Shearing force improving agent for water-based drilling fluid and preparation method of shearing force improving agent

A technology of water-based drilling fluid and cutting agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low temperature resistance and excessive viscosity increasing effect, and achieve low apparent viscosity and high The effect of dynamic-to-plastic ratio and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

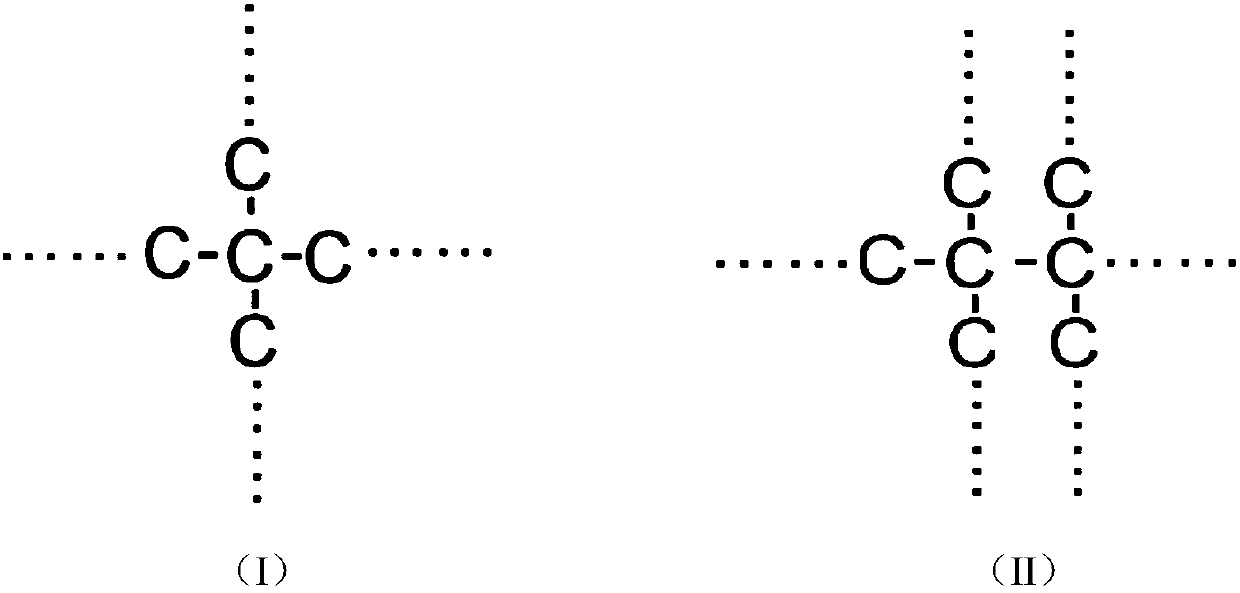

Method used

Image

Examples

Embodiment 1

[0045] Preparation of reactive 4-vinyl-1-(3-sulfopropyl)pyridine ylide monomer: take 52.55kg of tetravinylpyridine distilled under reduced pressure and add it to a reaction kettle with a volume of 1 cubic meter , and then slowly add 67.15kg of 1,3-propane sultone to the reaction kettle, control the temperature in the reaction kettle not to exceed 40°C during the addition process, add the required amount of 1,3-propane sultone and After stirring until the above-mentioned raw material mixture forms a uniform solution, heat the temperature of the reactor to 80°C and react at this temperature for 24 hours. After the reaction is completed, the temperature of the reactant is lowered to room temperature, and filtered. Wash 3 times, then transfer the resulting solid powder to a vacuum drying oven and dry at 50°C for 24 hours to obtain the reactive 4-vinyl-1-(3-sulfopropyl)pyridine ylide of the present invention Monomer (Monomer D).

Embodiment 2

[0047] Add 700 parts of deionized water to a reactor equipped with a stirrer, a temperature controller, an air duct and a reflux condenser, and add 54 parts of 2-acrylamide-2-methylpropanesulfonic acid (monomer A) under stirring, Stir until the 2-acrylamide-2-methylpropanesulfonic acid is completely dissolved, adjust the pH value of the solution to 7 with 30% sodium hydroxide solution, and add 36 parts of reactive 4-vinyl-1-(3-sulfopropyl) Pyridine ylide monomer (monomer D), add 1.8 parts of sodium chloride, stir until 4-vinyl-1-(3-sulfopropyl)pyridine ylide monomer and sodium chloride are completely dissolved, then add 36 Parts of N-vinylpyrrolidone (monomer B) and 54 parts of methacryloyloxyethyltrimethylammonium chloride (monomer C), add 120 parts of deionized water, then adjust with 30% sodium hydroxide solution The pH value of the monomer solution was 9, and finally 1.8 parts of pentaerythritol was added and stirred until the pentaerythritol was completely dissolved.

[...

Embodiment 3

[0050] Add 700 parts of deionized water to the reactor equipped with stirrer, temperature controller, gas guide pipe and reflux condenser, add 45 parts of 2-acrylamide-2-methylpropanesulfonic acid (monomer A) under stirring, Stir until the 2-acrylamide-2-methylpropanesulfonic acid is completely dissolved, adjust the pH value of the solution to 7 with 30% sodium hydroxide solution, and add 45 parts of reactive 4-vinyl-1-(3-sulfopropyl) Pyridine ylide monomer (monomer D), add 2.2 parts of sodium chloride, stir until 4-vinyl-1-(3-sulfopropyl)pyridine ylide monomer and sodium chloride are completely dissolved, then add 36 Parts of N-vinylpyrrolidone (monomer B) and 54 parts of methacryloyloxyethyltrimethylammonium chloride (monomer C), add 120 parts of deionized water, then adjust with 30% sodium hydroxide solution The pH value of the monomer solution was 9, and finally 1.8 parts of pentaerythritol was added and stirred until the pentaerythritol was completely dissolved.

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com