Composite waterproof layer for environmental engineering and preparing and constructing method thereof

A technology of environmental engineering and waterproof layer, applied in the field of materials, can solve the problems of large gap in waterproof effect, poor treatment of lap joints, and difficult treatment of lap joints, so as to reduce the risk of water leakage, facilitate construction, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

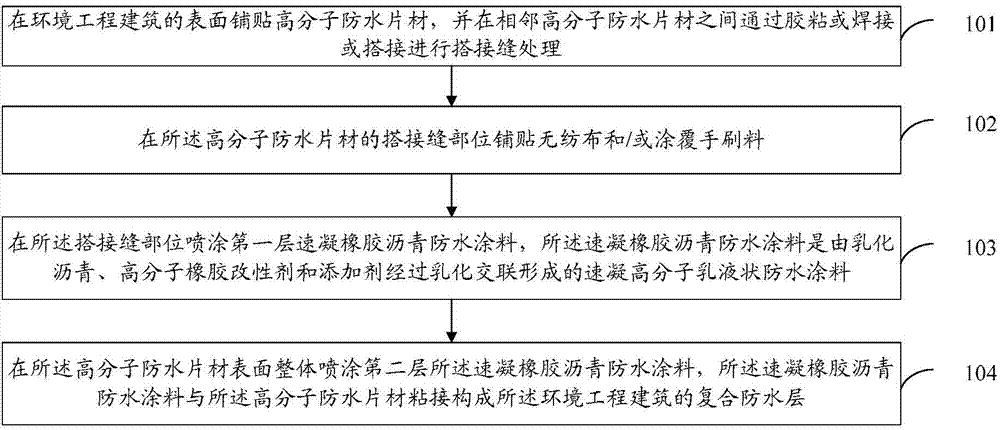

[0092] Embodiment 1. Lay composite geomembrane (two cloths and one film, one cloth and one film, etc.) at the bottom of the building. After the lap joints are processed, lay non-woven fabrics at the lap joints, and then apply hand brushing material , and then spray quick-setting rubber asphalt waterproof coating on a small area of the lap joints. After all the lap joints are sprayed, spray a large area on the surface of the composite geomembrane as a whole. The spray thickness varies according to the design.

Embodiment 2

[0093] Example 2. Lay natural sodium bentonite waterproof blanket on the bottom of the building. After the lap joints are processed, lay non-woven fabric on the lap joints, then apply hand brush material, and then spray the lap joints on a small area , after all the lap joints are sprayed, spray liquid rubber paint on the surface of the natural sodium bentonite waterproof blanket as a whole, and the spray thickness varies according to the design.

Embodiment 3

[0094] Embodiment 3, paving polymer sheets (related materials such as HDPE, LDPE, LLDPE, EVA) at building bottom, lap seam will carry out lap seam processing by the requirement of construction norms, then at lap seam position and high The entire surface of the molecular sheet is sprayed with quick-setting rubber asphalt waterproof coating. After curing, a complete composite coating is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com