Tunnel leakage water treatment method in alpine region

A technology for alpine areas, seepage water, applied in tunnels, drainage, earthwork drilling and other directions, can solve the problems of high project investment cost, difficult terrain to meet requirements, large amount of branch and drainage tunnel works, etc., to improve the foundation The effect of reducing the strength, engineering construction cost and solving the problem of water leakage in the tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

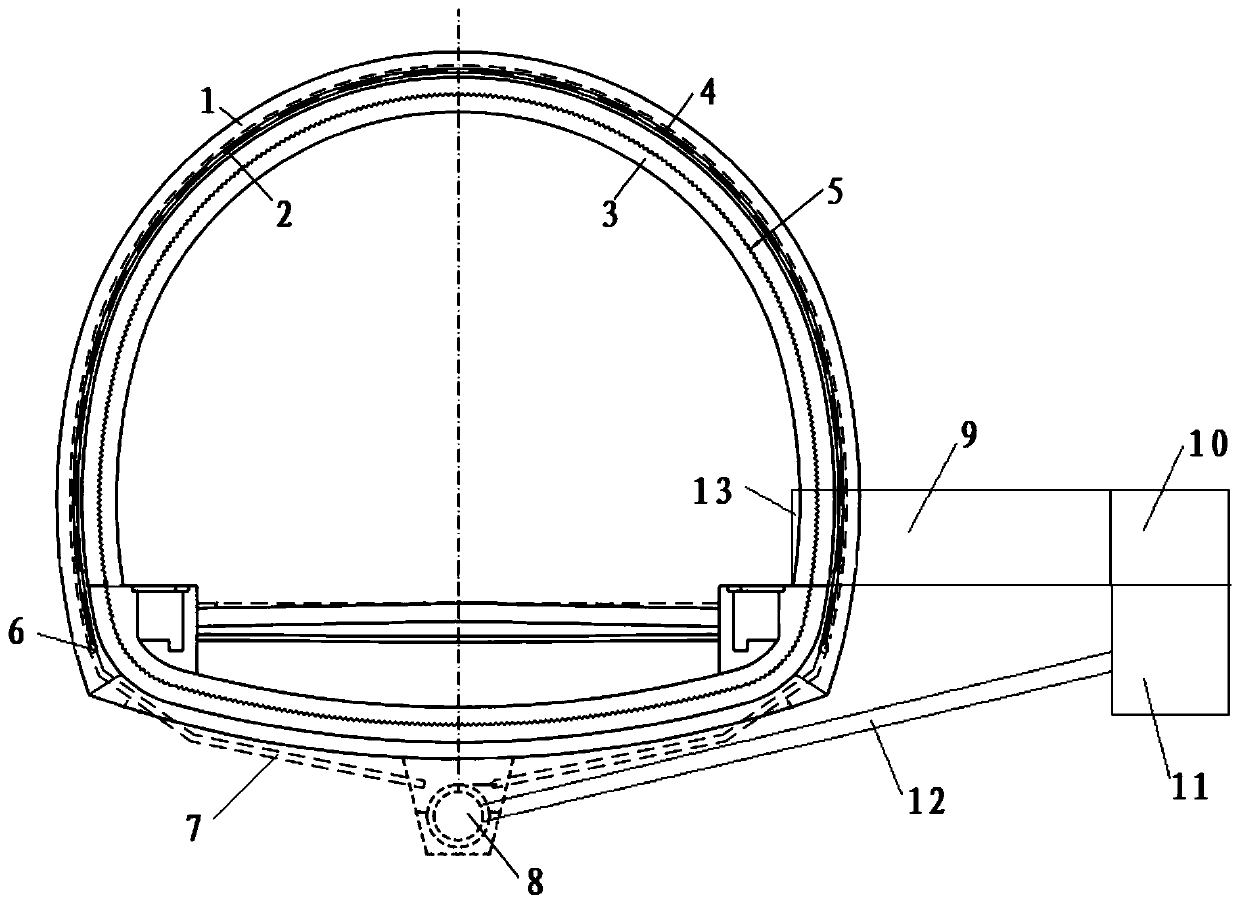

