Suspended ceiling structure of long span underground powerhouse and construction method thereof

An underground workshop and large-span technology, which is applied to underground chambers, ceilings, building components, etc., can solve problems such as construction difficulties, safety of suspended ceiling structures, and inability to arrange maintenance planks, so as to shorten the construction period, ensure safe and reliable structures, and facilitate The effect of ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

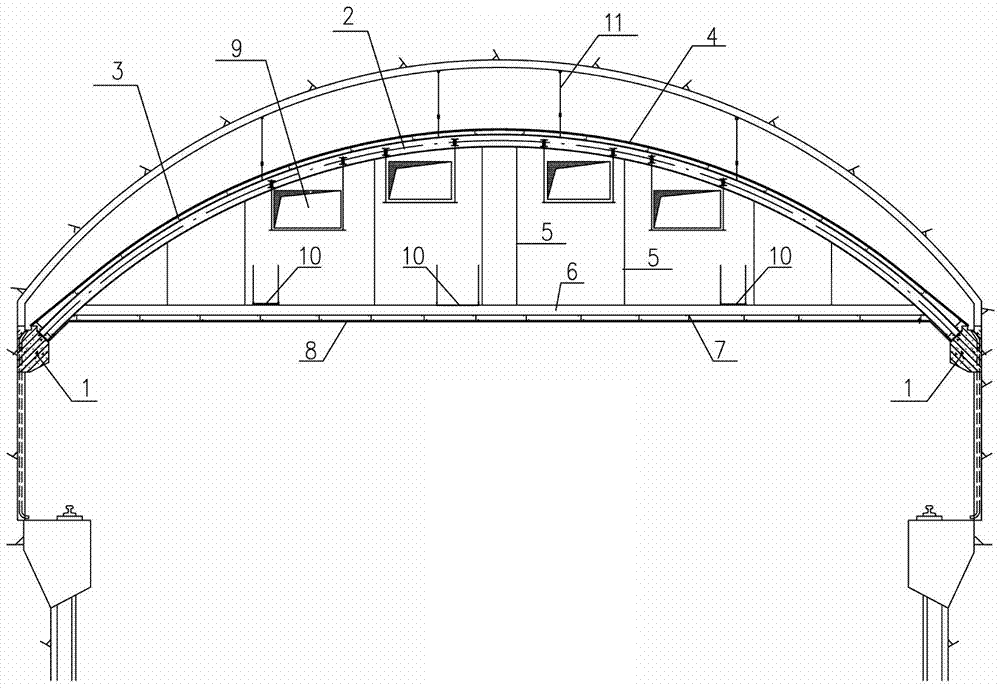

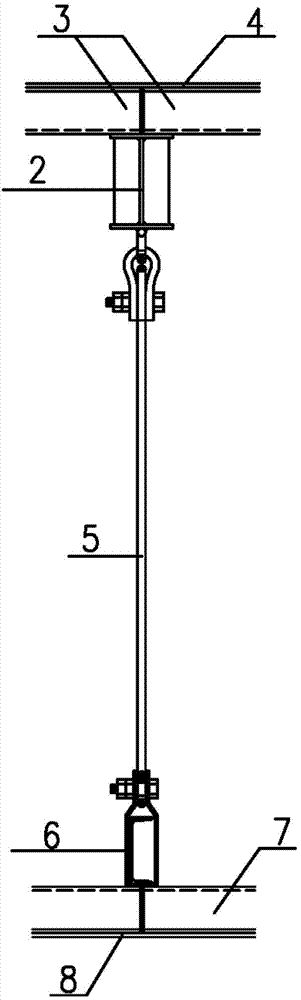

[0023] Such as figure 1 , 2 As shown, the suspended ceiling structure of the large-span underground powerhouse of the present invention includes two full-length rock anchor beams 1 located on the upstream and downstream sides that have been constructed, and are located between the two rock anchor beams 1 and span in the upstream and downstream directions. The steel arch beam 2, the arched waterproof layer purlin and the purlin 3 supported on the upper flange of the steel arch beam 2, the arched waterproof plate 4 fixed with the arch waterproof layer purlin 3, the lower flange of the steel arch beam 2 Hanging multiple steel rings and steel booms 5, the main keel 6 of the horizontal decoration layer is hung below the steel boom 5, and the horizontal decoration layer purlin 7 is fixed under the main keel 6, on the lower surface of the horizontal decorati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com