Expanded type aqueous facing fireproof coating and preparation method thereof

An intumescent technology for fire-resistant coatings, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of poor water resistance and insufficient adhesion of coatings, and achieve the effects of smooth and delicate coating films, improved fire resistance, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

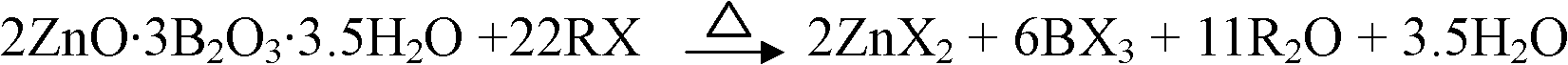

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of intumescent water-based decorative fireproof coating provided by the invention may further comprise the steps:

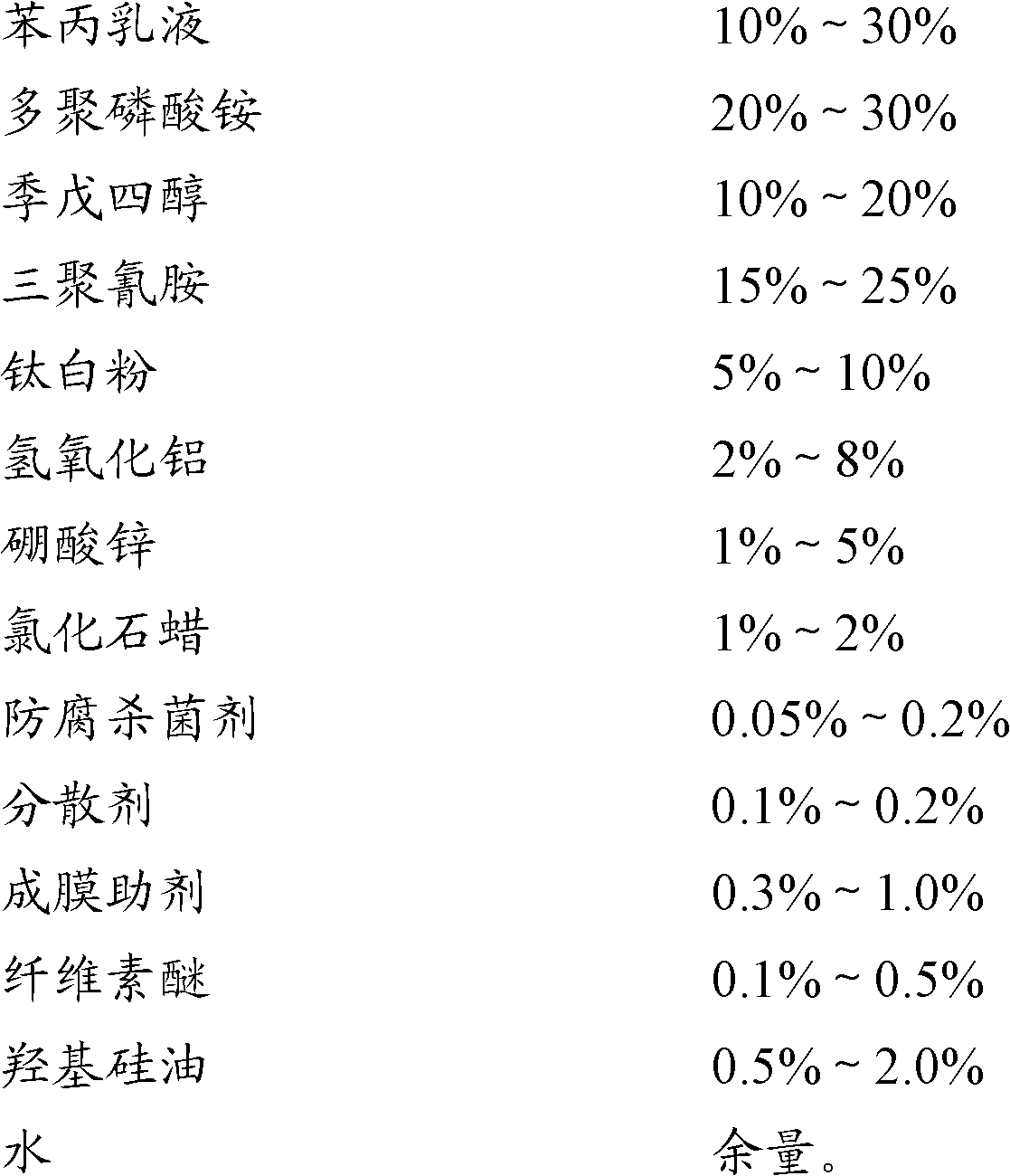

[0049] a) Mix the following components by weight percentage: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% titanium dioxide, 2% to 8% aluminum hydroxide, 1% to 5% zinc borate, 1% to 2% chlorinated paraffin, 0.05% to 0.2% antiseptic, 0.1% to 0.2% dispersant, 0.3% to 1.0% of film-forming aids, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxyl silicone oil and the rest of water, wherein the cellulose ether is added after wetting with water to obtain The mixture is dispersed and stirred at a lower speed of 100rpm to 150rpm.

[0050] The weight percent components mixed can be preferably 15%-25% of styrene-acrylic emulsion, 15%-25% of ammonium polyphosphate, 15%-20% of pentaerythritol, 20%-25% of melamine, 5%-10% of titanium dioxide, h...

