Alpine region tunnel sidewall pilot tunnel drainage structure

A technology for alpine regions and drainage structures, which is applied in drainage, tunnels, safety devices, etc., can solve the problems of large amount of works for branch and diversion tunnels, difficult terrain to meet requirements, and large engineering investment costs, and achieves engineering construction costs. The effect of reducing, engineering construction is simple and easy, and improving the strength of the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

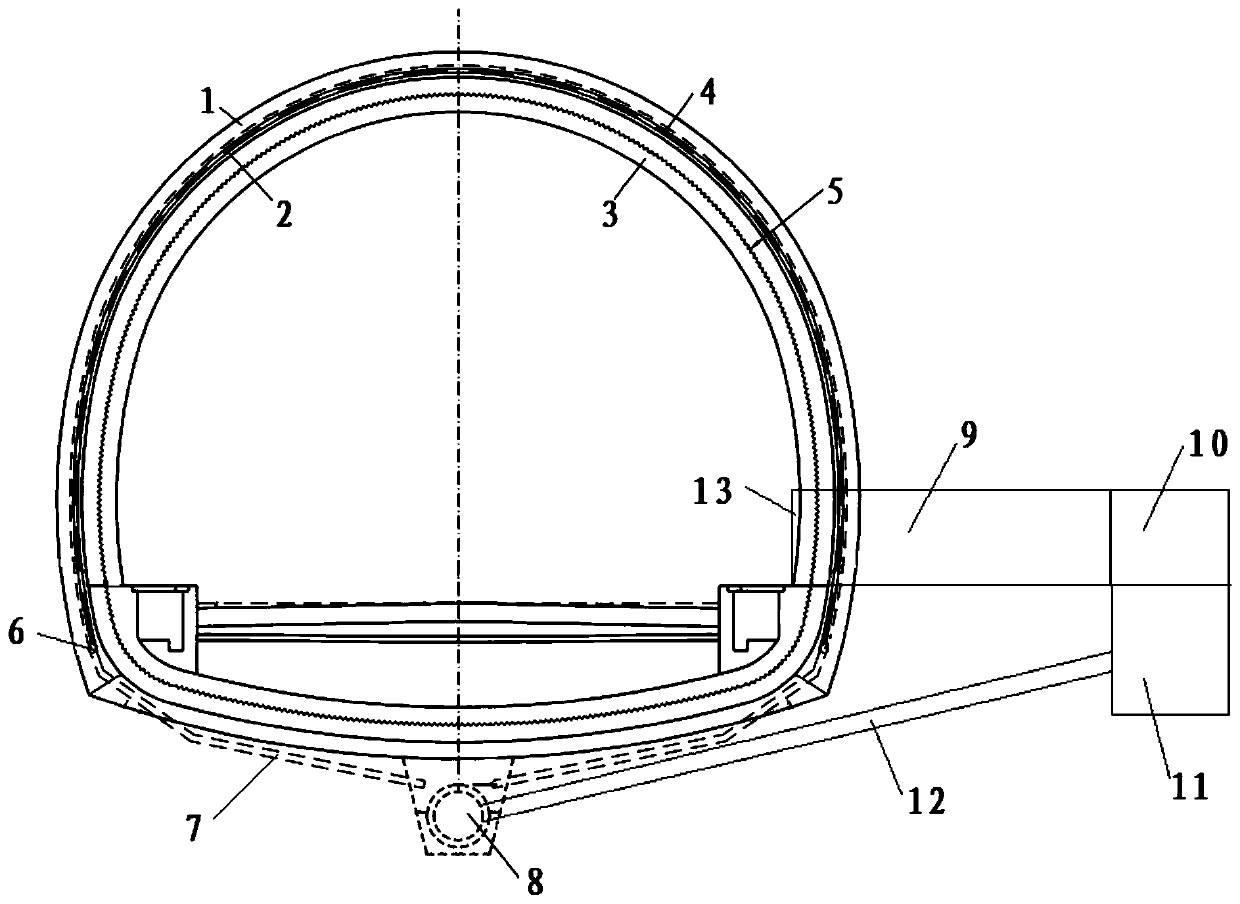