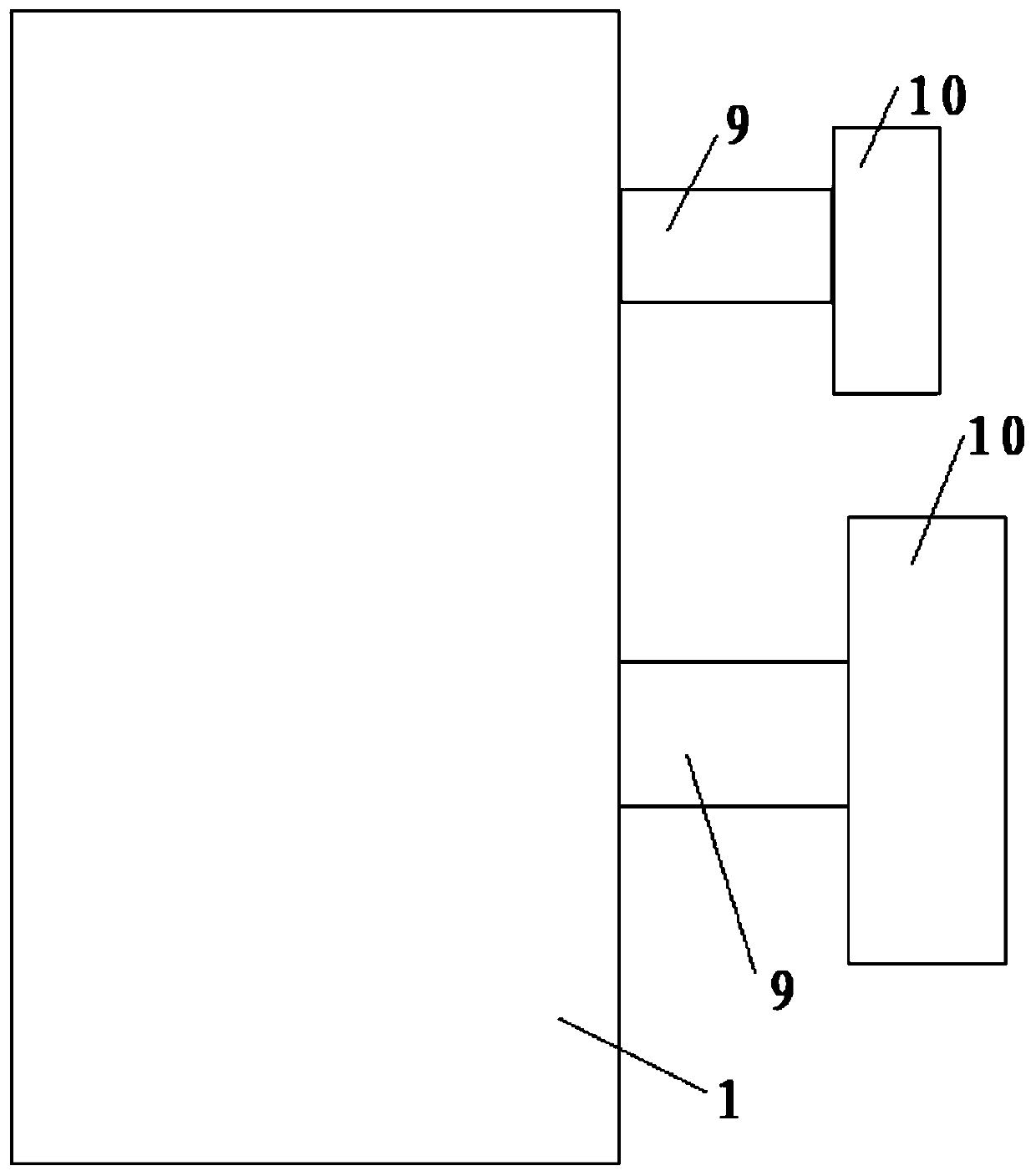

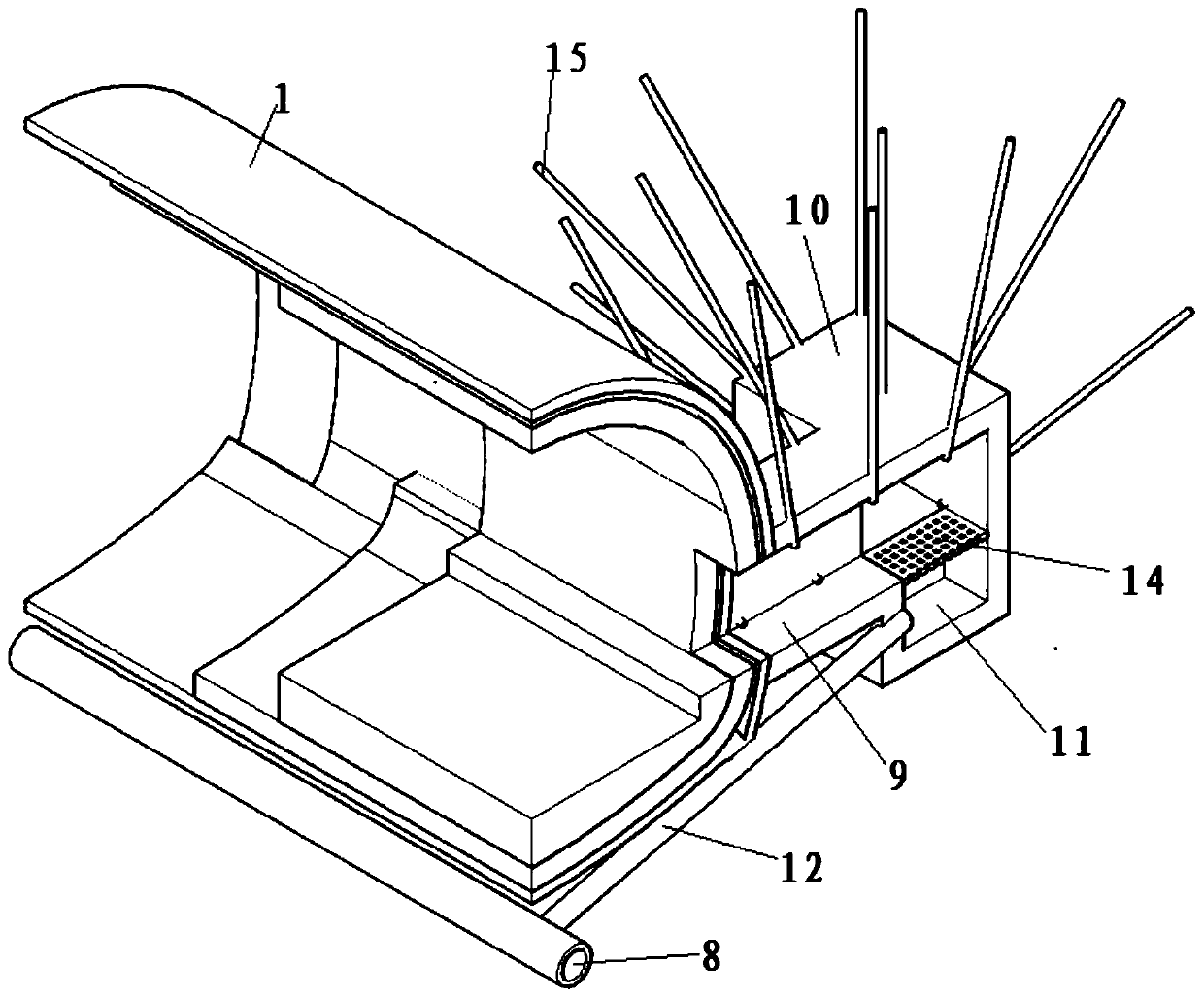

[0040] Such as Figure 1 to Figure 4 Shown, a kind of alpine region tunnel leakage water treatment method of the present invention comprises the following steps:

[0041] Step 1. Investigate the seepage section and water-rich section of the tunnel: According to the tunnel design drawings in the alpine region and the geological survey description during construction, circle the broken water-seepage section and the water-rich section of the tunnel surrounding rock in the alpine region, and break the tunnel surrounding rock Estimate the amount of water in the seepage section and the water-rich section;

[0042] Step 2. Determine the size of the drainage structure of the pilot pit on the side wall of the tunnel: According to the estimated water volume at the position of the broken water seepage section or water-rich section of the tunnel surrounding rock in the alpine region, and the broken water seepage section or water-rich section of the tunnel surrounding rock in the alpine ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com