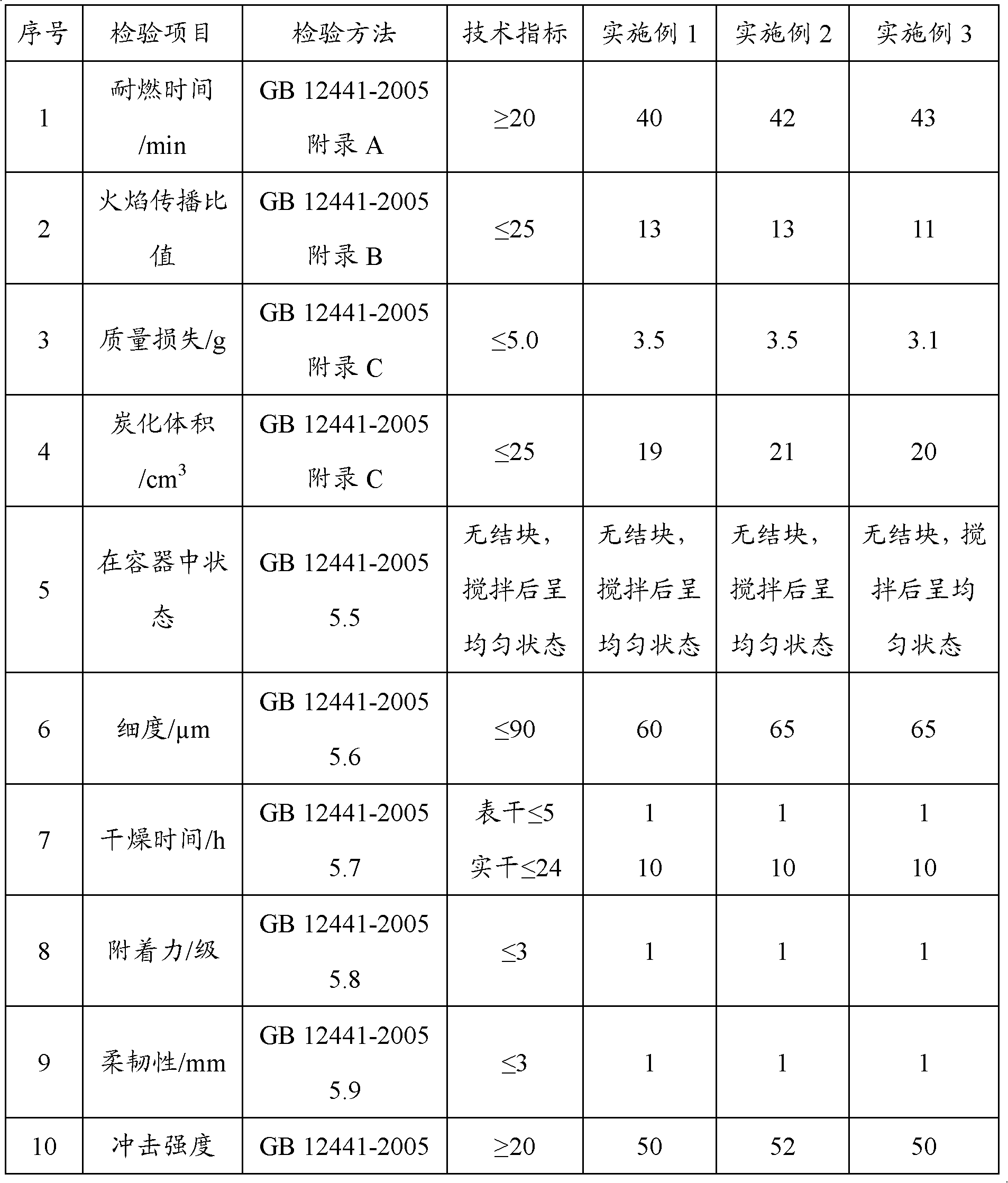

Embodiment 1

[0054] 20 parts of MW-161 styrene-acrylic emulsion from Shanghai Mowang Composite Material Technology Co., Ltd., 24 parts of ammonium polyphosphate, 12 parts of pentaerythritol, 15 parts of melamine, and 6 parts of R105 rutile titanium dioxide from DuPont Titanium Dioxide Technology (Shanghai) Co., Ltd. , 4 parts of aluminum hydroxide, 4 parts of zinc borate, 2 parts of 70 chlorinated paraffin, 0.1 part of isothiazolinone, XG-505 water-resistant dispersant produced by Hengshui Xinguang Chemical Co., Ltd. (hydrophobic modified polyacrylic acid ammonium salt ) 0.2 parts, 0.7 parts of dodecyl alcohol, 0.1 parts of hydroxyethyl cellulose, 1 part of hydroxy silicone oil from Qingdao Xingye Silicone New Material Co., Ltd., 1 part of antifreeze, 9.9 parts of water, dispersed at 1500-2000rpm for 10- 15 minutes, and grind in a basket sand mill for 20 minutes to make the fineness reach ≤80 μm, filter and discharge.

Embodiment 2

[0056] 25 parts of SD-800 styrene-acrylic emulsion from Nantong Shengda Chemical Co., Ltd., 20 parts of ammonium polyphosphate, 10 parts of pentaerythritol, 18 parts of melamine, 7 parts of R218 rutile titanium dioxide from Shanghai Yuejiang Titanium White Chemical Products Co., Ltd., hydrogen 2 parts of alumina, 2 parts of zinc borate, 2 parts of 70 chlorinated paraffin, 0.2 part of bromothalonil, 0.1 part of Dipas GA40 dispersant (acrylic acid copolymer ammonium salt) of Changzhou Yayuan Chemical Co., Ltd., lauryl alcohol 1 part of ester, 0.5 part of carboxymethyl cellulose, 1.4 parts of hydroxy silicone oil of Rudong Zhenfeng Yiyang Chemical Co., Ltd., 10.8 parts of water, disperse at 1500-2000rpm for 10-15 minutes, and grind in a basket sand mill Grind for 20 minutes to make the fineness ≤80μm, filter and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com