High-temperature-resistant oil-based drilling fluid shear strength improving agent as well as preparation method and application thereof

An oil-based drilling fluid and cutting agent technology, applied in chemical instruments and methods, earthwork drilling, wellbore flushing, etc., can solve the problems of easy sedimentation of drilling fluid, unsmooth drilling, poor suspension stability, etc. Excellent rheology and sedimentation stability, excellent cutting effect, small viscosity change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

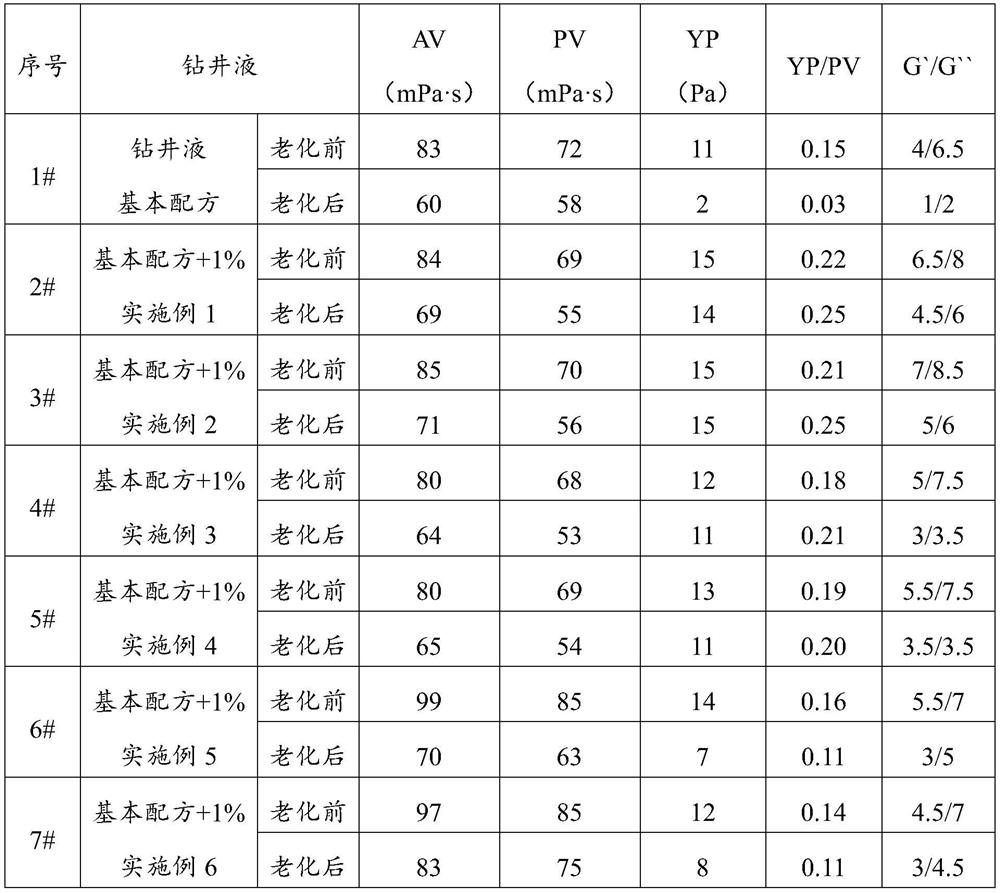

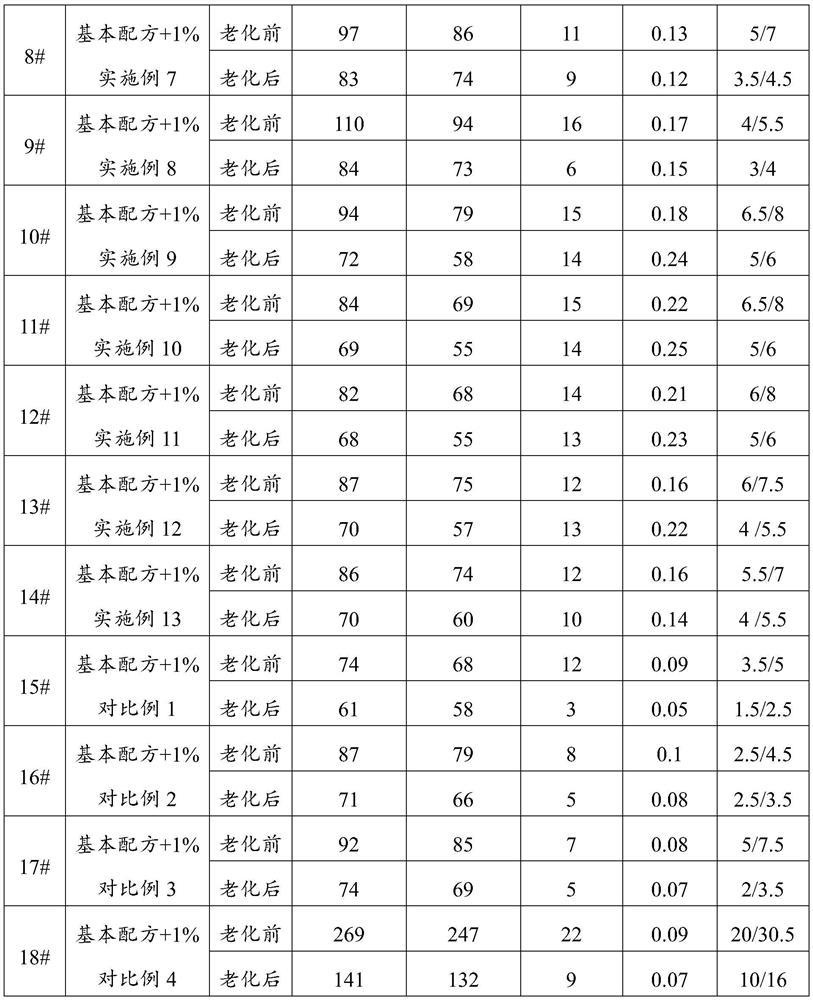

Examples

Embodiment 1

[0034] Embodiment 1: oil-based drilling fluid cutting agent 1#

[0035] 1) Take 80ml of deionized water in a beaker, add 5g of SDBS, emulsify at 2000r / min for 10min, add 10g of styrene and 30g of isoprene, stir at 2000r / min for 20min, then transfer to a high temperature and high pressure reactor , keep the pressure at 4.5MPa.

[0036] 2) Add 0.025g of ammonium persulfate dropwise to the reaction kettle, under the condition of 80°C, the stirring speed is 300r / min, react for 3h, add 0.12g of dodecanethiol to terminate the reaction.

[0037] 3) Keeping the pressure constant, reduce the temperature of the product in step 2) to 70°C, blow in nitrogen gas for 20 minutes, discharge excess gaseous diene monomers, add 10ml of itaconic acid solution containing 3g to it, and use a mass fraction of 20 % sodium hydroxide solution to adjust the pH to 7, 0.025BPO was added dropwise, the stirring speed was 300 r / min, and the reaction was carried out for 2 hours.

[0038] 4) Add 5g of N-meth...

Embodiment 2

[0040] Embodiment 2: oil-based drilling fluid cutting agent 2#

