Construction method suitable for penetrating water supply pipe below tunnel in composite stratum with soft upper part and hard lower part

A technology of composite strata and construction method, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of impact damage to the vault structure and large-scale settlement of the tunnel surface, so as to control the construction period, control the settlement of the tunnel and the surface , the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

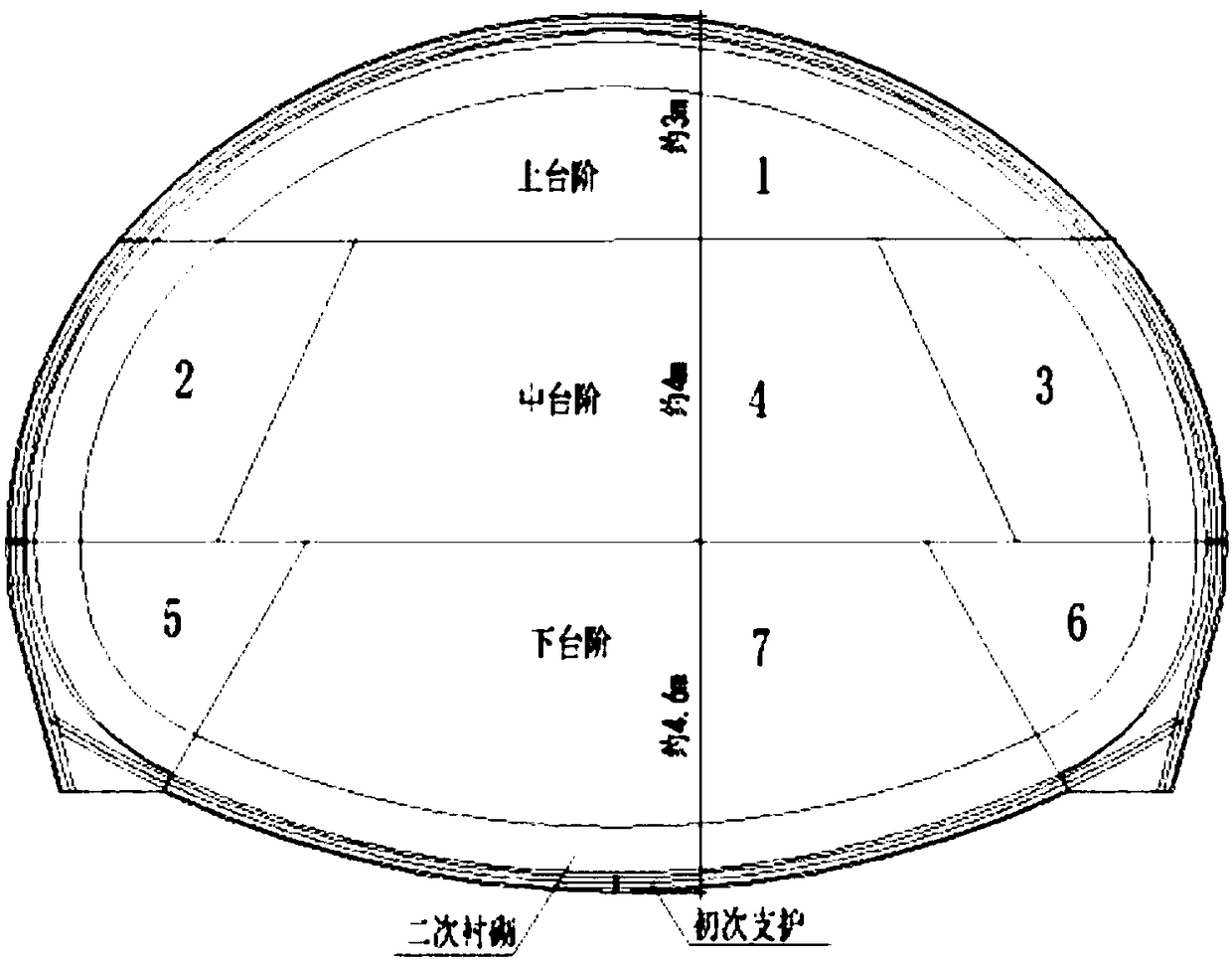

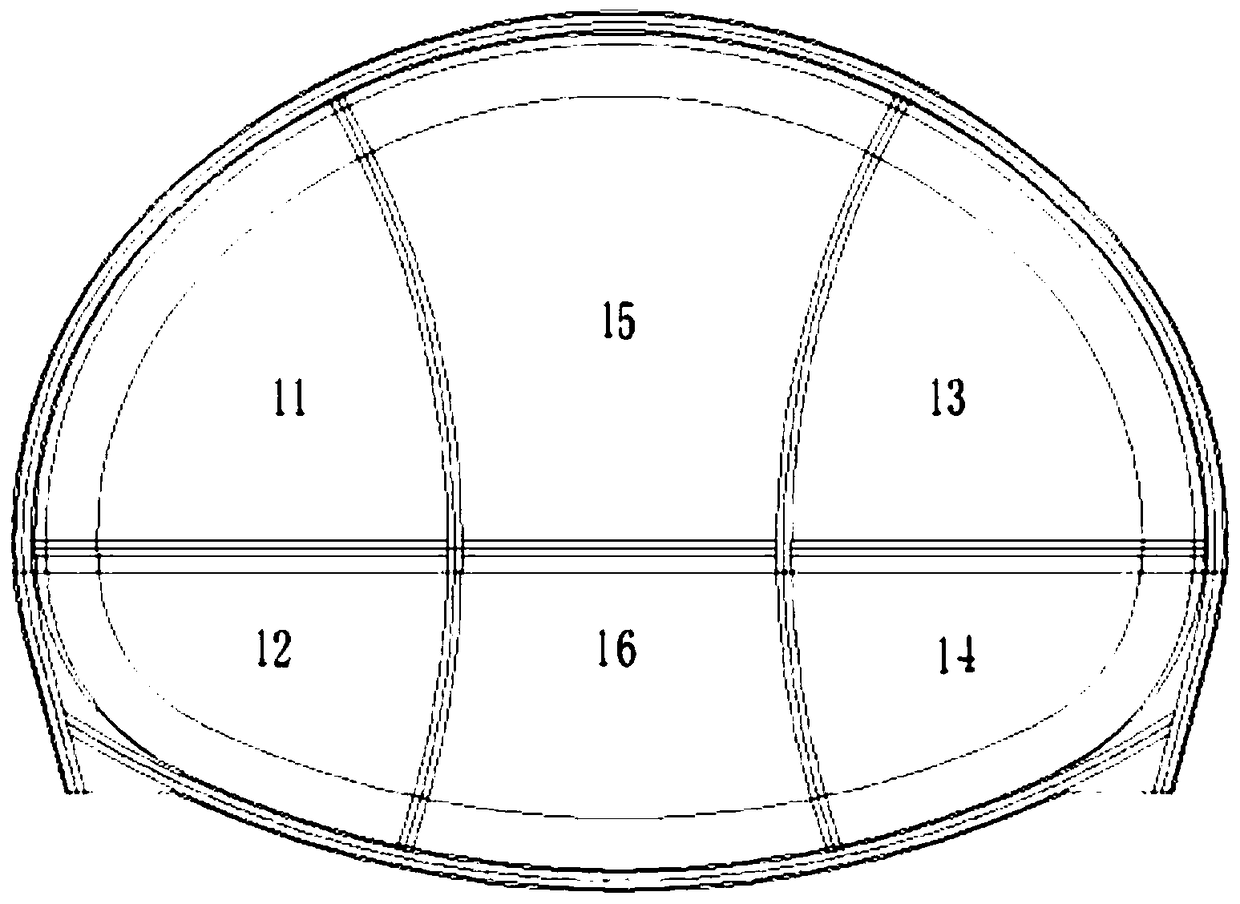

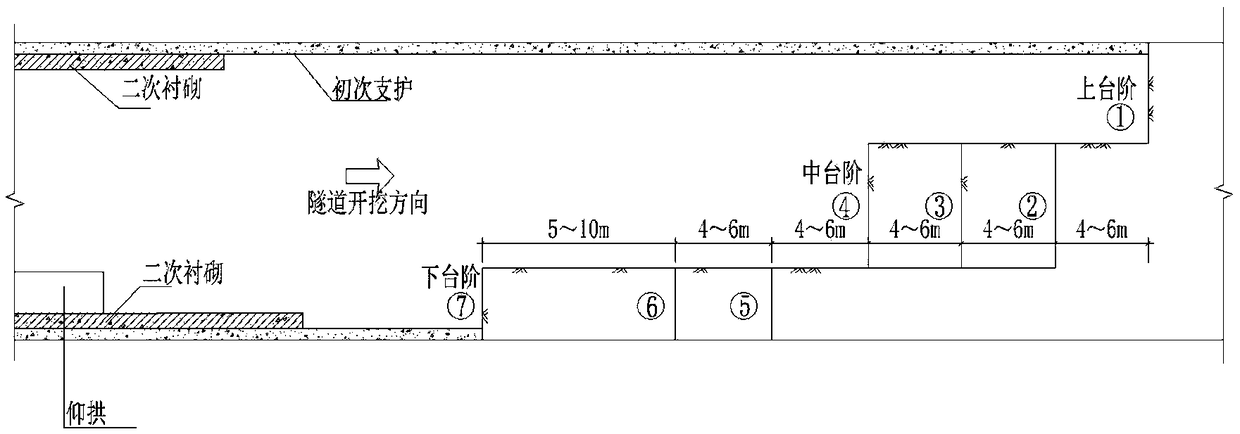

[0040] This embodiment relates to a construction method suitable for passing through a water supply pipe under a tunnel in an upper-soft and lower-hard composite stratum, and its specific process steps are carried out in the following manner:

[0041] S1. First, carry out advanced support for the excavated tunnel, including peripheral curtain grouting and advanced small conduit support. The peripheral curtain grouting construction method includes construction of slabs for preventing magma, setting out holes, drilling, and grouting construction;

[0042]S2. The surrounding curtain grouting construction is completed, and after the design effect is achieved through the test, the advanced small conduit support is started to further strengthen the surrounding rock to reduce the deformation and subsidence of the surrounding rock at the arch; at the same time, the excavation of the cave body Work under its protection to ensure construction safety. The construction methods include layi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com