Method and device for removing thickness of edge-wound coil in hydro generator or in motor rotor

A technology of hydro-generator and flat-wound coil, which is applied to electromechanical devices, manufacturing motor-generators, and electric components, etc., can solve the problems of large size, difficulty in manual grinding, and burning of motors, and achieves easy operation, saving manpower and time. , Improve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

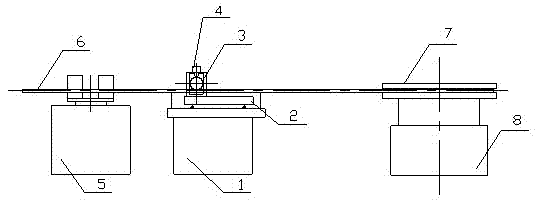

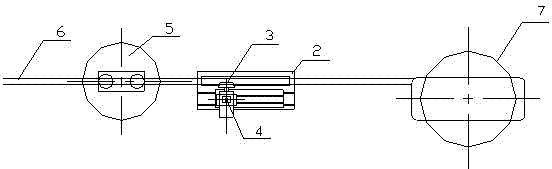

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] like Figure 1 to Figure 3 As shown in the figure, a device for removing the thickness of an edgewise coil in a hydroelectric generator or motor rotor includes a support 1 provided at the bottom, a grinder 2 is fixed above the support 1, and the grinder 2 is connected to a controller 3 , the top of the grinder 2 is also provided with a start button 4; the edgewise coil thickening device in the hydroelectric generator or motor rotor is arranged between the crimping device 5 and the edgewise forming die 7, and the edgewise coil A motor 8 is connected to the bottom of the molding die 7 .

[0022] The grinder 2 contains two grinding heads.

[0023] The height of the bracket 1 can be adjusted.

[0024] When the present invention works, first adjust the height of the support and the horizontal position of the grinder according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com