Anionic water-borne epoxy resin emulsion as well as preparation method and application thereof

A water-based epoxy resin, anionic technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of strong emulsion taste, poor storage stability, and easy delamination, etc. Achieve high solid content and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

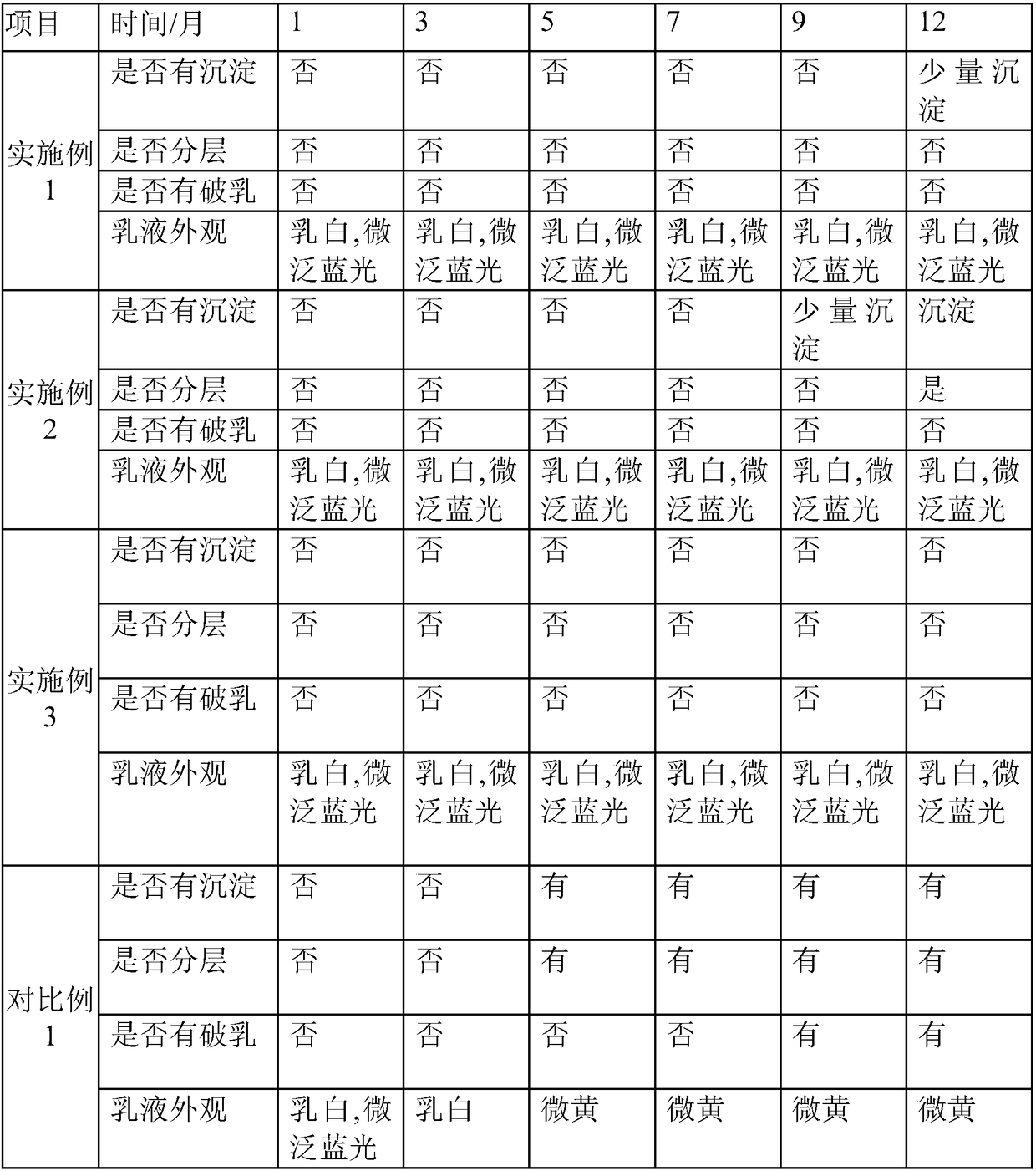

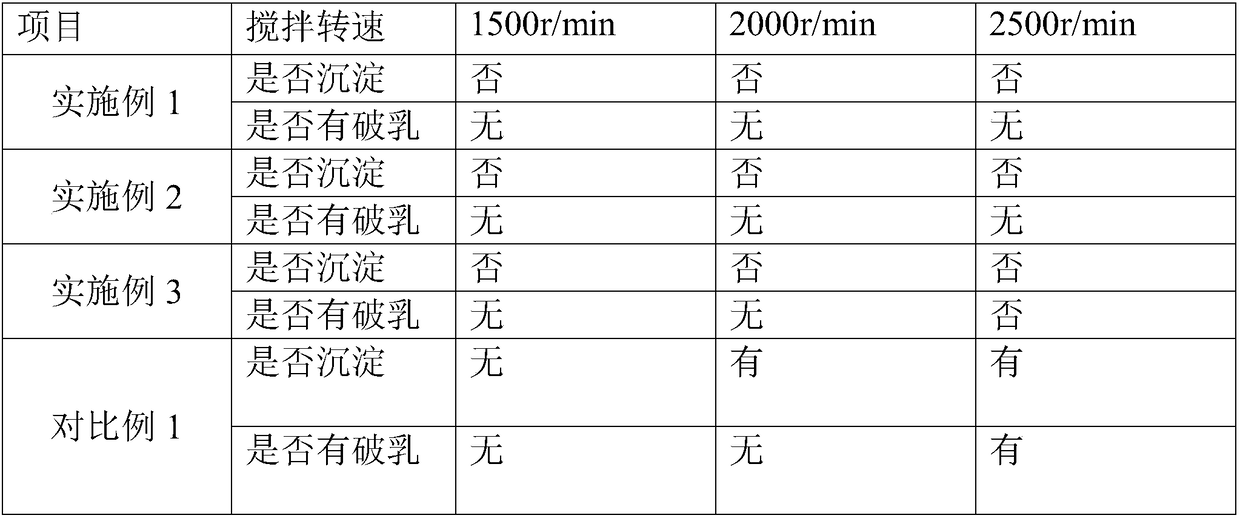

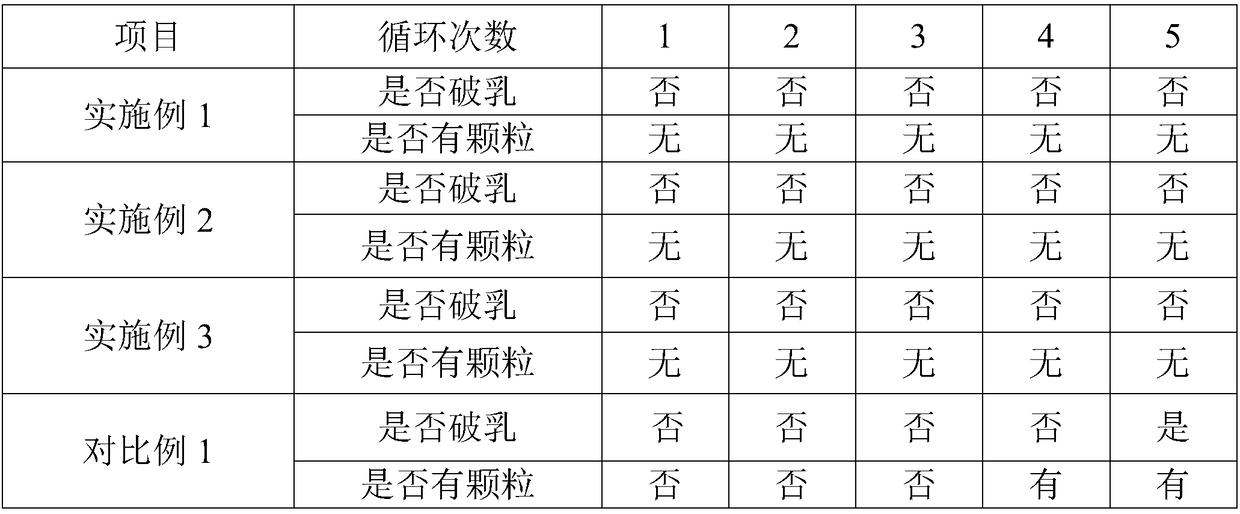

Examples

Embodiment 1

[0037] A kind of aqueous epoxy resin emulsion, its preparation process is as follows:

[0038]S1. Put 160 parts of epoxy resin E-44 into a four-necked flask, start stirring and slowly raise the temperature to 55°C to stop the temperature rise, add 90 parts of TDI, heat it up to 60°C for 40 minutes, and then add 126.54 parts of IPDI measured Add 3 drops of bismuth isooctanoate dropwise to a four-necked flask, and slowly raise the temperature to 68±2°C for 90 minutes;

[0039] S2. Add 40 parts of PCL with a molecular weight of 1500-2000 and 30 parts of 1,6-hexanediol into the four-neck flask, and keep warm at 68±2°C for 60 minutes;

