A kind of composite particle, its preparation method and application

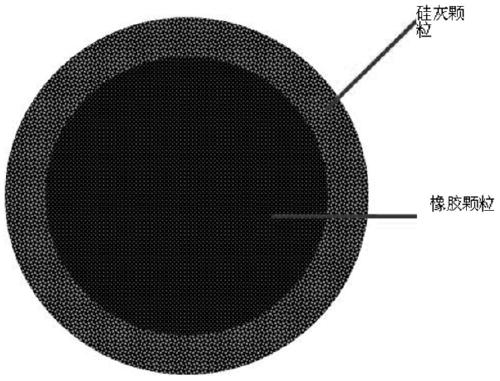

A technology of composite particles and elastic particles, applied in the field of oil and gas well cementing, can solve the problems of limited use, easy to float, temperature resistance, poor temperature resistance, etc., and achieves improved mechanical properties, improved hydrophilic properties, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

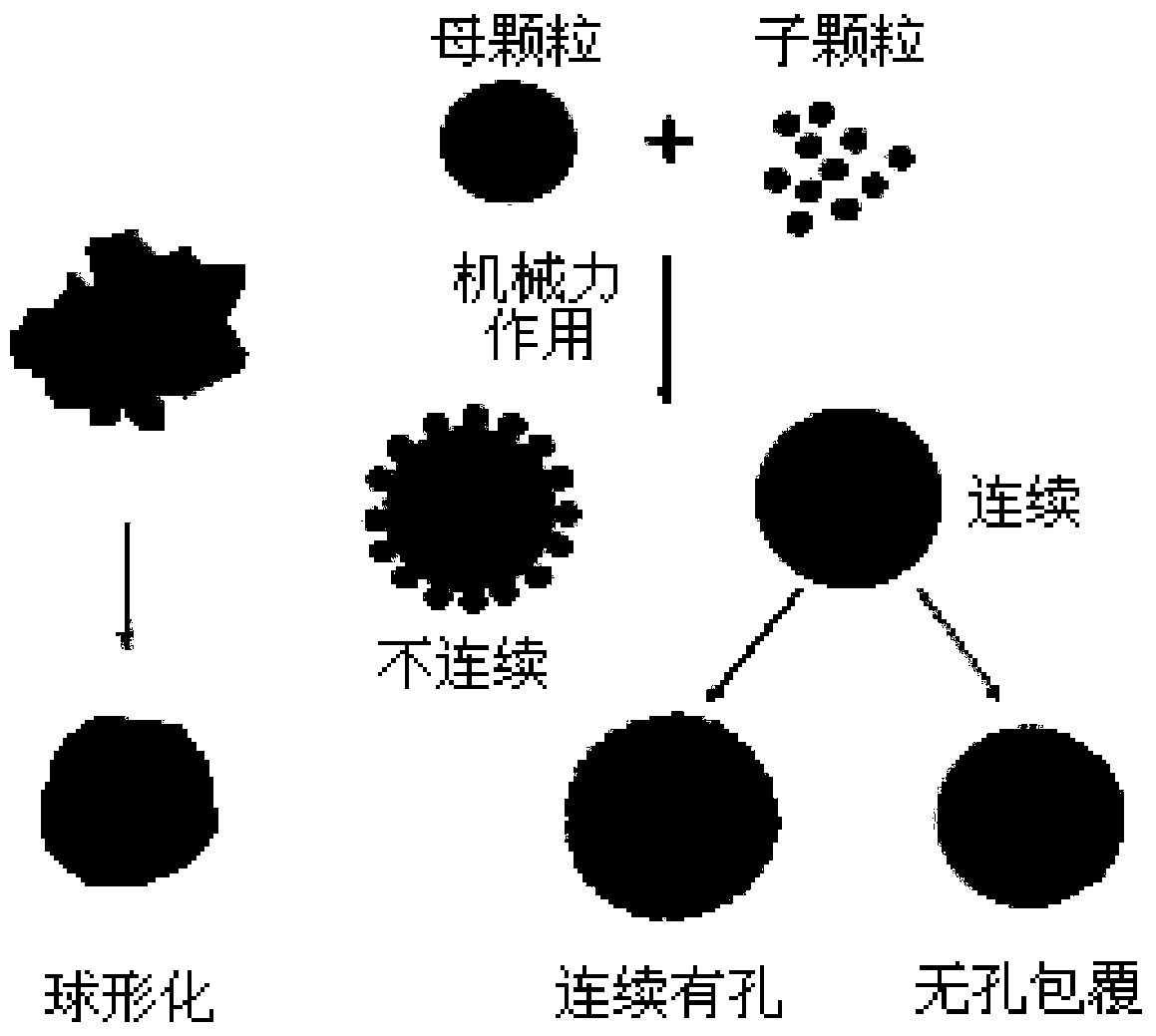

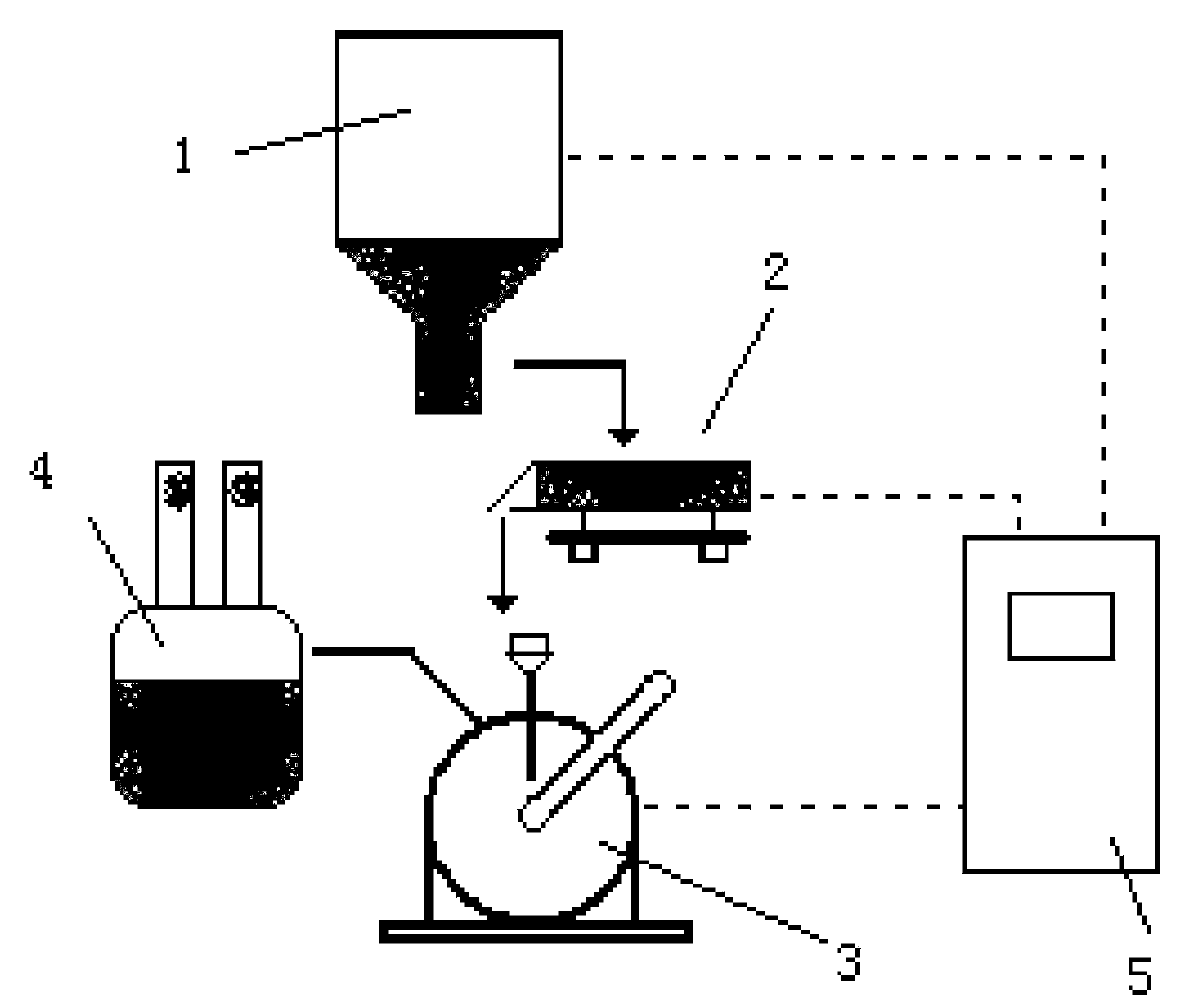

Method used

Image

Examples

Embodiment 1

[0033] With 100 parts by weight, the average particle size is 120 microns, and the particle size d 50 =123 micron, modulus of elasticity is 0.6GPa, Shore hardness is 70, and carbon content is that 30 parts of nitrile rubber particles of 0.5wt% add in the silica fume after spheroidization (average particle diameter is 1.45 micron, particle diameter d 50 =1.40 micron, stir evenly, and adjust composite particle mixing system (Tsinghua University, PCS-1) rotating speed 2500 rev / mins, control feed rate 5kg / min, coating time 30 minutes, collect average particle diameter and be 180 microns, particle diameter d 50 = Composite particles of 175 microns.

Embodiment 2

[0035] With 100 parts by weight, the average particle diameter is 180 microns, the particle diameter d 50 =165 microns, modulus of elasticity is 0.8GPa, Shore hardness is 85, carbon content is 0.5% styrene-butadiene rubber particles add 20 parts by weight after spheroidization, average particle diameter is 5.6 microns, particle diameter d 50 = 5.4 microns, in the fly ash with a carbon content of 0.5%, stir evenly, and adjust the PCS-1 rotating speed at 2000 rpm, control the feed rate at 5kg / min, cover the time for 20 minutes, and collect the average particle size of the product at 250 Micron, particle size d 50 = 240 micron composite particles.

Embodiment 3

[0037] With 100 parts by weight, the average particle size is 120 microns, and the particle size d 50 =125 microns, modulus of elasticity is 0.5GPa, Shore hardness is 60, carbon content is 0.5% styrene-butadiene rubber particles add 10 parts by weight after spheroidization, average particle diameter is 1.6 microns, particle diameter d 50 = In metakaolin of 1.2 microns, stir evenly, and adjust PCS-1 rotating speed 1000 revs / min, control feed rate 5kg / min, coating time 20 minutes, collect product average particle diameter 215 microns, particle diameter d 50 = 220 micron composite particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com