[0041]1) Take 80ml deionized water in a beaker, add 2.5g SDBS and 2.5g2A1, emulsify at 2000r / min for 10min, add 10g styrene and 30g isoprene, stir at 2000r / min for 20min, then transfer to In the high temperature and high pressure reactor, keep the pressure at 4.5MPa.

[0042] 2) Add 0.025g of ammonium persulfate dropwise to the reaction kettle, under the condition of 80°C, the stirring speed is 300r / min, react for 3h, add 0.12g of dodecanethiol to terminate the reaction.

[0043] 3) Keeping the pressure constant, reduce the temperature of the product in step 2) to 70°C, blow in nitrogen gas for 20 minutes, discharge excess gaseous diene monomers, add 10ml of itaconic acid solution containing 3g to it, and use a mass fraction of 20 % sodium hydroxide solution to adjust the pH to 7, 0.025BPO was added dropwise, the stirring speed was 300 r / min, and the reaction was carried out for 2 hours.

[0044] 4) Add 5g of N...

Embodiment 3

[0046] Embodiment 3: oil-based drilling fluid cutting agent 3#

[0047] 1) Take 80ml of deionized water in a beaker, add 5g of SDBS, emulsify at 2000r / min for 10min, then transfer to a high temperature and high pressure reactor, add 10g of styrene, stir at 2000r / min for 20min, then transfer to high temperature and high pressure In the reactor, inject 30g of butadiene gas into the reactor, pressurize and keep 4.5MPa to keep it in a liquid state.

[0048] 2) Add 0.025g of ammonium persulfate dropwise to the reaction kettle, under the condition of 80°C, the stirring speed is 300r / min, react for 3h, add 0.12g of dodecanethiol to terminate the reaction.

[0049] 3) Keeping the pressure constant, reduce the temperature of the product in step 2 to 70°C, feed nitrogen gas for 20 minutes, discharge excess gaseous diene monomers, add 10ml of itaconic acid solution containing 3g, and use a mass fraction of 20% The sodium hydroxide solution was adjusted to PH=7, 0.025BPO was added dropwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com