Numerical control flexible roll bending fully-automatic plate bending machine special for miniature motor enclosure

A micro-motor and fully automatic technology, applied in the field of plate rolling machine, can solve problems such as difficult control of inner diameter tolerance and shape tolerance, affecting product quality and use, and easy scratches on the outer surface of the shell, so as to save equipment investment and molds cost, save raw material cost, and not easy to be scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

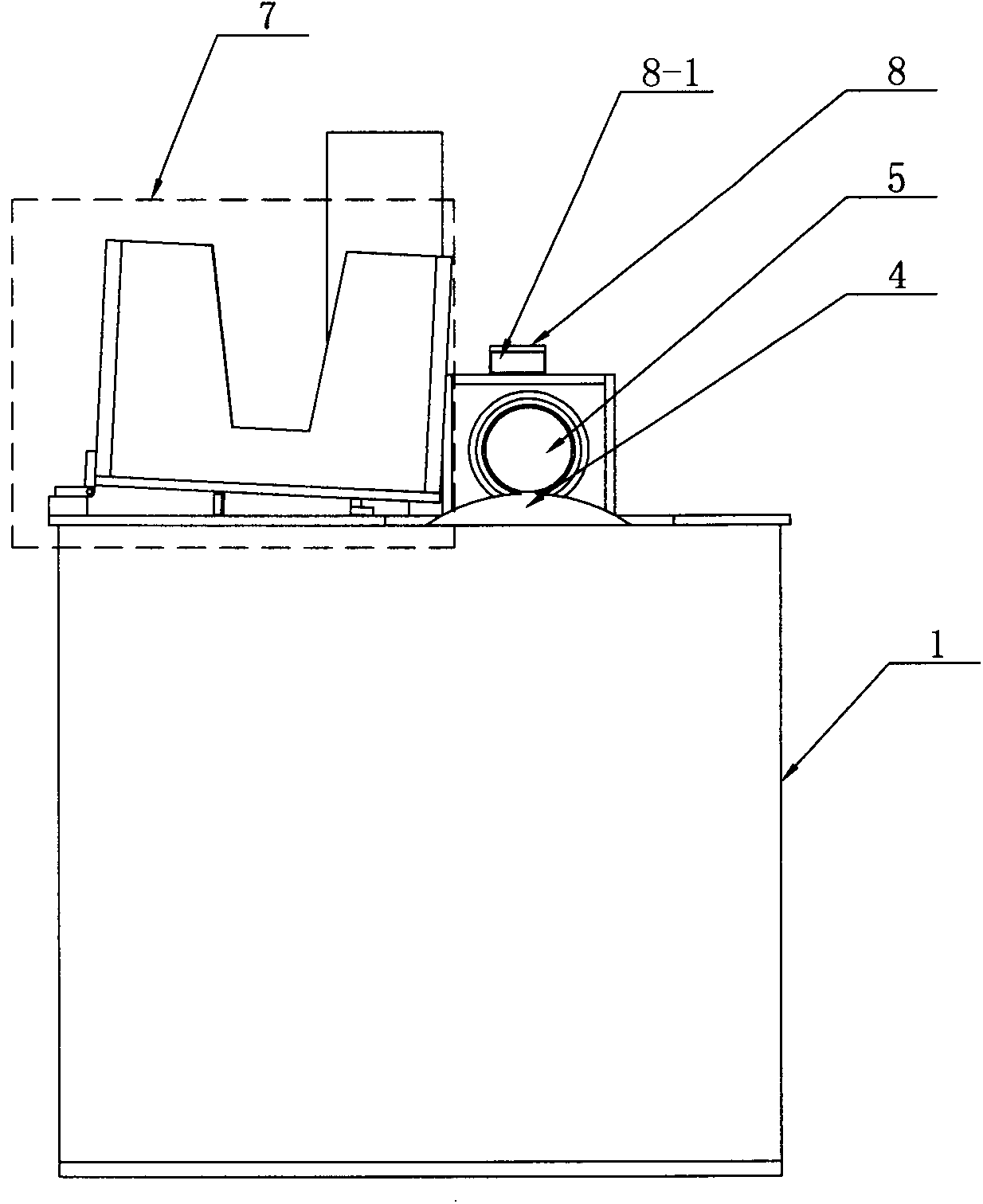

