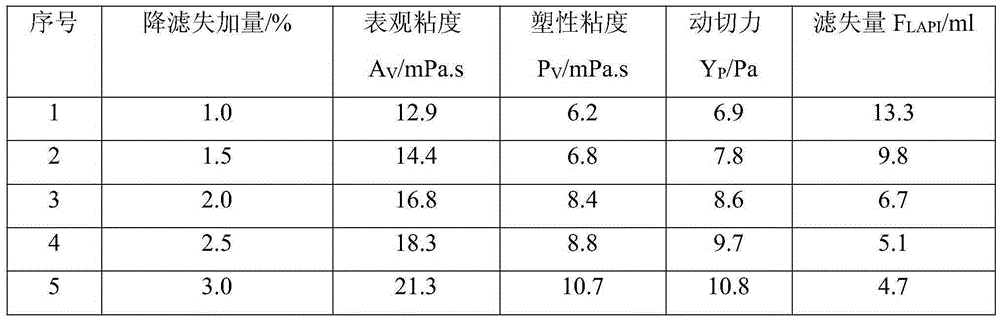

[0023] Specific embodiment 1: A kind of humic acid grafted fluid loss reducer for high temperature resistant drilling fluid in this embodiment is composed of acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, acrylic acid, sodium humate, It is prepared by copolymerization of water and initiator; the mass ratio of the acrylamide to 2-acrylamide-2-methylpropanesulfonic acid is 1: (0.5-1); the mass ratio of the acrylamide to acrylic acid The mass ratio is 1: (0.20-0.5); the mass ratio of the acrylamide to sodium humate is 1: (0.7-1.5); the mass ratio of the acrylamide to water is 1: (3.5-6) ; The initiator is a compound aqueous solution, wherein the solute of the compound aqueous solution is ammonium persulfate and sodium bisulfite, and the mass concentration of the solute in the compound aqueous solution is 1% to 1.5%. The mass ratio of described ammonium persulfate and sodium bisulfite is 1:1, and the solvent of wherein said composite aqueous solution is water; Described ac...

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass ratio of the acrylamide to 2-acrylamido-2-methylpropanesulfonic acid is 1:0.75; the acrylamide and The mass ratio of acrylic acid is 1:0.25; the mass ratio of acrylamide to sodium humate is 1:1; the mass ratio of acrylamide to water is 1:5. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the mass concentration of the solute in the compounded aqueous solution is 1.2%. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com