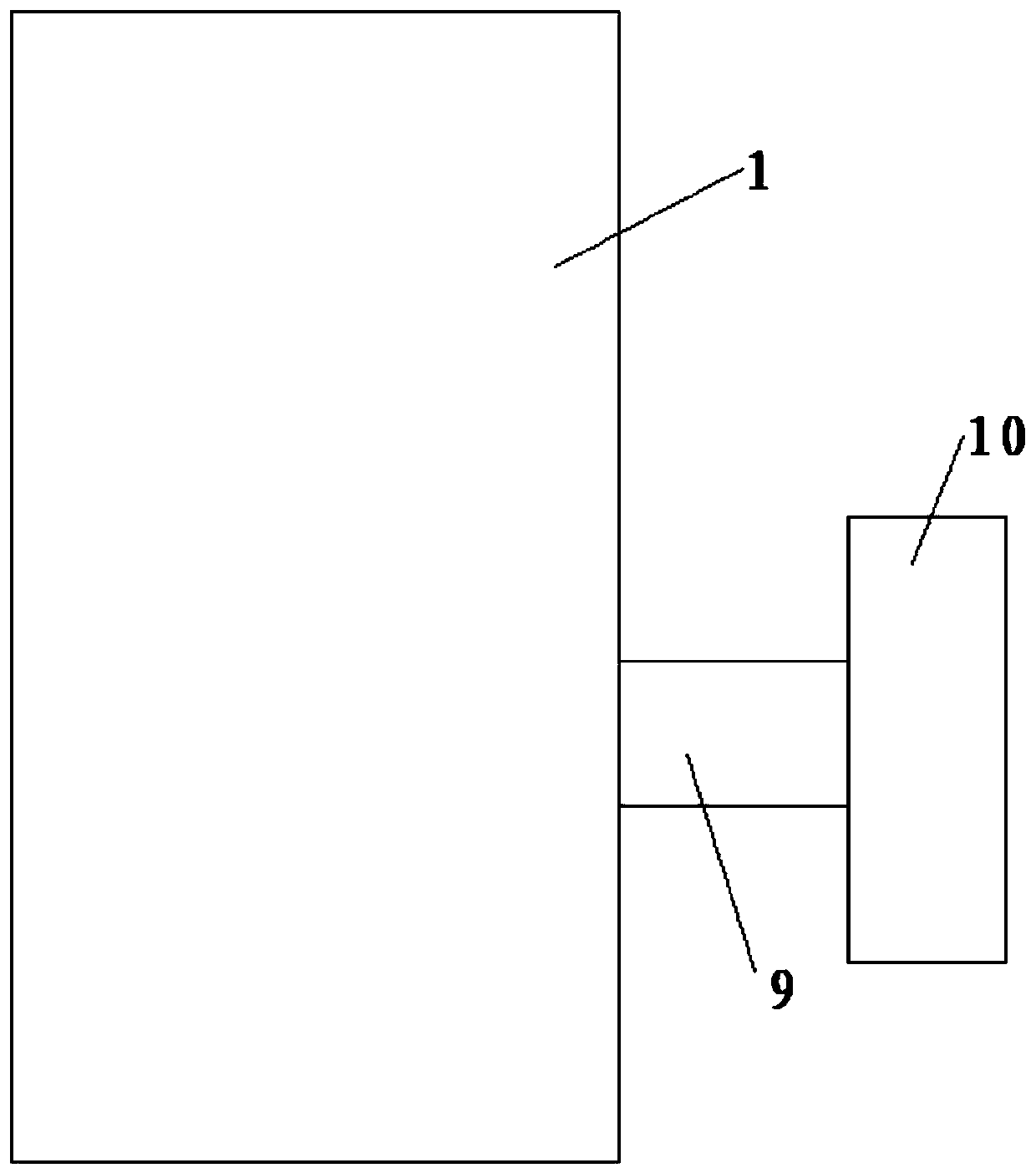

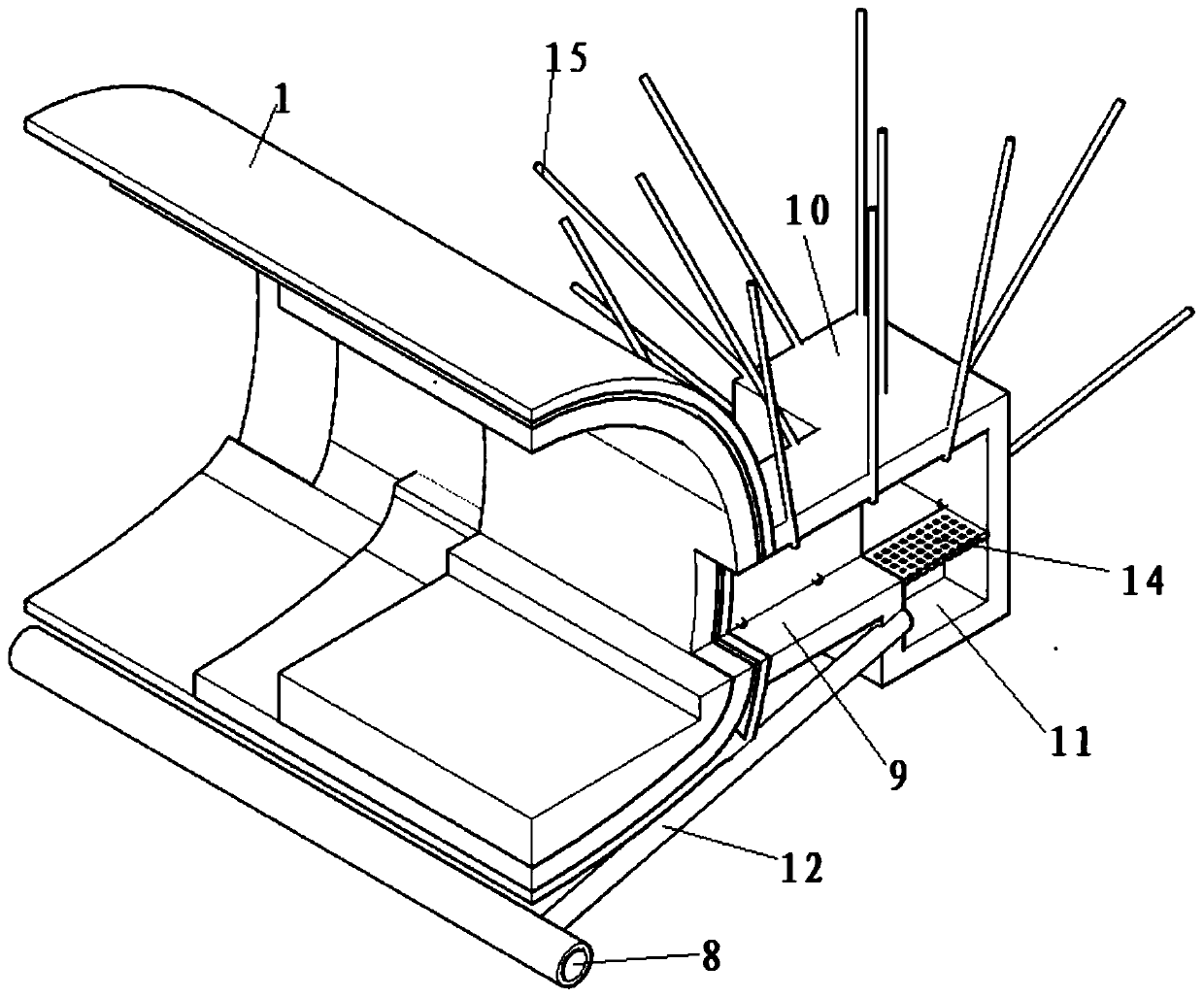

[0029] Such as Figure 1 to Figure 3As shown, the present invention includes a vertical pilot pit 9 excavated along a direction perpendicular to the tunnel lining at the central position of the tunnel side wall corresponding to the tunnel water seepage section or rich water section in the alpine region and a vertical pilot pit 9 excavated along a direction parallel to the tunnel lining and perpendicular to the tunnel lining. The pilot pit 9 is far away from the parallel pilot pit 10 connected to one end of the tunnel in the alpine region. The vertical pilot pit 9 and the parallel pilot pit 10 form a T-shaped tunnel sidewall pilot pit. The lower excavation has a water collection and sand settling well 11 that is connected with the vertical pilot pit 9 and the parallel pilot pit 10. The water collection and sand settlement well 11 is connected with the central drain pipe 8 through the connecting drain pipe 12, and the connecting drain pipe 12 is connected with the water collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com