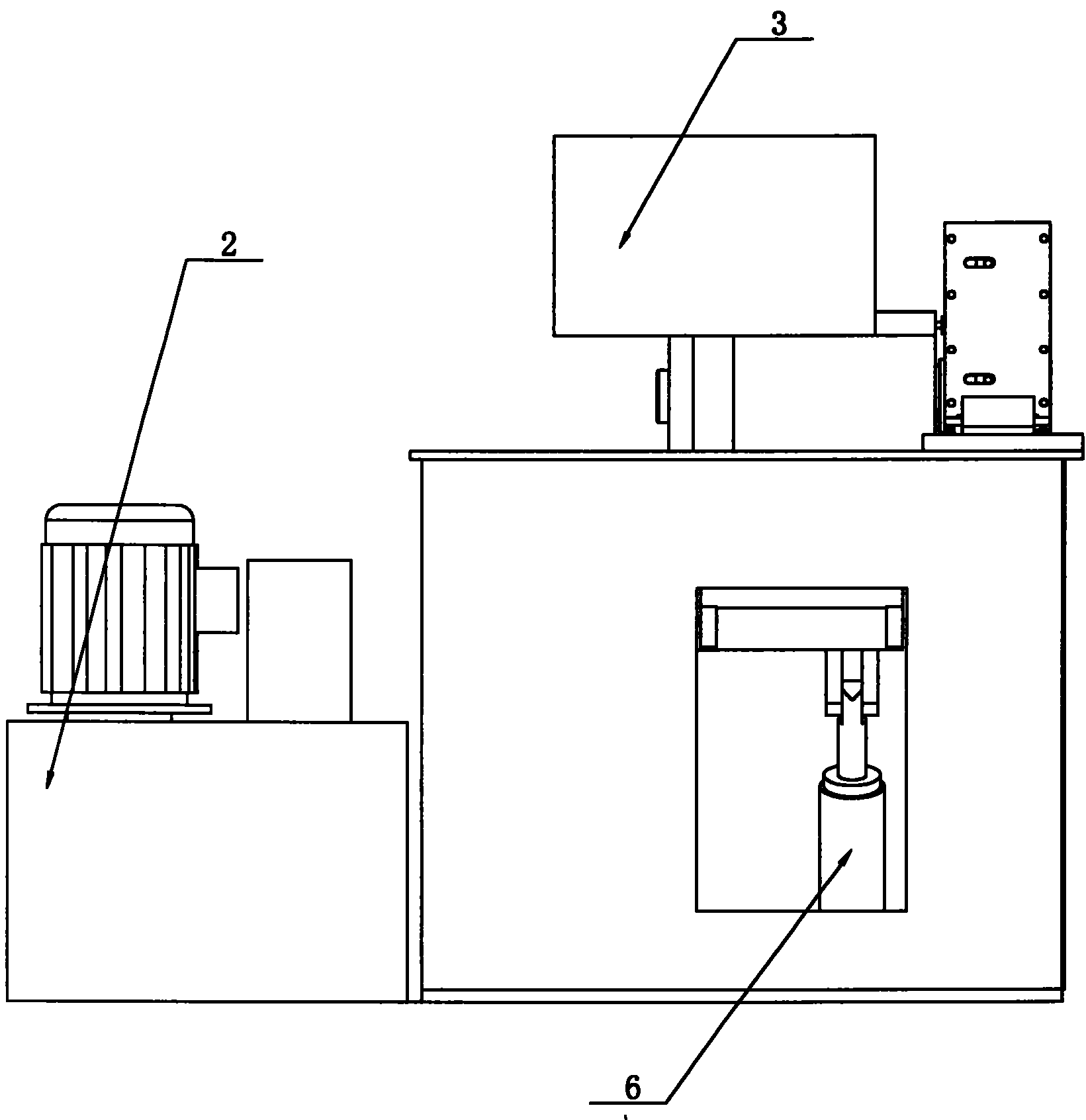

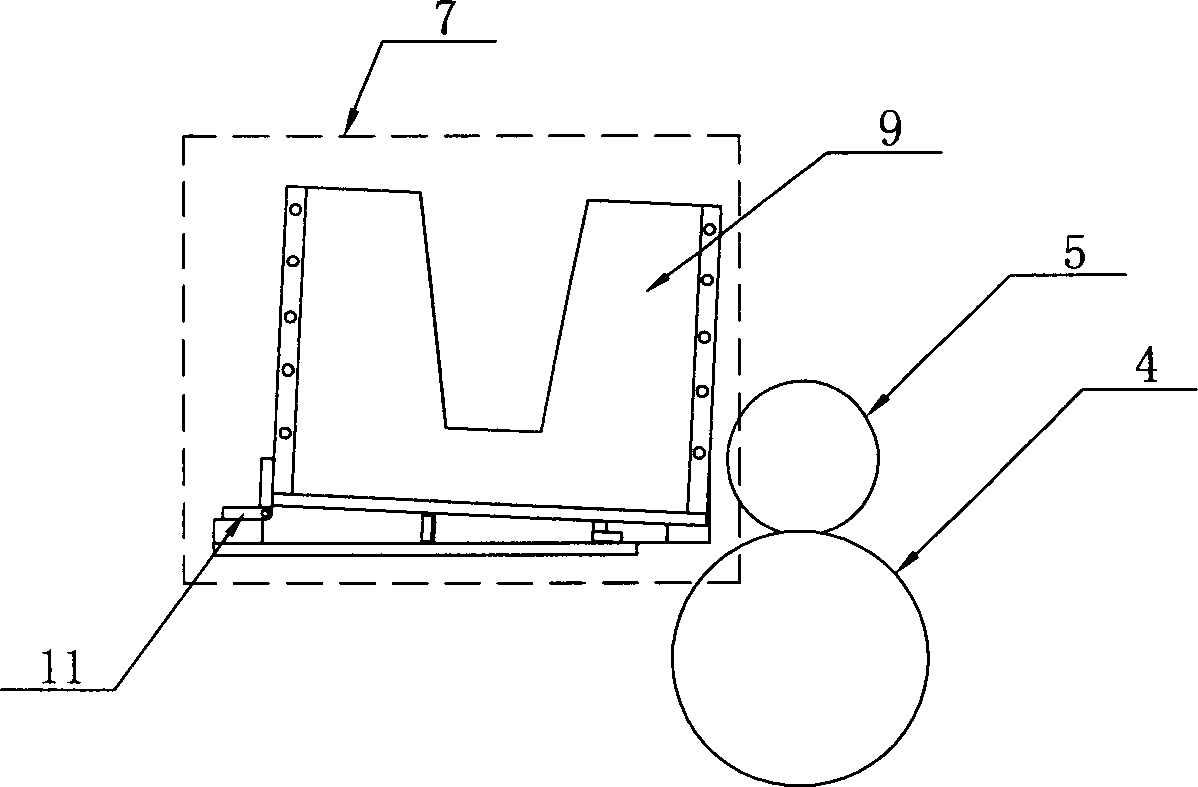

[0029] see Figure 1-Figure 5 , the specific embodiment adopts the following technical scheme: it includes a frame 1, a hydraulic station 2, a touch console 3, a lower rubber roller 4, an upper steel roller 5, and an oil cylinder 6; it also includes a feeding mechanism 7 and a discharging mechanism 8, The lower rubber roller 4 is installed on the frame 1, and the upper side of the lower rubber roller 4 is provided with an upper steel roller 5, and the upper side of the upper steel roller 5 is provided with a discharge mechanism 8, and the piston rod of the oil cylinder 6 and the lower rubber roller 4 The rotating shafts are connected, the hydraulic station 2 is arranged on one side of the frame 1, the touch console 3 is arranged on one side of the discharge mechanism 8, and the feeding mechanism 7 is arranged on one side of the lower rubber roller 4 and the upper steel roller 5.

[0030] Described feeding mechanism 7 comprises magazine 9 and feed push plate 10, and feed push p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com