[0040] S3. Add 32 parts of DMBA dissolved in DMF, drop 3 drops of stannous octoate and incubate at 68±2°C for 2 hours;

[0041] S4. The content of NCO in the system is detected by the di-n-butylamine method. When the NCO content reaches 3.0-4.0%, add 70 parts of epoxy resin E-51 and keep it at 66-68°C for 60 minutes, then raise the temperature to 7...

Embodiment 2

[0044] A kind of aqueous epoxy resin emulsion, its preparation process is as follows:

[0045] S1. Put 190 parts of epoxy resin E-44 into a four-necked flask, start stirring and slowly raise the temperature to 55°C to stop the temperature rise, add 90 parts of TDI, heat it up to 60°C for 40 minutes, and then add 160 parts of IPDI measured Add 4 drops of bismuth isooctanoate dropwise to a four-necked flask, and slowly raise the temperature to 68±2°C for 90 minutes;

[0046] S2. Add 50 parts of PCL with a molecular weight of 1500-2000 and 30 parts of 1,6-hexanediol into the four-neck flask, and keep warm at 68±2°C for 60 minutes;

[0047] S3. Add 38 parts of DMBA dissolved in DMF, add 4 drops of stannous octoate dropwise and incubate at 68±2°C for 2 hours;

[0048] S4. The content of NCO in the system is detected by the di-n-butylamine method. When the NCO content reaches 3.5-4.0%, add 52 parts of epoxy resin E-51 and keep it at 66-68°C for 60 minutes, then raise the temperatur...

Embodiment 3

[0051] A kind of aqueous epoxy resin emulsion, its preparation process is as follows:

[0052] S1. Put 170 parts of epoxy resin E-44 into a four-neck flask, start stirring and slowly raise the temperature to 55°C to stop the temperature rise, add 70 parts of TDI, heat it up to 60°C for 40 minutes, and then add 150 parts of IPDI measured Add 3 drops of bismuth isooctanoate dropwise to a four-necked flask, and slowly raise the temperature to 68±2°C for 90 minutes;

[0053] S2. Add 40 parts of PCL with a molecular weight of 1500-2000 and 40 parts of 1,6-hexanediol into the four-necked flask, and keep warm at 68±2°C for 60 minutes;

[0054] S3. Add 35 parts of DMBA dissolved in DMF, drop 3 drops of stannous octoate, and keep warm at 68±2°C for 2 hours;

[0055] S4. The NCO content in the system is detected by the di-n-butylamine method. When the NCO content reaches 1.8-2.45%, add 75 parts of epoxy resin E-51 and keep it at 66-68°C for 60 minutes, then raise the temperature to 75°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com